Beruflich Dokumente

Kultur Dokumente

MC Ac Installation

Hochgeladen von

Gg gOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MC Ac Installation

Hochgeladen von

Gg gCopyright:

Verfügbare Formate

CAT1011_CBL_AfcUS_Body_v16 11/1/10 2:50 PM Page 43

Installation Instructions for Traditional Type AC & MC Cables

Armored cable (Type AC) and metal clad cable (Type MC) provide Metal Clad (Type MC) Cable Construction

a fast and efficient way of wiring both new construction and As described by NEC® Article 330, Metal Clad Type MC cable is

remodeling work. Their flexible metal armor provides mechanical a “factory assembly of one or more insulated circuit conductors

protection of the electrical conductors while enabling them to bend with or without optical fiber members enclosed in an armor of

around corners. The cables are pre-wired at the factory eliminating interlocking metal tape or a smooth or corrugated metallic sheath.”

the need to pull conductors into a raceway, which in turn greatly

reduces the possibility of conductor damage. Traditional Type MC cable is manufactured to UL Standard 1569.

MC cables have 2 or more solid or stranded conductors in sizes 18

The National Electrical Code® has accepted AC and MC cables for AWG and larger. The number of conductors allowed in an MC cable

decades, with statistics showing that they have an excellent fire is not restricted by UL. The conductors may be of copper, aluminum

safety record. or copper-clad aluminum.

Because AC & MC cable can be fished for long distances, it is quick The metal armor may be a smooth tube, a corrugated tube, or

and easy to install. Its own weight can carry it between partitions an interlocked metal armor. AFC Cable Systems manufactures

and it can be run without concern for its contact with pipes or other MC cable with interlocked metal armor and copper conductors.

obstructions.

The make-up of AFC Cable Systems’ 600 volt interlocked armor

Wire pullers, fish ropes or tapes, dispensers and lubricants are traditional MC cable consists of:

eliminated. AC & MC cable does the job in less space, with fewer

bending restrictions as well as less cutting and connecting than • Copper circuit and grounding conductors covered with

most other wiring products. thermoplastic insulation

Armored cable (Type AC) and Metal Clad cable (Type MC) have a • An overall polypropylene cable assembly tape

flexible metal armor of similar outward appearance, but that is • An outer galvanized steel or aluminum interlocked armor

where the similarity ends. There are major differences in Unlike Type AC cable, the armor of interlocked Type MC cable is not

construction and uses permitted. an equipment grounding means and traditional Type MC cable

requires a bare or green grounding conductor.

Armored (Type AC) Cable Construction

As described by the National Electrical Code® Article 320, armored Differences between AC and traditional MC cables.

cable Type AC is a “fabricated assembly of insulated conductors in

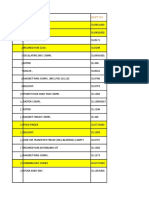

a flexible metallic enclosure.” TYPE AC CABLE TYPE MC CABLE

Type AC cable is manufactured to UL Standard 4. It consists of

NUMBER OF Limited to a maximum Not limited to the

2 to 4 copper conductors in sizes 14 AWG to 1 AWG inside an CONDUCTORS of 4 conductors plus a number of conductors.

interlocked metal armor of steel or aluminum construction. Type AC grounding conductor.

cable can have no more than four insulated conductors plus a

grounding conductor (for a total of 5 conductors only) and cannot SIZE OF 14 AWG to 1 AWG 18 AWG or larger

CONDUCTORS

be manufactured larger than 1 AWG per UL 4.

A 16 AWG aluminum bonding wire is inside of, and in physical GROUNDING Contains a 16 AWG Does not contain a

contact with, the metal armor providing a low-impedance fault- bond wire in constant bonding wire and the

contact with the armor is not an

return path required for the operation of overcurrent protection metal armor allowing equipment ground,

devices. The bonding wire is unique to AC cable and allows the the armor and bond but supplements the

outer metal armor in conjunction with the bonding wire to be used wire combination to be internal grounding

used as an equipment conductor equaling

as an equipment ground. ground. one grounding path.

It is important to remember that the bare bond wire is not an

equipment grounding conductor. It is the bond wire that, in CONDUCTOR Individual conductors Individual conductors are

combination with the interlocked metal armor, provides a low WRAPPING are wrapped in a not wrapped in fire

moisture resistant, Retardant paper but do

impedance equipment grounding path. fire retardant paper. have an overall poly-

Each of the copper conductors is covered with a thermoplastic propylene assembly tape.

insulation (THHN with a 90°C rating) and are individually wrapped

in a moisture resistant, fire retardant paper.

Along with these differences in construction, there are

According to NEC® Article 320.40, an insulated (anti-short) bushing

also differences in the uses permitted for these cables as

is required when installing Type AC cable. It is installed at the

discussed previously. (See pages14 and15 for installation details on

time of termination and designed to protect the conductors from

new MCI-A type MC cables.)

damage. AFC provides bushings in bags packaged with the cable.

AFC Cable Systems® 800-757-6996 www.afcweb.com 43

CAT1011_CBL_AfcUS_Body_v16 11/1/10 2:50 PM Page 44

Green Hospital Grade Type Cable

This additional ground allows HCF cables to be used in patient care

areas of health care facilities (other than hazardous locations)

including hospitals, nursing homes, dental offices, outpatient

™

facilities and medical centers per NEC® 517.13.

The separate green grounding conductor satisfies the requirement

of Article 517 that:

Temp-Lites

“In an area used for patient care, the grounding terminals of all

receptacles and all non-current-carrying conductive surfaces of fixed

electric equipment likely to become energized that are subject to A coil of MC cable

personal contact, operating at over 100 volts, shall be grounded

by an insulated copper conductor.” Bridging Cable Across Open Spaces

The armor and bonding strip combination satisfies the In general, AC and MC cable must hug the surface it is wired over.

requirement that: The NEC prohibits bridging across open spaces with the following

“…all branch circuits serving patient care areas shall be provided five exceptions:

with a ground path for fault current by installation in a metal 1) When the cable is fished.

raceway system or cable assembly. The metal raceway system, or 2) When flexibility is required, a box may be installed near a

cable armor or sheath assembly, shall itself qualify as an equipment motor or appliance using a short piece of free AC cable up

grounding return path in accordance with Section 250.118.” to 24 inches long, between the box and motor or appliance.

(NOTE: Read NEC 517.30(C)(3)(3) for complete details on wiring of emergency healthcare circuits.) 3) Lengths of not more than 6 feet from the last point of

support for connections within an accessible ceiling to

Installing AC & MC Cable lighting fixtures or equipment.

Type AC & MC cable is installed after the rough-in phase of locating 4) Where installed in cable trays.

and setting all boxes and enclosures. Rough-in occurs when all the 5a) For Type AC cable in other than vertical runs through holes

interior and exterior walls are framed but before the sheet rock is or notches in framing members where distance between

installed. members does not exceed 41⁄2 feet and is securely fastened

The first step in the rough-in phase is to determine the number of in place by an approved means within 12 inches of each

home run circuits and from where the wiring will originate. Once box, cabinet, conduit body or other cable termination.

this is done, time should be taken to determine the best and 5b) For Type MC cable in other than vertical runs through holes

shortest routes for each cable run. Long runs of spider web type or notches in framing members where the distance between

routing not only require more cable, but also increase voltage drop. members does not exceed 6 feet. Cables containing four or

This is very important to consider when locating boxes for fewer conductors sized no larger than AWG 10 must be

receptacles, lights and switches. If long runs are required, oversizing secured within 12 inches of each box, cabinet, fitting or

the circuit conductors is recommended to limit voltage drop. other cable termination.

Bending Radius

Care should be taken not to exceed the bending radius of the

cables when routing around corners. According to NEC Article

320.24, for AC cable, the radius of the curve of the inner edge of

any bend shall not be less than 5 times the diameter of the cable.

NEC Article 330.24(B) states that for MC Cable, the radius shall not

be less than 7 times the external diameter of the cable.

Terminating AC & traditional MC Cables

When terminating or splicing at a junction, outlet or switch box, cut

the cable so that 6 inches of free conductor is left for connections

or splices.

Use an approved connector and insure a proper bond by

firmly tightening the connectors to both the box and the cable.

AC & MC cable is available on reels and in coils. If using a reel,

Please note: set screw connectors cannot be used with aluminum

simply draw the cable from the end of the reel. If using a coil, draw

armor Type AC cable. To terminate an AC cable, insert an anti-short

the cable from the center of the coil to prevent kinking.

bushing and bend back the exposed length of bonding wire. The

bonding wire can be bent back before or after the bushing is

inserted. There are several techniques used for this procedure as

pictured on the next page.

44 800-757-6996 www.afcweb.com AFC Cable Systems®

CAT1011_CBL_AfcUS_Body_v16 11/1/10 2:50 PM Page 45

Terminating AC & traditional MC Cables

When terminating or splicing at a junction, outlet or switch box, cut

the cable so that 6 inches of free conductor is left for connections

or splices. Use an approved connector and insure a proper bond by

firmly tightening the connectors to

both the box and the cable.

Please note, set screw connectors

cannot be used with aluminum

armor Type AC cable.

To terminate an AC cable, insert an

anti-short bushing and bend back

the exposed length of bonding wire.

The bonding wire can be bent back

before or after the bushing is inserted. There are several techniques

used for this procedure as pictured on this page.

Insert the cable into the connector and secure the connector into

Supporting AC & MC Cables the box. Be sure that the anti-short bushing is plainly visible in the

connector for easy inspection. The same procedure is followed for

All cable runs must be continuous from outlet to outlet. According

traditional MC cable with the exception that there is no bonding

to NEC® Article 320.30, AC cable must be supported and secured

wire. Although anti-short bushings are only required by the NEC® for

at intervals of 41⁄2 feet or less (unless routed through a framing

AC cable, some manufacturers supply them for both cable types in

member) and within 12 inches of every termination.

the event that local codes override the NEC®.

According to NEC Article 330.30, MC cable must be supported

and secured at intervals of 6 feet or less (unless routed through a

framing member) and cables containing four or fewer conductors

sized no larger than 10 AWG must be secured within 12 inches of

every termination. (Bond wire may also be cut off

at the end of the armor)

As noted, AC and MC cable support requirements are waived

when the cable is fished. This is a major advantage of AC and MC

cable in remodeling work over other wiring products that cannot

be fished. MC cable installed in a box with 6 inches of free conductors left for connections or splices.

AC and MC cable may also be installed in cable tray, per NEC

Article 392. Cable is only required to be secured in this installation

for vertical runs.

AFC Cable Systems® 800-757-6996 www.afcweb.com 45

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 26 41 00 Surge Protective DeviceDokument4 Seiten26 41 00 Surge Protective DeviceLangzkie NalipaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Crimping A Category 5Dokument4 SeitenCrimping A Category 5mtguillermoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Section 1207. Stairs, Exits, and Section 1207. Stairs, Exits, and Occupant Loads Occupant LoadsDokument14 SeitenSection 1207. Stairs, Exits, and Section 1207. Stairs, Exits, and Occupant Loads Occupant LoadsIyah Arzobal100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- RESPONDALIGHT Product Guide 2010Dokument12 SeitenRESPONDALIGHT Product Guide 2010steve9581Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- EATSDokument10 SeitenEATSrsivanandNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 2.5 Cable Diagrams: Cable Diagram For RS232Dokument1 Seite2.5 Cable Diagrams: Cable Diagram For RS232VladimirAgeevNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Motor Designs Identified in NEMA MG1Dokument3 SeitenMotor Designs Identified in NEMA MG1Ansar AwanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Catalogo de Bornes ElectricosDokument53 SeitenCatalogo de Bornes ElectricosWalter ChavezNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- M1200 PinoutDokument2 SeitenM1200 PinoutRaviVelugulaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Te-Raychem Elb-15-28-600-J3-Al-StdDokument2 SeitenTe-Raychem Elb-15-28-600-J3-Al-StdEduardo FloresNoch keine Bewertungen

- Rikai IndustriesDokument14 SeitenRikai IndustriesDevendra ManiNoch keine Bewertungen

- SRS System GuideThe title "TITLE SRS System GuideDokument60 SeitenSRS System GuideThe title "TITLE SRS System GuideМиша ШаулаNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Parts RequestDokument4 SeitenParts RequestGopinath KalyanasundaramNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- TC513 TC203 TC303Dokument2 SeitenTC513 TC203 TC303Ajay Kumar GiriNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- What are roofs and their typesDokument66 SeitenWhat are roofs and their typespravin100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Door LocksDokument83 SeitenDoor LocksNilson BarbosaNoch keine Bewertungen

- Ruger SR22: Instruction Manual FORDokument44 SeitenRuger SR22: Instruction Manual FORJ.c. MasonNoch keine Bewertungen

- OTA External Alarm Solution V1 18 - FinalDokument32 SeitenOTA External Alarm Solution V1 18 - FinalKhaled NoNoch keine Bewertungen

- Laurie BakerDokument82 SeitenLaurie Bakersarath sarathNoch keine Bewertungen

- 2020 Honda Rebel Cowl InstallDokument2 Seiten2020 Honda Rebel Cowl InstallMarkDe Weekend TravellerNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- St150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedDokument1 SeiteSt150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedJamie CannellNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Vdocuments - MX - Manual Auto Start Deep Sea 7310 Controller Control Panel Auto Start Deep PDFDokument11 SeitenVdocuments - MX - Manual Auto Start Deep Sea 7310 Controller Control Panel Auto Start Deep PDFRath AsypadenNoch keine Bewertungen

- Fuel Injector Removal - Installation (Skyactiv-D 2.2)Dokument9 SeitenFuel Injector Removal - Installation (Skyactiv-D 2.2)Daniel Ungureanu100% (1)

- Engine J05C-TC ServiceDokument218 SeitenEngine J05C-TC ServiceAndrés Aroca0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Lightning Link Printable Template V1.0Dokument4 SeitenLightning Link Printable Template V1.0Gilberto Hill82% (22)

- Harga Lantai Kayu ParketDokument4 SeitenHarga Lantai Kayu ParketAliNoch keine Bewertungen

- Dynamic Laser Cruise Control: 2005 SIENNA (EWD613U)Dokument12 SeitenDynamic Laser Cruise Control: 2005 SIENNA (EWD613U)diemnganNoch keine Bewertungen

- EPS Toyota BackgroundDokument8 SeitenEPS Toyota BackgroundDilan Senarathne100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Mercury Mercruiser #24 - Marine Engines GM V-8 305 CID (5.0L) - 1Dokument189 SeitenMercury Mercruiser #24 - Marine Engines GM V-8 305 CID (5.0L) - 1薛泽绵Noch keine Bewertungen

- 400KV Protection PDFDokument140 Seiten400KV Protection PDFMuhammad Nasir100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)