Beruflich Dokumente

Kultur Dokumente

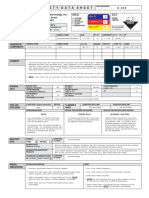

Brochure-KemGuard 2420 Fluorescent Tagged Scale Inhibitor-OG

Hochgeladen von

dimasfebriantoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Brochure-KemGuard 2420 Fluorescent Tagged Scale Inhibitor-OG

Hochgeladen von

dimasfebriantoCopyright:

Verfügbare Formate

KemGuard® 2420 KEY BENEFITS

Fluorescent-Tagged Scale Inhibitor BEST PERFORMANCE

AGAINST OILFIELD

SULFATE SCALES

TAGGED POLYMERIC INHIBITOR IMPROVES TREATMENT

DIFFERENTIATED

CONTROL AND DETECTABILITY IN OILFIELD OPERATIONS DETECTION

Mineral deposition is a major concern for the oil and gas industry, causing PEACE OF MIND

severe disruptions in production and failure of safety-critical components. The THROUGH ENHANCED

ability to mitigate mineral scaling through scale inhibitor application in oilfield DETECTABILITY

waters is critical for operators.

IMPROVED PRODUCTION

Kemira has developed KemGuard® 2420 fluorescent-tagged polymeric OPTIMIZATION

inhibitor to improve treatment control and detectability. This innovative

technology provides oilfield operators with the ability to monitor residual IMPROVED SCHEDULING

levels down to low minimum inhibitor concentration (MIC) onsite, delivering & TREATMENT OF WELLS

flow assurance and maximizing uptime.

KemGuard 2420 is a scale-inhibiting polymer incorporating a fluorescent

tag for enhanced detectability. Using spectrofluorometry, it is now possible

to accurately determine residual inhibitor concentration levels in produced

water on location. Proprietary, quick pre–treatment steps are used to

remove background fluorescence, often found in produced waters. These KemGuard 2420 scale

follow a simple instrument calibration, where signal intensity is correlated inhibitor provides oilfield

to product concentration. operators with accurate

on-site analysis using

KemGuard 2420 has been field tested in the North Sea on scale squeeze unique and discreet

deployment in sandstone formations, where good, long squeeze-life was fluorescent tagging. This

obtained. Fluorescent detection, with pre-cleaning steps, was used to innovative technology

determine concentration levels without the need to pre-concentrate the is suitable for downhole

squeeze application.

return samples. Detection was achieved down to low single-digit ppm levels,

providing the field operator with treatment analysis over the full squeeze-life.

KemGuard 2420 scale inhibitor was developed to work with its parent technology, KemGuard 269, and phosphorous-

tagged KemGuard 2490. Combining deployment of the multiple, similar yet distinctive chemistries into separate

subsea wells or production zones where produced fluids are routed through a single co-mingled flow line, allows for

multi-detectability of the residual inhibitor concentrations. The benefits for production optimization and treatment

scheduling are significant, and may include the ability to tie new discoveries to existing host-production facilities

delivering a fit-for-purpose scale management program with significantly reduced project capital expenditure.

BARIUM SULFATE INHIBITION WITH KEMGUARD 2420 & 269

120

100

Percent Inhibition (%)

80

KemGuard 269

60

40

KemGuard 2420

20

0

0.90 1.40 1.90 2.40 2.90

Active Inhibitor Dosage (ppm)

Performance data illustrates BaSO4 inhibition benefits of KemGuard 2420

compared to best-in-class KemGuard 269 in oilfield brines. Testing simulated

severe barium sulphate scaling tendency of 3.1 at 20°C in static jar tests. Full

inhibition was reached at similar active inhibitor concentration of only 2.7 ppm.

BARIUM SULFATE INHIBITION WITH KEMGUARD 2420 & 269 UNDER DYNAMIC CONDITIONS

12

KemGuard 269

10

Differential Pressure (psi)

Ba 225 ppm Barium sulphate inhibition

SO4 1,480 ppm KemGuard 2420

Na 10,890 ppm was also tested using

8 Cl 18,900 ppm dynamic conditions simulated

Mg 720 ppm

Ca 390 ppm with PMAC equipment. Water

6 K 312 ppm scaling tendency of 3.15 was

Sr 21ppm

80ºC simulated with the addition of

4 15 psi 225 ppm of barium and 1480

ppm of SO4, at a temperature

2

of 80°C and 15 psi. Again,

KemGuard 2420 fluorescent-

0

0 20 40 60 80 100 tagged inhibitor showed

Time (min) similar levels of inhibition to

KemGuard 269.

KEMGUARD 2420 SCREENING TEST RESULTS 200°C Slanhydrite=1

4.0

3.5

Differential Pressure (PSI)

3.0 No Inhibitor

2.5

2.0

KemGuard 2420

1.5

10 mg/L 5 mg/L 3 mg/L 1 mg/L

1.0

0.5

0

0 20 40 60 80 100 120 140

Time (min)

Critical to scale squeeze inhibition performance is product stability

at downhole temperature. Results from an external oilfield research

laboratory show favorable performance with KemGuard 2420 for

anhydrite scale inhibition when product was subjected to 200°C.

Specifically, anhydrite scale formation was simulated to ascertain

product performance for potential application where downhole

capillary injection of the inhibitor would be applied in production

wells receiving assisted recovery from a large steamflood operation.

KEMGUARD 2420 CALCIUM TOLERANCE

100

90

% Transmission @ 420 nm

80 KemGuard 2420

70

KemGuard 2700

60

BHTPMP

50

40 DTPMP

30

20

0 5,000 10,000 15,000 20,000

Scale Inhibitor (ppm)

Significant improvement in tolerance of calcium in brine conditions compared

to Bis(hexamethylene)triamine Penta(methylenephosphonic acid (BHPTMT) and

Diethylene Triamine Penta(Methylene Phosphonic Acid) (DTPMP) demonstrates

an enhanced seawater tolerance . Under these conditions, KemGuard 2420

retains solubility and is available to inhibit scale nucleation and crystal growth.

LET US SHOW YOU HOW OUR TECHNOLOGY CAN WORK FOR YOU

Where oilfield scaling operations call for unique solutions, Kemira’s

KemGuard technology with its novel tagged derivatives can be the

answer. Let us show you how our innovative products and applications

expertise can help improve your operations.

oilandmining@kemira.com

www.kemira.com

Kemira makes this information available as an accommodation to its customers and it is intended to be solely a guide in customer’s evaluation of the products. You must test our products,

to determine if they are suitable for your intended uses and applications, as well as from the health, safety and environmental standpoint. You must also instruct your employees, agents,

contractors, customers or any third party which may be exposed to the products about all applicable precautions. All information and technical assistance is given without warranty or guarantee

and is subject to change without notice. You assume full liability and responsibility for compliance with all information and precautions, and with all laws, statutes, ordinances and regulations

of any governmental authority applicable to the processing, transportation, delivery, unloading, discharge, storage, handling, sale and use of each product. Nothing herein shall be construed as a

recommendation to use any product in conflict with patents covering any material or its use.

KemGuard is a registered trademark of Kemira Oyj or its subsidiaries.

6/2015

Das könnte Ihnen auch gefallen

- Kurita Cetamine BrochureDokument2 SeitenKurita Cetamine BrochureDanielWheelerNoch keine Bewertungen

- KURITA - Boiler Preservation Methods (Part4) PDFDokument8 SeitenKURITA - Boiler Preservation Methods (Part4) PDFIyan MulyanaNoch keine Bewertungen

- Repeat Situations in Cycle Chemistry ControlDokument22 SeitenRepeat Situations in Cycle Chemistry ControlAnonymous lHiaDxlpkxNoch keine Bewertungen

- Anodamine HPFGDokument69 SeitenAnodamine HPFGmasgrahaNoch keine Bewertungen

- Carbohydrazide Vs Hydrazine: A Comparative Study: September 2019Dokument17 SeitenCarbohydrazide Vs Hydrazine: A Comparative Study: September 2019MohamedNoch keine Bewertungen

- Helamin 906 HDokument2 SeitenHelamin 906 HWong Peng ChiongNoch keine Bewertungen

- V 05 Galt ESKOM PDFDokument17 SeitenV 05 Galt ESKOM PDFAdel KlkNoch keine Bewertungen

- IAWPS GUIDELINE Volatile-2015Dokument32 SeitenIAWPS GUIDELINE Volatile-2015prakashNoch keine Bewertungen

- International Water Conference Proceedings - 1940-2009Dokument5.199 SeitenInternational Water Conference Proceedings - 1940-2009Alfonso Javier Medina PernethNoch keine Bewertungen

- Cooling Tower Institute Win 10 JournalDokument92 SeitenCooling Tower Institute Win 10 JournalprakashNoch keine Bewertungen

- 08 ACC Chemistry and Amines PDFDokument17 Seiten08 ACC Chemistry and Amines PDFLaszlo HiltNoch keine Bewertungen

- TR 108460Dokument242 SeitenTR 108460mtaha85100% (1)

- Odacon F 02.03.16 EnglDokument8 SeitenOdacon F 02.03.16 EnglOfer GardenNoch keine Bewertungen

- Rodine 213 & 214-EnDokument3 SeitenRodine 213 & 214-EnLouis MoralesNoch keine Bewertungen

- Cooling Tower Institute Journal Win 06Dokument88 SeitenCooling Tower Institute Journal Win 06prakashNoch keine Bewertungen

- Uk PDFDokument1 SeiteUk PDFabuzar khan almaniNoch keine Bewertungen

- BWA Belcor 575 Replaces Molybdate USA WF 0Dokument2 SeitenBWA Belcor 575 Replaces Molybdate USA WF 0dalton2003Noch keine Bewertungen

- PPChem 2017 19-02-92-102 Authors Copy PublicDokument11 SeitenPPChem 2017 19-02-92-102 Authors Copy PublicJan RusaasNoch keine Bewertungen

- BDooley ACC Corrosion FAC1Dokument19 SeitenBDooley ACC Corrosion FAC1DSGNoch keine Bewertungen

- Ecolab Permaclean PC 33 LDokument3 SeitenEcolab Permaclean PC 33 LKumbang KambingNoch keine Bewertungen

- Waterbox InspectionDokument2 SeitenWaterbox InspectionFallo SusiloNoch keine Bewertungen

- Impact of Film-Forming Amines On Condensate Polishing Ion-Exchange Resins PDFDokument72 SeitenImpact of Film-Forming Amines On Condensate Polishing Ion-Exchange Resins PDFmtaha85Noch keine Bewertungen

- LoSalt Polyamine CustomerDokument21 SeitenLoSalt Polyamine CustomerDavid Cruz ZamoraNoch keine Bewertungen

- IAPWS Guidance on Corrosion Monitoring and Cycle ChemistryDokument22 SeitenIAPWS Guidance on Corrosion Monitoring and Cycle ChemistrytedNoch keine Bewertungen

- Flocculants and Coagulants NALCO (LIT) PDFDokument6 SeitenFlocculants and Coagulants NALCO (LIT) PDFLily NurdianaNoch keine Bewertungen

- Tds Kemira Cop 183 Emea enDokument1 SeiteTds Kemira Cop 183 Emea enSteven CoultonNoch keine Bewertungen

- Antiscalant Patel Des 1999Dokument13 SeitenAntiscalant Patel Des 1999Alfonso José García LagunaNoch keine Bewertungen

- Chemicals Zetag DATA Inverse Emulsions Zetag 8816 - 0410Dokument2 SeitenChemicals Zetag DATA Inverse Emulsions Zetag 8816 - 0410PromagEnviro.comNoch keine Bewertungen

- ECO-FRIENDLY CORROSION & SCALING SOLUTIONS SINCE 1986Dokument4 SeitenECO-FRIENDLY CORROSION & SCALING SOLUTIONS SINCE 1986Wong Peng ChiongNoch keine Bewertungen

- Anodamine HPFGDokument69 SeitenAnodamine HPFGmasgrahaNoch keine Bewertungen

- Asesmen Chemistry Cycle by EPRIDokument14 SeitenAsesmen Chemistry Cycle by EPRIAbdul KadirNoch keine Bewertungen

- 7 Filming AmineDokument3 Seiten7 Filming Amineengp1922Noch keine Bewertungen

- Coloida Silica RemovalDokument9 SeitenColoida Silica RemovalAnthony LimNoch keine Bewertungen

- BWR Water Chemistry ML003722491 PDFDokument38 SeitenBWR Water Chemistry ML003722491 PDFcaloycaloy2Noch keine Bewertungen

- Corrosion Monitoring PDFDokument24 SeitenCorrosion Monitoring PDFMohamedGhanemNoch keine Bewertungen

- Chemicals Zetag DATA Magnasol 4000 G - 0410Dokument2 SeitenChemicals Zetag DATA Magnasol 4000 G - 0410PromagEnviro.comNoch keine Bewertungen

- Feedwater TreatmentDokument5 SeitenFeedwater TreatmentthanhhuyenNoch keine Bewertungen

- Betzdearborn CP1155Dokument7 SeitenBetzdearborn CP1155Romuel Pioquinto100% (1)

- Cation Conductivity Monitoring: A Reality CheckDokument7 SeitenCation Conductivity Monitoring: A Reality CheckPhạm Nhật MinhNoch keine Bewertungen

- Initial Treatment With Heat LoadDokument15 SeitenInitial Treatment With Heat LoadSunny OoiNoch keine Bewertungen

- Calcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionsDokument8 SeitenCalcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionssegundosoporteNoch keine Bewertungen

- Flow-Accelerated Corrosion in Steam Generating Plants: Barry Dooley and Derek ListerDokument51 SeitenFlow-Accelerated Corrosion in Steam Generating Plants: Barry Dooley and Derek Listerzerocool86Noch keine Bewertungen

- Harga Bahan KimiaDokument2 SeitenHarga Bahan KimiaAndre Gazali Malik100% (1)

- R 482Dokument9 SeitenR 482Andre Osmond Nugraha SimorangkirNoch keine Bewertungen

- HyderxDokument4 SeitenHyderxJonny DenNoch keine Bewertungen

- Ppchem Free 9 2004 2Dokument0 SeitenPpchem Free 9 2004 2rikumohanNoch keine Bewertungen

- Cetamine Products. For Boilers & Closed SystemsDokument19 SeitenCetamine Products. For Boilers & Closed SystemsAquasoul CoNoch keine Bewertungen

- Chemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410Dokument2 SeitenChemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410PromagEnviro.comNoch keine Bewertungen

- Water Parameter Deviations and Corrective ActionsDokument2 SeitenWater Parameter Deviations and Corrective ActionsFaizan Ahmed100% (1)

- Chemical Product Line Up For AutomotiveDokument4 SeitenChemical Product Line Up For AutomotiveLuan NguyenNoch keine Bewertungen

- Indonesia Customer Seminar Turbine-Generator FundamentalsDokument41 SeitenIndonesia Customer Seminar Turbine-Generator FundamentalsRajendran SrnNoch keine Bewertungen

- Condensate Polishing GuidelinesDokument294 SeitenCondensate Polishing GuidelinesGreg EverettNoch keine Bewertungen

- STD Spec For Boiler Chemical CompoundDokument21 SeitenSTD Spec For Boiler Chemical CompoundSunny Ooi100% (1)

- NALCO® EC9149A: Section 1. Identification of The Substance/Mixture and of The Company/UndertakingDokument14 SeitenNALCO® EC9149A: Section 1. Identification of The Substance/Mixture and of The Company/UndertakingDonatas BertasiusNoch keine Bewertungen

- Cooling Systems: Don'T Underestimate The Problems Caused by Condenser Tube LeaksDokument5 SeitenCooling Systems: Don'T Underestimate The Problems Caused by Condenser Tube Leakspym1506gmail.comNoch keine Bewertungen

- Sulphite Vs Tannin Oxygen Scavenger TreatmentsDokument5 SeitenSulphite Vs Tannin Oxygen Scavenger TreatmentsAhmed Taher100% (1)

- Certificate of Analysis: National Institute of Standards and TechnologyDokument5 SeitenCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNoch keine Bewertungen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- Determination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisVon EverandDetermination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisBewertung: 3 von 5 Sternen3/5 (1)

- KPI ExamplesDokument1 SeiteKPI ExamplesdimasfebriantoNoch keine Bewertungen

- 88-Sopus Products Rainex DeicerDokument8 Seiten88-Sopus Products Rainex DeicerdimasfebriantoNoch keine Bewertungen

- Concentrated Car Shampoo - SDS10656 - GBRDokument8 SeitenConcentrated Car Shampoo - SDS10656 - GBRdimasfebriantoNoch keine Bewertungen

- C 400 MSDSDokument2 SeitenC 400 MSDSdimasfebriantoNoch keine Bewertungen

- Air Intake System Cleaner DieselDokument8 SeitenAir Intake System Cleaner DieseldimasfebriantoNoch keine Bewertungen

- Anti Scale For Cooling Tower Water PDFDokument3 SeitenAnti Scale For Cooling Tower Water PDFdimasfebriantoNoch keine Bewertungen

- 3 in One23168479Dokument4 Seiten3 in One23168479dimasfebriantoNoch keine Bewertungen

- C H OCH CH (CH) OH (Major Isomer) : Dowanol™ PNBDokument3 SeitenC H OCH CH (CH) OH (Major Isomer) : Dowanol™ PNBdimasfebriantoNoch keine Bewertungen

- Spartan Chemical Company, Inc. Material Safety Data Sheet: Glass Cleaner (Bulk)Dokument2 SeitenSpartan Chemical Company, Inc. Material Safety Data Sheet: Glass Cleaner (Bulk)dimasfebriantoNoch keine Bewertungen

- Brochure-KemGuard 3010 Scale Inhibitor-OGDokument2 SeitenBrochure-KemGuard 3010 Scale Inhibitor-OGdimasfebriantoNoch keine Bewertungen

- MSDS EnglishDokument7 SeitenMSDS EnglishdimasfebriantoNoch keine Bewertungen

- H-AC-0010 Liquid Car PolishDokument1 SeiteH-AC-0010 Liquid Car PolishmayelimvNoch keine Bewertungen

- Brochure-KemGuard 269 and 2700 Scale Control-OGDokument2 SeitenBrochure-KemGuard 269 and 2700 Scale Control-OGdimasfebrianto0% (2)

- Bezpecnotni List EngDokument7 SeitenBezpecnotni List EngdimasfebriantoNoch keine Bewertungen

- Cetane ImproverDokument10 SeitenCetane ImproverdimasfebriantoNoch keine Bewertungen

- 3m Brake Cleaner PDFDokument14 Seiten3m Brake Cleaner PDFdimasfebriantoNoch keine Bewertungen

- AGP:CP/360, 1998 Replace AGP:CP/81: AmitroleDokument10 SeitenAGP:CP/360, 1998 Replace AGP:CP/81: AmitroledimasfebriantoNoch keine Bewertungen

- 95-1132-01 - Formulation Dowanol PDFDokument40 Seiten95-1132-01 - Formulation Dowanol PDFNeli Arias100% (1)

- AlleDokument15 SeitenAlledimasfebriantoNoch keine Bewertungen

- Using SurfactantsDokument12 SeitenUsing SurfactantsdimasfebriantoNoch keine Bewertungen

- Fishbone DiagramDokument1 SeiteFishbone DiagramdimasfebriantoNoch keine Bewertungen

- ACEPDokument13 SeitenACEPdimasfebriantoNoch keine Bewertungen

- Cleaning Product MSDSDokument2 SeitenCleaning Product MSDSdimasfebriantoNoch keine Bewertungen

- Surfactant Pesticide White Paper Final LoRezDokument12 SeitenSurfactant Pesticide White Paper Final LoRezdimasfebriantoNoch keine Bewertungen

- Formulasi Pasta GigiDokument19 SeitenFormulasi Pasta GigidimasfebriantoNoch keine Bewertungen

- Format RakerDokument16 SeitenFormat RakerdimasfebriantoNoch keine Bewertungen

- Dashboard Cleaner With SiliconeDokument5 SeitenDashboard Cleaner With SiliconedimasfebriantoNoch keine Bewertungen

- 3m Brake Cleaner PDFDokument14 Seiten3m Brake Cleaner PDFdimasfebriantoNoch keine Bewertungen

- 26-1382 Automotive Surfaces Product Selection Guide PDFDokument10 Seiten26-1382 Automotive Surfaces Product Selection Guide PDFdimasfebriantoNoch keine Bewertungen

- Delhi Public School, Gandhinagar SYLLABUS - 2019-20 Class - IxDokument12 SeitenDelhi Public School, Gandhinagar SYLLABUS - 2019-20 Class - IxAman MultaniNoch keine Bewertungen

- Test CertificateDokument127 SeitenTest CertificateMRezaNoch keine Bewertungen

- Growth of Kh2Po4 Crystals at Constant Temperature and Supersaturation G.M. Loiacono, J.J. Zola and G. KosteckyDokument12 SeitenGrowth of Kh2Po4 Crystals at Constant Temperature and Supersaturation G.M. Loiacono, J.J. Zola and G. KosteckyNguyễnTấnThànhNoch keine Bewertungen

- Gaussian Observation HMM For EEGDokument9 SeitenGaussian Observation HMM For EEGDeetovNoch keine Bewertungen

- A Comparative Mismatch Study of The 20 NM Gate-Last and 28 NM Bulk CmosDokument8 SeitenA Comparative Mismatch Study of The 20 NM Gate-Last and 28 NM Bulk Cmoshpnx9420Noch keine Bewertungen

- Week 1 Assignments - CE 2110 - Summer 12Dokument17 SeitenWeek 1 Assignments - CE 2110 - Summer 12James KwanNoch keine Bewertungen

- Steam Turbines Generators PDFDokument13 SeitenSteam Turbines Generators PDFPrince ChaudharyNoch keine Bewertungen

- Design and Manufacturing of Pneumatic Pipe Bending MachineDokument5 SeitenDesign and Manufacturing of Pneumatic Pipe Bending MachineSriram MuruganNoch keine Bewertungen

- Ijoaem 202109Dokument20 SeitenIjoaem 202109Sahadev RoyNoch keine Bewertungen

- Influence of The Clinker SO3 On The Cement CharacteristicsDokument1 SeiteInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896Noch keine Bewertungen

- 00hydr Fundamentals PDFDokument298 Seiten00hydr Fundamentals PDFpcalver2000Noch keine Bewertungen

- Annular Cavity 2Dokument8 SeitenAnnular Cavity 2Milind KshirsagarNoch keine Bewertungen

- General Physics 2 Electric FieldDokument28 SeitenGeneral Physics 2 Electric FieldAriah KaliNoch keine Bewertungen

- 22 Dead-End & Suspension InsulatorsDokument16 Seiten22 Dead-End & Suspension Insulatorsrye_eeNoch keine Bewertungen

- Patterned Sapphire SubstratesDokument4 SeitenPatterned Sapphire SubstratesSabri TraderNoch keine Bewertungen

- Wind Tunnel Lesson Plan Original PDFDokument3 SeitenWind Tunnel Lesson Plan Original PDFJones arun rajNoch keine Bewertungen

- H Ex PDFDokument24 SeitenH Ex PDFelgawadhaNoch keine Bewertungen

- Literature Review On FoundationDokument6 SeitenLiterature Review On FoundationAhmed Shah100% (3)

- Thermosense: Occupancy Thermal Based Sensing For Hvac ControlDokument8 SeitenThermosense: Occupancy Thermal Based Sensing For Hvac ControledgardoboieroNoch keine Bewertungen

- Bijlaard 2010Dokument15 SeitenBijlaard 2010xyxtofNoch keine Bewertungen

- Ch11 FootingsDokument16 SeitenCh11 FootingsMohamedNoch keine Bewertungen

- Marginal and Internal Adaptation of Zirconia CrownDokument7 SeitenMarginal and Internal Adaptation of Zirconia CrownAndrei AvîrvareiNoch keine Bewertungen

- Reduction of Vibrations G.B. Warburton, J. Wiley & Sons, Chichester, 1992, 91 Pages, 17.50 - 1993Dokument2 SeitenReduction of Vibrations G.B. Warburton, J. Wiley & Sons, Chichester, 1992, 91 Pages, 17.50 - 1993ciscoNoch keine Bewertungen

- STOKES DRAG Derivation PDFDokument4 SeitenSTOKES DRAG Derivation PDFVadiraj HemadriNoch keine Bewertungen

- Krytox GPL 226Dokument1 SeiteKrytox GPL 226Blanca MedinaNoch keine Bewertungen

- Statistical Consequences of Fat Tails Te PDFDokument390 SeitenStatistical Consequences of Fat Tails Te PDFtonitt100% (2)

- Ease 4 Physics Pointer Analyses and Practice QuestionsDokument11 SeitenEase 4 Physics Pointer Analyses and Practice QuestionsThe Deep Sea IdNoch keine Bewertungen

- Force AnalysisDokument152 SeitenForce AnalysisWang Han Zhu100% (1)

- As 1289.6.1.3-1998 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDokument2 SeitenAs 1289.6.1.3-1998 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACNoch keine Bewertungen

- Identifying and Preventing Dna Contamination in A Dna Typing LaboratoryDokument3 SeitenIdentifying and Preventing Dna Contamination in A Dna Typing LaboratoryDette de LaraNoch keine Bewertungen