Beruflich Dokumente

Kultur Dokumente

Ijpab 2017 5 4 84 92

Hochgeladen von

Tarang MalvaniyaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ijpab 2017 5 4 84 92

Hochgeladen von

Tarang MalvaniyaCopyright:

Verfügbare Formate

Available online at www.ijpab.

com

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

DOI: http://dx.doi.org/10.18782/2320-7051.3011 ISSN: 2320 – 7051

Int. J. Pure App. Biosci. 5 (4): 84-92 (2017)

Research Article

Preservation of Paneer Samples with Formalin under Vacuum Packaging

at 27ᵒC for Analytical Purpose

Meenatai Kamble1 and Raman Seth2*

1

M.Tech, ICAR-NDRI, Karnal-132001

2

Principal Scientists, Dairy Chemistry Division, ICAR-NDRI, Karnal-132001

*Corresponding Author E-mail: meenatai1193@gmail.com

Received: 23.05.2017 | Revised: 4.06.2017 | Accepted: 5.06.2017

ABSTRACT

Paneer is an acid cum heat coagulated milk product and is widely consumed in the northern part

of India. When the food safety officer collecting the paneer sample for chemical analysis,

formalin @0.4% is added to remain fit for analytical analysis. In the present study two different

packaging pouches i.e. seven layer NYLON/EVOH/70μ polyethylene and 12μPET/70μ

polyethylene were used to preserve paneer with or without formalin at 27±1ºC for 120 days. The

results revealed that on the addition of formalin @0.4% in paneer samples showed an increase

in moisture content (52.88±0.061 to 53.55±0.06%) and acidity (0.62±0.017 to 0.67±0.011% LA),

whereas fat percentage decreases (24.02±0.155 to 22.05±0.126%). Tyrosine value, acidity, FFA,

peroxide value, of paneer rapidly increased while moisture, fat percentage and pH decreased

during storage at 27±1ºC respectively. Paneer sample preserved with formalin in seven layer

NYLON/EVOH/70μ polyethylene showed no significant (P>0.05) difference in moisture content

(53.55±0.068 to 53.54±0.04%) and fat percentage (22.05±0.126 to 22.04±0.089%) up to 45 days

respectively. However, 12μPET/70μ polyethylene pouch showed, no significant (P>0.05)

difference in moisture content (53.55±0.068 to 53.53±0.076%) and fat percentage (22.05±0.127

to 21.95±0.080%) upto 30 days respectively. Based on above findings it can be concluded that

paneer samples preserved with formalin under vacuum packaging in seven layer

NYLON/EVOH/70μ polyethylene pouch at 27±1ºC remained fit for analytical purpose up to 45

days.

Key words: Food safety officer, Paneer, Formalin, Vacuum packaging, Chemical analysis.

INTRODUCTION antimicrobial. It inactivates the microorganism

Paneer is the product obtained from cow or by alkalytic amino group and sulfhydryl group

buffalo milk or combination thereof by of proteins and ring of nitrogen atoms of

precipitation with sour milk, lactic acid or purine bases i.e. adenine, cytosine and guanine

citric acid7. During the collection of milk and in nucleic acid components, denaturing them

milk product samples, Food safety officer and resulting in the inhibition of

(FSO) may add 37-40% formalin @0.4% to microorganism9.

remains fit for chemical analysis. Formalin is

Cite this article: Kamble, M. and Seth, R., Preservation of Paneer Samples with Formalin under Vacuum

Packaging at 27ᵒC for Analytical Purpose, Int. J. Pure App. Biosci. 5(4): 84-92 (2017). doi:

http://dx.doi.org/10.18782/2320-7051.3011

Copyright © August, 2017; IJPAB 84

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

The low shelf life of paneer is generally due to copper sulphate pentahydrate, glacial acetic

microbial spoilage and physicochemical acid, sodium thiosulphate and folin’s reagent

changes1. Vacuum packaging is an advanced were purchased from Sigma Aldrich Pvt. Ltd.

technique which can significantly prevent the USA.

aerobic spoilage of micro-organism thereby Analysis

reducing oxidative reactions by eliminating The paneer samples were analyzed for

oxygen12. It extends the shelf life of paneer by moisture10, fat %10, acidity (% LA)10, pH (pH

2-3 times using suitable packaging material2. meter), tyrosine value13, Free Fatty Acid %11,

Vacuum packaging has been carried out by Peroxide value11.

using two type of packaging material i.e. seven Statistical analysis

layer NYLON/EVOH/70µ polyethylene and Experimental analysis was performed in

12µPET/70µ polyethylene pouch. triplicates. Data was analyzed by Graph pad

The objective of this study was to prism 5.1 software. Significant differences

preserve the paneer samples with formalin between means were determined by two-way

under vacuum packaging in two types of analysis of variance at 5 % level of

packaging material i.e. seven layer significance.

NYLON/EVOH/70μ polyethylene and

12μPET/70μ polyethylene pouch for 120 days. RESULT AND DISCUSSION

The variation in chemical composition of the Effect of vacuum packaging on storage of

paneer samples during storage in two different paneer samples

packaging at 27ºC were monitored to remained Paneer samples without formalin were vacuum

fit for analytical purpose. packed in seven layer NYLON/EVOH/70µ

polyethylene and 12µ PET/70µ polyethylene

MATERIALS AND METHODS respectively and stored at 27ºC. During storage

Sample preparation of paneer and its vacuum foul smell and sticky surface appearance was

packaging observed in the both the packaging pouches on

The paneer samples were obtained from the 2th day respectively. Paneer packed in seven

experimental dairy of National Dairy Research layer NYLON/EVOH/70µ polyethylene

Institute, Karnal. (I) Seven-layer pouches was having in foul smell after 45th day

NYLON/EVOH/70µ polyethylene and (II) and in 12µ PET/70µ polyethylene pouches,

12µ PET/70µ polyethylene pouch were used to foul smell was suspected after 30th day 27ºC

pack the paneer cubes (1×1 cm size) followed respectively.

by addition of formalin @0.4% in paneer Effect of formalin under vacuum packaging

samples by inverting pouch 8-10 times. on chemical analysis of paneer during

Vacuum packaging was done in Indvac storage at 27ºC

vacuum packaging machine at negative Moisture content (%)

pressure (-760 mmHg) within 25 sec. It was Moisture content of freshly prepared paneer

stored at 27ºC for 120 days and analysed at a samples was 52.88±0.061% (Table 3.1).

regular interval of 15 days respectively and Moisture content of paneer packed in both the

without formalin were stored at 27ºC for 10 packaging pouches showed significant

days. Samples were analyzed at a regular (P<0.05) decrease on 4th and 2nd day

interval of 2 days respectively. respectively and continue to decrease upto 10

Chemicals and Reagents days respectively (Table 3.1 and Fig. 3.1.a).

All the chemicals used in present study were Moisture content of paneer preserved with

of Analytical Reagent (AR) grade. Diethyl formalin (0.4%) showed significantly increase

ether, petroleum ether, chloroform, ethanol, (P<0.005) in moisture content from

ammonia (25%), formalin solution (37-41%), 52.88±0.061 to 53.56±0.068% (Table 3.1 and

potassium iodide, phenolphthalein indicator, 3.2). Moisture content in both the packaging

sodium hydroxide pellets, sodium carbonate, pouches showed significant (P<0.05) decrease

Copyright © August, 2017; IJPAB 85

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

th th

on 75 and 60 day respectively and continue Increasing trends in % LA were observed,

to decrease upto 120 days respectively (Table thereby indicating bacterial spoilage by lactic

3.2 and Fig. 3.1.b). No significant (P>0.05) acid fermenting bacteria. Paneer samples

difference was observed in moisture content of preserved with formalin showed increased

paneer samples preserved with formalin in titratable acidity from 0.62±0.017 to

both packaging pouches (Fig. 3.1.b). 0.67±0.011% LA (Table 3.1- 3.2). It may be

Decreasing trends in moisture level was also due to the reaction of formalin with primary

reported by Haridas and Narayanan8 and amino group, amide groups and guanidyl

Singh14. groups of proteins and releases hydrogen ions.

Fat (%) Similar results were reported by Bansal and

The fat percentage of paneer samples Singhal3, Boghra and Borkhatriya4, Singh14, in

preserved with and without formalin were milk and paneer on the addition of formalin.

analyzed by Rose-Gottlieb method and results Paneer preserved with formalin showed

are presented in tables 3.1- 3.2. and fig. 3.2.a, significant (P<0.05) increase in titratable

b). The average fat percentage of fresh paneer acidity in both the packaging pouch on 30th and

samples was 24.02±0.155% (Table 3.1.). Fat 15th days. It was continue to increase upto 120

percentage of paneer samples packed in both days respectively (Table 3.2). Significant

the packaging pouch showed significant (P<0.05) differences were observed in

(P<0.05) decrease on 2nd day respectively and titratable acidity (%Lactic acid) of paneer

continue to decrease upto 10 days (Table 3.1 preserved with formalin in both packaging

and Fig. 3.2.a). The reduction in fat might be pouches (Fig. 3.3.b). Haridas and Narayanan8,

due to lipolytic activity of microorganisms in also reported that an addition of 0.4% formalin

paneer. No significant (P>0.05) difference was in the paneer showed no change in titratable

observed in fat percentage of paneer in both acidity upto 6th day at 37ºC and thereafter an

packaging pouches (Figure 3.2.a). Initial fat increase in titratable acidity of paneer was

percentage in paneer preserved with formalin observed upto a storage period of 21st day.

was decreased from 24.02±0.155 to pH

22.05±0.126%. Fat percentage in both the The pH value of fresh paneer samples was

packaging pouches showed significant 5.53±0.08. pH value of paneer in both the

(P<0.05) decrease on 60th and 45th day packaging pouch showed significant (P<0.05)

respectively. It was continued to decrease upto decrease on 2nd day respectively and continue

120 days respectively (Table 3.1 and Fig. to decrease upto 10 days (Table 3.1). Decrease

3.2.b). Lower values of fat percentage in in pH of paneer samples during storage may be

paneer preserved with formalin may be due to due to utilization of lactose by microorganism

aqueous formalin react with milk proteins5,6. and its conversion to lactic acid. No

No significant (P>0.05) difference was significant (P>0.05) difference was observed

observed in fat percentage of paneer preserved in pH value of paneer samples in both the

with formalin in both packaging pouches (Fig. packaging pouches. Average pH value of

3.2.b). Haridas and Narayanan8, also observed paneer samples preserved with formalin

a decrease in the fat percent of paneer when remains same. No significant change in pH

preserved with 0.4% formalin at 37°C after 6th value was observed on addition of formalin

day. (Table 3.1-3.2). pH value of paneer preserved

Titratable acidity (% LA) with formalin in both the packaging pouch

The average titratable acidity of fresh paneer showed significant (P<0.05) decrease on 15th

samples was 0.62±0.017% LA (Table 3.1). day respectively and continue to decrease upto

Titratable acidity of paneer in both the 120 days (Table 3.2). No significant (P>0.05)

packaging pouch showed significant (P<0.05) difference was observed in pH of paneer

increase on 2nd day respectively and continue preserved with formalin in both packaging

to increase upto 10 days (Table 3.1). pouches. Upadhyay15, also reported that pH of

Copyright © August, 2017; IJPAB 86

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

paneer samples preserved with formalin extracted from paneer was observed on

decreased with increase in storage period. addition of formalin (Table 3.1-3.2). The FFA

Tyrosine content of milk fat extracted from paneer preserved

The tyrosine content of paneer samples was with formalin in both the packaging pouch

6.28±2.732mg/100g. Tyrosine content of showed significant (P<0.05) increase on 30th

paneer packed in both the packaging pouch day respectively and continue to increase upto

showed significant (P<0.05) increase on 2nd 120 days (Table 3.2 and Fig. 3.4.b). An

day respectively and continue to increase upto increase in FFA of milk fat extracted from

10 days (Table 3.1 and Fig. 3.3.a). The paneer with formalin indicated lipolysis of

increase in tyrosine content of paneer was due milk fat in paneer during storage. No

to proteolysis of paneer. Significant (P>0.05) significant (P>0.05) difference was observed

difference was observed in tyrosine content of in FFA of milk fat extracted from paneer

paneer in both packaging pouches (Fig.3.3.a). preserved with formalin in both packaging

Tyrosine content of paneer sample preserved pouches (Fig. 3.4.b). The increase in FFA

with formalin remains same. No significant during storage may be due to inherent lipases

change in tyrosine content was observed on present in the paneer. Singh14, also reported

addition of formalin (Table 3.1-3.2). Tyrosine that FFA of milk fat extracted from paneer

content in paneer preserved with formalin in with 0.4% formalin were increased

both the packaging pouch showed significant significantly upto 6th month at 37°C.

(P<0.05) increase on 30th day respectively and Peroxide value

continued upto 120 days (Table 3.2 and Fig. Peroxides are an indicator of oxidative

3.3.b). No significant (P>0.05) difference was rancidity of milk fat. No peroxide value was

observed in tyrosine content of paneer observed in fresh paneer samples (Table 3.1).

preserved with formalin in both packaging The peroxide value of milk fat extracted from

pouches (Fig.3.3.b). During storage, increase paneer in both the packaging pouch showed

in tyrosine content revealed that milk proteins significant (P<0.05) increase on 4th day

present in paneer have been degraded thereby respectively and continue increase upto 10

releasing free amino acids. Haridas and days (Table 3.1). No significant (P>0.05)

Narayanan8, also reported that the significant difference was observed in peroxide value of

increase in tyrosine content of paneer milk fat extracted from paneer in both

preserved with 0.4% formalin at 30°C upto 21 packaging pouches. Peroxide value of milk fat

days. Upadhyay15, found that the tyrosine extracted from paneer preserved with formalin

content of paneer samples preserved with remains same. No significant change in

0.4% formalin, significantly increased after 1 peroxide value was observed on addition of

month at 37°C and further increased upto 6 formalin (Table 3.1-3.2). Peroxide value of

months of storage. milk fat extracted from paneer preserved with

Free fatty acid (% oleic acid) formalin in both the packaging pouch showed

The FFA (% oleic acid) of milk fat extracted significant (P<0.05) increase on 45th and 60th

from fresh paneer were 0.15±0.01% oleic acid day respectively and continue to increase upto

(Table 3.1). The FFA of milk fat extracted 120 days (Table 3.2). No significant (P>0.05)

from paneer samples in both the packaging difference was observed in peroxide value of

pouch showed significant (P<0.05) increase on milk fat extracted from paneer preserved with

4th and 2nd day respectively and continue to formalin in both packaging pouches. The

increase upto 10 days (Table 3.1 and Fig. increase in peroxide value of milk fat in paneer

3.4.a). Significant (P<0.05) difference were was directly proportional to the extent of auto

observed in FFA of milk fat extracted from oxidation of milk fat. Singh14, also reported

paneer in both packaging pouches (Fig. 3.4.a). that peroxide value of milk fat extracted from

FFA of milk fat extracted from fresh paneer paneer preserve with 0.4% formalin increases

sample preserved with formalin remains same. continuously during storage upto 6 months at

No significant change in FFA of milk fat 37°C.

Copyright © August, 2017; IJPAB 87

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

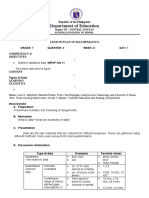

Table 3.1: Chemical analysis of paneer samples without formalin in seven layer NYLON/EVOH/70µ

polyethylene and 12µPET/70µ polyethylene pouch at 27°C.

Days 0 2 4 6 8 10

Moisture (I) 52.88±0.06 52.82±0.06 52.72±0.12 52.62±0.06 52.54±0.079 52.45±0.043

aA aA bA cA dA eA

content (%) 1 8 5

(II) 52.88±0.06 52.78±0.07 52.64±0.05 52.56±0.06 52.47±0.099 52.40±0.063

aA bA cA dA eA eA

1 7 2 7

Fat (%) (I) 24.02±0.15 23.95±0.16 23.87±0.17 23.77±0.07 23.64±0.175 23.52±0.131

aA bA cA dA eA fA

5 9 2 9

(II) 24.02±0.15 23.94 23.84±0.12 23.74±0.11 23.61±0.184 23.50±0.146

5aA ±0.154bA 2cA 6dA eA fA

Titratable (I) 0.62±0.017a 0.71±0.019 0.83±0.061 0.95±0.027 1.07±0.019e 1.27±0.018f

A bA cA dA A A

acidity

(%LA) (II) 0.62±0.017a 0.73±0.038 0.86±0.018 0.98±0.051 1.12±0.018e 1.30±0.024f

A bA cA dA A A

pH (I) 5.53±0.008a 5.45±0.017 5.40±0.008 5.35±0.006 5.30±0.008c 5.24±0.011d

A bA bA cA A A

(II) 5.53±0.008a 5.43±0.014 5.40±0.008 5.34±0.014 5.29±0.012d 5.23±0.008e

A bA bA cA A A

Tyrosine (I) 6.28±2.732a 15.30±0.98 28.14±2.73 35.52±2.77 49.18±0.473 57.38±1.639

A bB cC dD eE fF

content 5 2 2

(mg/100g) (II) 6.28±2.732a 21.58±1.66 31.42±1.79 37.16±1.91 51.64±2.062 63.93±1.706

B bC cD dE eF fG

1 1 2

FFA(% (I) 0.15±0.018a 0.20±0.016 0.24 0.30±0.018 0.41.±0.018c 0.48±0.029d

A aB

oleic acid) ±0.018bC bD E F

(II) 0.15±0.018a 0.22±0.008 0.27±0.010 0.33±0.020 dF

0.50±0.024e

B bC bD

0.44±0

8cE G

Peroxide (I) 0.13±0.06a 0.33±0.06b 0.67±0.06c 1.20±0.115e

0 A A A

1.00±0.06dA A

value

(meq/Kg) (II) 0.20±1.96a 0.39±0.012 0.73±0.06c 1.07±0.066d 1.27±0.066e

0 A bA A A A

(I) Seven layer NYLON/EVOH/70µ polyethylene pouch, (II) 12µ PET/70µ polyethylene pouch

Data is represented as means ± S.E (n=3) with different superscript (a, b, c,…) letters are significantly different within rows

at (P≤0.05) and mean values with different superscript (A, B, C,…) letters are significantly different within columns at

(P≤0.05).

Copyright © August, 2017; IJPAB 88

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

Table 3.2: Chemical analysis of paneer samples preserved with formalin in seven layer

NYLON/EVOH/70µ polyethylene and 12µPET/70µ polyethylene pouch at 27°C

Days 0 15 30 45 60 75 90 105 120

Moisture (I) 53.46 53.44

53.56±0 53.53± 53.54± 53.54± 53.53± 53.50± 53.41±0

content aA aA aA aA aA bA ±0.07 ±0.05

.068 0.06 0.06 0.04 0.081 0.023 .066bA

(%) 9bA 5bA

(II) 53.42 53.40

53.56±0 53.53± 53.53± 53.53± 53.49± 53.45± 53.38±0

aA aA aA aA bA bA ±0.09 ±0.06

.068 0.052 0.027 0.076 0.08 0.059 bA bA .032cA

8 3

Fat (%) (I) 21.77 21.72

22.05±0 22.05± 22.04± 22.04± 21.94± 21.82± 21.68±0

±0.12 ±0.10

.126aA 0.101aA 0.091aA 0.089aA 0.111bA 0.099cA dA dA .103eA

5 2

(II) 21.77 21.70

22.05±0 22.05± 22.04± 21.95± 21.83± 21.79± 21.66±0

±0.10 ±0.14

.127aA 0.105aA 0.093aA 0.080bA 0.085cA 0.215dA dA dA .089eA

1 6

Titratable (I) 1.05± 1.16±

0.67±0. 0.70±0. 0.72±0. 0.79±0. 0.87±0. 0.96±0. 1.28±0.

acidity 0.011 0.029

011aA 015aB 03bC 015bD 016cE 03dF eG fH 021gI

(% LA)

(II) 1.05± 1.22±

0.67±0. 0.70±0. 0.71±0. 0.77±0. 0.82±0. 0.93±0. 1.33±0.

aB bC bD bE cF dG 0.03e 0.013

011 016 01 018 013 036 H fI 030gJ

pH (I) 5.31± 5.28±

5.55±0. 5.44±0. 5.42±0. 5.41±0. 5.38±0. 5.36±0. 5.23±0.

0.008 0.008

012aA 008bA 008bA 006bA 008cA 005cA cA dA 008dA

(II) 5.30± 5.26±

5.55±0. 5.42±0. 5.40±0. 5.38±0. 5.36±0. 5.34±0. 5.23±0.

0.01b 0.005

012aA 014bA 01bA 011bA 01bA 015bA A cA 003cA

Tyrosine (I) 39.62 44.53

6.28±2. 6.28±2. 8.20±0. 14.48± 20.22± 29.78± 53.00±2

content ±1.19 ±2.73

732aA 732aA 718bA 0.722cA 0.985dA 1.791eA .236hA

(mg/100g) 0fA 2gA

(II) 43.17 46.99

6.28±2. 6.28±2. 9.016± 17.49± 23.50± 32.51± 57.10±0

±2.60 ±1.44

732aA 732aA 0bA 1.521cA 0.546dA 1.092eA .722hA

63fA 57gA

FFA(% (I) 0.43± 0.52±

0.15±0. 0.19±0. 0.21±0. 0.24±0. 0.30±0. 0.38±0. 0.60±0.

oleic acid) 0.017 0.015

018aA 018aA 018bA 018bA 018bA 011cA dA eA 025fA

(II) 0.45± 0.52±

0.15±0. 0.19±0. 0.21±0. 0.26±0. 0.32±0. 0.41±0. 0.62±0.

0.009 0.014

018aA 018aA 015bA 018bA 011cA 018dA dA eA 014fA

Peroxide (I) 0.67± 0.87±

0.067± 0.13±0. 0.27±0. 0.47±0. 1.07±0.

value 0 0 0.066 0.066

0.066aA 057aA 033bA 022cA dA eA 066fA

(meq/Kg)

(II) 0.73± 0.93±

0.07±0. 0.13±0. 0.27±0. 0.40±0. 0.53±0. 1.20±0.

0 0.066 0.066

066aA 066aA 066bA 115cA 066dA eA fA 115gA

(I) Seven layer NYLON/EVOH/70µ polyethylene pouch, (II) 12µ PET/70µ polyethylene pouch

Data is represented as means ± S.E (n=3) with different superscript (a, b, c,…) letters are significantly different within rows

at (P≤0.05) and mean values with different superscript (A, B, C,…) letters are significantly different within columns at

(P≤0.05)

Copyright © August, 2017; IJPAB 89

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

Moisture content (%) of paneer samples Moisture content (%) of paneer samples

without formalin at 27C preserved with formalin at 27C

56 58

Mois ture content (% )

Mois ture content (% )

54 56

7Layer NYLON /

7Layer NYLON /

52 54 EVOH/70µ polyethyelen

EVOH/70µ polyethylene

12µPET/70 µ 12µPET/70 µ

50 52 Polyethylene

Polyethylene

48 50

15

30

45

60

75

90

0

0

10

0

10

12

Days Days

Fig. 3.1 (a) Moisture content (%) of paneer samples without formalin in seven layer NYLON/EVOH/70µ

polyethylene and 12µPET/70µ polyethylene pouch at 27°C., (b) Moisture content (%) of paneer samples

preserved with formalin packed in seven layer NYLON/EVOH/70µ polyethylene and 12µPET/70µ

polyethylene pouch at 27°C

Fat (%) of paneer samples without Fat (%) of paneer samples preserved with

formalin at 27C formalin at 27C

26 24

25 23

7Layer NYLON

7Layer NYLON

Fat (% )

Fat (% )

/EVOH/70µ polyethylene

24 /EVOH/70µ polyethylene 22

12µPET/70 µ

12µPET/70 µ Polyethylene

23 Polyethylene 21

22 20

15

30

45

60

75

90

0

0

10

0

10

12

Days Days

Fig. 3.2 (a) Fat (%) of paneer samples without formalin in seven layer NYLON/EVOH/70µ polyethylene

and 12µPET/70µ polyethylene pouch at 27°C., (b) Fat (%) of paneer samples preserved with formalin

packed in seven layer NYLON/EVOH/70µ polyethylene and 12µPET/70µ polyethylene pouch at 27°C

Tyrosine content of paneer samples Tyrosine content of paneer samples preserved

without formalin at 27C with formalin at 27C

80

Tyros ine content (mg/100g)

60

Tyros ine content (mg/100g)

60

40

7Layer NYLON /

40 7Layer NYLON /

EVOH/70µ polyethylene

EVOH/70µ polyethylene

12µPET/70 µ 20 12µPET/70 µ

20 polyethylene

polyethylene

0 0

15

30

45

60

75

90

0

0

10

0

10

12

Days Days

Fig. 3.3 (a) Tyrosine content (mg/100g) of paneer samples without formalin in seven layer

NYLON/EVOH/70µ polyethylene and 12µPET/70µ polyethylene pouch at 27°C., (b) Tyrosine content

(mg/100g) of paneer samples preserved with formalin packed in seven layer NYLON/EVOH/70µ

polyethylene and 12µ PET/70 µ polyethylene pouch at 27°C

Copyright © August, 2017; IJPAB 90

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

Free fatty acids of paneer samples Free fatty acids of paneer samples preserved

without formalin at 27C with formalin at 27C

0.6 0.8

FFA (% Oleic acid)

FFA (% oleic acid)

0.6

0.4 7Layer NYLON /

EVOH/70µ polyethyelen 7Layer NYLON /

0.4

EVOH/70µ polyethylene

0.2 12µPET/70 µ

0.2 12µPET/70 µ

polyethylene

polyethylene

0.0 0.0

15

30

45

60

75

90

0

0

10

0

10

12

Days Days

Fig. 3.4 (a) FFA (%oleic acid) of milk fat extracted from paneer samples without formalin in seven layer

NYLON/EVOH/70µ polyethylene and 12µPET/70µ polyethylene pouch at 27°C., (b) FFA (%oleic acid) of

milk fat extracted from paneer samples preserved with formalin packed in seven layer

NYLON/EVOH/70µ polyethylene and 12µPET/70µ polyethylene pouch at 27°C

CONCLUSION 3. Bansal, A. and Singhal, O.P., Preservation

From present investigation it can be concluded of milk sample with formalin effect on

that Paneer samples preserved with (0.4%) acidity. Indian Journal of Dairy Science,

formalin under vacuum packaging in seven 44: 573-576 (1991).

layer NYLON/EVOH/70µ polyethylene pouch 4. Boghra, V.R. and Borkhatriya, V.N.,

at 27°C showed no change in major chemical Physico-chemical properties and

parameters upto 45th day i.e. moisture (%) and compositional profile of milk samples as

fat percentage. However in 12µ PET/70µ affected by formalin preservation- A

polyethylene pouch, no significant difference review. Indian Journal of Dairy Science

was observed in chemical parameters upto 30th 56(2): 65-71 (2003).

day. Therefore, it can be concluded that use of 5. Fraenkel-Conrat, H. and Olcott, H.S.,

seven layer NYLON/EVOH/70µ polyethylene Reaction of formaldehyde with protein. 2.

pouch for packaging of paneer samples Participation of guanidyl group and

preserved with formalin at 27°C increases the evidence of cross linking. Journal of

stability of paneer to remains fit for analytical American chemists Society, 68: 34-37

purpose as compaired to 12µ PET/70µ (1946).

polyethylene pouch. 6. Fraenkel-Conrat, H. and Olcott, H.S., The

reaction of formaldehyde with proteins. V

REFERENCES cross-linking between amino and primary

1. Ahuja, K.K. and Goyal, G.K., Effect of amide or guanidyl groups. Journal of

vacuum packaging and storage on the American chemists Society, 70: 2673-2684

shelf life of paneer tikka., In: Souvenir, Int (1948b).

Conference on “Innovations in food 7. FSSAI act, and Rules (2011) Food Safety

processing and ingredients towards and Standard Act, 2006. Professioal book

healthy India (IFPIHI-2011)”, AFST(I), publishers, new Delhi (2006).

Mumbai Chapter, Mumbai, 04–05 Jan, pp 8. Haridas, K.B. and Narayanan, K.M.,

52–53 (2011). Effect of addition of formalin and storage

2. Andress, E., Should I vacuum package on chemical composition of paneer.

food at home? Quality for Keeps. Journal of Food Science and Technology.,

University of Missouri, St Charles County 13(3): 155-156 (1976).

Extension Center, St Peters, MO, 21(1): 2- 9. Haselkorn, R. and Doty, P., The reaction

3 (2006). of formaldehyde with polynucleotides.

Copyright © August, 2017; IJPAB 91

Kamble and Seth Int. J. Pure App. Biosci. 5 (4): 84-92 (2017) ISSN: 2320 – 7051

Journal of Biological Chemistry, 236: with the folin phenol reagent. Journal of

2738-2745 (1961). Biological Chemists, 193(1): 265-275

10. IS: 10484, Specification for paneer. (1951).

Bureau of Indian standards, Manak 14. Singh. R., Darshan, Lal., Sharma, V. and

Bhavan, New Delhi (1983). Rao, P.S., Changes in chemical

11. IS: 3508, Methods of sampling and test for characteristics of market paneer samples

ghee. Bureau of Indian standards, Manak preserved with formalin. Indian Journal of

Bhavan, New Delhi (1966). Dairy Science, 68(6): 572-576 (2015).

12. Kykkidou, S. and Giatrakou. V., Effect of 15. Upadhyay, N., Goyal, A., Kumar, A.,

thyme essential oil and packaging Ghai, D.L. and Singh, R., Preservation of

treatment on fresh Mediterranean Milk and Milk Products for Analytical

swordfish fillets during storage at 4ºC. Purposes. Food Reviews International, 30:

Food Chemistry, 115(1): 169-175 (2009). 203–224 (2014).

13. Lowry, O.H., Rosebrough, N.J., Farr, A.

L. and Randall, R.J., Protein measurement

Copyright © August, 2017; IJPAB 92

Das könnte Ihnen auch gefallen

- UV-shielding Antimicrobial Zein Films Blended With Essential Oils For Active Food PackagingDokument10 SeitenUV-shielding Antimicrobial Zein Films Blended With Essential Oils For Active Food PackagingVero ArellanoNoch keine Bewertungen

- Effect of Recycled Content and rPET Quality On The Properties of IIDokument13 SeitenEffect of Recycled Content and rPET Quality On The Properties of IIPatrick MondoNoch keine Bewertungen

- Food Packaging and Shelf Life: A A A B ADokument7 SeitenFood Packaging and Shelf Life: A A A B AAnutza PopescuNoch keine Bewertungen

- Development and Validation of A Gas ChromatographicDokument5 SeitenDevelopment and Validation of A Gas ChromatographicMarcos GonzalesNoch keine Bewertungen

- Release and Antioxidant Activity of CarvDokument8 SeitenRelease and Antioxidant Activity of CarvFaaz AqeelNoch keine Bewertungen

- 39 Effectofglycerol PDFDokument9 Seiten39 Effectofglycerol PDFIJEAB JournalNoch keine Bewertungen

- Active Packaging From Triticale Flour Films For Prolonging Storage Life of Cherry TomatoDokument7 SeitenActive Packaging From Triticale Flour Films For Prolonging Storage Life of Cherry Tomatokumari svgNoch keine Bewertungen

- Characterization of Polylactic Acid Halloysite Nanotubes BionanocompositeDokument10 SeitenCharacterization of Polylactic Acid Halloysite Nanotubes BionanocompositeOvy NitaNoch keine Bewertungen

- Miljkovic - THE USE OF NANOEMULSION-BASED EDIBLE COATINGS TO PROLONG THE SHELF-LIFE OF CHEESEDokument7 SeitenMiljkovic - THE USE OF NANOEMULSION-BASED EDIBLE COATINGS TO PROLONG THE SHELF-LIFE OF CHEESEsladjad83Noch keine Bewertungen

- Pérez-Córdoba Et Al. 2018Dokument16 SeitenPérez-Córdoba Et Al. 2018Luis Jaime Perez CordobaNoch keine Bewertungen

- Annex 2.1. (Copy of The Article) Bayogan-7 (Secretaria Et Al. 2021)Dokument19 SeitenAnnex 2.1. (Copy of The Article) Bayogan-7 (Secretaria Et Al. 2021)Leizel SecretariaNoch keine Bewertungen

- 1 s2.0 S0268005X22000376 MainDokument12 Seiten1 s2.0 S0268005X22000376 Maincitra widyasariNoch keine Bewertungen

- Interaction Parenteral Emulsion and ContainersDokument10 SeitenInteraction Parenteral Emulsion and Containerspamy26250Noch keine Bewertungen

- hls-11-2-11778Dokument5 Seitenhls-11-2-11778Mary Claire ClaritoNoch keine Bewertungen

- Food Hydrocolloids: L.B. Norcino, J.F. Mendes, C.V.L. Natarelli, A. Manrich, J.E. Oliveira, L.H.C. MattosoDokument12 SeitenFood Hydrocolloids: L.B. Norcino, J.F. Mendes, C.V.L. Natarelli, A. Manrich, J.E. Oliveira, L.H.C. MattosoBianca LeyvaNoch keine Bewertungen

- IJFSNH Volume 3 Issue 1 Pages 1-32Dokument32 SeitenIJFSNH Volume 3 Issue 1 Pages 1-32Xochitl Ruelas ChaconNoch keine Bewertungen

- Food Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangDokument7 SeitenFood Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangpascapanenipbNoch keine Bewertungen

- shelt life extension of a bakery product using ethanol vaporDokument9 Seitenshelt life extension of a bakery product using ethanol vaporjj PaniaguaNoch keine Bewertungen

- Food Hydrocolloids: in Vitro and in Vivo Digestibility From Bionanocomposite Edible Films BasedDokument14 SeitenFood Hydrocolloids: in Vitro and in Vivo Digestibility From Bionanocomposite Edible Films BasedWilliam SeniorNoch keine Bewertungen

- Awasthi Et Al., 2017 PDFDokument9 SeitenAwasthi Et Al., 2017 PDFSelina DanNoch keine Bewertungen

- Envase de Almudon de Maiz en Pan y Extracto D Epectina, Ver Metodo y Propiedades Mecanicas NormaDokument8 SeitenEnvase de Almudon de Maiz en Pan y Extracto D Epectina, Ver Metodo y Propiedades Mecanicas NormaDeisy Paola Correa CardenasNoch keine Bewertungen

- Packaging for Nonthermal Processing of FoodVon EverandPackaging for Nonthermal Processing of FoodMelvin A. PascallNoch keine Bewertungen

- Food Migration Test On Process FoodDokument5 SeitenFood Migration Test On Process FoodRakibul HaqueNoch keine Bewertungen

- Active Intelligent Packaging Film Based On Ethylene Vinyl AcetateDokument9 SeitenActive Intelligent Packaging Film Based On Ethylene Vinyl AcetateAncuţa-IonelaPartinNoch keine Bewertungen

- 1 s2.0 S0268005X22000212 MainDokument11 Seiten1 s2.0 S0268005X22000212 Maincitra widyasariNoch keine Bewertungen

- Dry-Reagent Strips For Testing Milk PasteurizationDokument5 SeitenDry-Reagent Strips For Testing Milk PasteurizationJose GiraldoNoch keine Bewertungen

- Development of Biodegradable Hybrid Polymer Film For Detection of Formaldehyde in Seafood Products PDFDokument6 SeitenDevelopment of Biodegradable Hybrid Polymer Film For Detection of Formaldehyde in Seafood Products PDFnguyen ba trungNoch keine Bewertungen

- Antimicrobial Properties of CMC Films on Mycotoxigenic AspergillusDokument6 SeitenAntimicrobial Properties of CMC Films on Mycotoxigenic AspergillusSurya NegaraNoch keine Bewertungen

- International Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticDokument10 SeitenInternational Biodeterioration & Biodegradation: Toruloides Using An Open-Bubble-Column Reactor Under Non-AsepticFalcon ChauNoch keine Bewertungen

- Development of Organic-Inorganic Hybrid Antimicrobial Materials by Mechanical Force and Application For Active PackagingDokument10 SeitenDevelopment of Organic-Inorganic Hybrid Antimicrobial Materials by Mechanical Force and Application For Active Packagingabbas413Noch keine Bewertungen

- BHT Analysis in Polyethylene FilmDokument9 SeitenBHT Analysis in Polyethylene FilmrajdewaanNoch keine Bewertungen

- Nisin and α-tocopherol Coating for Antimicrobial and Antioxidative PackagingDokument7 SeitenNisin and α-tocopherol Coating for Antimicrobial and Antioxidative PackagingMay MaeNoch keine Bewertungen

- PE-hương thảo,quếDokument40 SeitenPE-hương thảo,quếNguyễn Trần Hòa HợpNoch keine Bewertungen

- Preservation of Fresh Meat With Active and Modified Atmosphere Packaging ConditionsDokument11 SeitenPreservation of Fresh Meat With Active and Modified Atmosphere Packaging ConditionsPiroinnovationNoch keine Bewertungen

- Wu 2019Dokument9 SeitenWu 2019Rahayu LestariNoch keine Bewertungen

- 1 Limonene 2010Dokument7 Seiten1 Limonene 2010alex robayoNoch keine Bewertungen

- A Study of Active Packaging (AP)Dokument5 SeitenA Study of Active Packaging (AP)Rajesh SheoranNoch keine Bewertungen

- Talanta: Yongliang Chen, Xiuling Li, Ming Yang, Libin Yang, Xiaoxia Han, Xin Jiang, Bing ZhaoDokument6 SeitenTalanta: Yongliang Chen, Xiuling Li, Ming Yang, Libin Yang, Xiaoxia Han, Xin Jiang, Bing ZhaoTangkilNoch keine Bewertungen

- PinepallDokument6 SeitenPinepallSESHADHIRI KIS-GROUPNoch keine Bewertungen

- Effect of Packaging Methods and Storage Periods On Physico-Chemical Characteristics of Goat MeatDokument19 SeitenEffect of Packaging Methods and Storage Periods On Physico-Chemical Characteristics of Goat Meatdilipgupta66Noch keine Bewertungen

- BNNI Volume 58 Issue 2 Pages 91-108Dokument18 SeitenBNNI Volume 58 Issue 2 Pages 91-108Karim KarimNoch keine Bewertungen

- Nanoencapsulation of Passion Fruit By-Products Extracts For Enhanced Antimicrobial ActivityDokument10 SeitenNanoencapsulation of Passion Fruit By-Products Extracts For Enhanced Antimicrobial ActivityJavier R. AmayaNoch keine Bewertungen

- 2 Migration of Photoinitiators, Phthalates and Plasticizers From Paper and Cardboard Materials Into Different Simulants and FoodstuffsDokument8 Seiten2 Migration of Photoinitiators, Phthalates and Plasticizers From Paper and Cardboard Materials Into Different Simulants and FoodstuffsFP Division TrainingNoch keine Bewertungen

- Pengaruh Penggunaan Kemasan Terhadap Mut PDFDokument15 SeitenPengaruh Penggunaan Kemasan Terhadap Mut PDFAmy LikurNoch keine Bewertungen

- Characterization of Postharvest Physiology of Thermised Dates (Phoenix Dactylifera L.), Packed Under A Modified Atmosphere (Map)Dokument15 SeitenCharacterization of Postharvest Physiology of Thermised Dates (Phoenix Dactylifera L.), Packed Under A Modified Atmosphere (Map)RedhaLavNoch keine Bewertungen

- LycopéneDokument7 SeitenLycopéneimene boulaalouaNoch keine Bewertungen

- 2010 Article 155Dokument6 Seiten2010 Article 155Chandrima JashNoch keine Bewertungen

- Bacillus Amyloliquefaciens - 040829Dokument9 SeitenBacillus Amyloliquefaciens - 040829Ekwan WiratnoNoch keine Bewertungen

- Migration From Polycarbonate Packaging To Food Simulants During Microwave HeatingDokument9 SeitenMigration From Polycarbonate Packaging To Food Simulants During Microwave Heatinggs67570Noch keine Bewertungen

- NaY-Ag Zeolite Chitosan Coating Kraft Paper ApplieDokument16 SeitenNaY-Ag Zeolite Chitosan Coating Kraft Paper ApplieBongolwethu MabuselaNoch keine Bewertungen

- Permeation - Oxygen Packaging - 18 - 2016Dokument11 SeitenPermeation - Oxygen Packaging - 18 - 2016muriloinnocentiniNoch keine Bewertungen

- Analysis of plasticiser migration to meat roasted in plastic bagsDokument6 SeitenAnalysis of plasticiser migration to meat roasted in plastic bagsHigor RodriguesNoch keine Bewertungen

- Ejemplo 1 - Superficie de RespuestaDokument13 SeitenEjemplo 1 - Superficie de RespuestaFernandoEstebanNoch keine Bewertungen

- Food Research International: Marta Fernanda Zotarelli, Bruno Augusto Mattar Carcio Fi, João Borges LaurindoDokument8 SeitenFood Research International: Marta Fernanda Zotarelli, Bruno Augusto Mattar Carcio Fi, João Borges LaurindorobertoNoch keine Bewertungen

- Li Et Al (2010) PDFDokument8 SeitenLi Et Al (2010) PDFGuillermo Marcelo Badillo MuñozNoch keine Bewertungen

- 1 s2.0 S0268005X2031852X MainDokument11 Seiten1 s2.0 S0268005X2031852X MainJack JackNoch keine Bewertungen

- Gamma irradiation and autoclave sterilization of peat and compost carriersDokument9 SeitenGamma irradiation and autoclave sterilization of peat and compost carriersSeptiana SariNoch keine Bewertungen

- Liu 2021-AdaptaçãoDokument9 SeitenLiu 2021-AdaptaçãoSâmilla GabriellaNoch keine Bewertungen

- Review Jurnal ShikoninDokument9 SeitenReview Jurnal ShikoninKhaznah Khalishah HidayatNoch keine Bewertungen

- Fanuc LATHE CNC Program Manual Gcodetraining 588Dokument104 SeitenFanuc LATHE CNC Program Manual Gcodetraining 588DOBJAN75% (12)

- 1529Dokument14 Seiten1529Tarang MalvaniyaNoch keine Bewertungen

- Shape Optimization of A 3D Slider With DimplesDokument9 SeitenShape Optimization of A 3D Slider With DimplesTarang MalvaniyaNoch keine Bewertungen

- 436-431 MECHANICS 4-Mechanical Vibration-Lecture NotesDokument247 Seiten436-431 MECHANICS 4-Mechanical Vibration-Lecture Noteskulov1592Noch keine Bewertungen

- Analysis of Hydrodynamic Lubrication in Infinitely Long Journal Bearing With Oscillating VelocityDokument4 SeitenAnalysis of Hydrodynamic Lubrication in Infinitely Long Journal Bearing With Oscillating VelocityTarang MalvaniyaNoch keine Bewertungen

- CPU SyllabusDokument2 SeitenCPU SyllabusaliasgarmtNoch keine Bewertungen

- Media Monitoring SlideDokument37 SeitenMedia Monitoring Slidegelfeto gebreNoch keine Bewertungen

- Psychological Aspects of Forensic Identification EvidenceDokument38 SeitenPsychological Aspects of Forensic Identification EvidencetNoch keine Bewertungen

- Factors Affecting Preparedness of University of Baguio Criminology ExamineesDokument16 SeitenFactors Affecting Preparedness of University of Baguio Criminology ExamineesJepoy Nisperos ReyesNoch keine Bewertungen

- The Problem and Its BackgroundDokument47 SeitenThe Problem and Its BackgroundJhon dave SurbanoNoch keine Bewertungen

- Study Unit 2.1 Basic ProbabilityDokument37 SeitenStudy Unit 2.1 Basic ProbabilitybronwyncloeteNoch keine Bewertungen

- Medical Testing Verification of Automated AnalysersDokument16 SeitenMedical Testing Verification of Automated AnalysersBob WongNoch keine Bewertungen

- Hal 119 No 3-1Dokument2 SeitenHal 119 No 3-1deka ferianaNoch keine Bewertungen

- Research Template 1Dokument26 SeitenResearch Template 1Rannie VichozoNoch keine Bewertungen

- Research Methodology and IPRDokument2 SeitenResearch Methodology and IPRHaran HariNoch keine Bewertungen

- ITEMA 2019 DRAFT Conference ProceedingsDokument268 SeitenITEMA 2019 DRAFT Conference ProceedingsradiccciNoch keine Bewertungen

- Telecare For Older People: Promoting Independence, Participation, and IdentityDokument18 SeitenTelecare For Older People: Promoting Independence, Participation, and IdentityAlejandro CardonaNoch keine Bewertungen

- PR2 - SLHT 2 - January 11 To 15Dokument4 SeitenPR2 - SLHT 2 - January 11 To 15JESSA SUMAYANGNoch keine Bewertungen

- The Impact of Social Media Influencers On Purchase Intention Towards Cosmetic Products in ChinaDokument18 SeitenThe Impact of Social Media Influencers On Purchase Intention Towards Cosmetic Products in ChinaHương MaiNoch keine Bewertungen

- What Is A Case StudyDokument3 SeitenWhat Is A Case StudyLara Delle100% (1)

- Methodology of Seismic RefractionDokument8 SeitenMethodology of Seismic Refractionelnaqa1760% (1)

- The Impact of Human Resource Management Practices On Turnover of Bank Employees in BangladeshDokument13 SeitenThe Impact of Human Resource Management Practices On Turnover of Bank Employees in BangladeshMuhammad AhmadNoch keine Bewertungen

- CJC h2 Math p2 SolutionDokument14 SeitenCJC h2 Math p2 SolutionjimmytanlimlongNoch keine Bewertungen

- Using Composition To Assess and Enhance Visual Values in LandscapesDokument31 SeitenUsing Composition To Assess and Enhance Visual Values in LandscapesTosia PlotaNoch keine Bewertungen

- Chap1 MazumdarDokument38 SeitenChap1 MazumdarMastersoyoNoch keine Bewertungen

- Analyzing The Changes in Sales and Consumption of Alcohol Upon The Imposition of Taxes in GurugramDokument23 SeitenAnalyzing The Changes in Sales and Consumption of Alcohol Upon The Imposition of Taxes in GurugramInternational Journal of Advance Study and Research WorkNoch keine Bewertungen

- Hars ManualDokument1 SeiteHars ManualsyafiqaNoch keine Bewertungen

- The Impact of Modular Learning on StudentsDokument4 SeitenThe Impact of Modular Learning on StudentsKlein Dugelio CunananNoch keine Bewertungen

- Distribution of Vertical Loads in a Machinery Support SystemDokument4 SeitenDistribution of Vertical Loads in a Machinery Support SystemnavinzhereNoch keine Bewertungen

- Reserchers in IBERIA - COLCHOLOGYDokument345 SeitenReserchers in IBERIA - COLCHOLOGYGeorgian National Museum100% (1)

- Testing A Multidimensional Theory of Person-Environment FitDokument21 SeitenTesting A Multidimensional Theory of Person-Environment FitNico SunicNoch keine Bewertungen

- Department of Education: Lesson Plan in MathematicsDokument2 SeitenDepartment of Education: Lesson Plan in MathematicsShiera SaletreroNoch keine Bewertungen

- AAI-Adult Attachment ProtocolDokument84 SeitenAAI-Adult Attachment Protocolpopoviciaida100% (2)

- BB 1 - 03 DMAIC RoadmapDokument31 SeitenBB 1 - 03 DMAIC RoadmapShri KumaranNoch keine Bewertungen

- Variance and Standard DeviationDokument16 SeitenVariance and Standard Deviationmehtab sanaNoch keine Bewertungen

- Haleeb Milk Reseasrch Project ReportDokument60 SeitenHaleeb Milk Reseasrch Project Reportabbas12178% (9)