Beruflich Dokumente

Kultur Dokumente

En 10255 (BS 1387)

Hochgeladen von

Burak KececiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

En 10255 (BS 1387)

Hochgeladen von

Burak KececiCopyright:

Verfügbare Formate

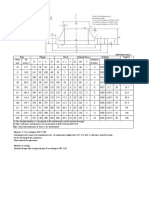

Standard Pipe for EN 10255

(Transition from BS 1387)

MATERIAL OF GRADE CHEMICAL COMPOSITION (%) MECHANICAL PROPERTIES

Yield Tensile Elongation

Steel Steel C Si Mn P S Strength Strength

Name Number Max Max Max Max Max

(MPa) (MPa) %

S 195 T 1.0026 0.20 - 1.40 0.035 0.03 195 320 to 520 20

H Series L Series

Outside Outside

Norminal Specified Wall Calculated Norminal Specified Wall Calculated

Deignation Diameter Deignation Diameter

Size Outside of Thickness Size Outside of Thickness

Diameter Plain End Threaded Diameter Plain End Threaded

Thread Max Min Thread Max Min

and and

Stocketed Stocketed

mm. mm. mm. mm. mm. kg./m. kg./m. mm. mm. mm. mm. mm. kg./m. kg./m.

6 10.2 1/8 10.6 9.8 2.6 0.487 0.490 8 13.5 1/4 13.9 13.2 2.0 0.567 0.571

8 13.5 1/4 14.0 13.2 2.9 0.765 0.769 10 17.2 3/8 17.4 16.7 2.0 0.750 0.756

10 17.2 3/8 17.5 16.7 2.9 1.02 1.30 15 21.3 1/2 21.7 21.0 2.3 1.08 1.09

15 21.3 1/2 21.8 21.0 3.2 1.44 1.45 20 26.9 3/4 27.1 26.4 2.3 1.40 1.41

20 26.9 3/4 27.3 26.5 3.2 1.87 1.88 25 33.7 1 34.0 33.2 2.9 2.20 2.22

25 33.7 1 34.2 33.3 4.0 2.93 2.95 32 42.4 1 1/4 42.7 41.9 2.9 2.82 2.85

32 42.4 1 1/4 42.9 42.0 4.0 3.79 3.82 40 48.3 1 1/2 48.6 47.8 2.9 3.25 3.29

40 48.3 1 1/2 48.8 47.9 4.0 4.37 4.41 50 60.3 2 60.7 59.6 3.2 4.51 4.58

50 60.3 2 60.8 59.7 4.5 6.19 6.26 65 76.1 2 1/2 76.0 75.2 3.2 5.75 5.87

65 76.1 2 1/2 76.6 75.3 4.5 7.93 8.05 80 88.9 3 88.7 87.9 3.2 6.76 6.93

80 88.9 3 89.5 88.0 5.0 10.3 10.5 90 101.6 3 1/2 101.2 100.3 3.6 8.70 8.88

100 114.3 4 115.0 113.1 5.4 14.5 14.8 100 114.3 4 113.9 113.0 3.6 9.83 10.1

125 139.7 5 140.8 138.5 5.4 17.9 18.4 125 139.7 5 140.8 138.5 4.5 15.0 15.5

150 165.1 6 166.5 163.9 5.4 21.3 21.9 150 165.1 6 166.5 163.9 4.5 17.8 18.4

M Series L1 Series

Outside Outside

Norminal Specified Wall Calculated Norminal Specified Wall Calculated

Deignation Diameter Deignation Diameter

Size Outside of Thickness Size Outside of Thickness

Diameter Plain End Threaded Diameter Plain End Threaded

Thread Max Min Thread Max Min

and and

Stocketed Stocketed

mm. mm. mm. mm. mm. kg./m. kg./m. mm. mm. mm. mm. mm. kg./m. kg./m.

6 10.2 1/8 10.6 9.8 2.0 0.404 0.407 8 13.5 1/4 13.9 13.2 2.0 0.570 0.574

8 13.5 1/4 14.0 13.2 2.3 0.641 0.645 10 17.2 3/8 17.4 16.7 2.0 0.742 0.748

10 17.2 3/8 17.5 16.7 2.3 0.84 0.845 15 21.3 1/2 21.7 21.0 2.3 1.08 1.09

15 21.3 1/2 21.8 21.0 2.6 1.21 1.22 20 26.9 3/4 27.1 26.4 2.3 1.39 1.40

20 26.9 3/4 27.3 26.5 2.6 1.56 1.57 25 33.7 1 34.0 33.2 2.9 2.20 2.22

25 33.7 1 34.2 33.3 3.2 2.41 2.43 32 42.4 1 1/4 42.7 41.9 2.9 2.82 2.85

32 42.4 1 1/4 42.9 42.0 3.2 3.10 3.13 40 48.3 1 1/2 48.6 47.8 2.9 3.24 3.28

40 48.3 1 1/2 48.8 47.9 3.2 3.56 3.60 50 60.3 2 60.7 59.6 3.2 4.49 4.56

50 60.3 2 60.8 59.7 3.6 5.03 5.10 65 76.1 2 1/2 76.3 75.2 3.2 5.73 5.85

65 76.1 2 1/2 76.6 75.3 3.6 6.42 6.54 80 88.9 3 89.4 87.9 3.6 7.55 7.72

80 88.9 3 89.5 88.0 4.0 8.36 8.5 100 114.3 4 114.9 113.0 4.0 10.8 11.1

100 114.3 4 115.0 113.1 4.5 12.2 12.5

125 139.7 5 140.8 138.5 5.0 16.6 17.1 L2 Series

150 165.1 6 166.5 163.9 5.0 19.8 20.4

Outside

Norminal Specified Wall Calculated

Deignation Diameter

Size Outside of Thickness

Dimension Tolerances Color Makring Plain End Threaded

Diameter Thread

Thickness H and M series and Type L : ± 10% Series/Type Color Max Min and

Type L1 and L2 : -8% with the plus H series Red Stocketed

tolerance limited by the mass tolerance

M series Blue mm. mm. mm. mm. mm. kg./m. kg./m.

Weight H and M series and Type L : ± 7.5% Type L Green 8 13.5 1/4 13.6 13.2 1.8 0.515 0.519

on budles of 10 tons or more 10 17.2 3/8 17.1 16.7 1.8 0.670 0.676

Type L1 White

Type L1 and L2 : +10%, -8%

Type L2 Brown 15 21.3 1/2 21.4 21.0 2.0 0.947 0.956

on individual tubes

20 26.9 3/4 26.9 26.4 2.3 1.38 1.39

Hydrostatictest test pressure 50 bar 25 33.7 1 33.8 33.2 2.6 1.98 2.00

32 42.4 1 1/4 42.5 41.9 2.6 2.54 2.57

40 48.3 1 1/2 48.4 47.8 2.9 3.23 3.27

50 60.3 2 60.2 59.6 2.9 4.08 4.15

65 76.1 2 1/2 76.0 75.2 3.2 5.71 5.83

80 88.9 3 88.7 87.9 3.2 6.72 6.89

100 114.3 4 113.9 113.0 3.6 9.75 10.0

Das könnte Ihnen auch gefallen

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNoch keine Bewertungen

- Spiral Wound GasketsDokument7 SeitenSpiral Wound GasketsPrem NautiyalNoch keine Bewertungen

- Standard en 10025 2Dokument1 SeiteStandard en 10025 2Lily MoniqueNoch keine Bewertungen

- DIN 2076 vs. ASTM A 877Dokument1 SeiteDIN 2076 vs. ASTM A 877tobypadfieldNoch keine Bewertungen

- A 299 - A 299M - 09 (2014) PDFDokument2 SeitenA 299 - A 299M - 09 (2014) PDFأسامة وحيد الدين رمضانNoch keine Bewertungen

- Fittings Din11852 Din11850Dokument14 SeitenFittings Din11852 Din11850dingobk1Noch keine Bewertungen

- Screw, IsO 14583, PAN, Metric, TorxDokument1 SeiteScrew, IsO 14583, PAN, Metric, TorxDerekNoch keine Bewertungen

- List of DIN Standards Pipe Tube and Fittings Standards and SpecificationsDokument14 SeitenList of DIN Standards Pipe Tube and Fittings Standards and SpecificationsRakeshKumarSinghNoch keine Bewertungen

- Iso 228 1 2000Dokument9 SeitenIso 228 1 2000Ulvi NebiyevNoch keine Bewertungen

- Din 1480 2005Dokument6 SeitenDin 1480 2005PacoNoch keine Bewertungen

- Astm A192Dokument11 SeitenAstm A192Marcelo VicentiniNoch keine Bewertungen

- Carl Stahl UAE CatalogDokument64 SeitenCarl Stahl UAE CatalogsuhailpmNoch keine Bewertungen

- Self Tapping ScrewDokument4 SeitenSelf Tapping Screwskalimuthu190Noch keine Bewertungen

- WEG Roller Table 50040456 Brochure EnglishDokument12 SeitenWEG Roller Table 50040456 Brochure EnglishjmartinezmoNoch keine Bewertungen

- Din 5401 PDFDokument12 SeitenDin 5401 PDFLuciano FontesNoch keine Bewertungen

- Round Washers SN 808: July 2000Dokument1 SeiteRound Washers SN 808: July 2000Maurício Duarte de AndradeNoch keine Bewertungen

- Spiral Welded Pipes - Web PDFDokument4 SeitenSpiral Welded Pipes - Web PDFeng7mohamed7hashimNoch keine Bewertungen

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDokument4 SeitenISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNoch keine Bewertungen

- Mild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603Dokument2 SeitenMild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603MantasNoch keine Bewertungen

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDokument2 SeitenAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Noch keine Bewertungen

- SN430-2 2006-12 SAP eDokument3 SeitenSN430-2 2006-12 SAP eChristopher LloydNoch keine Bewertungen

- 04 Buttweldfitt Tee Din2615Dokument7 Seiten04 Buttweldfitt Tee Din2615ivanmatijevicNoch keine Bewertungen

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Dokument3 SeitenNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'harisNoch keine Bewertungen

- CuZn39pb3 - DIN 12164Dokument1 SeiteCuZn39pb3 - DIN 12164Bruno FaveroNoch keine Bewertungen

- Thread Chart PDFDokument9 SeitenThread Chart PDFhisaj4uNoch keine Bewertungen

- Evraz CatalogDokument52 SeitenEvraz CatalogAhmad KhalifaNoch keine Bewertungen

- Steel AsiaDokument109 SeitenSteel AsiaHieu Do TatNoch keine Bewertungen

- Unf ThreadDokument1 SeiteUnf Threadhisaj4uNoch keine Bewertungen

- Pipes For Industrial Application enDokument60 SeitenPipes For Industrial Application enم.وليد شكرNoch keine Bewertungen

- Knives & Tools For The Tire IndustryDokument11 SeitenKnives & Tools For The Tire IndustryX800XLNoch keine Bewertungen

- Thread Standard BSPDokument7 SeitenThread Standard BSPĐạt TrầnNoch keine Bewertungen

- British Steel Sections DatasheetsDokument18 SeitenBritish Steel Sections DatasheetsAdnan NajemNoch keine Bewertungen

- Colly Pop Rivet 222Dokument95 SeitenColly Pop Rivet 222Andreas LidströmNoch keine Bewertungen

- Bossard Taptite Self Tapping Screw CatalogueDokument10 SeitenBossard Taptite Self Tapping Screw CataloguepmlmkpNoch keine Bewertungen

- Small Book EN en NLDokument1.595 SeitenSmall Book EN en NLOxbown91Noch keine Bewertungen

- En 10164-2005 PDFDokument15 SeitenEn 10164-2005 PDFUmut HızırNoch keine Bewertungen

- Jis g3131 HotDokument3 SeitenJis g3131 Hoteko_koesworoNoch keine Bewertungen

- HLN Applications enDokument27 SeitenHLN Applications enClint TcNoch keine Bewertungen

- MIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsDokument47 SeitenMIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsCemalNoch keine Bewertungen

- Mec PinDokument55 SeitenMec PinManikandan VeerasekaranNoch keine Bewertungen

- Din Flange Din 2627: (Dimensions in MM.)Dokument12 SeitenDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNoch keine Bewertungen

- Flat Products Catalogue: Coils SheetsDokument24 SeitenFlat Products Catalogue: Coils SheetsAmro HassaninNoch keine Bewertungen

- Boundary Dimensions and Bearing Number CodesDokument4 SeitenBoundary Dimensions and Bearing Number CodesPutra Kanjeng Romo RomoNoch keine Bewertungen

- General Tolerances - DIN - IsO - 2768Dokument2 SeitenGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheNoch keine Bewertungen

- Din 2576 PDFDokument1 SeiteDin 2576 PDFSabka PanayotovaNoch keine Bewertungen

- BS en 10273-2000 - Steel Bars For Pressure Purposes With Specified Elevated TemperatureDokument32 SeitenBS en 10273-2000 - Steel Bars For Pressure Purposes With Specified Elevated TemperatureengdanielmorenoNoch keine Bewertungen

- Metric DIN Hydraulic Fittings and Threads Chart & DimensionsDokument3 SeitenMetric DIN Hydraulic Fittings and Threads Chart & DimensionsTiago SucupiraNoch keine Bewertungen

- 2010 Catalogue AndertonDokument47 Seiten2010 Catalogue Andertonaiyubi2100% (1)

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Dokument6 SeitenKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranNoch keine Bewertungen

- Din 02076 1964 enDokument4 SeitenDin 02076 1964 envipin daveNoch keine Bewertungen

- Asme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesDokument69 SeitenAsme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesnitinNoch keine Bewertungen

- Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeDokument0 SeitenDin 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeAdrian MarinNoch keine Bewertungen

- Maryland Metrics - Thread Data Charts PDFDokument3 SeitenMaryland Metrics - Thread Data Charts PDFEnmanuel GuzmanNoch keine Bewertungen

- Definition of Steel Products: British Standard Bs en 10079:2007Dokument48 SeitenDefinition of Steel Products: British Standard Bs en 10079:2007Syed Shoaib RazaNoch keine Bewertungen

- En 10029Dokument5 SeitenEn 10029PHAMTOAINoch keine Bewertungen

- DIN13 ISO Metric Threads enDokument1 SeiteDIN13 ISO Metric Threads enwagner jrNoch keine Bewertungen

- 010-Din en 1092 2002 004 Aluminium Alloy FlangesDokument20 Seiten010-Din en 1092 2002 004 Aluminium Alloy FlangesQuality MSIPLNoch keine Bewertungen

- Metal Reinforcement - Term PaperDokument35 SeitenMetal Reinforcement - Term PaperDrei ServitoNoch keine Bewertungen

- Is 19781982Dokument5 SeitenIs 19781982Padakandla SumanNoch keine Bewertungen

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNoch keine Bewertungen

- EssayDokument4 SeitenEssayBurak KececiNoch keine Bewertungen

- EssayDokument4 SeitenEssayBurak KececiNoch keine Bewertungen

- ISO 9001:2008 vs. ISO 9001:2015: 1. General Changes at Committee Draft StageDokument4 SeitenISO 9001:2008 vs. ISO 9001:2015: 1. General Changes at Committee Draft StageBurak KececiNoch keine Bewertungen

- TS EN 10219-1 (Mart 2008)Dokument18 SeitenTS EN 10219-1 (Mart 2008)Burak KececiNoch keine Bewertungen

- Incoterms Shipping GuideDokument60 SeitenIncoterms Shipping GuidejumbotronNoch keine Bewertungen

- CauseDokument4 SeitenCauseBurak KececiNoch keine Bewertungen

- Steel Cargo GuideDokument100 SeitenSteel Cargo GuideBill Kelso100% (1)

- ISO 9001 2015 Vs ISO 9001 2008 Main Changes Webinar Presentation DeckDokument15 SeitenISO 9001 2015 Vs ISO 9001 2008 Main Changes Webinar Presentation DeckBurak KececiNoch keine Bewertungen

- Specs - ABSDokument3 SeitenSpecs - ABSBurak KececiNoch keine Bewertungen

- Astm A1011Dokument8 SeitenAstm A1011Burak KececiNoch keine Bewertungen

- Is 1449 MN Ore SamplingDokument18 SeitenIs 1449 MN Ore SamplingBurak Kececi100% (1)

- DownfileDokument20 SeitenDownfileBurak KececiNoch keine Bewertungen

- Construction Products en 10138Dokument3 SeitenConstruction Products en 10138Burak KececiNoch keine Bewertungen

- Steel Cargo GuideDokument100 SeitenSteel Cargo GuideBill Kelso100% (1)

- Erdemir Product Catalogue 2017Dokument334 SeitenErdemir Product Catalogue 2017Burak Kececi0% (1)

- Astm A615m PDFDokument12 SeitenAstm A615m PDFAnonymous q8HhQ4w50% (2)

- Roofing Manu. PRwebDokument1 SeiteRoofing Manu. PRwebBurak KececiNoch keine Bewertungen

- 1207Dokument18 Seiten1207Burak KececiNoch keine Bewertungen

- Spec PL e 2014Dokument47 SeitenSpec PL e 2014Gilang BhismaNoch keine Bewertungen

- Tolerances To ISO 9445 For Cold Rolled Narrow and Wide StripDokument8 SeitenTolerances To ISO 9445 For Cold Rolled Narrow and Wide StripBurak KececiNoch keine Bewertungen

- BPVC Code Cases 5Dokument54 SeitenBPVC Code Cases 5Burak KececiNoch keine Bewertungen

- Rebar Grades Comparison SheetDokument198 SeitenRebar Grades Comparison SheetBurak KececiNoch keine Bewertungen

- Specifications Ss400Dokument8 SeitenSpecifications Ss400Burak KececiNoch keine Bewertungen

- Galvanizado Entender Triple SpotDokument10 SeitenGalvanizado Entender Triple SpotEdgarDavidDiazCamposNoch keine Bewertungen

- Kangal Hacim HesapDokument2 SeitenKangal Hacim HesapBurak KececiNoch keine Bewertungen

- International Steel Grade Comparison ChartDokument1 SeiteInternational Steel Grade Comparison Chart마사유삼숟딘Noch keine Bewertungen

- Arfken Solutions Manual 7th Ed PDFDokument524 SeitenArfken Solutions Manual 7th Ed PDFBolaybalam84% (77)

- Vectors 05 Notes PDFDokument21 SeitenVectors 05 Notes PDFADSaksoulNoch keine Bewertungen

- Design of Induction Coil of A Coreless Induction Furnace To Melt AluminumDokument6 SeitenDesign of Induction Coil of A Coreless Induction Furnace To Melt AluminumKyawZawNoch keine Bewertungen

- Resistance and ResisitivityDokument18 SeitenResistance and ResisitivitySophiaFayeBiongNoch keine Bewertungen

- MEMS Design Chap 5 (P1-New) - MEMS DESIGN ProcessDokument27 SeitenMEMS Design Chap 5 (P1-New) - MEMS DESIGN ProcessvuonglupNoch keine Bewertungen

- Hiten Parmar: Physics byDokument5 SeitenHiten Parmar: Physics byKailas ArunNoch keine Bewertungen

- Sajb 411952 969Dokument18 SeitenSajb 411952 969samirNoch keine Bewertungen

- 05 PDFDokument1 Seite05 PDFdruwid6Noch keine Bewertungen

- 17 Capacitors and Inductors in AC CircuitsDokument12 Seiten17 Capacitors and Inductors in AC CircuitsAbhijit PattnaikNoch keine Bewertungen

- Basf Processing Styrinic Polymers and CopolymersDokument14 SeitenBasf Processing Styrinic Polymers and CopolymersTejender SinghNoch keine Bewertungen

- Murray Leinster - Sidewise in TimeDokument25 SeitenMurray Leinster - Sidewise in Timemiquester50% (2)

- Thermalrock S Data Sheet - inDokument2 SeitenThermalrock S Data Sheet - inlac ngoNoch keine Bewertungen

- Belt Bucket Elevator DesignDokument27 SeitenBelt Bucket Elevator DesignArmando80% (5)

- SDMII Section8 Phases Transformation ExercisesDokument28 SeitenSDMII Section8 Phases Transformation ExercisesPheng SeihaksethNoch keine Bewertungen

- Principles of Hydrostatic PressureDokument25 SeitenPrinciples of Hydrostatic PressureJherhamy BaguilatNoch keine Bewertungen

- Dow Elite 5401G TDSDokument3 SeitenDow Elite 5401G TDSAli RazuNoch keine Bewertungen

- Problem SetDokument2 SeitenProblem SetCrystal DimaanoNoch keine Bewertungen

- Buried Pipe NDTDokument224 SeitenBuried Pipe NDTDemian PereiraNoch keine Bewertungen

- Technical Manual Vapodest 20-30-40Dokument39 SeitenTechnical Manual Vapodest 20-30-40marianinha690% (1)

- BOF Plant Write UpDokument20 SeitenBOF Plant Write UpKalyan HalderNoch keine Bewertungen

- Fludex Md10 1 Flender Standard Couplings en 0909Dokument51 SeitenFludex Md10 1 Flender Standard Couplings en 0909Diego SilvaNoch keine Bewertungen

- Twinning and PHENIX: Peter ZwartDokument30 SeitenTwinning and PHENIX: Peter ZwartSarat chandra dashNoch keine Bewertungen

- Hardness Conversion Chart 3Dokument3 SeitenHardness Conversion Chart 3rajarshi6666Noch keine Bewertungen

- AluminioDokument14 SeitenAluminiobrauliocoroNoch keine Bewertungen

- Aee1 SkriptDokument186 SeitenAee1 SkriptCristian PanaNoch keine Bewertungen

- Lacan and Badiou: Logic of The Pas-Tout: Russell GriggDokument13 SeitenLacan and Badiou: Logic of The Pas-Tout: Russell Griggd_albickerNoch keine Bewertungen

- Corrosion Prediction Modelling PDFDokument102 SeitenCorrosion Prediction Modelling PDFmilecsa100% (1)

- Power Generation by Using Piezoelectric Transducer With Bending Mechanism SupportDokument6 SeitenPower Generation by Using Piezoelectric Transducer With Bending Mechanism SupportIAES IJPEDSNoch keine Bewertungen

- Topic 2 - ComplexationDokument48 SeitenTopic 2 - ComplexationLokesh JaiswalNoch keine Bewertungen

- TRUMPF Technical Data Sheet TruDiskDokument9 SeitenTRUMPF Technical Data Sheet TruDiskHLNoch keine Bewertungen