Beruflich Dokumente

Kultur Dokumente

2015 A Multi-Objective Based Evolutionary Algorithm and Social Network Analysis Approach For Dynamic Job Shop Scheduling Problem.

Hochgeladen von

Md AkhtarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2015 A Multi-Objective Based Evolutionary Algorithm and Social Network Analysis Approach For Dynamic Job Shop Scheduling Problem.

Hochgeladen von

Md AkhtarCopyright:

Verfügbare Formate

International Journal on Cybernetics & Informatics (IJCI) Vol. 4, No.

2, April 2015

A MULTI-OBJECTIVE BASED EVOLUTIONARY

ALGORITHM AND SOCIAL NETWORK ANALYSIS

APPROACH FOR DYNAMIC JOB SHOP SCHEDULING

PROBLEM

1

V.K.Manupati, 2N.Arudhra, 2P.Vigneshwar, 2D. RajaShekar and 2M.Yaswanth

1

Associate professor, Department of Mechanical engineering, KLUniversity, Vijayawada,

AP

2

Under Graduate Student, Department of Mechanical engineering,

KLUniversity,Vijayawada, AP

ABSTRACT

In this paper, a multi-objective based NSGA-II algorithm is proposed for dynamic job-shop scheduling

problem (DJSP) with random job arrivals and machine breakdowns. In DJSP schedules are usually

inevitable due to various unexpected disruptions. To handle this problem, it is necessary to select

appropriate key machines at the beginning of the simulation instead of random selection. Thus, this paper

seeks to address on approach called social network analysis method to identify the key machines of the

addressed DJSP. With identified key machines, the effectiveness and stability of scheduling i.e., makespan

and starting time deviations of the computational complex NP-hard problem has been solved with proposed

multi-objective based hybrid NSGA-ll algorithm. Several experiments studies have been conducted and

comparisons have been made to demonstrate the efficiency of the proposed approach with classical multi-

objective based NSGA-II algorithm. The experimental results illustrate that the proposed method is very

effective in various shop floor conditions.

KEYWORDS

Social network analysis, NP hard, NSGA-II algorithm, Dynamic job-shop scheduling problem.

1. INTRODUCTION

Recent manufacturing has been emphasized on short product life cycles, variety of products with

medium production. This can be achieved through current information and communication

technologies (ICT) due to their rapid advancements. Job shop scheduling problem (JSP) attracts

considerable attention over other production problems due to its varied applications in the field of

manufacturing industries [1]. From the Literature it is well proved that JSP is the most difficult

combinatorial optimization problems and it is well known as NP-hard problems [2]. It is

necessary to understand the behavior of the manufacturing system under real-time events, such as

random job arrivals, machine breakdowns, etc. The dynamic nature of the system can be called as

dynamic JSP, which is essential for the handling real- world scheduling problems [3].

In real shop floor conditions the production orders are executed after the schedule, this brings

large deviations to the original sequence. Thus, it is necessary to identify key machines at the

DOI: 10.5121/ijci.2015.4207 75

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- ManualDokument50 SeitenManualspacejung50% (2)

- Chronic Renal FailureDokument54 SeitenChronic Renal FailureAkia Cayasan BayaNoch keine Bewertungen

- Bharti Airtel Strategy FinalDokument39 SeitenBharti Airtel Strategy FinalniksforloveuNoch keine Bewertungen

- Method Statement FINALDokument61 SeitenMethod Statement FINALshareyhou67% (3)

- BSNL BillDokument3 SeitenBSNL BillKaushik GurunathanNoch keine Bewertungen

- E Voting PPT - 1Dokument11 SeitenE Voting PPT - 1madhu100% (2)

- Resume Rakesh KumarDokument6 SeitenResume Rakesh KumarMd AkhtarNoch keine Bewertungen

- Part Manual DG 380-KVA PDFDokument128 SeitenPart Manual DG 380-KVA PDFMd Akhtar100% (1)

- Reaction PaperDokument3 SeitenReaction PaperLois DolorNoch keine Bewertungen

- Driver Drowsiness Detection System Using Raspberry PiDokument7 SeitenDriver Drowsiness Detection System Using Raspberry PiIJRASETPublicationsNoch keine Bewertungen

- Format Final PDFDokument52 SeitenFormat Final PDFMd Akhtar100% (1)

- Resume Vickram PDokument2 SeitenResume Vickram PMd AkhtarNoch keine Bewertungen

- ResumeRanjith.R.V-BE-NO POWER PROJECT EXP, SAUDIDokument4 SeitenResumeRanjith.R.V-BE-NO POWER PROJECT EXP, SAUDIMd AkhtarNoch keine Bewertungen

- Resume Suda Mara IDokument5 SeitenResume Suda Mara IMd AkhtarNoch keine Bewertungen

- Resume Ashim DasguptaDokument9 SeitenResume Ashim DasguptaMd AkhtarNoch keine Bewertungen

- Resumerameshsingh-BE - NO POWER PROJECT EXPDokument3 SeitenResumerameshsingh-BE - NO POWER PROJECT EXPMd AkhtarNoch keine Bewertungen

- ResumeAbhimanyuMahato-DIPLOMA-SOLAR POWER EXP-NO POWER PORJECT EXPDokument4 SeitenResumeAbhimanyuMahato-DIPLOMA-SOLAR POWER EXP-NO POWER PORJECT EXPMd AkhtarNoch keine Bewertungen

- ResumeShivanandSingh-DIPLOMA-FGD EXP RIHAND NTPC, KUNALDokument4 SeitenResumeShivanandSingh-DIPLOMA-FGD EXP RIHAND NTPC, KUNALMd Akhtar100% (1)

- Resume Narendra SOntakkeDokument3 SeitenResume Narendra SOntakkeMd AkhtarNoch keine Bewertungen

- Resumeshashikantsingh-DIPLOMA-NO POWER PROJECT EXPDokument2 SeitenResumeshashikantsingh-DIPLOMA-NO POWER PROJECT EXPMd AkhtarNoch keine Bewertungen

- ResumeSitanshuSingh BE MTECH FRESHERDokument2 SeitenResumeSitanshuSingh BE MTECH FRESHERMd AkhtarNoch keine Bewertungen

- Skycrn 04 PDFDokument312 SeitenSkycrn 04 PDFMd AkhtarNoch keine Bewertungen

- ResumeShivamsharma-BE-NO POWER PROJECT EXPDokument2 SeitenResumeShivamsharma-BE-NO POWER PROJECT EXPMd AkhtarNoch keine Bewertungen

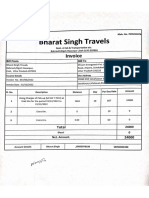

- Bharat Singh Travels Bill Dec'22 RevisedDokument1 SeiteBharat Singh Travels Bill Dec'22 RevisedMd AkhtarNoch keine Bewertungen

- Satyadev DubeyDokument2 SeitenSatyadev DubeyMd AkhtarNoch keine Bewertungen

- Web Based Decision Support System For Smartcity Development in Indian ContextDokument1 SeiteWeb Based Decision Support System For Smartcity Development in Indian ContextMd AkhtarNoch keine Bewertungen

- MEE 437 Operations Research Project Document Text Mining For Supplier Manufacturing IndustriesDokument25 SeitenMEE 437 Operations Research Project Document Text Mining For Supplier Manufacturing IndustriesMd AkhtarNoch keine Bewertungen

- Manufacturing Process ContentDokument4 SeitenManufacturing Process ContentMd AkhtarNoch keine Bewertungen

- Adaptive Production Control System For A Flexible Manufacturing Cell Using Support Vector Machine-Based ApproachDokument13 SeitenAdaptive Production Control System For A Flexible Manufacturing Cell Using Support Vector Machine-Based ApproachMd AkhtarNoch keine Bewertungen

- The Phases of The Moon Station Activity Worksheet Pa2Dokument3 SeitenThe Phases of The Moon Station Activity Worksheet Pa2api-284353863100% (1)

- 1KHW001492de Tuning of ETL600 TX RF Filter E5TXDokument7 Seiten1KHW001492de Tuning of ETL600 TX RF Filter E5TXSalvador FayssalNoch keine Bewertungen

- FIREBASE Edited PresentationDokument12 SeitenFIREBASE Edited PresentationNiraj MirgalNoch keine Bewertungen

- Lecture 19 Code Standards and ReviewDokument27 SeitenLecture 19 Code Standards and ReviewAdhil Ashik vNoch keine Bewertungen

- Kiraan Supply Mesin AutomotifDokument6 SeitenKiraan Supply Mesin Automotifjamali sadatNoch keine Bewertungen

- Communication Skill - Time ManagementDokument18 SeitenCommunication Skill - Time ManagementChấn NguyễnNoch keine Bewertungen

- Standard BMW PDFDokument19 SeitenStandard BMW PDFIna IoanaNoch keine Bewertungen

- Assignment - 1 AcousticsDokument14 SeitenAssignment - 1 AcousticsSyeda SumayyaNoch keine Bewertungen

- DHA - Jebel Ali Emergency Centre + RevisedDokument5 SeitenDHA - Jebel Ali Emergency Centre + RevisedJam EsNoch keine Bewertungen

- LU 5.1 ElectrochemistryDokument32 SeitenLU 5.1 ElectrochemistryNurAkila Mohd YasirNoch keine Bewertungen

- Current Harmonics: Electric Power System Power QualityDokument3 SeitenCurrent Harmonics: Electric Power System Power QualityAlliver SapitulaNoch keine Bewertungen

- 5045.CHUYÊN ĐỀDokument8 Seiten5045.CHUYÊN ĐỀThanh HuyềnNoch keine Bewertungen

- 2010 Information ExchangeDokument15 Seiten2010 Information ExchangeAnastasia RotareanuNoch keine Bewertungen

- Payment of Wages 1936Dokument4 SeitenPayment of Wages 1936Anand ReddyNoch keine Bewertungen

- Worksheet in Bio 102: Microbiology and Parasitology (WEEK 17)Dokument3 SeitenWorksheet in Bio 102: Microbiology and Parasitology (WEEK 17)DELOS SANTOS JESSIECAHNoch keine Bewertungen

- Flipkart Labels 06 Jul 2022 09 52Dokument37 SeitenFlipkart Labels 06 Jul 2022 09 52Dharmesh ManiyaNoch keine Bewertungen

- Previews 1633186 PreDokument11 SeitenPreviews 1633186 PreDavid MorenoNoch keine Bewertungen

- Art Integrated ProjectDokument14 SeitenArt Integrated ProjectSreeti GangulyNoch keine Bewertungen

- CV Ashish PDFDokument3 SeitenCV Ashish PDFRoshan KejariwalNoch keine Bewertungen

- EPMS System Guide For Subcontractor - V1 2Dokument13 SeitenEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Pyromet Examples Self StudyDokument2 SeitenPyromet Examples Self StudyTessa BeeNoch keine Bewertungen

- Stratum CorneumDokument4 SeitenStratum CorneumMuh Firdaus Ar-RappanyNoch keine Bewertungen