Beruflich Dokumente

Kultur Dokumente

DFMA Sample Checklist

Hochgeladen von

Anonymous VRspXsm0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

315 Ansichten1 SeiteThis document contains a checklist of opportunities for improving product design, assembly, packaging, and tooling. It identifies questions in each area to determine if standard parts are being used, processes can be simplified, materials reduced, automation opportunities exist, and safety and reliability can be enhanced. The goal is to streamline design, manufacturing, and packaging to lower costs.

Originalbeschreibung:

cc

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document contains a checklist of opportunities for improving product design, assembly, packaging, and tooling. It identifies questions in each area to determine if standard parts are being used, processes can be simplified, materials reduced, automation opportunities exist, and safety and reliability can be enhanced. The goal is to streamline design, manufacturing, and packaging to lower costs.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

315 Ansichten1 SeiteDFMA Sample Checklist

Hochgeladen von

Anonymous VRspXsmThis document contains a checklist of opportunities for improving product design, assembly, packaging, and tooling. It identifies questions in each area to determine if standard parts are being used, processes can be simplified, materials reduced, automation opportunities exist, and safety and reliability can be enhanced. The goal is to streamline design, manufacturing, and packaging to lower costs.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

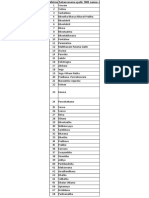

DFM/A CHECKLIST - OPPORTUNITES FOR IMPROVEMENT

1.1 PRODUCT DESIGN - General 4.1 PACKAGING - Package Design (Materials/Structure)

1.1.1 Are there standard parts that can be used? 4.1.1 Are there packaging materials that are considered standard that are not being used?

1.1.2 Are there existing parts from similar products that are not being used? 4.1.2 Is the package structure non-standard?

1.1.3 Can multiple parts be combined into one to reduce the number of parts in the assembly? 4.1.3 Are the intended package structure construction and packout methods not clearly defined?

1.1.4 Are there complicated mechanisms that can be simplified? 4.1.4 Is there an opportunity to reduce any package material thickness?

1.1.5 Are there areas of marginal strength that should be improved/ strengthened? 4.1.5 Are the package die lines optimized to best utilize sheet or roll sizes of paper and plastic material?

1.1.6 Are there materials that are considered standard that are not being used? 4.1.6 Is draft not adequate for a blister design?

1.1.7 Are the materials not suitable for the intended process? 4.1.7 Is flange not adequate for a blister design?

1.1.8 Can the part be confused with other parts of similar shape? (i.e. asymmetrical parts) 4.1.8 Does design tolerance meet process capability?

1.1.9 Are parts too small to handle or require a tool to pick it up? 4.1.9 Can instructions be printed on the package?

1.1.10 Can die cut components be reduced or eliminated? 4.1.10 Can existing instructions be used instead of creating new instructions?

1.2 PRODUCT DESIGN - Electronics 4.1.11 Can number of inserts/attachments be reduced?

1.2.1 Can the quantity of off-board components/assemblies be reduced? (i.e. switches, LEDs, PCBA, etc.) 4.1.12 Can double sided printing reduce the amount of cardboard used?

1.2.2 Are there opportunities for more cost-effective components? (i.e. speaker size, cheaper PCB, battery quantity, etc.) 4.1.13 Can tab-ins and clip art be combined and/or reduced?

1.2.3 Can the number of manual soldering operations be reduced? 4.1.14 Is package using new materials or printing process?

1.2.4 Are there electronic parts/components/ assemblies that are considered standard that are not being used? 4.2 PACKAGING - Assembly/Packout

1.2.5 Are there wire assemblies that are not color coded? 4.2.1 Can glue or tape for chip art be replaced with a standard mechanical locking approach?

1.2.6 Can the quantity of heat stakes and screws be reduced? 4.2.2 Is the product not being secured utilizing existing methods?

1.2.7 Can the number of wire harness interconnections be reduced or eliminated? (Keep in mind assembly or field service) 4.2.3 Is access restricted during assembly?

1.2.8 Can testing operations be automated, simplified or reduced? 4.2.4 Can the product be secured in a less labor intensive method?

2. ASSEMBLY 4.2.5 Can package structure be assembled in a less labor intensive method?

2.1 Do joining or assembly processes compromise the aesthetics? (i.e. sink marks) 4.2.6 Will the use of keylocks for securement be beneficial?

2.2 Can part materials be changed to improve the joining process? 4.2.7 Is there an opportunity for automation of packaging operations?

2.3 Are there parts design that do not allow for proper location and alignment? 4.2.8 If a J hook is required, are existing parts and attachment methods not being used?

2.4 Are there parts that do not nest properly? 4.2.9 Will packout potentially damage the product?

2.5 Are there parts not designed to meet mistake-proof Poke-Yoke assembly? 4.2.10 Can product components be easily detached or damaged by consumer?

2.6 Are there parts that are not designed to meet stack assembly requirements? 4.2.11 Can product be placed to make it easier to remove for end consumer?

2.7 Is part loading access restricted? 4.2.12 Can spot welding be used instead of glue?

2.8 Can the part design be improved for efficient joining and fastening? (i.e. screw reduction/removal, snap, cold/heat staker, rivet) 4.2.13 Is there a more cost-effective tie down material that can be used?

2.9 Are there any parts that can be confused with other parts of similar shape? 4.3 PACKAGING - Master Carton

2.10 Are there parts that are too large and/or heavy which can lead to worker fatigue? 4.3.1 Does master carton not use the optimum retail package arrangement for pallet, blank size and cube efficiency?

2.11 Are there parts/labels that are not easy to grasp, pick up, hold and/or require a tool for assembly? 4.3.2 Have appropriate precautions not been taken to avoid damage to window printing? (scratching in transit)

2.12 Are there parts that can tangled during assembly? 4.3.3 Have higher end collector quality items not been thoroughly protected to ensure zero defects (i.e. protective boxes)?

2.13 Is there no large base part where other parts can be added? 4.4 PACKAGING - Miscellaneous

2.14 Are there parts that will fall off easily during assembly? 4.4.1 Can parts be combined for multiple uses?

2.15 Are there partially- completed assemblies that require undesirable repositioning? 4.4.2 Can parts be designed to meet Mistake Proof assembly- Poke- Yoke requirements?

2.16 Are there assemblies that require two-hand operation? 4.4.3 Can parts be designed to meet Stack Assemblies requirements?

2.17 Are there multiple parts that can be modularized into single subassemblies for easier final assembly. 4.4.4 Can small product modifications result in packaging savings in labor or materials?

2.18 Are there any special cleanliness requirements that should be considered? 5. SAFETY AND RELIABILITY CONCERNS

2.19 Do any parts or assemblies require a special environment during manufacturing? (i.e. dust proofing, grounding, etc.) 5.1 Are there any "under 3" assemblies without a redundant system that may pose safety concerns?

3. TOOLING 5.2 Are there areas of potential sharp points or edges?

3.1 Are there parts that can be cored out with reasonably thin walls? 5.3 Are there any step on hazards?

3.2 Can the application of mini tools be applied? 5.4 Are there any areas of entrapment?

3.3 Are there any areas where parting line definition must be defined? 5.5 Are there any projectile concerns?

3.4 Are there any missing surface finishes/textures? 5.6 Are there any electrical safety hazards?

3.5 Are there parts that need better definition for ejector pin location/size? 5.7 Is the noise level unacceptable?

3.6 Are there any component materials incompatible with intended processes? 5.8 Are there undesired material interactions? (i.e. Color Migration, Galvanic Corrosion, Mechanical Deterioration)

3.7 Do parts require special cooling systems and/or mold design for deep or critical area? 5.9 Are there small parts that may cause safety concerns?

3.8 Are there alternate resins that result in cost-saving that can be used? (i.e. ABS to PP) 5.10 Are there any mechanisms of the product that may not meet life-cycle requirement?

3.9 Are there areas where gating locations will cause aesthetic issues? 5.11 Are there concerns with the comfort and the safety of the seating compartment?

3.10 Are there any molded parts with inadequate draft angles? 6. OTHER

3.11 Can irregular parting lines be eliminated?

Quality-One International | www.quality-one.com | (248) 280-4800

Das könnte Ihnen auch gefallen

- DFMEA Tutorial: Design Failure Mode and Effects Analysis GuideDokument18 SeitenDFMEA Tutorial: Design Failure Mode and Effects Analysis Guidepiero_rsNoch keine Bewertungen

- NPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QADokument441 SeitenNPI Job Responsibilities Detailed Jobs - Print 28-07-2021 - QAPirasanth VithuNoch keine Bewertungen

- 8DDokument8 Seiten8DRomie CubalNoch keine Bewertungen

- 8 D Report: 8 Discipline MethdologyDokument14 Seiten8 D Report: 8 Discipline MethdologyAshishkekreNoch keine Bewertungen

- Quality Gate Review Checklists and Best PracticesDokument15 SeitenQuality Gate Review Checklists and Best PracticesMOHAN SNoch keine Bewertungen

- Standard STD 105-0007: Special CharacteristicsDokument11 SeitenStandard STD 105-0007: Special CharacteristicsKrunal PandyaNoch keine Bewertungen

- APQP and PPAP ExplainedDokument3 SeitenAPQP and PPAP ExplainedignaunaqNoch keine Bewertungen

- NPD Procedure PDFDokument5 SeitenNPD Procedure PDFRohit AttriNoch keine Bewertungen

- Problem Solving Worksheet AnalysisDokument6 SeitenProblem Solving Worksheet AnalysismfritzNoch keine Bewertungen

- GM Machining CP REV 03Dokument17 SeitenGM Machining CP REV 03Suraj RawatNoch keine Bewertungen

- DFMEA Sample For A PenDokument3 SeitenDFMEA Sample For A PenVinay GowdaNoch keine Bewertungen

- Quality Control PlanDokument1 SeiteQuality Control PlanScha Affin100% (1)

- Appendix 11 Design FMEA ChecklistDokument16 SeitenAppendix 11 Design FMEA ChecklistDearRed FrankNoch keine Bewertungen

- DFMEADokument2 SeitenDFMEASumeet SainiNoch keine Bewertungen

- First Article Inspection Report: Purchase Order Number Supplier NameDokument8 SeitenFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNoch keine Bewertungen

- Apqp PQP Flow ChartDokument1 SeiteApqp PQP Flow ChartmjapmgNoch keine Bewertungen

- Feasibility Report for New Part EnquiryDokument2 SeitenFeasibility Report for New Part EnquiryaslamNoch keine Bewertungen

- Procedure Name: Amendment RecordDokument6 SeitenProcedure Name: Amendment RecordsubbuNoch keine Bewertungen

- Engineering Design Review and ChecklistDokument40 SeitenEngineering Design Review and ChecklistwnaciNoch keine Bewertungen

- CPKDokument39 SeitenCPKbadge700Noch keine Bewertungen

- Global supplier quality 8D processDokument1 SeiteGlobal supplier quality 8D processAlex NogueiraNoch keine Bewertungen

- Draft in Qa Form 01 EcnDokument2 SeitenDraft in Qa Form 01 EcnSuraj RawatNoch keine Bewertungen

- 02 - Control of Non Corforming Product Sep13Dokument67 Seiten02 - Control of Non Corforming Product Sep13Mojtaba MousaviNoch keine Bewertungen

- What Is An 8D ReportDokument2 SeitenWhat Is An 8D ReportKó ChitNoch keine Bewertungen

- Product Part Approval Process: Automotive Quality Management SystemDokument3 SeitenProduct Part Approval Process: Automotive Quality Management SystemrajaNoch keine Bewertungen

- 8D Corrective Actions ReportDokument2 Seiten8D Corrective Actions ReportsenthilromNoch keine Bewertungen

- Optimize Company Control PlanDokument6 SeitenOptimize Company Control Planazadsingh1Noch keine Bewertungen

- Volvo Global Deviation FormDokument3 SeitenVolvo Global Deviation FormAnonymous oxdF07Ot0ENoch keine Bewertungen

- Design Fmea ExampleDokument2 SeitenDesign Fmea ExampleSenthil_KNoch keine Bewertungen

- Process Flow Chart AnalysisDokument4 SeitenProcess Flow Chart Analysisakav123Noch keine Bewertungen

- Best Maintenance Technician PracticesDokument3 SeitenBest Maintenance Technician PracticesFery HartantoNoch keine Bewertungen

- General Objectives of Phase: Schematic DesignDokument7 SeitenGeneral Objectives of Phase: Schematic DesignScott M B GustafsonNoch keine Bewertungen

- Fmea CastingDokument4 SeitenFmea CastingSuraj RawatNoch keine Bewertungen

- Capacity VerificationDokument4 SeitenCapacity VerificationLucinei SantosNoch keine Bewertungen

- Ok Part NG: (Vendor Non-Conformance Report)Dokument2 SeitenOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNoch keine Bewertungen

- MRM PresentationDokument32 SeitenMRM PresentationIndrajit Chattopadhyay100% (2)

- Vendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHDokument39 SeitenVendor PPAP Readiness for MEMBER EXTENSION LONGITUDINAL FRONT LH/RHSanjay KumarNoch keine Bewertungen

- Lean FormsDokument103 SeitenLean FormsWashington Fonseca100% (1)

- PPAPDokument7 SeitenPPAPsunnysunsationNoch keine Bewertungen

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDokument6 SeitenDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNoch keine Bewertungen

- Procedure - Special CharacteristicsDokument13 SeitenProcedure - Special Characteristicsalexandru.ghiniaNoch keine Bewertungen

- Supplier PFMEA Workshop Rev 120814 OutvideoDokument32 SeitenSupplier PFMEA Workshop Rev 120814 OutvideoVladimir Rodriguez BeltranNoch keine Bewertungen

- Control Plan: Prelaunch Prototype ProductionDokument2 SeitenControl Plan: Prelaunch Prototype ProductionBharathNoch keine Bewertungen

- Apqp Advanced Product Quality PlanningDokument27 SeitenApqp Advanced Product Quality PlanningRajesh KumarNoch keine Bewertungen

- A3 Toyota 8 Step TemplatesDokument11 SeitenA3 Toyota 8 Step TemplatesBharathNoch keine Bewertungen

- Packaging Details: Vendor Name & AddressDokument4 SeitenPackaging Details: Vendor Name & AddressPk NimiwalNoch keine Bewertungen

- Bgl-Fm-Qa - Red Bin Analysis RuleDokument1 SeiteBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNoch keine Bewertungen

- Production Part Approval Process (Ppap)Dokument20 SeitenProduction Part Approval Process (Ppap)Primoz Cermelj100% (1)

- PPAP Fourth Edition 2006Dokument5 SeitenPPAP Fourth Edition 2006Đại Hữu Tuấn MaiNoch keine Bewertungen

- APQP Documents and TimelineDokument72 SeitenAPQP Documents and Timelinesaby aroraNoch keine Bewertungen

- R&D Procedure - Control of Drawing Engg Specification P2Dokument1 SeiteR&D Procedure - Control of Drawing Engg Specification P2sumanNoch keine Bewertungen

- Layout Inspection Report XH5DR June 20 2012Dokument17 SeitenLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Work Instruction Template PDFDokument2 SeitenWork Instruction Template PDFdrg. Bobet Evih Hedi I.R., MMRNoch keine Bewertungen

- Engineering Change NoteDokument2 SeitenEngineering Change NoteasderbvaNoch keine Bewertungen

- SOP Quality ProceduresDokument28 SeitenSOP Quality ProceduresUttam KumarNoch keine Bewertungen

- 8D Problem SolvingDokument14 Seiten8D Problem SolvingHiệp Hài HướcNoch keine Bewertungen

- Forging Die Design For Gear BlankDokument4 SeitenForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Forging Die Design For Gear BlankDokument4 SeitenForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNoch keine Bewertungen

- MM Reference Guide 2016Dokument72 SeitenMM Reference Guide 2016InaamNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument2 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsm100% (1)

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- An Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersDokument12 SeitenAn Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersAnonymous VRspXsmNoch keine Bewertungen

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDokument5 SeitenMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNoch keine Bewertungen

- KMT Orifice-Cutting Speeds Data PDFDokument2 SeitenKMT Orifice-Cutting Speeds Data PDFAnonymous VRspXsmNoch keine Bewertungen

- KMT Orifice-Cutting Speeds DataDokument1 SeiteKMT Orifice-Cutting Speeds DataAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDokument1 SeiteWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNoch keine Bewertungen

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDokument5 SeitenMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNoch keine Bewertungen

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDokument6 SeitenCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- Section 2 Tooling Fo Die Casting OptDokument22 SeitenSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNoch keine Bewertungen

- EML2322L-Tolerances Vs ProcessDokument7 SeitenEML2322L-Tolerances Vs ProcessAnonymous VRspXsmNoch keine Bewertungen

- Section 2 Tooling Fo Die Casting OptDokument22 SeitenSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNoch keine Bewertungen

- Principle of Powder Metallurgy PDFDokument10 SeitenPrinciple of Powder Metallurgy PDFAnonymous VRspXsmNoch keine Bewertungen

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDokument6 SeitenCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNoch keine Bewertungen

- Cutting Data Ramax HH EngDokument7 SeitenCutting Data Ramax HH EngAnonymous VRspXsmNoch keine Bewertungen

- 1000 names of Vishnu from Vishnu SahasranamaDokument40 Seiten1000 names of Vishnu from Vishnu SahasranamaAnonymous VRspXsmNoch keine Bewertungen

- Book 1Dokument2 SeitenBook 1Anonymous VRspXsmNoch keine Bewertungen

- DimensionsDokument22 SeitenDimensionsanmol6237Noch keine Bewertungen

- CastingDokument18 SeitenCastingAnonymous VRspXsmNoch keine Bewertungen

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDokument6 SeitenCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNoch keine Bewertungen

- LangeDokument13 SeitenLangeAnonymous VRspXsmNoch keine Bewertungen

- Ring Gear Blank Case BriefDokument6 SeitenRing Gear Blank Case BriefAnonymous VRspXsmNoch keine Bewertungen

- 7 Shpaper PlanerDokument29 Seiten7 Shpaper PlanerfamilyumaNoch keine Bewertungen

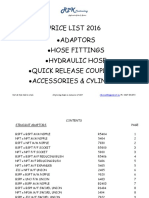

- r2k Contracting Price List 2016Dokument129 Seitenr2k Contracting Price List 2016Anonymous VRspXsmNoch keine Bewertungen

- Sprint Capacity Planner 27 NovDokument11 SeitenSprint Capacity Planner 27 NovAnonymous VRspXsmNoch keine Bewertungen

- CRM Implementation ofDokument13 SeitenCRM Implementation ofarcherselevators50% (4)

- Dual Upright Chiller & Freezer (246 Doors)Dokument1 SeiteDual Upright Chiller & Freezer (246 Doors)DAMIA SARA BINTI MOHD DIYAH MoeNoch keine Bewertungen

- Defrost Timers TypesDokument3 SeitenDefrost Timers TypesPrimadi AnantoNoch keine Bewertungen

- Application Examples Overview enDokument26 SeitenApplication Examples Overview enArunagiriNoch keine Bewertungen

- Real World Case 2Dokument2 SeitenReal World Case 2natasyaNoch keine Bewertungen

- Service Now GuideDokument10 SeitenService Now GuidevinitNoch keine Bewertungen

- Conceptsforauto IDokument23 SeitenConceptsforauto ImskcegNoch keine Bewertungen

- RL New Features ZCC-3.3 En-UsDokument26 SeitenRL New Features ZCC-3.3 En-UsjajjjNoch keine Bewertungen

- 1.1 Mechatronics Technology PRESENTATIONDokument46 Seiten1.1 Mechatronics Technology PRESENTATIONInnocent katengulaNoch keine Bewertungen

- Base PaperDokument4 SeitenBase PaperAayush AnshuNoch keine Bewertungen

- Improving Food Production PerformanceDokument3 SeitenImproving Food Production Performancematias matiasNoch keine Bewertungen

- Warehousingstandards2022 19september2022 0Dokument90 SeitenWarehousingstandards2022 19september2022 0Rakesh JangraNoch keine Bewertungen

- TQM (Terminologies)Dokument6 SeitenTQM (Terminologies)Suazo JessaNoch keine Bewertungen

- COM600Dokument51 SeitenCOM600castrojpNoch keine Bewertungen

- TedTalk Speech - The Golden Age of Automation - Emir Aden DiniDokument5 SeitenTedTalk Speech - The Golden Age of Automation - Emir Aden DiniCoffeeluvr614Noch keine Bewertungen

- Smart Industry and Smart ManufacturingDokument12 SeitenSmart Industry and Smart ManufacturingAndyBarredaMoscosoNoch keine Bewertungen

- Etap Help PDFDokument2 SeitenEtap Help PDFRebeccaNoch keine Bewertungen

- Process Design Document (PDD) : Order-to-CashDokument12 SeitenProcess Design Document (PDD) : Order-to-CashGlo JosNoch keine Bewertungen

- Robotics With: ROS WorkshopDokument30 SeitenRobotics With: ROS WorkshopViba R UdupaNoch keine Bewertungen

- AI and Its Impact On The Finance IndustryDokument6 SeitenAI and Its Impact On The Finance IndustrySandy WellsNoch keine Bewertungen

- Saya Suka AwakDokument6 SeitenSaya Suka AwakNazif JaafarNoch keine Bewertungen

- Hvac Zona 1 - Edif ADokument8 SeitenHvac Zona 1 - Edif AFranklin Cisneros PradoNoch keine Bewertungen

- 2021 BIT Admission BookDokument32 Seiten2021 BIT Admission BookabdessamedNoch keine Bewertungen

- Introduction To PLC PDFDokument8 SeitenIntroduction To PLC PDFKhodr ChehadeNoch keine Bewertungen

- Rockwell Automation PLCDokument212 SeitenRockwell Automation PLCramorado0% (1)

- Ijetae 0416 05Dokument4 SeitenIjetae 0416 05Rahul ShrivastavaNoch keine Bewertungen

- XDR DatasheetDokument7 SeitenXDR DatasheetElmer QuispeNoch keine Bewertungen

- Supco 1Dokument12 SeitenSupco 1Anoop Jacob KunnappuzhaNoch keine Bewertungen

- Unit 1 Digital Economy Lecture 4Dokument12 SeitenUnit 1 Digital Economy Lecture 4Atyandra pratapNoch keine Bewertungen

- Reconfigurable Marine Control Systems and Electrical PropulsionDokument16 SeitenReconfigurable Marine Control Systems and Electrical PropulsionforcamilanNoch keine Bewertungen