Beruflich Dokumente

Kultur Dokumente

3.EHVS 132 KV - Empalme

Hochgeladen von

pablodcabrera0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten2 SeitenEmpalmes para 132kV

Originaltitel

3.EHVS 132 KV_Empalme

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenEmpalmes para 132kV

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten2 Seiten3.EHVS 132 KV - Empalme

Hochgeladen von

pablodcabreraEmpalmes para 132kV

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

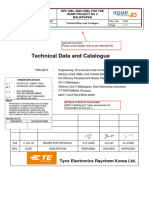

Energy Division

Raychem Inline and

Shield-Break Joint EHVS

for 123 kV up to 170 kV

EHVS Raychem Inline and Shield-Break Joint

for 123 kV up to 170 kV

Application Major Design Elements

The joint is a pre-fabricated three-piece The joint consists of connector (1), cable adapters (2) – including stress cones

design for voltage classes up to 170 kV. and main joint body (3) – containing Faraday cage (7) and outer serving by

Polymeric insulated cables of various heat-shrink technology (9,12). The conductors of the cable are connected by a

designs can be adopted with respect mechanical connector sleeve (1) using torque controlled shear-off bolts. The

to shielding and metal sheath. connector sleeve is suitable for stranded aluminium and copper conductors.

The Si-rubber cable adapters (2), accommodating the various cable insulation

diameters, build up the connection area to an almost constant diameter. This

allows to cover different cable cross-sections with just one main insulation joint

Features body (3). Therefore cross-section transitions are possible without any extra

• Pre-fabricated three-piece joint components. No extra tooling is needed to push-on the Si-rubber cable

design adapters (2) and the Si-rubber joint main body (3) due to its excellent elasticity.

• Torque-controlled conductor sleeves A metal shielding clamp (7) on top of the connector ensures perfect heat

• Integrated moisture barrier using transmission and a smooth interface fit. The fixing rings (6) keep the cable

H/S components adapter and the cable dielectric in position. During the installation the main

• Short cut-back dimensions body is parked on the over sheath of the cable. This keeps the cut back length

• No special tools required to install and cable preparation time as short as possible. Mechanical solderless connector

the joint technologies (8) are used to connect metal shields – copper wires, metal sheath

• Can adapt shield-break applications and CAS. Heat-shrink technologies (9,12) replace the cable serving and the

• Cable size transition is possible moisture barrier. The joint concept is similar for the shield-break joints, despite

• Factory tested Si-rubber parts the shield continuity. Special sealant components make it possible to use

• Type tested according to IEC 60840 double-insulated ground leads, and thereby to utilise the proven heat-shrink

and IEEE 404 standards technology.

Inline Joint

8 4 2 3 5 6 1 7 9 10 11 12

Shield-Break Joint

4 2 3 5 6 1 7 9 10 11 12

© Tyco Electronics EPP 1061 11/07

1 Mechanical connector 5 HV electrode 9 Conductive tubing

2 Adapter 6 Fixing ring 10 Copper mesh

3 Main body 7 Metal shielding clamp 1 1 Insulating tubing

4 Stress cone 8 Solderless shield connection 12 Outer protection with integrated

moisture barrier

All of the above information, including drawings, illustrations and graphic designs, reflects our present understanding and is to the best of our knowledge and belief correct and reliable.

Users, however, should independently evaluate the suitability of each product for the desired application. Under no circumstances does this constitute an assurance of any particular quality

or performance. Such an assurance is only provided in the context of our product specifications or explicit contractual arrangements. Our liability for these products is set forth in our

standard terms and conditions of sale. Raychem, TE Logo and Tyco Electronics are trademarks.

Energy Division – innovative and economical solutions for the electrical power industry: cable accessories, connectors &

fittings, insulators & insulation, surge arresters, switching equipment, lighting controls, Power Measurement and Control.

Tyco Electronics Raychem GmbH

Energy Division

Finsinger Feld 1

85521 Ottobrunn/Munich, Germany

Phone: +49-89-6089-0

Fax: +49-89-6096345

http://energy.tycoelectronics.com

Das könnte Ihnen auch gefallen

- Raychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVDokument2 SeitenRaychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVwael El-BegearmiNoch keine Bewertungen

- Raychem Power Cable AccessoriesDokument17 SeitenRaychem Power Cable AccessoriesPower TechNoch keine Bewertungen

- Outdoor Composite Termination Ohvt For 123 KV Outdoor Composite TerminationDokument2 SeitenOutdoor Composite Termination Ohvt For 123 KV Outdoor Composite TerminationTXEMANoch keine Bewertungen

- Medium Voltage Terminations: Catalogue 2017Dokument32 SeitenMedium Voltage Terminations: Catalogue 2017zaheerNoch keine Bewertungen

- Rsti 69 CCDokument4 SeitenRsti 69 CCGuilherme VillaçaNoch keine Bewertungen

- CIGRE 2016: 21, Rue D'artois, F-75008 PARISDokument12 SeitenCIGRE 2016: 21, Rue D'artois, F-75008 PARISMarko KojicNoch keine Bewertungen

- Cable TrayDokument28 SeitenCable Traykirink73Noch keine Bewertungen

- Accesorios para ADSS-PreformedDokument6 SeitenAccesorios para ADSS-Preformeddwas1314Noch keine Bewertungen

- Elmex-Terminal Block CatalogDokument144 SeitenElmex-Terminal Block CatalogHansen LaMessiah SaputraNoch keine Bewertungen

- MEDIUM VOLTAGE TERMINATIONS CATALOGUE 2017Dokument24 SeitenMEDIUM VOLTAGE TERMINATIONS CATALOGUE 2017Ahmad SyaukaniNoch keine Bewertungen

- Presentation Lightning Protection System by JMV LPSDokument62 SeitenPresentation Lightning Protection System by JMV LPSMahesh Chandra ManavNoch keine Bewertungen

- Raychem Screened, Separable Connection System RSTI-Large For Large Cross Sections 1250 A Up To 42 KVDokument4 SeitenRaychem Screened, Separable Connection System RSTI-Large For Large Cross Sections 1250 A Up To 42 KVgiovany_vq91Noch keine Bewertungen

- Joint (Up To 72.5kV)Dokument4 SeitenJoint (Up To 72.5kV)des1982Noch keine Bewertungen

- Technical Specification Joint Kits and TerminationsDokument10 SeitenTechnical Specification Joint Kits and TerminationsYörükNoch keine Bewertungen

- IPD and Illumination: Electrical Connectors GuideDokument14 SeitenIPD and Illumination: Electrical Connectors GuideMilan AcharyaNoch keine Bewertungen

- Epp 2154Dokument4 SeitenEpp 2154RazkulNoch keine Bewertungen

- Form C 1608 AnchorLoc3 Install GuideDokument4 SeitenForm C 1608 AnchorLoc3 Install GuideKelvin JinNoch keine Bewertungen

- IBB CatalogueDokument12 SeitenIBB Cataloguedabic_zoranNoch keine Bewertungen

- 3M Terminales 3MDokument92 Seiten3M Terminales 3MEDGARPRADOCNoch keine Bewertungen

- Technical User Guide for 127 - 500 kV High Voltage XLPE Cable SystemsDokument12 SeitenTechnical User Guide for 127 - 500 kV High Voltage XLPE Cable Systemsmani_208eeNoch keine Bewertungen

- Product CAT IXSU - DatasheetDokument10 SeitenProduct CAT IXSU - DatasheetRicardo Gomez GuevaraNoch keine Bewertungen

- Reliable Internal Interconnects: For Magnetic SMT ComponentsDokument8 SeitenReliable Internal Interconnects: For Magnetic SMT ComponentsSusanoo12Noch keine Bewertungen

- Application Notes Proton Electrotex EngDokument27 SeitenApplication Notes Proton Electrotex Engocr4121Noch keine Bewertungen

- Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BusDokument4 SeitenPowell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BuslongnguyenNoch keine Bewertungen

- Raychem Solder Sleeves ENG DS 2347480-1 Raychem-Devices 021912Dokument88 SeitenRaychem Solder Sleeves ENG DS 2347480-1 Raychem-Devices 021912kalle ankaNoch keine Bewertungen

- Medium Voltage CableDokument5 SeitenMedium Voltage CableNaveenNavabNoch keine Bewertungen

- Cable Accessories: Systems, IncDokument4 SeitenCable Accessories: Systems, IncLuis MurilloNoch keine Bewertungen

- Nexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFDokument25 SeitenNexans MV 11kV 33kV Cable Terminations - Slip On and Cold Shrink PDFnicesreekanthNoch keine Bewertungen

- E-7 Electric Heat Trace PDFDokument15 SeitenE-7 Electric Heat Trace PDFvikingNoch keine Bewertungen

- Fundamentals of SolenoidDokument9 SeitenFundamentals of SolenoidArun BabuNoch keine Bewertungen

- FEWA HV Joints & TerminationsDokument29 SeitenFEWA HV Joints & TerminationsMuhammad RazaNoch keine Bewertungen

- Medium Voltage Cable Construction and SpecificationsDokument34 SeitenMedium Voltage Cable Construction and SpecificationsNelson GarvizuNoch keine Bewertungen

- High voltage cable accessories design and manufacturingDokument22 SeitenHigh voltage cable accessories design and manufacturingMuhAinun16Noch keine Bewertungen

- XLPE cable for ungrounded 33kV systemsDokument12 SeitenXLPE cable for ungrounded 33kV systemssaurabh kumarNoch keine Bewertungen

- HarnessDokument21 SeitenHarnessthulasi_krishnaNoch keine Bewertungen

- Practical Construction Tips For Coils Using Iron Powder CoresDokument14 SeitenPractical Construction Tips For Coils Using Iron Powder CoresltcmenishadNoch keine Bewertungen

- RSTI-59 e 69Dokument4 SeitenRSTI-59 e 69Guilherme VillaçaNoch keine Bewertungen

- Tyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFDokument8 SeitenTyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFYolnner SerranoNoch keine Bewertungen

- KEC Induction Training Program OverviewDokument96 SeitenKEC Induction Training Program OverviewShubhendu SinghNoch keine Bewertungen

- Technical Data and CatalogueDokument16 SeitenTechnical Data and CatalogueHery MukhlisNoch keine Bewertungen

- 2 Wiring SystemsDokument7 Seiten2 Wiring SystemsBRIAN CLIFFNoch keine Bewertungen

- Coaxial Cable - WikipediaDokument15 SeitenCoaxial Cable - WikipediaAkiHiro San Carcedo100% (1)

- Design & Testing of ZnO Lightening ArresterDokument19 SeitenDesign & Testing of ZnO Lightening ArrestersureshnfclNoch keine Bewertungen

- Lectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1Dokument6 SeitenLectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1William PinzonNoch keine Bewertungen

- Mineral Insulated Cables: Long Life, Safety, and Small DiameterDokument2 SeitenMineral Insulated Cables: Long Life, Safety, and Small DiameterkmiqdNoch keine Bewertungen

- Keywords: Hybrid Insulators, Polymeric Insulator, Composite Insulators, HDPE Pin InsulatorDokument10 SeitenKeywords: Hybrid Insulators, Polymeric Insulator, Composite Insulators, HDPE Pin InsulatorTimoteo RomeroNoch keine Bewertungen

- Chapter - 06 Power CableDokument50 SeitenChapter - 06 Power Cabledewidar1234100% (5)

- Stress On Outer Cable Connection of MV Gas-InsulatDokument5 SeitenStress On Outer Cable Connection of MV Gas-Insulatsajind3883Noch keine Bewertungen

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Dokument14 SeitenEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNoch keine Bewertungen

- CM Dc9000-Eng-Int-DDokument20 SeitenCM Dc9000-Eng-Int-DJavier CutipaNoch keine Bewertungen

- Instrumentation Cables Questions & AnswersDokument7 SeitenInstrumentation Cables Questions & AnswersJêmš NavikNoch keine Bewertungen

- Qse 93af600 DataDokument9 SeitenQse 93af600 DataPutraAdityaNoch keine Bewertungen

- Macalloy Cable StructuresDokument12 SeitenMacalloy Cable Structuresjmcc2Noch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Neurobionics: The Biomedical Engineering of Neural ProsthesesVon EverandNeurobionics: The Biomedical Engineering of Neural ProsthesesRobert K. ShepherdNoch keine Bewertungen

- The IEE Wiring Regulations Explained and IllustratedVon EverandThe IEE Wiring Regulations Explained and IllustratedBewertung: 4 von 5 Sternen4/5 (14)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsVon EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNoch keine Bewertungen

- NF Apeendix ADokument2 SeitenNF Apeendix ApablodcabreraNoch keine Bewertungen

- Brugg Cables User GuideDokument27 SeitenBrugg Cables User GuideMehdi_Mashayekhi_172Noch keine Bewertungen

- Writing EmailsDokument5 SeitenWriting EmailsFiorella LeonNoch keine Bewertungen

- PEMA IP07 Tyre Selection and MaintenanceDokument22 SeitenPEMA IP07 Tyre Selection and MaintenanceJeremiah BeltranNoch keine Bewertungen

- As511protocol DescriptionDokument16 SeitenAs511protocol DescriptionpablodcabreraNoch keine Bewertungen

- AFE ManualDokument191 SeitenAFE ManualpablodcabreraNoch keine Bewertungen

- PMSP DDDokument1 SeitePMSP DDpablodcabreraNoch keine Bewertungen

- 15.folleto Manguitos de Union y Terminales MetalicosDokument4 Seiten15.folleto Manguitos de Union y Terminales MetalicospablodcabreraNoch keine Bewertungen

- Arrester Book Ed 3 enDokument128 SeitenArrester Book Ed 3 enNilan Suranga Karavita VidanelageNoch keine Bewertungen

- AFE1Dokument4 SeitenAFE1Ahmad SarifudinNoch keine Bewertungen

- 03 Hoisting GearDokument89 Seiten03 Hoisting GearpablodcabreraNoch keine Bewertungen

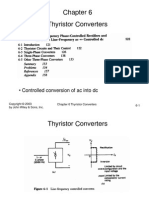

- Thyristors RectifiersDokument39 SeitenThyristors RectifierspablodcabreraNoch keine Bewertungen

- APC 200 5 - 4207049 - Rev1.1Dokument65 SeitenAPC 200 5 - 4207049 - Rev1.1pablodcabrera88% (8)

- Drive and Control Components For CranesDokument420 SeitenDrive and Control Components For Cranespablodcabrera100% (5)

- MM4 Hoisting GearDokument47 SeitenMM4 Hoisting GearpablodcabreraNoch keine Bewertungen

- Arduino - LearningDokument711 SeitenArduino - LearningAwais TunioNoch keine Bewertungen

- FusionX Parts Manual For WebsiteDokument63 SeitenFusionX Parts Manual For WebsitepablodcabreraNoch keine Bewertungen

- NW Simatic Net Glossar 76Dokument112 SeitenNW Simatic Net Glossar 76pablodcabreraNoch keine Bewertungen

- Negotiation - Course Outline APR17Dokument8 SeitenNegotiation - Course Outline APR17ravindrarao_mNoch keine Bewertungen

- L P - The Dear Departed-Drama-10thDokument5 SeitenL P - The Dear Departed-Drama-10thVritika Shorie100% (2)

- C++ FundamentalsDokument207 SeitenC++ Fundamentalsbrm1shubhaNoch keine Bewertungen

- Sumit Pandey CVDokument3 SeitenSumit Pandey CVSumit PandeyNoch keine Bewertungen

- Xeon c5500 c3500 Non Transparent Bridge PaperDokument28 SeitenXeon c5500 c3500 Non Transparent Bridge Papersureshr_42Noch keine Bewertungen

- Manual de ServicioDokument196 SeitenManual de ServicioJuan P. Ibanez CorreaNoch keine Bewertungen

- Introduction To Data Analytics - AnnouncementsDokument16 SeitenIntroduction To Data Analytics - AnnouncementsAmit GuptaNoch keine Bewertungen

- Customize AutoCAD P&ID with Engineering ItemsDokument33 SeitenCustomize AutoCAD P&ID with Engineering ItemsnunosobralNoch keine Bewertungen

- Srinivas ReportDokument20 SeitenSrinivas ReportSrinivas B VNoch keine Bewertungen

- Client Needs and Software Requirements V2.2Dokument43 SeitenClient Needs and Software Requirements V2.2Mehmet DemirezNoch keine Bewertungen

- CatDokument27 SeitenCatGovarthanan GopalanNoch keine Bewertungen

- Is 9459Dokument13 SeitenIs 9459Anonymous mcHqIfbnV1Noch keine Bewertungen

- Chapter 5: Solid Waste ManagementDokument40 SeitenChapter 5: Solid Waste ManagementRehan IbrahimNoch keine Bewertungen

- Tommy Matsumoto, AT&T Jens Co. Yoshitaka Senoo, Daiichi Co.,LtdDokument7 SeitenTommy Matsumoto, AT&T Jens Co. Yoshitaka Senoo, Daiichi Co.,Ltdpostscript100% (1)

- Turn-to-Turn Fault Protection Schemes For Magnetically-Controlled Shunt Reactors (MCSR)Dokument57 SeitenTurn-to-Turn Fault Protection Schemes For Magnetically-Controlled Shunt Reactors (MCSR)Muhammad Asghar KhanNoch keine Bewertungen

- Maintain Safe Systems with Maintenance Free EarthingDokument12 SeitenMaintain Safe Systems with Maintenance Free EarthingRavi Shankar ChakravortyNoch keine Bewertungen

- Owner's Manual Safety Instructions Operating InstructionsDokument16 SeitenOwner's Manual Safety Instructions Operating InstructionsKevin CharlesNoch keine Bewertungen

- AEON BINH DUONG CANARY - CONSTRUCTION SCHEDULE 2014Dokument5 SeitenAEON BINH DUONG CANARY - CONSTRUCTION SCHEDULE 2014LantNoch keine Bewertungen

- General CRT tester notesDokument64 SeitenGeneral CRT tester notesImran AliNoch keine Bewertungen

- Construction Site Safety ReportDokument35 SeitenConstruction Site Safety ReportAkshay Waim100% (1)

- Oops NotesDokument79 SeitenOops NotesaminNoch keine Bewertungen

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDokument4 SeitenEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruNoch keine Bewertungen

- Terra Point White PaperDokument10 SeitenTerra Point White Paperobi SalamNoch keine Bewertungen

- Learn The Powerful Memory Techniques Used by TheDokument2 SeitenLearn The Powerful Memory Techniques Used by TheAchieverNoch keine Bewertungen

- Aksa Lte NW AssessmentDokument43 SeitenAksa Lte NW AssessmentSenthilkumar Purushothaman100% (2)

- Computer LiteracyDokument5 SeitenComputer LiteracyMazaasach MazaNoch keine Bewertungen

- Une Preuve Facile de L'existence de Dieu L'ordre Du Monde - Pe. Joseph de Tonquedéc S.JDokument30 SeitenUne Preuve Facile de L'existence de Dieu L'ordre Du Monde - Pe. Joseph de Tonquedéc S.JRenan MarquesNoch keine Bewertungen

- Creative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your CameraDokument146 SeitenCreative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your Camerajwestmister100% (2)

- FULLTEXT01Dokument14 SeitenFULLTEXT01Văn Tuấn NguyễnNoch keine Bewertungen

- Lighting Lighting: Greenup WaterproofDokument2 SeitenLighting Lighting: Greenup WaterproofAngie Paola CórdobaNoch keine Bewertungen