Beruflich Dokumente

Kultur Dokumente

Pages From ASME SEC IX 2017-3 PDF

Hochgeladen von

Akhtar AnsariOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pages From ASME SEC IX 2017-3 PDF

Hochgeladen von

Akhtar AnsariCopyright:

Verfügbare Formate

ASME BPVC.

IX-2017

zone shall exhibit complete fusion and freedom from (c) The essential variable, of QW-3 5 0 and QW-3 60,

cracks. The essential variables for welding operator qua- shall apply for welders and welding operators, respec-

lification shall be in accordance with QW-361. tively, except there is no limit on the maximum thickness

of hard ‐ facing overlay that may be applied in production.

QW- 363 STU D WELDI N G When specified as essential variables, the limitations of

Stud welding operators shall be performance qualified position and diameter qualified for groove welds shall ap-

in accordance with the test requirements of QW-1 92 .2 ply to overlay welds except the limitations on diameter

and the position requirements of QW-303.4. qualified shall apply only to welds deposited in the cir-

cumferential direction.

(d) Qualification with one AWS classification within an

QW-380 SPECI AL PROCESSES SFA specification qualifies for all other AWS classifica-

tions in that SFA specification.

QW- 381 CORROSI O N - RESI STAN T WELD M ETAL

OVERLAY (e) A change in welding process shall require welder

and welding operator requalification.

QW-381. 1 Qu ali fi cati on Test.

(a) The size of test coupons, limits of base metal thick-

ness qualification, required examinations and tests, and

test specimens shall be as specified in Table QW-453. QW- 383 J OI N I N G OF CLAD M ATERI ALS AN D

(b) Welders or welding operators who pass the tests APPLI ED LI N I N G S

for corrosion ‐ resistant weld metal overlay cladding shall

QW-383. 1 Clad M ateri als.

only be qualified to apply corrosion ‐ resistant weld metal

overlay portion of a groove weld joining composite clad (a) Welders and welding operators who will j oin the

or lined materials. base material portion of clad materials shall be qualified

for groove welding in accordance with QW-301. Welders

(c) The essential variables of QW-3 5 0 and QW-3 60

and welding operators who will apply the cladding por-

shall apply for welders and welding operators, respec-

tion of a weld between clad materials shall be qualified

tively, except there is no limit on the maximum thickness

in accordance with QW-381. Welders and welding opera-

of corrosion ‐ resistant overlay that may be applied in pro-

tors need only be qualified for the portions of composite

duction. When specified as essential variables, the limita-

welds that they will make in production.

tions of position and diameter qualified for groove welds

shall apply to overlay welds, except the limitations on dia- (b) As an alternative to (a), welders and welding opera-

meter qualified shall apply only to welds deposited in the tors may be qualified using composite test coupons. The

circumferential direction. test coupon shall be at least 3/8 in. (10 mm) thick and of

dimensions such that a groove weld can be made to join

QW- 3 81. 2 Q u a l i fi c a t i o n o n C o m p o s i t e W e l d s . A

the base materials and the corrosion ‐ resistant weld metal

welder or welding operator who has qualified on compo-

overlay can be applied to the completed groove weld.

s ite we lds in cl ad o r li ned m aterial , as p ro vi ded in

Four side-bend test specimens shall be removed from

QW- 3 8 3 . 1 (b ) is als o qualified to dep o s it co rro s io n ‐

the completed test coupon and tested. The groove weld

resistant weld metal overlay.

portion and the corrosion ‐ resistant weld metal overlay

Q W- 3 81. 3 Alte rn ati ve Q u ali fi cati o n W i th G ro o ve portion of the test coupon shall be evaluated using the re-

Weld Tests. When a chemical composition is not specified spective criteria in QW-163. Welders and welding opera-

in the WPS, welders or welding operators who success- tors qualified using composite test coupons are qualified

fully complete a groove weld performance qualification to join base materials as provided by QW-3 01, and they

test meeting the corrosion ‐ resistant overlay bend test re- are qualified to apply corrosion ‐ resistant weld metal

quirements of QW-163 may be considered qualified for overlay as provided by QW-381.

corrosion ‐ resistant overlay welding within the ranges de-

fined in QW-350 or QW-360. QW- 383. 2 Appli ed Li n i n g s.

(a) Welders and welding operators shall be qualified

QW- 382 H ARD-FACI N G WELD M ETAL OVERLAY following the rules for making groove or fillet welds in ac-

(WEAR RESI STAN T) cordance with QW-301. Plug welds for attaching applied

(a) The size of the test coupons, limits of base metal linings shall be considered equivalent to fillet welds for

thickness qualification, required examinations and tests, the purpose of performance qualification.

a n d te s t s p e c i m e n s s h a l l b e a s s p e c i fi e d i n T a b l e (b) An alternate test coupon shall consist of the geome-

QW-453. Base material test coupons may be as permitted try to be welded, except the base material need not ex-

in QW-423. ce e d 1 i n . (2 5 m m ) i n th i c kn e s s . T h e we l d e d te s t

(b) Welders and welding operators who pass the tests coupon shall be sectioned and etched to reveal the weld

for hard ‐ facing weld metal overlay are qualified for hard ‐ and heat‐ affected zone. The weld shall show penetration

facing overlay only. into the base metal.

76

Das könnte Ihnen auch gefallen

- ASME Sec IXDokument5 SeitenASME Sec IXkirubha_karan2000Noch keine Bewertungen

- Welder Performance QualificationDokument31 SeitenWelder Performance QualificationParvee K Nakwal100% (3)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Astm A513 PDFDokument20 SeitenAstm A513 PDFpradelles89% (9)

- KPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFDokument67 SeitenKPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFMohamed F Morsy60% (5)

- Load Test Report For Spreader Bar A & BDokument2 SeitenLoad Test Report For Spreader Bar A & BAkhtar AnsariNoch keine Bewertungen

- QW 381Dokument1 SeiteQW 381Waqas WaqasNoch keine Bewertungen

- Extracted Pages From ASME BPVC 2021 Section IX-2Dokument2 SeitenExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazNoch keine Bewertungen

- API 510 - DAY 3: G T Technical & Management Institute PVT - LTD.Dokument102 SeitenAPI 510 - DAY 3: G T Technical & Management Institute PVT - LTD.hamedNoch keine Bewertungen

- Asme Section IxDokument71 SeitenAsme Section Ixranjitkumar1977100% (2)

- QW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Dokument2 SeitenQW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Gangadhar SahuNoch keine Bewertungen

- Asme 9 DatosDokument47 SeitenAsme 9 Datosvichu_villamarNoch keine Bewertungen

- API 570 DAY 3 BOOK (1 To 108) (PP)Dokument106 SeitenAPI 570 DAY 3 BOOK (1 To 108) (PP)melvinNoch keine Bewertungen

- Sis Book Asme IxDokument107 SeitenSis Book Asme IxHamza AlamNoch keine Bewertungen

- Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsDokument1 SeiteExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsRudolph RednoseNoch keine Bewertungen

- Asme Ix QW PDFDokument183 SeitenAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- 303 2Dokument1 Seite303 2SARSAN NDTNoch keine Bewertungen

- Welder Performance Qualification WPQDokument3 SeitenWelder Performance Qualification WPQramzi5ben5ahmed100% (1)

- QW-191.2 Ultrasonic ExaminationDokument1 SeiteQW-191.2 Ultrasonic ExaminationJuan ortega castellarNoch keine Bewertungen

- Asme Boiler & Pressure Vessel CodeDokument33 SeitenAsme Boiler & Pressure Vessel CodeYuwantoniAl100% (1)

- Welder Qualification Radiography Acceptance CriteriaDokument2 SeitenWelder Qualification Radiography Acceptance CriteriaKamalnath KpNoch keine Bewertungen

- Asme B31.4 - 2016 EndDokument1 SeiteAsme B31.4 - 2016 Endwilliam cordero valverdeNoch keine Bewertungen

- H 99 Sec 9 QwivDokument79 SeitenH 99 Sec 9 QwivJhon HernandezNoch keine Bewertungen

- ASME IX Temper Bead WeldingDokument4 SeitenASME IX Temper Bead WeldingAhmadiBinAhmadNoch keine Bewertungen

- QW-171 Toughness Tests: (A) The Two Base Metals, or (B) The Weld Metal and The Base MetalDokument1 SeiteQW-171 Toughness Tests: (A) The Two Base Metals, or (B) The Weld Metal and The Base MetalMo ZeroNoch keine Bewertungen

- Module 1: Code Basics: Part QW WeldingDokument12 SeitenModule 1: Code Basics: Part QW WeldingaliNoch keine Bewertungen

- Ix+ 3. (WPQ) Welding Performance QualificationsDokument7 SeitenIx+ 3. (WPQ) Welding Performance QualificationsAMAL VISHNUNoch keine Bewertungen

- Asme Sec Ix-WpqDokument47 SeitenAsme Sec Ix-WpqKaushal Sojitra100% (1)

- Pages From Asme Sec Ix 2017-4Dokument1 SeitePages From Asme Sec Ix 2017-4Akhtar AnsariNoch keine Bewertungen

- RT Asme IxDokument3 SeitenRT Asme Ixhernando gelves100% (1)

- IX Exercise Rev 02 PDFDokument11 SeitenIX Exercise Rev 02 PDFweerasinghekNoch keine Bewertungen

- Part QW Welding Article IDokument13 SeitenPart QW Welding Article IHiago BragaNoch keine Bewertungen

- AsmeDokument11 SeitenAsmeManoj BallaNoch keine Bewertungen

- CASTI Connecting The Codes Temper Bead WeldingDokument18 SeitenCASTI Connecting The Codes Temper Bead WeldingqcselvaNoch keine Bewertungen

- Asme IX BQ Art 11Dokument5 SeitenAsme IX BQ Art 11Maria Alexandra Lange LenzNoch keine Bewertungen

- 2-Asme BPVC Section Ix-2013Dokument2 Seiten2-Asme BPVC Section Ix-2013Reda ElsawyNoch keine Bewertungen

- 5welding BasicsDokument70 Seiten5welding BasicssreeNoch keine Bewertungen

- Asme Sec Ix PT QW Article IVDokument139 SeitenAsme Sec Ix PT QW Article IVjorgeNoch keine Bewertungen

- Codes and StandardsDokument33 SeitenCodes and StandardsMohd AmaniNoch keine Bewertungen

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDokument1 SeiteZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNoch keine Bewertungen

- ASME Sec IX Flashcards - QuizletDokument10 SeitenASME Sec IX Flashcards - Quizletqazi12Noch keine Bewertungen

- ANSI AWS Writing and Qualifying Welding Procedures - Technical BulletinsDokument4 SeitenANSI AWS Writing and Qualifying Welding Procedures - Technical Bulletinscleiton.wtecNoch keine Bewertungen

- Interview ASME SEC IX & General QUESTIONSDokument45 SeitenInterview ASME SEC IX & General QUESTIONSabdo50% (2)

- PW3Dokument49 SeitenPW3Mujaffar ShaikhNoch keine Bewertungen

- Sec 3Dokument3 SeitenSec 3Ajay SinghNoch keine Bewertungen

- QW-196 Resistance Weld Testing: ASME BPVC - IX-2019Dokument1 SeiteQW-196 Resistance Weld Testing: ASME BPVC - IX-2019Tahar DabbarNoch keine Bewertungen

- Thickness Qualification Range For PQR and WPQDokument5 SeitenThickness Qualification Range For PQR and WPQOuled BladiNoch keine Bewertungen

- Solved Paper On Section IxDokument25 SeitenSolved Paper On Section IxNasir Javed90% (20)

- ASME IX QW (Welding General Requirements)Dokument12 SeitenASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- Api 510 PTR 7Dokument3 SeitenApi 510 PTR 7HemaNoch keine Bewertungen

- Asme Section Ix-Welding - Practice Quest PDFDokument3 SeitenAsme Section Ix-Welding - Practice Quest PDFRajesh KumarNoch keine Bewertungen

- ASME IX ExerciseDokument11 SeitenASME IX ExerciseRanaweera Ariyamanjula100% (1)

- W32 Qualification Scheme For Welders of Hull Structural Steels W32Dokument15 SeitenW32 Qualification Scheme For Welders of Hull Structural Steels W32Muhamad ShakyreenNoch keine Bewertungen

- AWS D1.5 Criterios RXDokument6 SeitenAWS D1.5 Criterios RXJuan NavaNoch keine Bewertungen

- Asme Sec IxDokument3 SeitenAsme Sec IxMd Ashikur RahmanNoch keine Bewertungen

- Table QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023Dokument1 SeiteTable QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023ahmadrizkiqcNoch keine Bewertungen

- SA 516-70 PWHT at 1100 F For 1 Hr. Satisfy UG-84 Reqmn't (Impact Test)Dokument4 SeitenSA 516-70 PWHT at 1100 F For 1 Hr. Satisfy UG-84 Reqmn't (Impact Test)Subhan HarahapNoch keine Bewertungen

- Note 7 - Welder Test - Mechanical Test and X-RayDokument29 SeitenNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiNoch keine Bewertungen

- Non Destructive Testing in Welder QualificationDokument3 SeitenNon Destructive Testing in Welder QualificationsulemankhanNoch keine Bewertungen

- 4 Asme Sec Ix Wps PQR Slide 71 To 105Dokument35 Seiten4 Asme Sec Ix Wps PQR Slide 71 To 105dhasdj100% (1)

- Asme Sect. Ix Part QW Art. I 2005 PDFDokument12 SeitenAsme Sect. Ix Part QW Art. I 2005 PDFarlyNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Think and Grow Rich Made EasyDokument116 SeitenThink and Grow Rich Made EasyAkhtar AnsariNoch keine Bewertungen

- Inspection Call Request Format - 46967 - 018 - Dated 04.08.2022Dokument1 SeiteInspection Call Request Format - 46967 - 018 - Dated 04.08.2022Akhtar AnsariNoch keine Bewertungen

- Inspection Call Request Format - 441715 - 003 - Dated 04.08.2022Dokument1 SeiteInspection Call Request Format - 441715 - 003 - Dated 04.08.2022Akhtar AnsariNoch keine Bewertungen

- Inspection Call Request Format - 47758 - 004 - Dated 04.08.2022Dokument1 SeiteInspection Call Request Format - 47758 - 004 - Dated 04.08.2022Akhtar AnsariNoch keine Bewertungen

- Photo Annexure To IR No.189123-231221-01Dokument3 SeitenPhoto Annexure To IR No.189123-231221-01Akhtar AnsariNoch keine Bewertungen

- EXCEL Formulas BibleDokument42 SeitenEXCEL Formulas BibleParkash Chander RughaniNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- ST 52 DIN 2391 Part 2 (Germany) : StandardsDokument1 SeiteST 52 DIN 2391 Part 2 (Germany) : StandardsKandregula Mohan BabuNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Akhtar Ansari - TPI - FRT PDFDokument5 SeitenAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNoch keine Bewertungen

- Attendance Sheet - 5S Housekeeping TrainingDokument1 SeiteAttendance Sheet - 5S Housekeeping TrainingAkhtar Ansari100% (1)

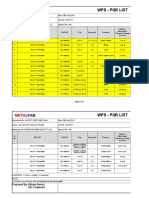

- Wps - PQR List: Page 1 of 4Dokument4 SeitenWps - PQR List: Page 1 of 4Akhtar AnsariNoch keine Bewertungen

- Equipment AssemblyDokument8 SeitenEquipment AssemblyAkhtar AnsariNoch keine Bewertungen

- Project CharterDokument27 SeitenProject CharterAkhtar AnsariNoch keine Bewertungen

- Training On: 5S Housekeeping TrainingDokument1 SeiteTraining On: 5S Housekeeping TrainingAkhtar AnsariNoch keine Bewertungen

- Rir 0002Dokument1 SeiteRir 0002Akhtar AnsariNoch keine Bewertungen

- Memo StyleDokument5 SeitenMemo StyleAkhtar AnsariNoch keine Bewertungen

- MFJO723 - As Built DrawingDokument9 SeitenMFJO723 - As Built DrawingAkhtar AnsariNoch keine Bewertungen

- MFJO738A - RT Film - Pipe SpoolDokument2 SeitenMFJO738A - RT Film - Pipe SpoolAkhtar AnsariNoch keine Bewertungen

- MFJO738A - Prssure Test CertificateDokument10 SeitenMFJO738A - Prssure Test CertificateAkhtar AnsariNoch keine Bewertungen

- Memo StyleDokument5 SeitenMemo StyleAkhtar AnsariNoch keine Bewertungen

- Mfjo770 Activity ScheduleDokument1 SeiteMfjo770 Activity ScheduleAkhtar AnsariNoch keine Bewertungen

- NDE Request: Metalfab Middle East FZ LLCDokument1 SeiteNDE Request: Metalfab Middle East FZ LLCAkhtar AnsariNoch keine Bewertungen

- Product Catalogue - RotaryDokument36 SeitenProduct Catalogue - Rotaryeko sunaryoNoch keine Bewertungen

- 2 TS SS STR R8 030309 060213Dokument16 Seiten2 TS SS STR R8 030309 060213dkshtdkNoch keine Bewertungen

- Aluminium Alloy en Aw 6063 Material Data Sheet AlumincoDokument1 SeiteAluminium Alloy en Aw 6063 Material Data Sheet AlumincoVinayak ImadiNoch keine Bewertungen

- Tool PresettingDokument22 SeitenTool PresettingAtulMaurya100% (1)

- TLV - Air & Drain TrapsDokument8 SeitenTLV - Air & Drain TrapsLuis RojasNoch keine Bewertungen

- Marpol - Coatings - Series - Tech - Specs PDFDokument12 SeitenMarpol - Coatings - Series - Tech - Specs PDFYashwant RajeshirkeNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument35 SeitenDisclosure To Promote The Right To InformationRanganathan SekarNoch keine Bewertungen

- 304 Chromic Acid AnodizingDokument6 Seiten304 Chromic Acid AnodizingPuguh Cahpordjo BaeNoch keine Bewertungen

- Specific Heat MetalsDokument1 SeiteSpecific Heat Metalsagibson556Noch keine Bewertungen

- Part1 Icho 1 5 PDFDokument64 SeitenPart1 Icho 1 5 PDFManuel GuilhermeNoch keine Bewertungen

- Phosphorus, Sulfur, and Silicon and The Related ElementsDokument18 SeitenPhosphorus, Sulfur, and Silicon and The Related ElementsGerry Mark GubantesNoch keine Bewertungen

- Types of Steel PDFDokument8 SeitenTypes of Steel PDFIyappan MuruganNoch keine Bewertungen

- Daimler - MBN 11250 ENG - 07-09Dokument26 SeitenDaimler - MBN 11250 ENG - 07-09gültekin gökNoch keine Bewertungen

- Saes W 011Dokument2 SeitenSaes W 011hendraox3996Noch keine Bewertungen

- Specification For Seamless Copper Pipe, Standard SizesDokument8 SeitenSpecification For Seamless Copper Pipe, Standard SizesVCNoch keine Bewertungen

- Engineering Materials - Module 2Dokument5 SeitenEngineering Materials - Module 2Albert Cereno SerranoNoch keine Bewertungen

- Marking and Mechanical Requirements For Bolts, Screws and Studs of SteelDokument7 SeitenMarking and Mechanical Requirements For Bolts, Screws and Studs of SteelTimoNoch keine Bewertungen

- Corrosion Aspects of A Nuclear Power Plant: Chemical LabDokument19 SeitenCorrosion Aspects of A Nuclear Power Plant: Chemical LabSourav BasakNoch keine Bewertungen

- 1 - Boq of Phase-Vii Dha LHR Exten Sec U & TDokument8 Seiten1 - Boq of Phase-Vii Dha LHR Exten Sec U & TZafar BakhshNoch keine Bewertungen

- Experimental ScenariosDokument5 SeitenExperimental ScenariosAnonymous vVEu59idvHNoch keine Bewertungen

- Product Data Sheet OK 84.78: E 'Manual Metal-Arc Welding'Dokument2 SeitenProduct Data Sheet OK 84.78: E 'Manual Metal-Arc Welding'KARLNoch keine Bewertungen

- How and Why Are Butterfly Valves UsedDokument2 SeitenHow and Why Are Butterfly Valves UsedMOHAMMAD ASIFNoch keine Bewertungen

- 1 WPS 132Dokument2 Seiten1 WPS 132VishnuGK100% (1)

- 3 MC HL Armored 5 8 KV Epr 3 ConductorsDokument1 Seite3 MC HL Armored 5 8 KV Epr 3 ConductorsJavier MaldonadoNoch keine Bewertungen

- EPR Series CatalogueDokument20 SeitenEPR Series Cataloguetpelly7Noch keine Bewertungen

- Corrosion Behaviour of CIDokument1 SeiteCorrosion Behaviour of CIBaher ElsheikhNoch keine Bewertungen

- Aml PertaminaDokument35 SeitenAml Pertaminar124L engineer0% (1)

- Siemens NEMA IEC Selection and Pricing Guide 2009 2010Dokument383 SeitenSiemens NEMA IEC Selection and Pricing Guide 2009 2010lduong40% (1)

- 2 ESAB Arc Welding PDFDokument6 Seiten2 ESAB Arc Welding PDFcengizarda1979Noch keine Bewertungen