Beruflich Dokumente

Kultur Dokumente

5-Axis Milling Machine

Hochgeladen von

Sero Ghazarian0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

77 Ansichten1 Seite5-Axis

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden5-Axis

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

77 Ansichten1 Seite5-Axis Milling Machine

Hochgeladen von

Sero Ghazarian5-Axis

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

|'

Linear measuring system machined surface during the return

stroke, where applicable, to prevent

Unveiled recently, Heidenham's Certo scoring.

comprises a CT60 digital length gauge, The system is designed to be

granite base stand and VRZ 210 used in combinatfon with any post

display. An accuracy of -+ 0.1 /~m over process gauging system; the gauging

the full travel of 60mm (at 19°-21 ° C) equipment feeds back signals to a

~s claimed for the system. The incre- m=croprocessor-based control unit

mental measuring principle of the which operates a stepping motor

length gauge incorporates a quartz attached to the compensator. Th~s, m

scale with a 'Diadur' grating which is turn, adjusts the setting of the cutting

scanned photoelectrically. A marker edge. Metric or imperial operation can

pulse on the scale allows simple be chosen. Radial range of the compen-

re-establishment of datum point after sation movement is 0.001 mm to

power interruption, switch.ng off or 0 199 mm while the range of retrac-

zeroing. tlon is 0.01 mm to 0.39 ram. A Marposs automatic too/wear

Heidenhain (GB) Ltd, 200 Metalworking Products Division, compensation system to fit to special

London Road, Burgess Hall, West Sandvik Limited, Manor Way, Hales- purpose boring machines is available

Sussex RH159RD, U K o r Dr Johannes owen, West Midlands B62 8QZ, UK from Sandvik

Heldenham GmbH, Postfach 1260,

D-8225 Traunreut, FRG

by its own closed loop, dc servo system

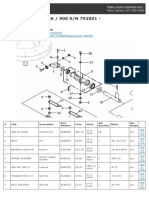

5-axis milling machine with optical encoder feedback, System

Designed primarily for the aerospace resolution =s 0.0001 in (2.54/~m).

industry, the BostoMatic 5-Axis profile The A-axis swing is 12 in (305 mm)

milling machine uses a programmable with 26 in (660 ram) between head-

5th-axis tilting spindle, with rotation stock and tailstock, and the B-axis

centred about the cutting tool tip. In pivots 100 ° either side of vertical. The

the machining of centrifugal impellers fifth ax=s tilt mechanism consists of a

and axial flow rotors the tilting spindle pre4oaded gearset for smooth, backlash-

technique has resulted in greater free, bi-directional movement, a large

accuracy of the blade profile, substan- diameter bearing for rigidity and a

tially shorter program tapes, and simple spring and cable counterbalance

improved cutting rate control and tool system for stable control of the head

rigidity. through its 200 degrees of motion.

The Certo display counter has a digital Boston Digital Corporation, 86

Accuracy at the part is stated to

step of O. 1 #rn. The V24 data output South Street, Hopkinton, MA 01748,

be -+ 0.0003 in (7.6 #m) - -+ 1 minute

permits connection to a printer or USA

of arc rotational accuracy - because

input to a computer for data proces-

the working distance from the pivot of

sing of the measuring value.

the B-axis is only the depth of the cut.

The tilting head eliminates the problem

of maintaining a constant feed rate

Tool wear compensation while one slide is chasing the part; the

tool tip tracks the junction of the hub

Special-purpose boring machines can and the blade as though it were a 3-axis

be fitted with an automatic tool wear die sinking operation. The constant

compensation system developed feed rate is completely independent of

jointly by Sandvik and Marposs. The the B-axis movement and enhances

system allows the cutting edge of a cutter life and finish.

rotating tool to be repos~tioned to A rotary 4th axis and tailstock,

compensate for wear in variable steps bolted solidly to the table, provide rigid

from 0.001 rnm to 0.099 mm to a support for integral shaft rotary com-

presentable maximum deflection up to ponents. A three-point cast iron base

0.200 mm. and box section castings, used for all

Tool wear compensation may be structural members, produce rigidity,

negative or positive, depending on the good damping and lasting alignment

d~mensional variation of the previously accuracy.

machined part. Backlash elimination ~s The 5-ax~s milling machine has a Bostomatic's 5-Axis milling machine

incorporated m the system and, in working envelope of 26 in (660 ram) features a programmable fifth~xis

addition, the Autocomp system allows in the X-axis and 14 in (356 mm) in tilting spindle which results in improved

retraction of the cutting edge from the the Y and Z axes. Each axis =s drzven cutting rate control and tool rigidity

60 A P R 1983 V O L 5 NO 2

Das könnte Ihnen auch gefallen

- Eumach - Umc - 5 Axis VMC Umc-1000Dokument16 SeitenEumach - Umc - 5 Axis VMC Umc-1000Abhishek VelagaNoch keine Bewertungen

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- 2018 - UMC-1000 2016 - NewDokument16 Seiten2018 - UMC-1000 2016 - NewAbhishek VelagaNoch keine Bewertungen

- Excellon 136lspecsDokument13 SeitenExcellon 136lspecsAntonio BermudezNoch keine Bewertungen

- KXG Series - English - 2019 12Dokument8 SeitenKXG Series - English - 2019 12adrienbridel80Noch keine Bewertungen

- Jobber XLDokument4 SeitenJobber XLDeva RajNoch keine Bewertungen

- Vi 40Dokument12 SeitenVi 40shendam520Noch keine Bewertungen

- CNC Lathe Machines PDFDokument7 SeitenCNC Lathe Machines PDFMetwally Naser100% (1)

- Cat-14 UWIFDokument8 SeitenCat-14 UWIFudaysahgalNoch keine Bewertungen

- Ybm 15 TDokument12 SeitenYbm 15 Tdoanthanh_hpNoch keine Bewertungen

- Hyt - Ypl-02Dokument8 SeitenHyt - Ypl-02guna rx100Noch keine Bewertungen

- PM2000,3000,4000Dokument8 SeitenPM2000,3000,4000rago4uNoch keine Bewertungen

- Minimax Gen. - Rev01 - Jan18 - IngDokument136 SeitenMinimax Gen. - Rev01 - Jan18 - IngWagner MenezesNoch keine Bewertungen

- Quot. 070g Mos-23 Al Areen Projects Spacifications.Dokument22 SeitenQuot. 070g Mos-23 Al Areen Projects Spacifications.Abuelgassim GarelnabiNoch keine Bewertungen

- D1 D19 (Vertex 33)Dokument19 SeitenD1 D19 (Vertex 33)Giane NavasNoch keine Bewertungen

- WC67-160 3200 Bending Machine From JIUYING LydiaDokument9 SeitenWC67-160 3200 Bending Machine From JIUYING LydiaSantiago LeivaNoch keine Bewertungen

- ATM RollsDokument2 SeitenATM RollsDipankar MishraNoch keine Bewertungen

- CNC Cylindrical Grinder: EGP, EGA & EPA-A SeriesDokument10 SeitenCNC Cylindrical Grinder: EGP, EGA & EPA-A SeriesLộc HuỳnhNoch keine Bewertungen

- Highly Accurate Large Vertical Machining CenterDokument17 SeitenHighly Accurate Large Vertical Machining Centerletrongthoai18Noch keine Bewertungen

- Mori Seiki ZT 1000 y enDokument16 SeitenMori Seiki ZT 1000 y enOswald muñoz100% (1)

- GantryToolSpecSheet NOV2020Dokument4 SeitenGantryToolSpecSheet NOV2020Mohamed Zied ChaariNoch keine Bewertungen

- SMS Meer Blankstahl-Schaelen enDokument16 SeitenSMS Meer Blankstahl-Schaelen enSukhvinder SinghNoch keine Bewertungen

- SW 300Dokument4 SeitenSW 300Irving RojasNoch keine Bewertungen

- Servocut 302: Abrasive CuttingDokument9 SeitenServocut 302: Abrasive CuttingburcuNoch keine Bewertungen

- Baxis CatalogDokument6 SeitenBaxis CatalogMarcos BustamanteNoch keine Bewertungen

- VX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDokument2 SeitenVX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81Noch keine Bewertungen

- Blohm Planomat HP CNC 10 05Dokument8 SeitenBlohm Planomat HP CNC 10 05hamedadibiNoch keine Bewertungen

- Metkon Cutting Machine Servocut 302Dokument9 SeitenMetkon Cutting Machine Servocut 302Technosys SalesNoch keine Bewertungen

- Fresadora FAMCO Model 100Dokument11 SeitenFresadora FAMCO Model 100Carlos MedranoNoch keine Bewertungen

- Agma MachineDokument6 SeitenAgma Machinemurali036Noch keine Bewertungen

- Kel Univ ECatDokument8 SeitenKel Univ ECatShAi_MyStERiOuSNoch keine Bewertungen

- VMC & HMC PDFDokument103 SeitenVMC & HMC PDFNARENDER SINGHNoch keine Bewertungen

- VX Series - English - 2019 09Dokument8 SeitenVX Series - English - 2019 09Kiril AngelovNoch keine Bewertungen

- Linear Way Vertical Machining Center: MM SeriesDokument16 SeitenLinear Way Vertical Machining Center: MM Seriesjimmy_biker100% (1)

- Band Saw Arg-400-PlusDokument10 SeitenBand Saw Arg-400-PlusOccasionmachinesMetalworkingNoch keine Bewertungen

- EV Series CNC Vertical Machining Center2019Dokument32 SeitenEV Series CNC Vertical Machining Center2019SamiNoch keine Bewertungen

- 1260 VMC JyotiDokument3 Seiten1260 VMC JyotiPavan KhengarNoch keine Bewertungen

- Horizontal Balancing Machines: Series HM4/HM40, HM5/HM50Dokument4 SeitenHorizontal Balancing Machines: Series HM4/HM40, HM5/HM50Samuel TanNoch keine Bewertungen

- Tachyon Series - English - 2019 09Dokument4 SeitenTachyon Series - English - 2019 09Kiril AngelovNoch keine Bewertungen

- Mitsubishi m700 CNC BrochureDokument13 SeitenMitsubishi m700 CNC BrochureDmitryNoch keine Bewertungen

- SCM-C6200CNC 型数控卷簧机: 20mm CNC Compression Spring Coiling MachineDokument1 SeiteSCM-C6200CNC 型数控卷簧机: 20mm CNC Compression Spring Coiling Machinejaswand2010Noch keine Bewertungen

- Namsung 2015 CatalogueDokument10 SeitenNamsung 2015 CataloguekimsonvuNoch keine Bewertungen

- Product Description Height Control KHC1 ARCDokument2 SeitenProduct Description Height Control KHC1 ARChollabackcockNoch keine Bewertungen

- Speedline Abc: Production Turning MachineDokument12 SeitenSpeedline Abc: Production Turning MachinebaumgconradoNoch keine Bewertungen

- CUT - 200 300 400 MS SP - ENDokument24 SeitenCUT - 200 300 400 MS SP - ENMoustaffaNoch keine Bewertungen

- (GT-15Y Y-Axis Model Gang Lathes) : Machine Features & SpecificationsDokument18 Seiten(GT-15Y Y-Axis Model Gang Lathes) : Machine Features & Specificationsjimy46Noch keine Bewertungen

- Servocut 302Dokument9 SeitenServocut 302Representaciones y Distribuciones FALNoch keine Bewertungen

- Specification For CNC MachineDokument3 SeitenSpecification For CNC MachineSONAL P JOSEPH 1561363Noch keine Bewertungen

- Schroder Brochure - PowerBend - Professional - ENDokument12 SeitenSchroder Brochure - PowerBend - Professional - ENIlian AvramovNoch keine Bewertungen

- Crc-p-600 Welding Machine Spec. Brochure 2Dokument4 SeitenCrc-p-600 Welding Machine Spec. Brochure 2gdgfd100% (1)

- TUU 1250 2018 EN Electron.Dokument4 SeitenTUU 1250 2018 EN Electron.Khhg AgddsNoch keine Bewertungen

- KX Large Series - English - 2019 12Dokument12 SeitenKX Large Series - English - 2019 12Rajiv GandhiNoch keine Bewertungen

- CammDokument177 SeitenCammbrar352Noch keine Bewertungen

- BuselattoDokument4 SeitenBuselattoMilanko MarjanovicNoch keine Bewertungen

- Series AX: High Precision Turning / Turn-Mill CentersDokument7 SeitenSeries AX: High Precision Turning / Turn-Mill CentersRAJIV GandhiNoch keine Bewertungen

- YCKT-Balancing Machine CEMBDokument7 SeitenYCKT-Balancing Machine CEMBNguyễn Quốc PhượngNoch keine Bewertungen

- YCM TV SeriesDokument20 SeitenYCM TV SeriesCNC SYSTEMSNoch keine Bewertungen

- Agma MachineDokument6 SeitenAgma MachineNursena SEVİNÇNoch keine Bewertungen

- EG Series BrochureDokument6 SeitenEG Series BrochureHani AlmuftiNoch keine Bewertungen

- Miter & Bevel Gears: Section ContentsDokument16 SeitenMiter & Bevel Gears: Section ContentsHarsha BmNoch keine Bewertungen

- Chapter 2 (Operating Characteristics)Dokument45 SeitenChapter 2 (Operating Characteristics)zoro3samaNoch keine Bewertungen

- Gas Turbine Engine: The Brayton CycleDokument16 SeitenGas Turbine Engine: The Brayton CycleJhun Paul ArcanoNoch keine Bewertungen

- Alfa Laval Aalborg i-OC: Modular Composite BoilerDokument2 SeitenAlfa Laval Aalborg i-OC: Modular Composite BoilerJohn Earl TejamoNoch keine Bewertungen

- GP1200R Service ManualDokument245 SeitenGP1200R Service ManualCZJake100% (4)

- Propeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Dokument7 SeitenPropeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Alexis Kidema0% (1)

- Pompe SUMO FCB - FIVES - SUGAR - BIOENERGY - SUMO - EN - 290316 - BDDokument4 SeitenPompe SUMO FCB - FIVES - SUGAR - BIOENERGY - SUMO - EN - 290316 - BDSAHOMA OMARINoch keine Bewertungen

- 03 HVAC EquipmentDokument26 Seiten03 HVAC EquipmentMohammed AbbasNoch keine Bewertungen

- Stepper MotorsDokument26 SeitenStepper MotorsRam Kumar GogadaNoch keine Bewertungen

- Catalogo Partes y Piezas GRAM HC 8100Dokument28 SeitenCatalogo Partes y Piezas GRAM HC 8100yoye1968100% (3)

- Wilroy Manual 30958Dokument24 SeitenWilroy Manual 30958Sutink9069Noch keine Bewertungen

- Klockner Moeller Contactors 1Dokument1 SeiteKlockner Moeller Contactors 1jorsueNoch keine Bewertungen

- FM480 - 10X4 Dump Truck - 24cum Rock Body - Overburden TransportationDokument24 SeitenFM480 - 10X4 Dump Truck - 24cum Rock Body - Overburden TransportationAprizal AzisNoch keine Bewertungen

- Technical Specification - Prima P2B Pump: GeneralDokument2 SeitenTechnical Specification - Prima P2B Pump: GeneralLuisMi SerranoNoch keine Bewertungen

- Books For OralDokument16 SeitenBooks For OralSubramoniam MarineNoch keine Bewertungen

- Honda CBR250R Engine CutoutDokument7 SeitenHonda CBR250R Engine CutoutOmkar SheteNoch keine Bewertungen

- So Do Dien D7RDokument2 SeitenSo Do Dien D7RVinh Trinhvinhub50% (2)

- Perforadora Montabert HC 50: ReseminDokument12 SeitenPerforadora Montabert HC 50: ReseminAdolfo MarcosNoch keine Bewertungen

- 9FA Installation GuideDokument71 Seiten9FA Installation GuideLandon Mitchell89% (9)

- 4024TF270 66hp t2Dokument2 Seiten4024TF270 66hp t2Irwin JoseNoch keine Bewertungen

- ClutchDokument15 SeitenClutchwidanto0apriawanNoch keine Bewertungen

- Takeuchi TL120 Crawler Loader Parts Manual (SN 21200008 and Up)Dokument16 SeitenTakeuchi TL120 Crawler Loader Parts Manual (SN 21200008 and Up)neeraj0% (1)

- MERA-603 Robotics Engineering L T/P C 4 0 4Dokument2 SeitenMERA-603 Robotics Engineering L T/P C 4 0 4SumanAgarwalNoch keine Bewertungen

- L30-L75 Fixed Speed Rotary Screw Compressor BrochureDokument2 SeitenL30-L75 Fixed Speed Rotary Screw Compressor BrochureSpark ElectricNoch keine Bewertungen

- LMU 2600 Install - Guide PDFDokument5 SeitenLMU 2600 Install - Guide PDFeduardoNoch keine Bewertungen

- FME OP BrochureDokument2 SeitenFME OP BrochureMartin KratkyNoch keine Bewertungen

- KR 96068 237899 569585Dokument4 SeitenKR 96068 237899 569585Ronald BosNoch keine Bewertungen

- CK Range CK120 Dimension Data Sheet-Technical Drawings-EnglishDokument4 SeitenCK Range CK120 Dimension Data Sheet-Technical Drawings-EnglishDiana AlexandraNoch keine Bewertungen

- Motors For Rotax Kiln DriveDokument17 SeitenMotors For Rotax Kiln DrivesreeganeshrNoch keine Bewertungen

- Tutorial 1 Impact of JetDokument1 SeiteTutorial 1 Impact of JetBhuvanesh MuleyNoch keine Bewertungen