Beruflich Dokumente

Kultur Dokumente

Dura Seal

Hochgeladen von

Ugur AydinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dura Seal

Hochgeladen von

Ugur AydinCopyright:

Verfügbare Formate

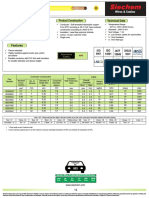

• Resistance to moisture and

abrasion DuraSeal

• Strain relief Heat-shrinkable nylon crimp

• Protection from wire pull-out splices and terminals

• Easy installation

DuraSeal products insulate and protect rugged, heat-shrinkable nylon tubing lined DuraSeal devices accommodate wire

electrical connections from mechanical with a special hot-melt adhesive, resists gauge sizes 22 to 10. They are color-

abuse, wire pull-out, and abrasion while damage from abrasions and cuts. coded for easy identification of gauge

resisting water, salt, and other sizes, yet transparent for inspection of the

contaminants. DuraSeal devices retain flexibility and finished splice.

impact-resistance long after similar

DuraSeal devices provide a tough, products have become brittle.

environmentally sealed wire connection.

Their crimp barrel or terminal, encased in

Product dimensions (inches)

Butt splices

L nom.

ØA min.

Wire dimensions

Butt splice dimensions

Insulation Insulation

Part A L Conductor O.D. O.D.

number min. nom. Color (AWG) (max.) (min.)

D-406-0001 .145 1.25 Red 22–18 .140 .055

D-406-0002 .180 1.25 Blue 16–14 .175 .080

D-406-0003 .250 1.50 Yellow 12–10 .245 .110

Fork terminals

L max.

ØA min. ØB nom. C nom.

Fork terminal dimensions Wire dimensions

B-stud Insulation Insulation

Part A recommended C L Conductor O.D. O.D.

number min. size nom. max. Color (AWG) (max.) (min.)

B-106-2401 .15 8 .31 1.26 Red 22–18 .150 .055

B-106-2402 .18 8 .31 1.38 Blue 16–14 .175 .080

B-106-2502 .18 10 .39 1.38 Blue 16–14 .175 .080

B-106-2403 .25 8 .31 1.50 Yellow 12–10 .250 .110

B-106-2503 .25 10 .39 1.58 Yellow 12–10 .250 .110

Product dimensions (inches)

Ring terminals

L max.

ØA min. B nom. ØC nom.

Ring terminal dimensions Wire dimensions

B-stud Insulation Insulation

Part A recommended C L Conductor O.D. O.D.

number min. size nom. max. Color (AWG) (max.) (min.)

B-106-1401 .15 8 .31 1.26 Red 22–18 .150 .055

B-106-1501 .15 10 .39 1.34 Red 22–18 .150 .055

B-106-1601 .15 1/4 .47 1.42 Red 22–18 .150 .055

B-106-1801 .15 5/16 .55 1.54 Red 22–18 .150 .055

B-106-1991 .15 3/8 .70 1.70 Red 22–18 .150 .055

B-106-1402 .18 8 .31 1.30 Blue 16–14 .175 .080

B-106-1502 .18 10 .39 1.38 Blue 16–14 .175 .080

B-106-1602 .18 1/4 .47 1.44 Blue 16–14 .175 .080

B-106-1802 .18 5/16 .55 1.58 Blue 16–14 .175 .080

B-106-1992 .18 3/8 .70 1.73 Blue 16–14 .175 .080

B-106-1403 .25 8 .31 1.50 Yellow 12–10 .250 .110

B-106-1503 .25 10 .39 1.58 Yellow 12–10 .250 .110

B-106-1603 .25 1/4 .47 1.64 Yellow 12–10 .250 .110

B-106-1803 .25 5/16 .55 1.78 Yellow 12–10 .250 .110

B-106-1993 .25 3/8 .70 1.85 Yellow 12–10 .250 .110

Push-on terminals

L max.

C nom.

A min. B nom.

Push-on terminal dimensions Wire dimensions

Insulation Insulation

Part A B C L Conductor O.D. O.D.

number min. nom. nom. max. Color (AWG) (max.) (min.)

B-106-3631 .150 .250 .032 1.20 Red 22–18 .150 .055

B-106-3632 .180 .250 .032 1.26 Blue 16–14 .175 .080

B-106-3633 .250 .250 .032 1.300 Yellow 12–10 .250 .110

B-106-3281 .150 .110 .020 .900 Red 22–18 .150 .055

Product dimensions (inches)

Tab terminals

L max.

C nom.

ØA min. B nom.

Tab terminal dimensions Wire dimensions

Insulation Insulation

Part A B C L Conductor O.D. O.D.

number min. nom. nom. max. Color (AWG) (max.) (min.)

B-106-4631 .150 .250 .032 1.20 Red 22–18 .150 .055

B-106-4632 .180 .250 .032 1.26 Blue 16–14 .175 .080

Pin terminals

L max.

A min.

ØB

Pin terminal dimensions Wire dimensions

Insulation Insulation

Part A B L Conductor O.D. O.D.

number min. nom. max. Color (AWG) (max.) (min.)

B-106-6201 .150 .080 1.22 Red 22–18 .150 .055

Bullet terminals

L max. Fig. 1

ØA min. B nom.

L max. Fig. 2

ØA min. ØB nom. ØC min.

Bullet terminal dimensions Wire dimensions

Insulation Insulation

Part A B C L Conductor O.D. O.D.

number Fig. Type min. nom. min. max. Color (AWG) (max.) (min.)

B-106-7401 1 M .150 .150 - 1.32 Red 22–18 .150 .055

B-106-7502 1 M .180 .200 - 1.36 Blue 16–14 .175 .080

B-106-8401 2 F .150 .150 .220 1.20 Red 22–18 .150 .055

B-106-8502 2 F .180 .200 .240 1.28 Blue 16–14 .175 .080

Product characteristics

Property Unit Requirement Method of test

Physical Dimensions Inches None See product dimensions

Tensile strength Pounds 8 to 40 lbs depend- UL486C, IEC512-8

ing on AWG

Property Unit Typical value Method of test

Electrical Voltage drop Millivolts Less than equal MIL-S-81824, IEC512-2

length of wire

Insulation resistance Megohms 103 min. MIL-STD-202 method 302

Dielectric withstand Kilovolts 2.5 MIL-STD-202F method 301,

voltage IEC512-2

Property Unit Requirement Method of test

Chemical Diesel fuel Meet electrical test ASTM D 3032, ESA-603D

Brake fluid listed above after

Antifreeze conditioning.

5% salt water

Motor oil

Environmental Humidity Meet electrical test MIL-STD-202F method 106, IEC68-2-30

(Fluid resistance) Immersion listed above after MIL-STD-202F condition C, IEC68-2-14 test NC

Vibration conditioning. MIL-STD-202F method 201, IEC68-2-6

Bending UL486C, IEC512-8

Thermal shock MIL-STD-202F method 107, IEC68-2-14 test N

Heat aging (168° @ 85°C) MIL-STD-202F, IEC68-2-2

Salt spray MIL-STD-202F method 101, IEC68-2-11

Operating Temperature rating –55°C to +125°C None

conditions Minimum shrink temperature 180°C None

Voltage rating 600 Volt max None

Approvals and reference documents

Agency approvals UL listed component, file E87681, butt splices and terminals except

quick connect terminals; file E157833, quick connect terminals

Reference documents Raychem specifications RB-107, Specification DuraSeal crimp splices

Raychem specifications RB-108, Specification DuraSeal crimp terminals

DuraSeal selection guide (H54153)

DuraSeal installation guidelines (H54154)

Ordering information

Standard packaging Product supplied in bulk, 500 or 1000 pieces per box, depending on size.

For other packaging options consult factory.

©1992, 1997, 2000 Tyco Electronics Corporation Printed in USA H54150 10/00

DuraSeal is a trademark of Tyco Electronics Corporation.

All information, including illustrations, is believed to be reliable. Users, however, should independently evaluate the suitability of each product for their

application. Tyco Electronics makes no warranties as to the accuracy or completeness of the information, and disclaims any liability regarding its use. Tyco Electronics

only obligations are those in the Standard Terms and Conditions of Sale for this product and in no case will Tyco Electronics be liable for any incidental, indirect or

consequential damages arising from the sale, resale, use, or misuse of the product. Tyco Electronics Specifications are subject to change without notice. In addition,

Tyco Electronics reserves the right to make changes in materials or processing without notification to the Buyer which do not affect compliance with any applicable

specification.

Tyco Electronics Corporation Tyco Electronics UK Ltd. Tyco Electronics Raychem K.K. Raychem Singapore Pte. Ltd.

Raychem Raychem Raychem Raychem

305 Constitution Drive Cheney Manor Industrial Estate 3816 Noborito, Tama-ku No. 26 Ang Mo Kio Ind. Park

Menlo Park, CA 94025 Swindon, Wiltshire SN2 2QE Kawasaki 214-8533 Singapore 569507

U.S.A. U.K. Japan

www.tycoelectronics.com

Das könnte Ihnen auch gefallen

- Ricoh 4055 PDFDokument1.280 SeitenRicoh 4055 PDFPham Nguyen Hoang Minh100% (1)

- SANA Electrical & Telephone Cable GlandsDokument12 SeitenSANA Electrical & Telephone Cable Glandsjehad azoozNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Electrical Solutions: Disco-Lok Female Disconnect, Nylon Fully Insulated - Funnel EntryDokument1 SeiteElectrical Solutions: Disco-Lok Female Disconnect, Nylon Fully Insulated - Funnel EntryGabriel VargasNoch keine Bewertungen

- Vibration Isolation Product GuideDokument22 SeitenVibration Isolation Product GuideLợi TrầnNoch keine Bewertungen

- Single Core Insulated and Sheathed PDFDokument1 SeiteSingle Core Insulated and Sheathed PDFalamNoch keine Bewertungen

- Single Core Insulated and SheathedDokument1 SeiteSingle Core Insulated and SheathedImthiyasNoch keine Bewertungen

- Kelani Cable - ArmouredDokument1 SeiteKelani Cable - Armouredsukiraj Rasalingam100% (1)

- HOUSE WIRING FLEXIBLE CABLE GUIDEDokument16 SeitenHOUSE WIRING FLEXIBLE CABLE GUIDENitinNoch keine Bewertungen

- Utility Pressure Gauge - Economical - India Pressure GaugeDokument4 SeitenUtility Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNoch keine Bewertungen

- Application Product Construction Technical Data: 2D ViewDokument1 SeiteApplication Product Construction Technical Data: 2D ViewUttrakhand Vibes- OriginalNoch keine Bewertungen

- App 2037023000Dokument6 SeitenApp 2037023000danielNoch keine Bewertungen

- 0.050" PVC, Stranded & Hi-Flex 19 Stranded: ApplicationsDokument1 Seite0.050" PVC, Stranded & Hi-Flex 19 Stranded: Applicationsfrancisco lopez moyaNoch keine Bewertungen

- LX Chống Rung-catalogue Mới Nhất 2018Dokument34 SeitenLX Chống Rung-catalogue Mới Nhất 2018Tuyen NguyenNoch keine Bewertungen

- RoHS Compliant MIL-DTL-5015 Circular ConnectorsDokument18 SeitenRoHS Compliant MIL-DTL-5015 Circular Connectorspratik septaNoch keine Bewertungen

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDokument1 SeitePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNoch keine Bewertungen

- ITC Cable Glands & Accessories CatalogDokument32 SeitenITC Cable Glands & Accessories CatalogAntony ChackoNoch keine Bewertungen

- Multi Core Unarmoured Shaped Conductor - XLPE InsulatedDokument1 SeiteMulti Core Unarmoured Shaped Conductor - XLPE InsulatedMohamed InshafNoch keine Bewertungen

- RhinoDokument2 SeitenRhinoValeria Rendon NoyolaNoch keine Bewertungen

- Hudetech Spring IsolatorDokument28 SeitenHudetech Spring IsolatorThanh DoNoch keine Bewertungen

- HS-901D Technical Data SheetDokument4 SeitenHS-901D Technical Data SheetAji SetiawanNoch keine Bewertungen

- Alfa Laval Shutter Valve Product Leaflet PDFDokument4 SeitenAlfa Laval Shutter Valve Product Leaflet PDFJohn Michea CortesNoch keine Bewertungen

- PICOD - 131 - AK DatasheetDokument2 SeitenPICOD - 131 - AK DatasheetWarr SteelNoch keine Bewertungen

- Type 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesDokument1 SeiteType 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesArun BabuNoch keine Bewertungen

- Dms3106a22-14p CPDokument14 SeitenDms3106a22-14p CPnishank srivastavaNoch keine Bewertungen

- SP 12 314Dokument23 SeitenSP 12 314Quantudogon DangNoch keine Bewertungen

- LOW VOLTAGE AUTO WIRESDokument4 SeitenLOW VOLTAGE AUTO WIRESsarveshgupta1Noch keine Bewertungen

- List Technickych Udaju 602045 3m 170010 100 SF Plochy Kabel Rastr Roztec 127 MM 10 X 008 MM Barevna Metrove ZboziDokument3 SeitenList Technickych Udaju 602045 3m 170010 100 SF Plochy Kabel Rastr Roztec 127 MM 10 X 008 MM Barevna Metrove Zbozibekik55141Noch keine Bewertungen

- Midea Ductable DetailsDokument9 SeitenMidea Ductable DetailsYUVI RAJNoch keine Bewertungen

- STD - Cu-Pvc 450-750 V BS en 50525-2-31Dokument2 SeitenSTD - Cu-Pvc 450-750 V BS en 50525-2-31Angelina JunioNoch keine Bewertungen

- 7/16 Coaxial Connectors: Parts Name Material FinishDokument10 Seiten7/16 Coaxial Connectors: Parts Name Material FinishBambang NurrahmantoNoch keine Bewertungen

- Continental Device India Data Sheet for Schottky Barrier RectifiersDokument5 SeitenContinental Device India Data Sheet for Schottky Barrier RectifiersMariano CalandroniNoch keine Bewertungen

- Adjustment range for 22/130 rail clipDokument2 SeitenAdjustment range for 22/130 rail clipAshley Dean100% (1)

- 08 - Instrument CableDokument15 Seiten08 - Instrument CablemlutfimaNoch keine Bewertungen

- FD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Dokument2 SeitenFD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Guilherme ZanotelliNoch keine Bewertungen

- CBBT CablesDokument1 SeiteCBBT CablesKristaNoch keine Bewertungen

- SOT-23 SMD switching diodesDokument3 SeitenSOT-23 SMD switching diodesJosé Miguel Barbosa Hernández67% (3)

- Microwave SLC Capacitors with Bordered DesignsDokument2 SeitenMicrowave SLC Capacitors with Bordered DesignsrolandseNoch keine Bewertungen

- Nycy Cycy FDokument5 SeitenNycy Cycy Fstupard1989Noch keine Bewertungen

- Building Wire and CablesDokument24 SeitenBuilding Wire and CablesVipuchit SirikhemapornNoch keine Bewertungen

- Adi Artech: DescriptionDokument1 SeiteAdi Artech: DescriptionkumarNoch keine Bewertungen

- For Laboratory Applications: To OrderDokument7 SeitenFor Laboratory Applications: To OrderSUPERGOICONoch keine Bewertungen

- technical_datasheet_resilient_seat_gate_valve_f4_ctc_epdm_acs_flanged_pn10-16Dokument18 Seitentechnical_datasheet_resilient_seat_gate_valve_f4_ctc_epdm_acs_flanged_pn10-16Benny 37Noch keine Bewertungen

- R4 CableDokument1 SeiteR4 CableVijay KarthikeyanNoch keine Bewertungen

- BS170 PDFDokument14 SeitenBS170 PDFsaleh67msNoch keine Bewertungen

- HS-901C Technical Data SheetDokument3 SeitenHS-901C Technical Data SheetAji SetiawanNoch keine Bewertungen

- FLRY11Y CablesDokument1 SeiteFLRY11Y CablesKristaNoch keine Bewertungen

- MultiCore - ClassD - ThickWall IS19642Dokument1 SeiteMultiCore - ClassD - ThickWall IS19642Tumbin DilseNoch keine Bewertungen

- 3 Outdoor Cables - Copper Conductor: 3.7 Single Core Armoured Circular Conductor - XLPE InsulatedDokument1 Seite3 Outdoor Cables - Copper Conductor: 3.7 Single Core Armoured Circular Conductor - XLPE Insulatedරුසිරු ගුරුගේ (rusig)Noch keine Bewertungen

- Dlo RHH RHW-2 RW90-2000VDokument1 SeiteDlo RHH RHW-2 RW90-2000VSalvatierra Rojas MoisesNoch keine Bewertungen

- Unnamed Gornja GredaDokument7 SeitenUnnamed Gornja GredasehmediaNoch keine Bewertungen

- Instrumentation Cable BSDokument42 SeitenInstrumentation Cable BSShivaniNoch keine Bewertungen

- Raychem: Specification Control DrawingDokument1 SeiteRaychem: Specification Control Drawingqwe123Noch keine Bewertungen

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Dokument2 Seiten3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNoch keine Bewertungen

- Tyco Connectors For UG ApplicationsDokument138 SeitenTyco Connectors For UG Applicationseugene oneillNoch keine Bewertungen

- Resilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmDokument18 SeitenResilient Seat Gate Valve Pn10/16 Short Pattern Din 3202-F4 CTC EpdmG DilemaNoch keine Bewertungen

- Universal Cables Limited Single Core FRLS ZH Insulated Flexible Cables for Working Voltages up to 1100 VoltsDokument1 SeiteUniversal Cables Limited Single Core FRLS ZH Insulated Flexible Cables for Working Voltages up to 1100 VoltsBinesh MenonNoch keine Bewertungen

- Threaded Mechanical Branch TeeDokument2 SeitenThreaded Mechanical Branch TeeJulian RiverosNoch keine Bewertungen

- Conductivity sensor-SC4Dokument12 SeitenConductivity sensor-SC4Ziyaur RahmanNoch keine Bewertungen

- Proposal Anguria Pasta NewDokument24 SeitenProposal Anguria Pasta NewNOOR IRDINA HAFIZAH BT TAUPISNoch keine Bewertungen

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDokument7 SeitenEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersNoch keine Bewertungen

- Problem SolutionsDokument5 SeitenProblem SolutionskkappaNoch keine Bewertungen

- Phenomenological of in Church and TV WorshipDokument18 SeitenPhenomenological of in Church and TV WorshipCindy TirtaNoch keine Bewertungen

- Sradham ChecklistDokument9 SeitenSradham ChecklistpswaminathanNoch keine Bewertungen

- Flowing Gas Material BalanceDokument4 SeitenFlowing Gas Material BalanceVladimir PriescuNoch keine Bewertungen

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDokument13 SeitenLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- Proceedings of The 16 TH WLCDokument640 SeitenProceedings of The 16 TH WLCSabrinaNoch keine Bewertungen

- VT6050 VT6010 QuickGuide ENDokument19 SeitenVT6050 VT6010 QuickGuide ENPriyank KumarNoch keine Bewertungen

- Idioms & Phrases Till CGL T1 2016Dokument25 SeitenIdioms & Phrases Till CGL T1 2016mannar.mani.2000100% (1)

- 1.2 - Sewing Machine and Special AttachmentsDokument3 Seiten1.2 - Sewing Machine and Special Attachmentsmaya_muth0% (1)

- Xii Neet Chemistry Mcqs PDFDokument30 SeitenXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- Survey Report on Status of Chemical and Microbiological Laboratories in NepalDokument38 SeitenSurvey Report on Status of Chemical and Microbiological Laboratories in NepalGautam0% (1)

- A Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastDokument82 SeitenA Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastJacques LeBlanc100% (18)

- Mechanical Specifications For Fiberbond ProductDokument8 SeitenMechanical Specifications For Fiberbond ProducthasnizaNoch keine Bewertungen

- SRS Design Guidelines PDFDokument46 SeitenSRS Design Guidelines PDFLia FernandaNoch keine Bewertungen

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Dokument5 SeitenUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarNoch keine Bewertungen

- A Study On Customer Satisfaction Towards Honda Bikes in CoimbatoreDokument43 SeitenA Study On Customer Satisfaction Towards Honda Bikes in Coimbatorenkputhoor62% (13)

- 07 Raction KineticsDokument43 Seiten07 Raction KineticsestefanoveiraNoch keine Bewertungen

- Aircraft Design Project 2Dokument80 SeitenAircraft Design Project 2Technology Informer90% (21)

- Is.4162.1.1985 Graduated PipettesDokument23 SeitenIs.4162.1.1985 Graduated PipettesBala MuruNoch keine Bewertungen

- BMW Motronic CodesDokument6 SeitenBMW Motronic CodesxLibelle100% (3)

- 3D Area Clearance Strategies for Roughing ComponentsDokument6 Seiten3D Area Clearance Strategies for Roughing ComponentsMohamedHassanNoch keine Bewertungen

- SOR 8th Ed 2013Dokument467 SeitenSOR 8th Ed 2013Durgesh Govil100% (3)

- WOOD Investor Presentation 3Q21Dokument65 SeitenWOOD Investor Presentation 3Q21Koko HadiwanaNoch keine Bewertungen

- Discuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?Dokument4 SeitenDiscuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?harryNoch keine Bewertungen

- The CongoDokument3 SeitenThe CongoJoseph SuperableNoch keine Bewertungen

- SECTION 303-06 Starting SystemDokument8 SeitenSECTION 303-06 Starting SystemTuan TranNoch keine Bewertungen