Beruflich Dokumente

Kultur Dokumente

Hyd

Hochgeladen von

ashwaniv_60 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten1 Seitehyd

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenhyd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

11 Ansichten1 SeiteHyd

Hochgeladen von

ashwaniv_6hyd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Provided that a material has these characteristics, be it a metal or polymer,

the elementary stress analysis of bars, beams, frames, pressure vessels,

columns, etc. using these assumptions is quite accurate and useful. However,

when these assumptions are violated serious errors can occur if the same analysis

approaches are used. It is therefore incumbent upon engineers

to thoroughly understand these fundamental definitions as well as

how to determine if they are appropriate for a given situation. As a result,

the reader is encouraged to gain a thorough understanding of the following

terms:

Linearity: Two types of linearity are normally assumed: Material linearity

(Hookean stress-strain behavior) or linear relation between stress

and strain; Geometric linearity or small strains and deformation.

Elastic: Deformations due to external loads are completely and instantaneously

reversible upon load removal.

Continuum: Matter is continuously distributed for all size scales, i.e.

there are no holes or voids.

Homogeneous: Material properties are the same at every point or material

properties are invariant upon translation.

Inhomogeneous or Heterogeneous: Material properties are not the

same at every point or material properties vary upon translation.

Amorphous: Chaotic or having structure without order. An example

would be glass or most metals on a macroscopic scale.

Crystalline: Having order or a regular structural arrangement. An example

would be naturally occurring crystals such as salt or many metals

on the microscopic scale within grain boundaries.

Isotropic: Materials which have the same mechanical properties in all

directions at an arbitrary point or materials whose properties are invariant

upon rotation of axes at a point. Amorphous materials are isotropic.

Anisotropic: Materials which have mechanical properties which are

not the same in different directions at a point or materials whose properties

vary with rotation at a point. Crystalline materials are anisotropic.

Plastic: The word comes from the Latin word plasticus, and from the

Greek words plastikos which in turn is derived from plastos (meaning

molded) and from plassein (meaning to mold). Unfortunately, this term

is often used as a generic name for a polymer (see definition below)

probably because many of the early polymers (cellulose, polyesters,

etc.) appear to yield and/or flow in a similar manner to metals and

could be easily molded. However, not all polymers are moldable, exhibit

plastic flow or a definitive yield point.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Tutorial ABAQUSDokument38 SeitenTutorial ABAQUSRabee Shammas0% (1)

- GateDokument1 SeiteGateashwaniv_6Noch keine Bewertungen

- Otherwise It Shall Be Terminated at The Depth 20.0m. Otherwise It Shall Be Terminated at The Depth 20.0mDokument1 SeiteOtherwise It Shall Be Terminated at The Depth 20.0m. Otherwise It Shall Be Terminated at The Depth 20.0mashwaniv_6Noch keine Bewertungen

- Data RequiredDokument1 SeiteData Requiredashwaniv_6Noch keine Bewertungen

- Co VersionsDokument1 SeiteCo Versionsashwaniv_6Noch keine Bewertungen

- Data RequiredDokument1 SeiteData Requiredashwaniv_6Noch keine Bewertungen

- Water Conservation CampaignDokument8 SeitenWater Conservation Campaignashwaniv_6Noch keine Bewertungen

- SolutionDokument3 SeitenSolutionashwaniv_6Noch keine Bewertungen

- brochureDDA PDFDokument19 SeitenbrochureDDA PDFLiyakat AliNoch keine Bewertungen

- Specs I GengDokument1 SeiteSpecs I Gengashwaniv_6Noch keine Bewertungen

- Learn More Earn MoreDokument31 SeitenLearn More Earn Moreashwaniv_6Noch keine Bewertungen

- GlossoryDokument76 SeitenGlossoryisnindianNoch keine Bewertungen

- Competency Dictionary For The Civil ServicesDokument37 SeitenCompetency Dictionary For The Civil ServicesAbhishekTiwariNoch keine Bewertungen

- Calibration TableDokument1 SeiteCalibration Tableashwaniv_6Noch keine Bewertungen

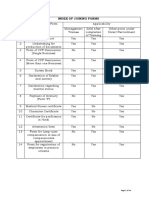

- List of Medical Abbreviations - Latin Abbreviations - WikipediaDokument4 SeitenList of Medical Abbreviations - Latin Abbreviations - Wikipediaashwaniv_6Noch keine Bewertungen

- Latest CGHS Rate File979Dokument43 SeitenLatest CGHS Rate File979Inder0% (1)

- Pec Vocational PresentationDokument20 SeitenPec Vocational Presentationashwaniv_6Noch keine Bewertungen

- Syllabus - MBBSDokument167 SeitenSyllabus - MBBStariqayubNoch keine Bewertungen

- WFA Girls 0 13 Percentiles PDFDokument1 SeiteWFA Girls 0 13 Percentiles PDFashwaniv_6Noch keine Bewertungen

- Embankment PropertiesDokument1 SeiteEmbankment Propertiesashwaniv_6Noch keine Bewertungen

- Joined FormDokument19 SeitenJoined Formashwaniv_6Noch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument19 SeitenDisclosure To Promote The Right To Informationashwaniv_6Noch keine Bewertungen

- New Latest List of Delhi Updated December2017Dokument61 SeitenNew Latest List of Delhi Updated December2017ashwaniv_6Noch keine Bewertungen

- HP Getting Started Color LaserJet Pro MFP M377dwDokument20 SeitenHP Getting Started Color LaserJet Pro MFP M377dwashwaniv_6Noch keine Bewertungen

- Embankment PropertiesDokument2 SeitenEmbankment Propertiesashwaniv_6Noch keine Bewertungen

- DetailsDokument1 SeiteDetailsashwaniv_6Noch keine Bewertungen

- Telephone Chart August-2018Dokument1 SeiteTelephone Chart August-2018ashwaniv_6Noch keine Bewertungen

- ScribdDokument1 SeiteScribdashwaniv_6Noch keine Bewertungen

- Bulk Modulus (K) Granite 50 Gpa Shale 10 Gpa Limestone 65 Gpa Chalk 9 Gpa Sandstone 0.7 Gpa 4Dokument1 SeiteBulk Modulus (K) Granite 50 Gpa Shale 10 Gpa Limestone 65 Gpa Chalk 9 Gpa Sandstone 0.7 Gpa 4ashwaniv_6Noch keine Bewertungen

- Use of Geosynthetics in WR ProjectsDokument3 SeitenUse of Geosynthetics in WR Projectsashwaniv_6Noch keine Bewertungen

- Design and Construction of Embankment DamsDokument1 SeiteDesign and Construction of Embankment Damsashwaniv_6Noch keine Bewertungen

- Mechanical Properties of Stainless SteelDokument8 SeitenMechanical Properties of Stainless SteelFahrul Nur ArifinNoch keine Bewertungen

- Using The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureDokument15 SeitenUsing The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureMohammed EljammalNoch keine Bewertungen

- The Effect of Porosity On The Fatigue Life of Cast Aluminium-SiliconDokument12 SeitenThe Effect of Porosity On The Fatigue Life of Cast Aluminium-SiliconSatis MrtNoch keine Bewertungen

- Advanced Nonlinear Materials: Section 4Dokument116 SeitenAdvanced Nonlinear Materials: Section 4hakan demirNoch keine Bewertungen

- MSC Inf14Dokument46 SeitenMSC Inf14Karan DoshiNoch keine Bewertungen

- S.Y. Metallurgy SyllabusDokument50 SeitenS.Y. Metallurgy SyllabusKrushnankur PoreNoch keine Bewertungen

- Fracture and FatigueDokument21 SeitenFracture and FatigueLeandro MarchiNoch keine Bewertungen

- 6-Flow Behavior of Diffusion Bonding Interface of Ti6Al4V Alloy Over A WideDokument9 Seiten6-Flow Behavior of Diffusion Bonding Interface of Ti6Al4V Alloy Over A WideNisa Yağmur BilgiNoch keine Bewertungen

- Fracture Mechanics of Concrete and Its Role in Explaining Structural BehaviourDokument11 SeitenFracture Mechanics of Concrete and Its Role in Explaining Structural Behaviours s kattiNoch keine Bewertungen

- 07 Strength of MaterialsDokument17 Seiten07 Strength of MaterialsManoj PokharelNoch keine Bewertungen

- كاملهDokument216 SeitenكاملهTRNADEWNoch keine Bewertungen

- Surface Properties and Activation Energy of Superplastically Carburized Duplex Stainless SteelDokument5 SeitenSurface Properties and Activation Energy of Superplastically Carburized Duplex Stainless SteelElina AkbarzadeNoch keine Bewertungen

- Elasticity and PlasticityDokument26 SeitenElasticity and PlasticityRAMA BAGAS ADITYA TM 2DNoch keine Bewertungen

- Casing Hanger Calculation PDFDokument3 SeitenCasing Hanger Calculation PDFMinhaj AkbarNoch keine Bewertungen

- 3D F.E.M. Analysis of A Roman Arch BridgeDokument8 Seiten3D F.E.M. Analysis of A Roman Arch BridgeAkhilesh GojeNoch keine Bewertungen

- Physics Part 2 Guess 2023Dokument19 SeitenPhysics Part 2 Guess 2023Mehran ChaudryNoch keine Bewertungen

- CVEN3302 Structural Design CVEN3302 Structural DesignDokument404 SeitenCVEN3302 Structural Design CVEN3302 Structural Designroy jackNoch keine Bewertungen

- Lab Hardness MemoDokument4 SeitenLab Hardness MemoJan YsNoch keine Bewertungen

- Structural and Mechanical Behaviour of Severe Plastically Deformed High Purity Aluminium Sheets Processed by Constrained Groove Pressing TechniqueDokument7 SeitenStructural and Mechanical Behaviour of Severe Plastically Deformed High Purity Aluminium Sheets Processed by Constrained Groove Pressing TechniqueMoin ANoch keine Bewertungen

- Physical, Chemical and Mechanical PropertiesDokument42 SeitenPhysical, Chemical and Mechanical PropertiesAwais Jamil100% (1)

- Design of Steel Structures - 2016 - Da Silva - Front MatterDokument16 SeitenDesign of Steel Structures - 2016 - Da Silva - Front MatterYasser Hamed0% (1)

- Broaching - Sawing ProcessesDokument33 SeitenBroaching - Sawing ProcessesashutoshNoch keine Bewertungen

- Aluminium Alloys, Theory and Applications - Tibor KvackajDokument412 SeitenAluminium Alloys, Theory and Applications - Tibor KvackajFrancisco TorresNoch keine Bewertungen

- Failure Theories PDFDokument2 SeitenFailure Theories PDFBenNoch keine Bewertungen

- MMS Unit IDokument7 SeitenMMS Unit IAdula RajasekharNoch keine Bewertungen

- Chapter 3-Fundamentals of Metal FormingDokument6 SeitenChapter 3-Fundamentals of Metal FormingG. Dancer GhNoch keine Bewertungen

- EC2 Ch03aDokument15 SeitenEC2 Ch03asunilarunaNoch keine Bewertungen

- INTRODUCTION (Cont..) : TIN 205-TIN31 Engineering MechanicsDokument47 SeitenINTRODUCTION (Cont..) : TIN 205-TIN31 Engineering Mechanicsgundul paculNoch keine Bewertungen