Beruflich Dokumente

Kultur Dokumente

Analysis of Radiation at Different Surfaces in A Domestic Used

Hochgeladen von

Hitesh Kumar Prajapati0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten3 SeitenThis is the research paper based on the analysis of radiation on different surfaces of the thermally insulated chamber with the help of electrical analogy.

Originaltitel

Analysis of Radiation at Different Surfaces in a Domestic Used

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis is the research paper based on the analysis of radiation on different surfaces of the thermally insulated chamber with the help of electrical analogy.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten3 SeitenAnalysis of Radiation at Different Surfaces in A Domestic Used

Hochgeladen von

Hitesh Kumar PrajapatiThis is the research paper based on the analysis of radiation on different surfaces of the thermally insulated chamber with the help of electrical analogy.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Analysis Of Radiation At Different Surfaces Of A Thermally Insulated

Chamber (For Cooking & Baking) By Electrical Analogy Network

Hitesh Kr. Prajapati, Rahul Agrawal, Kajal Sarmah

Abstract heated mainly by radiation and only little

In a thermally insulated chamber hot air part of the heat is transferred by

flows by natural or forced convection convection which is less than 10%. To

while heat is distributed from the heating analyze the individual mode of heat

element by radiation. Heat is also transfer during baking process is very

transfered by conduction from the metal complicated. Several studies have used

container to the product. Radiation is heat flux meters or h-monitors to measure

considered as the main process of heat the heat flux inside the chamber [2], [3].

transfer occurred in the chamber. Use of But, the disadvantage of using this tool is

electrical analogy network provides a that it could not measure the individual

useful tool for visualizing radiation mode of heat transfer. Network

exchange. The network is built based on representation method seems to be useful

identifying nodes associated with to analyze radiation in an enclosure such

radiosities of each surfaces in the chamber. as chamber and furnace. It was first

Analysis is concentrated on the effect of introduced by Oppenheim [4] in year

radiation heat transfer inside the chamber 1956. A few study has been accomplished

under natural and forced convection. The using this technique in this field of

radiation rates of all surface involved were research [5], [6].The network is developed

successfully determined. With the from radiation properties including view

calculated radiation rate, analysis on the factors, reflectivites, emissivities and

effects of radiation under natural radiosities.

convection and forced convection modes

were performed. Nomenclature

qi radiation rate at surface i

Keywords: Radiation Heat Transfer, Ai area of surface i

Radiosity, Electrical Analogy Network, Ji radiosity at surface i

Surface resistance, Space Resistance. Jj radiosity at surface j

Gi irradiation energy at surface i

Introduction Єi emissivity of surface i

In chamber, typically there is a heating Ebi emissive power of surface i

element, a heat transfer medium such as a Fij view factor between surface i and j

pan or tray and the food itself. The heat

moves from the heating element through Methodology

the medium to the food. Temperature and I. Chamber surface temperature

heat are often used interchangeably, but measurement

they are not the same thing. Thermal Heating process in the chamber under

radiation is considered one of the main natural convection mode was conducted

processes of heat transfer occurred in the for 30 minutes at 220°C.Six

chamber during operation. According to thermocouples were placed at each surface

Zheleva and Kambourva [1], the top inside the chamber. Data logger was used

surface of the product in the chamber is to record the temperature during the

heating process. The experiment was

repeated two times. The thermocouple surfaces inside the chamber, a total of 36

placement inside the chamber with top view factors need to be determined.

surface as surface 1, back surface as

surface 2, left surface as surface 3, front III. Electrical Analogy For Network

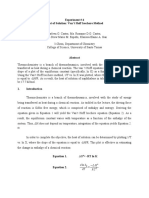

surface as surface 4, right surface as The radiative energy balances can be

surface 5 and bottom surface as surface 6. represented in a electrical analogy for

network. Compared with an electric

II. Radiation heat transfer analysis network, Eb and Ji are analogous to the

Radiation heat transfer rate was calculated potential; qi and qij are analogous to the

using electrical analogy network. The current and resistances, respectively. The

analysis of radiation inside the chamber network analogy provides a useful way for

was carried out by assuming the walls of visualizing radiation exchange in an

the chamber are modelled as diffuse, enclosure and is a convenient tool for

opaque and gray surfaces [7]. Each surface calculating the radiative exchange in an

of the chamber is assumed isothermal and enclosure consisting of two or more

uniform radiosity. During radiation, no surfaces. Defining the following variables

conduction and convection is assumed. to simplify the notation:

The net radiation heat transfer per unit

surface area, qi , is determined from each = Surface resistance (6)

surface. Radiosity, J, is the radiation heat

transfer energy that leaves a surface and

Where,

irradiation, G, accounts for all of the

radiation heat transfer energy received by a (7)

surface.

qij

The net rate at which radiation leaves

surface i, qi , is equal to the difference

between the radiosity and

irradiation of surface i:

qi = Ai(Ji-Gi) (1) Ji Jj

For an opaque surface, the radiosity,

𝐴𝑖𝐹𝑖𝑗

written as:

Ji = Єi Ebi+(1- Єi)Gi (2)

Substituting equation (2) into equation (1), qij = Radiation Rate

it follows that:

(3) Substituting equation (6) and (7) into

equation (5), the following equation will

Using the reciprocity relation for view be obtain:

factors (AiFij = AjFji), an alternative

expression can be obtained for the net

radiation heat flux from surface i: ∑ (8)

∑ (4)

Expanding and rearranging equation (8)

where, N is the total number of surfaces in for surface 1gives:

the chamber. Combining equations (3) and

(4):

∑ (5)

To calculate radiation exchange of in an

enclosure of N surfaces, a total of N2 view The radiosity equations (J1 to J6) were

factors is needed. Therefore, for six solved simultaneously using Gauss-Seidel

iteration method. Once radiosity value is

obtained, the radiation heat transfer at tunnel type industrial oven. Journal of

surface i (q1 to q6) can be calculated using Food Science. 1999, 64(4): 688-694.

equation (4). Net radiation heat transfer [4] K. Oppenheim. Radiation Analysis by

rate, qi was computed by adding the the Network Method. Transactions of the

radiation rates for each surface, qij. Table 1 ASME. 1956, 54: 725-735.

represents the values of view factor, [5] S. Saedodin, M. Torabi, J. M.

radiosity and radiation rate for between Kandelousi and N. Maghsodloo.

surface 1 and other surfaces. Application of Net Radiation Transfer

Method for Optimization and Calculation

of Reduction Heat Transfer, Using

Spherical Radiation Shields. World

Applied Sciences Journal. 2010, 11 (4):

457-461.

[6] J. Zueco, P. Eguía, E. Granada, J. L.

Míguez and O. A. Bég. An electrical

network for the numerical solution of

transient mhd couette flow of a dusty fluid:

Effects of variable properties and hall

current. International Communications in

Heat and Mass Transfer,

Fig.1. Electrical Analogy For Network 2010, 37: 1432–1439.

[7] F. P. Incropera, D. P. DeWitt, T. L.

Table1. Radiation rate values Bergmann and A. S. Lavine.

Fundamentals of Heat and Mass Transfer.

Surfaces,ij View Radiosity,Ji(W) Radiation John Wiley & Sons,2007.

factor,Fij Rate,qij(w)

11 0 J1=4210.36 0

12 0.192 J2=3568.25 24.36

13 0.179 J3=3410.21 28.30

14 0.192 J4=2397.62 68.78

15 0.179 J5=3317.90 31.57

16 0.259 J6=3943.48 12.68

Net radiation 165.7

rate,q1

References

[1] I. Zheleva and V. Kambourova.

Identification of Heat and Mass Transfer

Processes in Bread during Baking.

Thermal Science. 2005, 2: 73-86.

[2] M. R. Zareifard, V. Boissonneault and

M. Marcotte. Bakery Product

Characteristics as Influenced by

Convection Heat Flux. Food Research

International. 2006, 42: 856-864.

[3] O. D. Baik, S. Grabowski, M. Trigui,

M. Marcotte and F. Castaigne. Heat

transfer coefficients on cakes baked in a

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- BSEEP Active Design GuidebookDokument218 SeitenBSEEP Active Design GuidebookArvensisdesignNoch keine Bewertungen

- Refrigeration and Air Conditioning Sample PaperDokument52 SeitenRefrigeration and Air Conditioning Sample PaperkregdNoch keine Bewertungen

- SUMMATIVE TEST 6. Quarter 4 Science 9Dokument2 SeitenSUMMATIVE TEST 6. Quarter 4 Science 9Colleen RubiaNoch keine Bewertungen

- Chapter 3 0114Dokument15 SeitenChapter 3 0114Cyduck Guevarra100% (2)

- ConductionDokument159 SeitenConductionNugi100% (1)

- PH Control Using CO2Dokument38 SeitenPH Control Using CO2Bob SmithNoch keine Bewertungen

- Avg NormsDokument1 SeiteAvg NormsHitesh Kumar PrajapatiNoch keine Bewertungen

- Avg NormsDokument1 SeiteAvg NormsHitesh Kumar PrajapatiNoch keine Bewertungen

- 15 Days WorkingDokument17 Seiten15 Days WorkingHitesh Kumar PrajapatiNoch keine Bewertungen

- An Sys PaperDokument13 SeitenAn Sys PaperHitesh Kumar PrajapatiNoch keine Bewertungen

- 15 Days WorkingDokument17 Seiten15 Days WorkingHitesh Kumar PrajapatiNoch keine Bewertungen

- Gujarat Technological UniversityDokument2 SeitenGujarat Technological UniversityShivam PanchalNoch keine Bewertungen

- Unsteady State Heat TransferDokument4 SeitenUnsteady State Heat TransferRaghavendra PrasadNoch keine Bewertungen

- Crossflow Paper Final Draft M WalliDokument64 SeitenCrossflow Paper Final Draft M Walliapi-392769552Noch keine Bewertungen

- Equilibrium Staged Operations: A1 SlotDokument18 SeitenEquilibrium Staged Operations: A1 SlotErmias NigussieNoch keine Bewertungen

- Exp. 7 Gas DiffusionDokument2 SeitenExp. 7 Gas DiffusionElaine PuiNoch keine Bewertungen

- Heat Transfer Modes ConvectionDokument4 SeitenHeat Transfer Modes ConvectionMark Angelo UyNoch keine Bewertungen

- Desiccant DehumidificationDokument23 SeitenDesiccant DehumidificationleeyiulunNoch keine Bewertungen

- Cooling Tower Design CalculationsDokument4 SeitenCooling Tower Design CalculationsAnand kesanakurtiNoch keine Bewertungen

- Science Form 2 Chapter 5.3 Evaporation of Water NoteDokument21 SeitenScience Form 2 Chapter 5.3 Evaporation of Water NoteMiNH Hayat100% (5)

- Measure Specific Latent Heat of WaterDokument4 SeitenMeasure Specific Latent Heat of WaterMMGNoch keine Bewertungen

- Banco de TubosDokument9 SeitenBanco de TubosArturo Arévalo FloresNoch keine Bewertungen

- Calibrating a Peltier Element to Measure Thermal ConductivityDokument56 SeitenCalibrating a Peltier Element to Measure Thermal Conductivitysack2003Noch keine Bewertungen

- The Second Law of ThermodynamicsDokument17 SeitenThe Second Law of ThermodynamicsPalash BoliaNoch keine Bewertungen

- MODULE 2 ClimatologyDokument23 SeitenMODULE 2 ClimatologyRAKSHITHA JAVAGALNoch keine Bewertungen

- Heat Transfer Fundamentals and Rate EquationsDokument29 SeitenHeat Transfer Fundamentals and Rate EquationsBilal ArqubNoch keine Bewertungen

- 1) New Standards For Neutral Thermal Environment ofDokument5 Seiten1) New Standards For Neutral Thermal Environment ofroselNoch keine Bewertungen

- Hermal Efficiency: Thermal Efficiency Providing Ways of Improvement of Thermal EnginesDokument2 SeitenHermal Efficiency: Thermal Efficiency Providing Ways of Improvement of Thermal EnginesVohid KadirzhanovNoch keine Bewertungen

- حساب أحمال التبريد والتدفئةDokument44 Seitenحساب أحمال التبريد والتدفئةAhmed SayedNoch keine Bewertungen

- Potentiometric Titration of Acid Base enDokument20 SeitenPotentiometric Titration of Acid Base enmayankbishtNoch keine Bewertungen

- Presentation 2 Cooling TowerDokument29 SeitenPresentation 2 Cooling Towereng_moh04Noch keine Bewertungen

- 1996 Methods of Evaluating Hood Drying Rates - Tappi JournalDokument6 Seiten1996 Methods of Evaluating Hood Drying Rates - Tappi JournalCamilo RicoNoch keine Bewertungen

- Experiment # 4 Heat of Solution: Van't Hoff Isochore Method: DLNK DT H RTDokument5 SeitenExperiment # 4 Heat of Solution: Van't Hoff Isochore Method: DLNK DT H RTIzzyNoch keine Bewertungen

- Acid and Base Worksheet: © 2004 Cavalcade Publishing, All Rights ReservedDokument3 SeitenAcid and Base Worksheet: © 2004 Cavalcade Publishing, All Rights ReservedDaniel Monclear CatiloNoch keine Bewertungen

- Answer The Questions Below Correctly!: Lesson Topic: Acid and Base Grade: Y11 NameDokument2 SeitenAnswer The Questions Below Correctly!: Lesson Topic: Acid and Base Grade: Y11 NameRiky GunawanNoch keine Bewertungen