Beruflich Dokumente

Kultur Dokumente

Question Paper

Hochgeladen von

ravi033190 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten1 SeiteDME

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDME

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

10 Ansichten1 SeiteQuestion Paper

Hochgeladen von

ravi03319DME

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

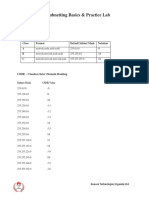

PART—A

Instructions : (1) Answer all questions.

(2) Each question carries three marks.

(3) Answer should be brief and straight to the point and shall not

exceed five simple sentences.

1. Differentiate between destructive and non-destructive tests. 1½+1½=3

2. Describe the factors prompting grain size. 3

3. Name various raw materials required for production of iron. 3

4. What is thermal equilibrium diagram? 3

5. Distinguish between interstitial and substitutional solid

solutions. 1½+1½=3

6. Define heat treatment. What are the stages in heat treatment? 1½+1½=3

7. Differentiate between annealing and normalising. 1½+1½=3

8. State the influence of silicon and manganese on plain carbon

steels. 1½+1½=3

9. Name three types of aluminium alloy. Give examples for each.

1+1+1=3

10. What is meant by powder metallurgy? 3

PART --- B. (1) Answer any five questions.

(2) Each question carries ten marks.

(3) Answers should be comprehensive and the criterion

for valuation is the content but not the length of the

answer.

11. Explain the ultrasonic testing with a neat sketch. 4+6=10

12. Determine the effective number of atoms in the following

structures with neat sketches : 5+5=10

(a) Face-centered cubic

(b) Body-centered cubic

13. (a) Describe L-D converter with a neat sketch .5

(b) Compare L-D process with Bessemer process. 5

14. Sketch the iron-carbon equilibrium diagram and mark the

salient points. 10

15. (a) Explain briefly the tempering of steel. 5

(b) Distinguish between austempering and martempering. 5

16. Based on carbon content, how are the plain carbon steels

classified? Discuss in detail the use of these steels. 10

17. (a) Write the applications of at least five metals. 2½+2½=5

(b) State the properties and uses of lead and magnesium.

2½+2½=5

18. Explain the following processes : 4+3+3=10

(a) Rolling

(b) Explosive compacting

(c) Slip casting

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Assembly DrawaingDokument17 SeitenAssembly Drawaingravi03319Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Finite FGM PDFDokument14 SeitenFinite FGM PDFravi03319Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Criteria 6 NaacDokument2 SeitenCriteria 6 Naacravi03319Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- LatheE - BookDokument6 SeitenLatheE - Bookravi03319Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Drawing Mid2 QuestionDokument2 SeitenDrawing Mid2 Questionravi03319Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Dedication Preface Chapter 1: Introduction To FEA and ANSYSDokument8 SeitenDedication Preface Chapter 1: Introduction To FEA and ANSYSravi03319Noch keine Bewertungen

- c01 Ansys 11Dokument48 Seitenc01 Ansys 11pooria892Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- ANSYS For Designers - ExtractDokument74 SeitenANSYS For Designers - ExtractNono_geotecNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- JNTU World Mechanics of Solids Lab ManualDokument47 SeitenJNTU World Mechanics of Solids Lab Manualravi03319100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- .Systematic ReviewsDokument3 Seiten.Systematic Reviewsravi03319Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Literature ReviewDokument2 SeitenLiterature ReviewReham IsmailNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Dynamic and Bending For FGTDokument11 SeitenDynamic and Bending For FGTravi03319Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- InTech-Vibration Analysis of Beams With and Without Cracks Using The Composite Element ModelDokument15 SeitenInTech-Vibration Analysis of Beams With and Without Cracks Using The Composite Element ModeltribleprinceNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- X Air F Flight & Maintenance ManualDokument57 SeitenX Air F Flight & Maintenance Manualravi03319Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- 171 - New CAN-filter For Cran Com. SCS4 and MidrangeDokument4 Seiten171 - New CAN-filter For Cran Com. SCS4 and MidrangeMohamed ElnagdyNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Nord Factory Restore Instructions Edition CDokument1 SeiteNord Factory Restore Instructions Edition CTonino CannavacciuoloNoch keine Bewertungen

- Excel Gantt Chart Template: Enter Your Project Details HereDokument14 SeitenExcel Gantt Chart Template: Enter Your Project Details HereBarselaNoch keine Bewertungen

- Determination of Voltage DropDokument6 SeitenDetermination of Voltage DropFahmi CumiNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- PDS - GulfSea Hydraulic AW Series-1Dokument2 SeitenPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNoch keine Bewertungen

- Network Layer: Computer Networking: A Top Down ApproachDokument83 SeitenNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadNoch keine Bewertungen

- Probability Statistics and Random Processes Third Edition T Veerarajan PDFDokument3 SeitenProbability Statistics and Random Processes Third Edition T Veerarajan PDFbhavyamNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Microstation V8I Accudraw Basics: Bentley Institute Course GuideDokument80 SeitenMicrostation V8I Accudraw Basics: Bentley Institute Course Guideh_eijy2743Noch keine Bewertungen

- GX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Dokument64 SeitenGX-2009 - Personal Multigas Detector. Operator's Manual (RKI, 2009)Stasio80Noch keine Bewertungen

- Introduction - Week 2Dokument37 SeitenIntroduction - Week 2Tayyab AhmedNoch keine Bewertungen

- Reboilers and VaporizersDokument20 SeitenReboilers and Vaporizers58 - Darshan ShahNoch keine Bewertungen

- ANSYS ACT Developers GuideDokument506 SeitenANSYS ACT Developers GuideEDIZONNoch keine Bewertungen

- Camshaft Test SheetDokument4 SeitenCamshaft Test SheetsughieantoNoch keine Bewertungen

- IMChap 014 SDokument14 SeitenIMChap 014 STroy WingerNoch keine Bewertungen

- Canalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Dokument324 SeitenCanalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Rubén González CabreraNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDokument16 SeitenGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNoch keine Bewertungen

- Sip TrainingDokument96 SeitenSip Trainingronics123Noch keine Bewertungen

- Bellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechDokument15 SeitenBellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechofanimenochNoch keine Bewertungen

- SUBstation Equipmens TLDokument12 SeitenSUBstation Equipmens TLJecer Casipong NuruddinNoch keine Bewertungen

- Color Order SystemsDokument30 SeitenColor Order SystemsBeyene DumechaNoch keine Bewertungen

- Unit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharDokument18 SeitenUnit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharAthira SomanNoch keine Bewertungen

- Sensors 22 09378 v2Dokument13 SeitenSensors 22 09378 v2FahdNoch keine Bewertungen

- 1/2" Cellflex Superflexible Foam-Dielectric Coaxial Cable: SCF12-50JDokument2 Seiten1/2" Cellflex Superflexible Foam-Dielectric Coaxial Cable: SCF12-50JpeguigonsoNoch keine Bewertungen

- Records of Intervention On The Findings of Test Results and Other Forms of AssessmentDokument10 SeitenRecords of Intervention On The Findings of Test Results and Other Forms of AssessmentLea May MagnoNoch keine Bewertungen

- SubNetting Practice LabDokument3 SeitenSubNetting Practice LabOdoch HerbertNoch keine Bewertungen

- Transportation Planning ProcessDokument43 SeitenTransportation Planning ProcessAncheta Suzanne ClarisseNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Product - 20V4000G24F 3B FODokument32 SeitenProduct - 20V4000G24F 3B FOmohammed khadrNoch keine Bewertungen

- Employee performance factors analysis electronic companyDokument10 SeitenEmployee performance factors analysis electronic companyAmrithaNoch keine Bewertungen

- Recommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Dokument38 SeitenRecommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Crismaruc Maria-madalinaNoch keine Bewertungen

- Fans Reference GuideDokument160 SeitenFans Reference Guidekarthikraja21100% (13)