Beruflich Dokumente

Kultur Dokumente

A Sample Preventative Maintenance Schedule PDF

Hochgeladen von

redaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Sample Preventative Maintenance Schedule PDF

Hochgeladen von

redaCopyright:

Verfügbare Formate

Appendix A

Sample - Preventive Maintenance Schedule

Note: To create a page like this, an inventory should be taken of each assembly and piece

of equipment in the building that requires maintenance. For each item, maintenance

information is compiled, primarily from the manufacturer’s instruction manual, or from

generic sources if appropriate

Equipmen Personnel

Equipment Maintenanc Initial

t, Tools, responsible Maintenance Interval

or Part e and

Supplies

description procedure date

required Daily Weekly Monthly Other

Emergency See manual

Power for detailed

Equipment: definitions

General “Operator Maintenanc - Inspect - Check Every 6 mo.: Pleas

Maintenanc maintenan e staff set air - Check e

e ce - Check cleaner cooling initial

schedule – fuel - Clean system each

standby - Check injector - Change oil entry

unit” coolant linkage - Replace oil

level - Inspect filter

- Check fan belt - Clean,

lube inspect

- Drain battery

fuel charging

sediment alternator

- Run - Check

system battery

Annually:

- Check

starter

- Check

injector

nozzles

- Replace fuel

filter

Engine Lubrication SAE 30W Maintenanc - Before Every 6 mo.:

oil e staff engine - Change oil &

Allis- startup: fullflow filter

Chalmers Use only check - Lubricate

3500 Mk II; “SC” rated dipstick on throttle

6-cyl diesel oil for side swivels

Serial # compressi marked

100-1350 on “Stopped” Annually:

Installed: engines; - Check oil - Test oil every

2/14/75 Do not pressure 30 hrs of

use multi- when operation

grade oil running

(30-50 psi)

or (207-

379 kN/m2)

Maintenance Planning Handbook Appendix A – 1

Sample – Preventive Maintenance Schedule

Generator There are - Inspect

no brushes, generator

Onan brush bearing

UR 15R springs, or while unit

60Hz collector is running

Serial #: rings on - Check

973-0012 this unit. connection

s

- Check

voltage

under load

Maintenance Planning Handbook

Appendix B – Page 2

Das könnte Ihnen auch gefallen

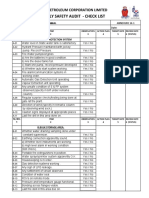

- Job Safety Analysis (Jsa) : Damage and Personal InjuryDokument2 SeitenJob Safety Analysis (Jsa) : Damage and Personal InjuryReda Bouali100% (1)

- GD380A-L ListDokument6 SeitenGD380A-L ListNam Won HongNoch keine Bewertungen

- Flow Chart For Fire Drill Operation:: Emerrgency ControllerDokument1 SeiteFlow Chart For Fire Drill Operation:: Emerrgency ControllerIwan Ms100% (2)

- Sop Installing PumpDokument4 SeitenSop Installing PumpilhamNoch keine Bewertungen

- Boom Placer Inspection ChecklistDokument1 SeiteBoom Placer Inspection ChecklistMyo LwinNoch keine Bewertungen

- Compressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019Dokument2 SeitenCompressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019MOHAMMEDNoch keine Bewertungen

- CNPC/BGP 8611 HSE Audit Checklists TitleDokument67 SeitenCNPC/BGP 8611 HSE Audit Checklists TitleDale Wearpack100% (1)

- Stacker Preventive Maintenance Weekly: Clean and InspectDokument1 SeiteStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- JHA For Installation 2 Inch Nozzle..Dokument6 SeitenJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Fire Water TankDokument1 SeiteFire Water TankAnonymous yCpjZF1rFNoch keine Bewertungen

- SOP 4 - Coal Bed Leveling in PGPDokument18 SeitenSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNoch keine Bewertungen

- Know Your Safety ZoneDokument14 SeitenKnow Your Safety ZoneSiwakoti HSENoch keine Bewertungen

- Cutting Machine Inspection ChecklistDokument1 SeiteCutting Machine Inspection ChecklistThein Myint OoNoch keine Bewertungen

- Fire Fighting Equipment Monthly Inspection ReportDokument2 SeitenFire Fighting Equipment Monthly Inspection Reportnadeem mallickNoch keine Bewertungen

- EHS 2-F8 PTW LiftingDokument2 SeitenEHS 2-F8 PTW LiftingLee Xiao YuNoch keine Bewertungen

- HSMC Employee Induction Procedure (Offices)Dokument3 SeitenHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNoch keine Bewertungen

- Schedule For Inspection Nov 19Dokument1 SeiteSchedule For Inspection Nov 19Siddharth RanaNoch keine Bewertungen

- Lifting Activity Permit To WorkDokument1 SeiteLifting Activity Permit To WorkBig ZaddyNoch keine Bewertungen

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Dokument14 SeitenInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040Noch keine Bewertungen

- 45 Job Specific Attendance SheetDokument3 Seiten45 Job Specific Attendance SheetJunard Lu HapNoch keine Bewertungen

- MSU Vehicle Fueling SOPDokument2 SeitenMSU Vehicle Fueling SOPsarge18100% (1)

- Closed PTW AuditDokument1 SeiteClosed PTW Auditf.BNoch keine Bewertungen

- Towed Scraper Checklist V0810.1 PDFDokument1 SeiteTowed Scraper Checklist V0810.1 PDFcherifNoch keine Bewertungen

- SHEM-SP-08.10 Work Permits ProcedureDokument74 SeitenSHEM-SP-08.10 Work Permits ProcedureAjith Kumar AjithNoch keine Bewertungen

- Equipment Maintenance and Measuring Equipment ProcedureDokument2 SeitenEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Stringing, Welding and Coating Process.Dokument3 SeitenStringing, Welding and Coating Process.Beyar. ShNoch keine Bewertungen

- Weekly Monthly Inspection-Pdf-En PDFDokument1 SeiteWeekly Monthly Inspection-Pdf-En PDFMohamed Moustafa ElashwahNoch keine Bewertungen

- Weekly Tower Light Check ListDokument1 SeiteWeekly Tower Light Check ListpjosesmNoch keine Bewertungen

- Lifting Hoisting Hazard HuntDokument1 SeiteLifting Hoisting Hazard Hunt曹庆园100% (1)

- Dr. Nirali Patel Pediatric Emergency MedicineDokument31 SeitenDr. Nirali Patel Pediatric Emergency Medicinemarsan12Noch keine Bewertungen

- Fuel Transfer Activity From Awb To VesselDokument1 SeiteFuel Transfer Activity From Awb To Vesseljumansyahamid1988Noch keine Bewertungen

- JSA PRE-TEST UploadDokument2 SeitenJSA PRE-TEST UploadDenny Kurniawan PrawiraNoch keine Bewertungen

- 3 SOP - Emergency Procedure - Final Sent To Zones Without PhotDokument20 Seiten3 SOP - Emergency Procedure - Final Sent To Zones Without PhotVijayNoch keine Bewertungen

- Daily Safety ChecklistDokument4 SeitenDaily Safety ChecklistKalyan ReddyNoch keine Bewertungen

- Check ListDokument88 SeitenCheck ListRaafat SaadNoch keine Bewertungen

- FirmDokument3 SeitenFirmTatiana Garcia MendozaNoch keine Bewertungen

- Weekly excavator checklist template for construction projectsDokument4 SeitenWeekly excavator checklist template for construction projectssamiran RouthNoch keine Bewertungen

- SWP 03 Heavy EquipmentDokument7 SeitenSWP 03 Heavy Equipmentমমিন মানব100% (1)

- PPE - Distribution FormDokument1 SeitePPE - Distribution FormNuno LopesNoch keine Bewertungen

- Permit To DigDokument3 SeitenPermit To DigMarco DonatiNoch keine Bewertungen

- Borang Pemeriksaan Air KompressorDokument1 SeiteBorang Pemeriksaan Air KompressorAndara Asifa YudianaNoch keine Bewertungen

- Jsa Bearing Replacement-OverhaulingDokument2 SeitenJsa Bearing Replacement-Overhaulingashish engineeringNoch keine Bewertungen

- Standard Operating ProcedureDokument55 SeitenStandard Operating Procedureboy tryadi100% (1)

- 675Dokument2 Seiten675Rameese MuhammedNoch keine Bewertungen

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDokument1 SeiteJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Updated Checklist of TractorDokument1 SeiteUpdated Checklist of TractorparthaNoch keine Bewertungen

- Foam InductorDokument6 SeitenFoam InductorDipanjan Chakrabarti100% (1)

- Checklist For Equipment Inspection Air CompressorDokument1 SeiteChecklist For Equipment Inspection Air CompressorStephenNoch keine Bewertungen

- Chklist HEXDokument3 SeitenChklist HEXluisNoch keine Bewertungen

- YZ12HD Vibratory Roller SpecsDokument4 SeitenYZ12HD Vibratory Roller SpecsIwa RizaNoch keine Bewertungen

- Safety Daily Site Checklist Mastoura co-SA-1-12Dokument12 SeitenSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceNoch keine Bewertungen

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDokument1 SeiteForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNoch keine Bewertungen

- JOB SAFETY ANALYSIS FORMDokument7 SeitenJOB SAFETY ANALYSIS FORMIulian Costin IonNoch keine Bewertungen

- Daily Checklist For DGDokument2 SeitenDaily Checklist For DG7Days Facility ManagementNoch keine Bewertungen

- Coshh: Risk Assessment No Product NameDokument2 SeitenCoshh: Risk Assessment No Product NameshameerNoch keine Bewertungen

- Checklist ERDMP 100919Dokument3 SeitenChecklist ERDMP 100919varunkumar415Noch keine Bewertungen

- Scissor Lift Pre-Use Inspection Checklist 2Dokument1 SeiteScissor Lift Pre-Use Inspection Checklist 2Harun SaniNoch keine Bewertungen

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyDokument1 SeitePlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyMdrahaman Mithu100% (2)

- Inspection and Preventive Maintenance: ServicereportDokument2 SeitenInspection and Preventive Maintenance: ServicereportMoz KamalNoch keine Bewertungen

- SIS 2.0 Maintenance Interval Schedule - Prime (M0124697-02)Dokument2 SeitenSIS 2.0 Maintenance Interval Schedule - Prime (M0124697-02)Carlos U. CallirgosNoch keine Bewertungen

- Guidelines For Preventing Torsional Vibration Problems in Reciprocating Machinery PDFDokument48 SeitenGuidelines For Preventing Torsional Vibration Problems in Reciprocating Machinery PDFredaNoch keine Bewertungen

- Compressor Fundamentals, Performance CurvesDokument69 SeitenCompressor Fundamentals, Performance Curvesใบบอนสิชล100% (3)

- Electrical Installation Guide ForewordDokument380 SeitenElectrical Installation Guide ForewordVlad Santos100% (10)

- Festo PLC Basic Level TP301-218Dokument218 SeitenFesto PLC Basic Level TP301-218Marcos Aldana Villalda0% (1)

- Advantages of Hydraulic CranesDokument37 SeitenAdvantages of Hydraulic Craneskunbasukiadi86% (7)

- Experion Network Best Practices WP PDFDokument41 SeitenExperion Network Best Practices WP PDFredaNoch keine Bewertungen

- Reciprocating Compressor PDFDokument12 SeitenReciprocating Compressor PDFredaNoch keine Bewertungen

- Compressor Fundamentals, Performance CurvesDokument69 SeitenCompressor Fundamentals, Performance Curvesใบบอนสิชล100% (3)

- Mechanical Seal Presentation (2009)Dokument28 SeitenMechanical Seal Presentation (2009)LelosPinelos123100% (5)

- Pump and Compressor 2 PDFDokument52 SeitenPump and Compressor 2 PDFredaNoch keine Bewertungen

- PLC Programming PDFDokument42 SeitenPLC Programming PDFredaNoch keine Bewertungen

- ADAPCTL Honeywell Experion PDFDokument50 SeitenADAPCTL Honeywell Experion PDFredaNoch keine Bewertungen

- Turbo-Air 3000Dokument6 SeitenTurbo-Air 3000SISOYDANNYNoch keine Bewertungen

- Experion Network Best Practices WP PDFDokument41 SeitenExperion Network Best Practices WP PDFredaNoch keine Bewertungen

- The SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing LifeDokument36 SeitenThe SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing Lifejarneberg100% (3)

- Corrosion Guide PDFDokument23 SeitenCorrosion Guide PDFredaNoch keine Bewertungen

- 3 Compressed Air System N PDFDokument35 Seiten3 Compressed Air System N PDFredaNoch keine Bewertungen

- 3 Compressed Air System N PDFDokument35 Seiten3 Compressed Air System N PDFredaNoch keine Bewertungen

- Pump and Compressor 2 PDFDokument52 SeitenPump and Compressor 2 PDFredaNoch keine Bewertungen

- Rehab8 1 HvacDokument43 SeitenRehab8 1 Hvacapi-3859258100% (2)

- Evaluation D Une Motopompe Kirloskar TV 1 NW9ME A Kakondji Tombouctou Mali PDFDokument21 SeitenEvaluation D Une Motopompe Kirloskar TV 1 NW9ME A Kakondji Tombouctou Mali PDFkamelNoch keine Bewertungen

- Aluminum Extrusion Fsi PDFDokument9 SeitenAluminum Extrusion Fsi PDFredaNoch keine Bewertungen

- Midea Commercial Air Conditioner Malfunction HandbookDokument121 SeitenMidea Commercial Air Conditioner Malfunction Handbookambuenaflor50% (4)

- Aluminum Extrusion Fsi PDFDokument9 SeitenAluminum Extrusion Fsi PDFredaNoch keine Bewertungen

- ASHRAE How Chillers React To Building Loads PDFDokument6 SeitenASHRAE How Chillers React To Building Loads PDFredaNoch keine Bewertungen

- Steve Jobs: The Man Who Thought DifferentDokument10 SeitenSteve Jobs: The Man Who Thought DifferentMacmillan Publishers56% (18)

- 31019Dokument14 Seiten31019Asad HamidNoch keine Bewertungen

- Steve Jobs: The Man Who Thought DifferentDokument10 SeitenSteve Jobs: The Man Who Thought DifferentMacmillan Publishers56% (18)

- La Reporting-Tableau de BordDokument23 SeitenLa Reporting-Tableau de Bordseka_dalle100% (1)

- Haier Air Conditioners Owners ManualDokument24 SeitenHaier Air Conditioners Owners Manuale-ComfortUSANoch keine Bewertungen

- Material Science: Ceramics Properties and ApplicationsDokument122 SeitenMaterial Science: Ceramics Properties and ApplicationstheoNoch keine Bewertungen

- PMM CATALOGUE RACKiNgDokument15 SeitenPMM CATALOGUE RACKiNgHawary NabiyillahNoch keine Bewertungen

- Buoys-Dolphins 0 RotterdamDokument2 SeitenBuoys-Dolphins 0 RotterdamVisveswaran InbasekaranNoch keine Bewertungen

- Engineering InsuranceDokument2 SeitenEngineering InsuranceBikash KumarNoch keine Bewertungen

- MSDS Polvo QuimicoDokument2 SeitenMSDS Polvo QuimicoÁlvaro MartínezNoch keine Bewertungen

- Wall CladdingDokument24 SeitenWall CladdingRemya R. KumarNoch keine Bewertungen

- The Basic Functions of LV Switchgear PDFDokument32 SeitenThe Basic Functions of LV Switchgear PDF2zeceNoch keine Bewertungen

- PSC Girder Before Concreting MIPL CL 32Dokument2 SeitenPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- Boiler Operators HandbookDokument159 SeitenBoiler Operators HandbookSynesiusNoch keine Bewertungen

- High Voltage Diesel Generator Sets, High Voltage Diesel Gensets, High VoltagDokument3 SeitenHigh Voltage Diesel Generator Sets, High Voltage Diesel Gensets, High VoltagBalamurugan ArumugamNoch keine Bewertungen

- Six Weeks Industrial Training ReportDokument35 SeitenSix Weeks Industrial Training ReportPRABHMEET KAUR100% (3)

- 7300 CV Quick Start Programming GuideDokument10 Seiten7300 CV Quick Start Programming Guidenitin hadkeNoch keine Bewertungen

- Mach 3 Brochure enDokument3 SeitenMach 3 Brochure enIsaías AguilarNoch keine Bewertungen

- Current SSPC Standards June2019Dokument7 SeitenCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- Product Specifications Product Specifications: RHHTT RHHTT - 65A 65A - R4 R4Dokument4 SeitenProduct Specifications Product Specifications: RHHTT RHHTT - 65A 65A - R4 R4Nicola Leonardo VilardoNoch keine Bewertungen

- Makan Construction Real Estate New Home New York Buyer Harriman MonroeDokument22 SeitenMakan Construction Real Estate New Home New York Buyer Harriman Monroekumar1023Noch keine Bewertungen

- English Solar Farm Proposal by TSF Oct 123Dokument38 SeitenEnglish Solar Farm Proposal by TSF Oct 123Atiqah HamzahNoch keine Bewertungen

- Annexure Classification of ServicesDokument20 SeitenAnnexure Classification of Servicesamitkap00rNoch keine Bewertungen

- Turbine ElsterDokument4 SeitenTurbine Elsterpalotito_eNoch keine Bewertungen

- Distal Extremities AnchorsDokument4 SeitenDistal Extremities AnchorsCarolina Velasco de CampoverdeNoch keine Bewertungen

- Group - 6 MobileyeDokument14 SeitenGroup - 6 MobileyevNoch keine Bewertungen

- ASTM D95 Water ContentDokument6 SeitenASTM D95 Water ContentMuhammad Syarif Hidayatullah100% (1)

- Atomizer Study For Processing PGMDokument6 SeitenAtomizer Study For Processing PGMAFLAC ............Noch keine Bewertungen

- Sample Project Completion ReportDokument1 SeiteSample Project Completion ReportAndroNoch keine Bewertungen

- Syllabusmodule 15. Gas Turbine EngineDokument4 SeitenSyllabusmodule 15. Gas Turbine EngineSanooj N J KurupNoch keine Bewertungen

- New sofa collection and 7 home makeoversDokument173 SeitenNew sofa collection and 7 home makeoversCarmen Draghia100% (1)

- Study Report of DC Servo MotorDokument99 SeitenStudy Report of DC Servo Motoribrahim100% (1)

- Brochure of ICM'10Dokument38 SeitenBrochure of ICM'10Sherif EltoukhiNoch keine Bewertungen

- My Green Trips 2Dokument12 SeitenMy Green Trips 2api-376387010Noch keine Bewertungen

- Roll CoolingDokument14 SeitenRoll Coolingzakarii100% (1)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- How to Design and Install In-Car Entertainment SystemsVon EverandHow to Design and Install In-Car Entertainment SystemsBewertung: 5 von 5 Sternen5/5 (1)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- Automotive Vehicle Strategies and ECM ModesVon EverandAutomotive Vehicle Strategies and ECM ModesBewertung: 4 von 5 Sternen4/5 (7)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVVon EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVBewertung: 5 von 5 Sternen5/5 (2)

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- LS Swaps: How to Swap GM LS Engines into Almost AnythingVon EverandLS Swaps: How to Swap GM LS Engines into Almost AnythingBewertung: 3.5 von 5 Sternen3.5/5 (2)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersVon EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (53)

- Driver CPC – the Official DVSA Guide for Professional Goods Vehicle Drivers: DVSA Safe Driving for Life SeriesVon EverandDriver CPC – the Official DVSA Guide for Professional Goods Vehicle Drivers: DVSA Safe Driving for Life SeriesNoch keine Bewertungen

- Automotive Electronic Diagnostics (Course 1)Von EverandAutomotive Electronic Diagnostics (Course 1)Bewertung: 5 von 5 Sternen5/5 (6)

- Why We Drive: Toward a Philosophy of the Open RoadVon EverandWhy We Drive: Toward a Philosophy of the Open RoadBewertung: 4 von 5 Sternen4/5 (6)

- Making Toys, Revised Edition: Heirloom Cars & Trucks in WoodVon EverandMaking Toys, Revised Edition: Heirloom Cars & Trucks in WoodBewertung: 4 von 5 Sternen4/5 (3)

- How to Drive an Exotic Car and get PaidVon EverandHow to Drive an Exotic Car and get PaidBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Taking Charge of Your Automotive Repairs and Servicing: Save Time and Money Without Doing It YourselfVon EverandTaking Charge of Your Automotive Repairs and Servicing: Save Time and Money Without Doing It YourselfBewertung: 5 von 5 Sternen5/5 (1)

- The Official DVSA Guide to Driving Buses and Coaches: DVSA Safe Driving for Life SeriesVon EverandThe Official DVSA Guide to Driving Buses and Coaches: DVSA Safe Driving for Life SeriesNoch keine Bewertungen

- Driving Theory Test Questions & AnswersVon EverandDriving Theory Test Questions & AnswersBewertung: 5 von 5 Sternen5/5 (3)

- Auto Repair For Beginners: The Complete Guide To Understanding Auto Fundamentals And Maintenance | How To Maintain Your Car So It Lasts LongerVon EverandAuto Repair For Beginners: The Complete Guide To Understanding Auto Fundamentals And Maintenance | How To Maintain Your Car So It Lasts LongerNoch keine Bewertungen

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingVon EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingBewertung: 4.5 von 5 Sternen4.5/5 (9)

- The Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tVon EverandThe Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tNoch keine Bewertungen