Beruflich Dokumente

Kultur Dokumente

Qualitest Broucher Final

Hochgeladen von

Bala Singam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten8 SeitenQualitest Canada metallurgical testing Brochure

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenQualitest Canada metallurgical testing Brochure

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

35 Ansichten8 SeitenQualitest Broucher Final

Hochgeladen von

Bala SingamQualitest Canada metallurgical testing Brochure

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

780-851-2020 www.qualitests.com admin@qualitests.

com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Metallurgical Testing Services

Qualitest Canada is Top Ranked

testing facility situated in Nisku, Alberta.

Our facility consists of a wide range of

testing equipment for evaluating the

mechanical properties of ferrous and non-

ferrous alloys, composites, and ceramics.

Our specialties in Materials Science will

provide fast and reliable response to your

needs regarding the qualification of your

products. For obtaining accurate results,

you can bring your material to us and we will

prepare the test specimens for various

mechanical tests based on your

specifications and project requirements. We

have experience with numerous testing

standards such as ASTM, ASME, CSA, API,

AWS and many more. Qualitest offers a

broad range of material testing as

described in the below:

Tensile Testing Flaws and defects

Material composition

Compression Testing

Corrosion susceptibility

Guided Bend Tests

Charpy V-notch (CVN) Impact

Hardness Tests Including Brinell,

Test

Rockwell and Vickers

Chemical Analysis

Low Temperature Testing

Macro-structure Examination

Micro-structure Examination

Failure Assessment and Root Other Mechanical Testing

Cause Analysis (RCA)

Positive Material Identification Ferrite counting

(PMI)

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Our Capabilities includes

Fracture Mechanics – fatigue

Chemical Analysis – instrumental crack growth and fracture

and classical wet chemistry toughness

Mechanical Testing – wide-range Metallurgical Examination –

of tests to measure material microscopic, macroscopic and

strength, ductility, hardness, and micro-hardness examinations

more

Nondestructive Testing – ultrasonic,

Corrosion Testing – accelerated

hydrostatic pressure, X-ray,

inter-granular corrosion, salt spray,

magnetic particle, liquid penetrant

humidity, passivation and more

Our highly experienced

Our in-house machine shop allows Engineering team can also

for quick cost effective sample research material failures. Please

preparation, saving you time and contact us to get more details for

money the below.

Microscopic product features

Mechanical properties

Heat treat upgrade

Qualitest Canada’s metallurgical testing lab is fully equipped to prepare test

specimens and samples for all metal tests performed in our destructive testing

departments. Our non-destructive metal testing services can be performed on a wide-

range of products such as tubing, pipe, bar, plates, castings, fasteners and other

machined parts in all sizes, shapes and weights. Once the testing is completed, our

Engineers will prepare a detailed technical report with metal test results, accreditation,

and specifications etc. as per our client’s project requirements.

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Welding Procedure Specification

Qualitest Canada is a world leader in designing, testing and documenting Welding

Procedure Specifications (WPS) for various applications. Our highly experienced welding

engineers and technicians will design welding procedure specification (WPS) based on

your requirements and applicable codes and standards such as ASME, CWB, API, CSA,

AWS and etc.

We are proud of having experienced Welding Engineers who have a long history in

successfully designing and documentation of welding procedures for a broad range of

applications. Our experienced engineers solve challenging problems regarding welding

procedures and WPS preparation. Qualitest provide additional services as following:

Perform welding quality control Supervise and inspect critical weld

inspections and prepare procedures in the field

documentation

Evaluate existing welding

Prepare quotes for the welding part

procedures

of a project

Welder Testing / Training

Qualitest provides convenient, hassle-

free welder testing according to your

project requirements. Based on your request,

Qualitest will arrange the welder qualification

tests either at our location or yours and will

provide all the required test materials and

equipment. Qualitest welder testing facility is

approved by ABSA and CWB.

Qualitest will issue the test results on the

same day of exam using our in-house

machine shop and advanced laboratory

equipment. Our fully equipped testing facility

is located in Nisku which is minutes away from

the Edmonton International Airport. Give us a

call today to book your next test.

At present we provide Welder

Qualification and Weld Procedure Testing

Services in Alberta, but we can also provide

our services to other provinces upon requests

from clients.

** CWB WELDER TESTING ON EVERY TUESDAYS **

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Geotechnical Testing Services

Qualitest Canada provides subsurface exploration and investigation for a broad

range of projects, such as municipal and commercial projects, industrial, subdivision,

institutional, oil and gas processing plants, pipelines, medium to high-rise buildings, energy

development, housing and condominium, roads and bridges. We provide

comprehensive review and recommendations to clients for their ambitious projects. We

provide the excellent geotechnical consultancy services to meet our clients need such

as the following:

Geotechnical investigation and Soils and aggregate sampling and

exploration testing

Test pit excavation, sampling and

Materials engineering and quality

testing

control

Shallow and deep foundation Slope stability and assessment of

analysis and design retaining wall structures

recommendations

Pavement analysis and design

Pile design, construction, monitoring

recommendations

and inspection

Project management and

Soil drilling and rock anchoring inspection

Soil investigation and soil QA/QC Inspection and Testing

stabilization

The above-mentioned consultancy services are backed up by the laboratory

testing services that we have. We are pleased to offer the following inspection and

materials testing services for various stages of construction for your projects:

Foundation inspection and

Soil compaction testing and

monitoring

inspection

Steel fabrication and rebar

Earthworks quality control testing

installation inspection

and monitoring

Compressive strength tests for

Non-destructive testing for

concrete cylinders

concrete structures

Groundwater monitoring and Concrete testing and inspection

inspection

Pile inspection and monitoring

Shotcrete monitoring and testing

Proctor and sieve analysis

Mortar and grout testing

Concrete mix designs Base inspection

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Land Surveying

Geodetic Surveys – Surveys, which establish control networks on a mathematical

datum so that measurements will reflect the curved (ellipsoidal) shape of the earth.

Land Surveys – Surveys, which include retracement of existing land ownership

boundaries or the creation of new boundaries.

Engineering Surveys – Surveys performed for the location, design, construction,

maintenance and operation of engineering projects.

Construction Surveys – Surveys, which establish stakes in the ground, and other like

reference points, at known horizontal and vertical positions to define location and

size of each component of the facility to be constructed, enable inspection of

contract items, and serve as a basis of payment for work.

Cartographic Surveys – Map making from the original survey.

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Non-Destructive Testing

Qualitest is a world leader in developing and performing of Non-Destructive Testing

(NDT) techniques. We are one of the best NDT/NDE Service Provider in British Colombia,

Saskatchewan and Alberta. Our highly skilled and knowledgeable engineers and

certified technicians use a wide range of equipment to solve various NDT problems.

NDE/NDT can be applied for both metallic and non-metallic (e.g. polymers and

composites) materials. We perform the NDE/NDT during production, post-production or in

service in accordance with the project requirements. Qualitest Canada perform the

following Non-Destructive Tests (NDT):

Magnetic Particle Testing (MT or

Weld Visual Inspection (VT) MPI)

Liquid Dye Penetrate Examination X-ray Fluorescence (XRF) Analysis

(PT)

Coating Inspection and Coating

Conventional and Computed- Failure Analysis (NACE certified

Gamma Radiography procedures)

Ultrasonic Testing (UT) for Obtaining

Ultrasonic Testing (UT) for flaw

the Materials’ Thickness and the

detection

Corrosion Mapping- zero Degree

Scan

Ferrite Testing

Production Hardness Testing

Advanced NDE Services

Our services operate a full range of state-of-the-art computerized inspection

utilizing high technology equipment and delivering unparalleled accuracy and

resolution. Our client or third party inspector will have the access to review all the stored

data files. We can provide test solutions to whatever thickness or diameter you would

require:

Our Capabilities includes:

Automated Ultrasonic Testing (AUT)

Phased Array Ultrasonic Testing (PAUT)

Time of Flight Diffraction (ToFD)

Tube Inspection – ECT/IRIS/MFL/RFT

Video scope (Manual / Borescope)

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Preservation and Equipment Maintenance

Qualitest Canada deliver high-quality preservation and maintenance for a wide

range of mechanical equipment to ensure the health and safety of your employees and

the environment. We offer preservation and maintenance services for various type of

mechanical equipment starting from receiving until turnover to field operations as

following:

Perform inspection on receiving equipment for any damages

Conduct regular inspections of designated equipment to ensure that they are

stored and protected properly

Manage equipment storage and maintenance record

Organize and maintain the storage environment clean and tidy

Supervise storage and maintenance of equipment while maintaining in the

warehouse or lay-down areas until transfer to the construction site

Record and organize “Material Tracking System” to facilitate equipment delivery,

storage and maintenance

Perform and record required preventive maintenance, suggested by field

inspectors

Ensure that the preservation and maintenance requirements are included in the

purchase order and have been applied to equipment prior to delivery in

accordance with supplier documents

Provide the material safety data sheet (MSDS) for any products and equipment

that the Contractor uses and procures at the site

Procure the required preservation and maintenance materials

Facilitate a regular inspection by the principal to verify compliance with

preservation procedures

Control weather condition of the storage location, including the moisture,

temperature and pressure level based on the required specifications

Provide preservation status report, including preservation and maintenance

record on a weekly basis or the interval required by the project.

Our experienced employees execute regular risk assessment and suggest valuable

recommendations based on their findings which prevent any further loss. Qualitest is

happy to provide the best Industrial Equipment Preservation Services in Alberta and other

provinces of Canada.

780-851-2020 www.qualitests.com admin@qualitests.com

702 – 23 Avenue, Nisku, Alberta, T9E 7Y6

Das könnte Ihnen auch gefallen

- Projects' Issue Management 2017Dokument8 SeitenProjects' Issue Management 2017Css AspirantNoch keine Bewertungen

- Template For Actual Vs Planned GraphDokument3 SeitenTemplate For Actual Vs Planned Graphsilence_10007Noch keine Bewertungen

- IT Project Management-Cost Estimation Process.J.nicholos.08Dokument9 SeitenIT Project Management-Cost Estimation Process.J.nicholos.08kksbabu05Noch keine Bewertungen

- Project Delivery ModelDokument3 SeitenProject Delivery ModelAnonymous ciKyr0tNoch keine Bewertungen

- Sunera Technologies Pvt. LTD.: Standard Operating Procedure TemplateDokument14 SeitenSunera Technologies Pvt. LTD.: Standard Operating Procedure Templatesastrylanka_1980Noch keine Bewertungen

- Stage-Gate Process For Life Sciences and Medical Innovation InvestmentDokument8 SeitenStage-Gate Process For Life Sciences and Medical Innovation InvestmentRizki KresnaNoch keine Bewertungen

- IT Project Management: Chapter 4 Resource Plan and Cost EstimationDokument44 SeitenIT Project Management: Chapter 4 Resource Plan and Cost EstimationZeeshan BhattiNoch keine Bewertungen

- Ansi/Tia-942 Audit & Certification Services: Uptime InstituteDokument4 SeitenAnsi/Tia-942 Audit & Certification Services: Uptime InstituteInsan ArdiansyahNoch keine Bewertungen

- TA202 A Lecture 1: Tutor: Shantanu BhattacharyaDokument12 SeitenTA202 A Lecture 1: Tutor: Shantanu BhattacharyaRajat JainNoch keine Bewertungen

- Project Charter: Project Name: Project Number: Start Date: Revision NumberDokument2 SeitenProject Charter: Project Name: Project Number: Start Date: Revision NumberHoàng BùiNoch keine Bewertungen

- Pre-Shipment Inspection: Product PhotoDokument35 SeitenPre-Shipment Inspection: Product Photo123456Noch keine Bewertungen

- Primavera 6 Arabic Book PDFDokument154 SeitenPrimavera 6 Arabic Book PDFmounirNoch keine Bewertungen

- DEKRA Certification Group: Jos Versteegen Sales & Business Development ManagerDokument13 SeitenDEKRA Certification Group: Jos Versteegen Sales & Business Development ManagerMuraryspottyNoch keine Bewertungen

- Nordic Group 2020Dokument116 SeitenNordic Group 2020Ronald LengNoch keine Bewertungen

- Trai Qa R 45 Process Audit - FormatDokument5 SeitenTrai Qa R 45 Process Audit - FormatRS MANIKANDANNoch keine Bewertungen

- Software Engineering Project ReportDokument5 SeitenSoftware Engineering Project ReportRana afaqNoch keine Bewertungen

- Risk Management and Information Technology Projects PDFDokument9 SeitenRisk Management and Information Technology Projects PDFArup DasNoch keine Bewertungen

- Definition of Quality: Difference Between Qa and QCDokument7 SeitenDefinition of Quality: Difference Between Qa and QCDenisho DeeNoch keine Bewertungen

- NL07T0583Dokument5 SeitenNL07T0583roger.chyneNoch keine Bewertungen

- PM READ THIS FIRST Project Management Checklist Summary v1Dokument4 SeitenPM READ THIS FIRST Project Management Checklist Summary v1jvigier100% (1)

- Prioritization MatricesDokument5 SeitenPrioritization MatricesSteven Bonacorsi100% (2)

- Project Sizing Analysis Grid: General Interpretation GuideDokument1 SeiteProject Sizing Analysis Grid: General Interpretation Guideanirban_surNoch keine Bewertungen

- Quotation - Cotation: Description Du Travail / Work DescriptionDokument1 SeiteQuotation - Cotation: Description Du Travail / Work DescriptionmkpqNoch keine Bewertungen

- Session-2 & 3 Quality - Evolution of QualityDokument20 SeitenSession-2 & 3 Quality - Evolution of Qualitymatten yahyaNoch keine Bewertungen

- ECI Booking Form-V1.7 O# 90058401 PDFDokument2 SeitenECI Booking Form-V1.7 O# 90058401 PDFdevNoch keine Bewertungen

- ELECTREX General CatalogueDokument52 SeitenELECTREX General CatalogueO TottaNoch keine Bewertungen

- (Project Title) : Earned Value Analysis ReportDokument4 Seiten(Project Title) : Earned Value Analysis ReportccemilovaNoch keine Bewertungen

- Process Capability BaselineDokument19 SeitenProcess Capability BaselinecamilaskishoreNoch keine Bewertungen

- Templates Package 1 ContentDokument1 SeiteTemplates Package 1 Contentسيلفا سيلفاNoch keine Bewertungen

- PMD 913 - Module 4 - Earned Value Management May22Dokument24 SeitenPMD 913 - Module 4 - Earned Value Management May22Abdallah HabeebNoch keine Bewertungen

- Contract Planning NotesDokument108 SeitenContract Planning NotesGodwin Acquah100% (1)

- Project SampleDokument60 SeitenProject Sampleyara alaskar100% (1)

- 11RCFA-CPF2-HP Gas CompBDokument5 Seiten11RCFA-CPF2-HP Gas CompBJinlong SuNoch keine Bewertungen

- Equipment InspectionDokument8 SeitenEquipment InspectionRakesh MenonNoch keine Bewertungen

- Supplier RegisterDokument12 SeitenSupplier RegisterBeauty MurewaNoch keine Bewertungen

- Nexteer Quality Alert: Response RequiredDokument1 SeiteNexteer Quality Alert: Response RequiredsimsonNoch keine Bewertungen

- 019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Dokument3 Seiten019-RCFA Disposal Pump-14520a 1'' Inlet Line Repair On 4th November 2016Jinlong SuNoch keine Bewertungen

- PMI Workshop 2017Dokument47 SeitenPMI Workshop 2017iqblsatwikaNoch keine Bewertungen

- Introduction To Earned Value Analysis (EVA) : CSSE 372 Software Project ManagementDokument22 SeitenIntroduction To Earned Value Analysis (EVA) : CSSE 372 Software Project Managementmufratul muslimNoch keine Bewertungen

- Crc-p-600 Welding Machine Spec. Brochure 2Dokument4 SeitenCrc-p-600 Welding Machine Spec. Brochure 2gdgfd100% (1)

- ASME Understanding Codes & Stds CourseDokument4 SeitenASME Understanding Codes & Stds CourseChandrasekharNoch keine Bewertungen

- Inbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsDokument1 SeiteInbound Storage Tank Management - Process Manufacturing (3UK) - Process DiagramsEddy ChenNoch keine Bewertungen

- Lecture 7 - Project ControlDokument35 SeitenLecture 7 - Project ControlJoseph KariukiNoch keine Bewertungen

- EcoSys Product Brochure 2017Dokument4 SeitenEcoSys Product Brochure 2017Alvaro BesoainNoch keine Bewertungen

- W2 - Project Life Cycle Models & Project SelectionDokument58 SeitenW2 - Project Life Cycle Models & Project SelectionThảo My TrươngNoch keine Bewertungen

- EVM Template ExampleDokument5 SeitenEVM Template ExampleEusebio NavarroNoch keine Bewertungen

- Quotation: Escherichia ColiDokument3 SeitenQuotation: Escherichia ColiayuNoch keine Bewertungen

- Example Project Sizing ToolDokument1 SeiteExample Project Sizing Toolanirban_surNoch keine Bewertungen

- Cep Exam Study PlanDokument1 SeiteCep Exam Study PlanPaul Ticla PuenteNoch keine Bewertungen

- Dash Board Sheet With Base DataDokument7 SeitenDash Board Sheet With Base Datavivek1312Noch keine Bewertungen

- Cost Control - It ' S Not Just About NumbersDokument12 SeitenCost Control - It ' S Not Just About NumbersShabbeer ZafarNoch keine Bewertungen

- SRD Tollgate BasedProjectManagementDokument9 SeitenSRD Tollgate BasedProjectManagementKulanthaivelu RamasamyNoch keine Bewertungen

- RACI Chart EXCELDokument2 SeitenRACI Chart EXCELsharjeel hussainNoch keine Bewertungen

- Project Report, Business Plan, Feasibility ReportDokument15 SeitenProject Report, Business Plan, Feasibility ReportPrakash Choudhary100% (2)

- PMP ROWPAMS FinalDokument33 SeitenPMP ROWPAMS FinalVaibhav Paithankar100% (1)

- COCOMODokument21 SeitenCOCOMOanirban_surNoch keine Bewertungen

- PM05 - Change Request V1.0Dokument3 SeitenPM05 - Change Request V1.0Nur Iklil FairuzNoch keine Bewertungen

- Siemens Internship ReportDokument17 SeitenSiemens Internship ReportmirfanbilalNoch keine Bewertungen

- This Domain Is Registered at NamecheapDokument3 SeitenThis Domain Is Registered at NamecheapBala SingamNoch keine Bewertungen

- Calibration Block - BIGPROBEDokument19 SeitenCalibration Block - BIGPROBEBala SingamNoch keine Bewertungen

- Hha Brochure Pmi Master SmartDokument5 SeitenHha Brochure Pmi Master SmartBala SingamNoch keine Bewertungen

- ThiruvarutpaDokument19 SeitenThiruvarutpaBala SingamNoch keine Bewertungen

- Dumond Smart Strip SdsDokument7 SeitenDumond Smart Strip SdsBala SingamNoch keine Bewertungen

- Vickers 30kg ManualDokument12 SeitenVickers 30kg ManualBala SingamNoch keine Bewertungen

- 1 Indeed Public ViewDokument4 Seiten1 Indeed Public ViewBala SingamNoch keine Bewertungen

- Industrial Building For Sale/Lease: Asking Price: $4,650,000Dokument3 SeitenIndustrial Building For Sale/Lease: Asking Price: $4,650,000Bala SingamNoch keine Bewertungen

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDokument48 SeitenSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamNoch keine Bewertungen

- Muffle FurnaceDokument2 SeitenMuffle FurnaceBala SingamNoch keine Bewertungen

- Canadian DRIP List - Canadian DRIP PrimerDokument6 SeitenCanadian DRIP List - Canadian DRIP PrimerBala SingamNoch keine Bewertungen

- AC Coupon TM GuideDokument4 SeitenAC Coupon TM GuideBala SingamNoch keine Bewertungen

- X-Ray Pipeline CrawlerDokument4 SeitenX-Ray Pipeline CrawlerBala SingamNoch keine Bewertungen

- Choose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorDokument2 SeitenChoose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorBala SingamNoch keine Bewertungen

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDokument15 SeitenAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNoch keine Bewertungen

- Multi Channel IndicatorDokument1 SeiteMulti Channel IndicatorBala SingamNoch keine Bewertungen

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDokument15 SeitenAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNoch keine Bewertungen

- Replica Metallography and Penetrant TestingDokument14 SeitenReplica Metallography and Penetrant TestingBala Singam100% (1)

- Proth Psgs Manual PDFDokument106 SeitenProth Psgs Manual PDFBala SingamNoch keine Bewertungen

- Hardness Test TrainingDokument18 SeitenHardness Test TrainingBala SingamNoch keine Bewertungen

- P45 To P45 PQR CertifiedDokument7 SeitenP45 To P45 PQR CertifiedBala SingamNoch keine Bewertungen

- PDF Catalogue PDFDokument42 SeitenPDF Catalogue PDFBala SingamNoch keine Bewertungen

- Supervisor: Job/Location: Date: Work To Be Done: Task LocationDokument1 SeiteSupervisor: Job/Location: Date: Work To Be Done: Task LocationBala SingamNoch keine Bewertungen

- Prorod Spec SheetDokument2 SeitenProrod Spec SheetBala SingamNoch keine Bewertungen

- 1D Elasticity 02 ElastodynamicsDokument17 Seiten1D Elasticity 02 Elastodynamics박남수Noch keine Bewertungen

- Investigation of Automobile Radiator Using Nanofluid-Cuo/Water Mixture As CoolantDokument10 SeitenInvestigation of Automobile Radiator Using Nanofluid-Cuo/Water Mixture As Coolantdheerendra vermaNoch keine Bewertungen

- E.Physics-Assignments - Unit 3,4,5Dokument3 SeitenE.Physics-Assignments - Unit 3,4,5Naresh SinghNoch keine Bewertungen

- Nanomaterials 08 00676Dokument10 SeitenNanomaterials 08 00676CatalinNoch keine Bewertungen

- Materials Science and Engineering Mime-260 Midterm: Mid Term Test, Feb. 27, 2014 Duration: 2 HrsDokument10 SeitenMaterials Science and Engineering Mime-260 Midterm: Mid Term Test, Feb. 27, 2014 Duration: 2 Hrsredviolet7371Noch keine Bewertungen

- Compressibility RubberDokument11 SeitenCompressibility Rubber2007rlwjdtnNoch keine Bewertungen

- Roll List 20EL-Batch 5TH Sem IDokument1 SeiteRoll List 20EL-Batch 5TH Sem IAisha ShaikhNoch keine Bewertungen

- DenalDokument1 SeiteDenalNORDBNoch keine Bewertungen

- A Review On NSM-CFRP Technique Using in Shear Strengthening of RC Deep BeamsDokument18 SeitenA Review On NSM-CFRP Technique Using in Shear Strengthening of RC Deep Beamsbassem kooliNoch keine Bewertungen

- Ph302 Tutorial Sheet 1Dokument2 SeitenPh302 Tutorial Sheet 1Manik MalhotraNoch keine Bewertungen

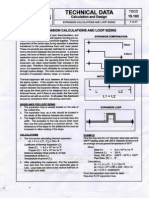

- Expansion Calculation and Loop Sizing001Dokument2 SeitenExpansion Calculation and Loop Sizing001Joseph R. F. DavidNoch keine Bewertungen

- Seismic Design of Shallow Foundations PDFDokument40 SeitenSeismic Design of Shallow Foundations PDFNicon Paul100% (1)

- Surface Erosion of Wind Turbine Blades:: Leon Mishnaevsky JRDokument16 SeitenSurface Erosion of Wind Turbine Blades:: Leon Mishnaevsky JRLeonNoch keine Bewertungen

- 2E4B BucklingDokument4 Seiten2E4B BucklingMohd Ridzuan Ahmad100% (1)

- Jacket Area CalculationDokument12 SeitenJacket Area CalculationPraveen Prajapati100% (2)

- Strength Enhancement in Concrete Confined by Spirals: AbstractDokument6 SeitenStrength Enhancement in Concrete Confined by Spirals: AbstracthemalcmistryNoch keine Bewertungen

- Porosity or PermeabilityDokument30 SeitenPorosity or PermeabilitytabibkarimNoch keine Bewertungen

- Blister FormationDokument4 SeitenBlister FormationPrasant Kumar BeheraNoch keine Bewertungen

- Materials and Jacketing TechniqueDokument5 SeitenMaterials and Jacketing TechniqueHSY79Noch keine Bewertungen

- Slender Column and Two Way SlabsDokument83 SeitenSlender Column and Two Way Slabsshakirhamid6687100% (1)

- Pump System Analysis and Centrifugal Pump SizingDokument158 SeitenPump System Analysis and Centrifugal Pump Sizingme24370100% (4)

- ExperimentDokument13 SeitenExperimentHandcrafting BeautiesNoch keine Bewertungen

- Metallurgy 5th Ed 1977 PDFDokument483 SeitenMetallurgy 5th Ed 1977 PDFanon_435115635Noch keine Bewertungen

- Geomet 500 PDFDokument2 SeitenGeomet 500 PDFKaran Chadha100% (1)

- Radiative Recombination in SemiconductorsDokument12 SeitenRadiative Recombination in SemiconductorsrvrbangNoch keine Bewertungen

- Up To 31 of 28-4Dokument38 SeitenUp To 31 of 28-4sami mujahidNoch keine Bewertungen

- 22 Shear & Diagonal Tension in Beams 02Dokument41 Seiten22 Shear & Diagonal Tension in Beams 02S. M. ZAHIDUR RAHMAN 1301129Noch keine Bewertungen

- Notes On Nanotechnology 11 10 2017 PDFDokument31 SeitenNotes On Nanotechnology 11 10 2017 PDFAtharva BankarNoch keine Bewertungen

- Root Cause Assessment - Fractured Girder Flanges: Transbay (Salesforce) Transit Center, San FranciscoDokument44 SeitenRoot Cause Assessment - Fractured Girder Flanges: Transbay (Salesforce) Transit Center, San Franciscogulilero_yoNoch keine Bewertungen

- Physics Notes Class 11 CHAPTER 13 KINETIC THEORY With SOLUTIONSDokument6 SeitenPhysics Notes Class 11 CHAPTER 13 KINETIC THEORY With SOLUTIONSSk ShivamNoch keine Bewertungen