Beruflich Dokumente

Kultur Dokumente

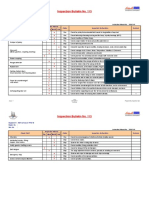

Rig Evaluation Rules of Inspection: Item Action Safety Issue Assistance Required

Hochgeladen von

Cerón Niño SantiagoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rig Evaluation Rules of Inspection: Item Action Safety Issue Assistance Required

Hochgeladen von

Cerón Niño SantiagoCopyright:

Verfügbare Formate

Rig Evaluation Rules of Inspection

Rig Evaluation Safety Rule

The accuracy and collection of data during a rig evaluation will be sacrificed before

any safety rule will be violated.

Procedures and operating rules

Some assistance by rig personnel is normally required during an inspection. Listed below is a detailed

outline of the amount of help that may be required during survey. M-I/Swaco personnel do not wish to be

responsible for dismantling Contractor or third party owned equipment.

Shale Shakers

Item Action Safety Issue Assistance required

Check shaker level Place level on shaker bed Slip Hazard, mechanical None required

hazard-check for guards &

covers

Inspect jacking Loosen locking bolts, Slip Hazard, mechanical None required

system function test jacks. hazard-check for guards &

covers

Check counter Turn off shaker, remove Slip hazard, mechanical Contractor rep. with

weight setting counter weight covers, hazard, lockout-tagout unit proper authorization

observe weights

Check condition of Turn off shaker remove Slip Hazard, mechanical Contractor rep

screen rails & screens. Check for hazard-check for guards &

basket excessive rust & wear. covers depending upon

location and unit type may

need lockout-tagout

Check direction, Apply measuring instrument, Slip & mechanical hazard None required

type of motion, read & record information possible, check for guards

stroke length and covers.

Visually inspect Observe conditions Slip & mechanical hazard None required

exposed wiring possible, check for guards

and covers.

Check drive belt Turn off unit. Lockout- Slip hazard, mechanical Contractor rep. with

tension tagout, remove guard, check hazard, lockout-tagout unit proper authorization

tension

Inspect lubrication Remove non-sealed access Slip & mechanical hazard None required

mechanism panel. View as per possible, check for guards

manufacture specifications and covers.

Function test spray Contact proper personnel Slip & mehcanical hazzard, Contractor rep

bars function valves, and angle possible, check for guards

adjustment and covers, possible contact

with drilling fluid.

Page 1/3 03/30/18

Rig Evaluation Rules of Inspection

Hydrocyclones

Item Action Safety Issue Assistance required

Function test unit Receive permission from Slip hazard , possible Contractor rep,

operator to operate unit, mechanical hazard if unit is and/or mud engineer

read operating pressure, mounted over shaker on location

check for plugged cone,

observe type of discharge,

check density of discharge

Inspect cones Turn off unit, lockout-tagout Slip hazard Slip hazard , Contractor rep. with

unit, remove and inspect possible mechanical hazard if proper authorization

cones for wear. unit is mounted over shaker if

unit is mounted over shaker,

lockout-tagout unit

Function test valves Turn off unit. Function Slip hazard , possible No assistance

valves mechanical hazard if unit is required

mounted over shaker

Check the pump Turn off unit, isolate pump, Slip hazard , possible Contractor rep. with

impeller size & lockout-tagout remove mechanical hazard. lockout- proper authorization

condition if housing, observe tagout unit

necessary.

Check sheave size Turn off unit, lockout-tagout Mechanical hazard, lockout – Contractor rep.

if necessary unit, remove safety guards tagout.

and measure diameters

Degasser

Function test the Receive permission from Slip hazard, mechanical Contractor rep,

unit. operator to operate unit, hazard check for guards and and/or mud engineer

read operating pressures, covers on location

check for plugged lines

Centrifuges – If Rig Owned—have Contractor representative present.

Item Action Safety Issue Assistance required

Check for free Turn off unit, Mechanical hazard, trapped Contractor rep. with

movement of bow, lockout/tagout, remove bolts kinetic energy. proper authorization

proper direction, l open lid, observe. Lockout/tagout

Check existence of Turn off unit, lockout/tagout Mechanical hazard, trapped Contractor rep. with

torque overload unit. Observe type and kinetic energy. proper authorization

safety device. condition of device Lockout/tagout

Check existence of Observe & function test the Slip hazard, No assistance

dilution rate flow valves. Note location and required

meter condition of lines and hoses

Check condition of Turn off unit, lockout/tagout Mechanical hazard, trapped Contractor rep. with

belts unit, remove belt guards, kinetic energy. proper authorization

check belts Lockout/tagout

Check for proper Check bearing temp., check Slip hazard Contractor rep.

lubrication for evidence of recent

grease addition, check

proper fluid level in

gearbox.

Determine Bowl Check with service Mechanical hazard, Contractor rep. with

speed personnel, measure sheave Lockout/tagout unit proper authorization

diameters

Check for Operate unit, Slip hazard, mechanical No assistance

excessive vibration hazard check for guards required

Page 2/3 03/30/18

Rig Evaluation Rules of Inspection

Mud pits:

Item Action Safety Issue Assistance required

Function test all Operate all valves, or valves Pressure hazard, slip hazard. Contractor rep,

valves no currently being used possible disruption in and/or mud engineer

operations on location

Test equalizer Close valve with unequal Slip hazard possible Contractor rep,

valves pressure on each side, disruption in operations and/or mud engineer

observe pit levels. on location

Function test Turn on agitators Mechanical hazard, check or Contractor rep,

agitators injury to others and/or mud engineer

on location

Measure pit Slip hazard No assistance

dimensions required

Observe piping View piping , both exterior Slip hazard, possible Contractor rep, with

and interior of pits, record , confined space , proper authorization

data lockout/tagout

Test mixing Mix, observe mixing of mud Slip hazard, chemical Contractor rep,

equipment material, read pressures contact, wear PPE, Possible and/or mud engineer

while mixing disruption in operations on location

Page 3/3 03/30/18

Das könnte Ihnen auch gefallen

- IFT Forklift Inspection 1Dokument1 SeiteIFT Forklift Inspection 1HSE ENL GCLOUDNoch keine Bewertungen

- Elevator ChecklistDokument2 SeitenElevator ChecklistHarris ShehzadNoch keine Bewertungen

- Pre Shutdown ChecklistDokument12 SeitenPre Shutdown ChecklistasanNoch keine Bewertungen

- CS76 Before OperationDokument4 SeitenCS76 Before OperationJosé Carlos CarvalhoNoch keine Bewertungen

- Centrifuge 5Dokument1 SeiteCentrifuge 5admin ptkmiNoch keine Bewertungen

- OI Training - Passing Valve Training PackDokument36 SeitenOI Training - Passing Valve Training Packعبدالهادي كاظم معله الخفاجي100% (1)

- Sabp J 701Dokument13 SeitenSabp J 701Hassan Mokhtar50% (2)

- Lock Out Tag-Out Tank Hydrotesting: Petrol Steel Company LimitedDokument24 SeitenLock Out Tag-Out Tank Hydrotesting: Petrol Steel Company Limitedmohammed harrisNoch keine Bewertungen

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDokument4 SeitenJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Crown Block Warning Devices - IADC - International Association of Drilling ContractorsDokument4 SeitenCrown Block Warning Devices - IADC - International Association of Drilling ContractorsEmanuel Lopez RoperoNoch keine Bewertungen

- BVM Corporation Maintenance Manual: Pneumatic / Hydraulic Tubing SpiderDokument17 SeitenBVM Corporation Maintenance Manual: Pneumatic / Hydraulic Tubing SpiderDean ReinNoch keine Bewertungen

- New Air Hoist Practices and Procedures Updated 8.16.2012Dokument21 SeitenNew Air Hoist Practices and Procedures Updated 8.16.2012QHSE Manager100% (1)

- Elevator (MR) Certificate Standard FormatDokument2 SeitenElevator (MR) Certificate Standard FormatAkhil100% (2)

- Pre Operational InspectionDokument89 SeitenPre Operational InspectionGustavo ArancibiaNoch keine Bewertungen

- ESCALATOR-Bk Gulf OnlyDokument3 SeitenESCALATOR-Bk Gulf OnlySHARAFUDHEEN TKNoch keine Bewertungen

- W-ENG-5525-045-AH AquaJack Tensioner Operating InstructionsDokument41 SeitenW-ENG-5525-045-AH AquaJack Tensioner Operating InstructionsAndyNoch keine Bewertungen

- Indtruck Checklist Inspect Pallet JackDokument1 SeiteIndtruck Checklist Inspect Pallet Jackprakash senapatiNoch keine Bewertungen

- Belt Conveyor RT45-BDokument2 SeitenBelt Conveyor RT45-BMahmoud HanafyNoch keine Bewertungen

- COE LUISA-Main Class Annual-Requirements-SignedDokument6 SeitenCOE LUISA-Main Class Annual-Requirements-SignedNavo MareNoch keine Bewertungen

- Work Instruction VCBDokument3 SeitenWork Instruction VCBTAHIR HUSAINNoch keine Bewertungen

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDokument17 SeitenTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNoch keine Bewertungen

- Usaglasavanje MakazaDokument6 SeitenUsaglasavanje MakazaДражен ПетковићNoch keine Bewertungen

- Worksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsDokument4 SeitenWorksafe Bulletin: Conveyor Hazards in Shake and Shingle MillsJanardhan KNoch keine Bewertungen

- Direct Push Inspection Form 6-15-2023Dokument2 SeitenDirect Push Inspection Form 6-15-2023Mohd Firdaus OthmanNoch keine Bewertungen

- The Scope of This Exercise Is Limited To Induction Cap Sealing MachineDokument5 SeitenThe Scope of This Exercise Is Limited To Induction Cap Sealing MachinejaimurugeshNoch keine Bewertungen

- GPS Rig Acceptance SurveysDokument5 SeitenGPS Rig Acceptance Surveyssurendra kumarNoch keine Bewertungen

- Chain Block & Lever HoistDokument8 SeitenChain Block & Lever HoistHarris ShehzadNoch keine Bewertungen

- Risk Assessment For Unit-65 02-065-01-P238-01 Air Blowing and Gross Air Leak Test-Shutdown JobDokument8 SeitenRisk Assessment For Unit-65 02-065-01-P238-01 Air Blowing and Gross Air Leak Test-Shutdown Jobarun kumarNoch keine Bewertungen

- JSA9 - ABP OWS Manhole Sealant ProjectDokument9 SeitenJSA9 - ABP OWS Manhole Sealant ProjectadeelkhanafeNoch keine Bewertungen

- How To Analyze Gear FailuresDokument6 SeitenHow To Analyze Gear FailuresHossein100% (1)

- Portable Electrical Equipment or Tools Inspection Checklist FormDokument1 SeitePortable Electrical Equipment or Tools Inspection Checklist Formkhrayzie bhone100% (1)

- Loss Prevention Insight - Crane IncidentsDokument8 SeitenLoss Prevention Insight - Crane IncidentsVladimir KuzmichNoch keine Bewertungen

- A Plant Packing Weekly FT120 ChecksDokument1 SeiteA Plant Packing Weekly FT120 ChecksivoNoch keine Bewertungen

- Window CradleDokument10 SeitenWindow CradleHarris ShehzadNoch keine Bewertungen

- Welding, Cutting and GrindingDokument6 SeitenWelding, Cutting and GrindingMohammed MinhajNoch keine Bewertungen

- Belt Conveyor RFBE-B1800 X 9.7Dokument2 SeitenBelt Conveyor RFBE-B1800 X 9.7Mahmoud HanafyNoch keine Bewertungen

- Lole Hse Perspective Total TucnDokument34 SeitenLole Hse Perspective Total TucnOmosigho OsaroNoch keine Bewertungen

- 501-20A Safety Belt System PICKUP JMCDokument10 Seiten501-20A Safety Belt System PICKUP JMCRusonegroNoch keine Bewertungen

- Safety Alert 21 1Dokument2 SeitenSafety Alert 21 1raouf shalabyNoch keine Bewertungen

- Aerial Lift Safety TrainingDokument28 SeitenAerial Lift Safety TrainingMonika GokarnNoch keine Bewertungen

- PV System Operations & Maintenance FundamentalsDokument9 SeitenPV System Operations & Maintenance FundamentalsSolar - Marketing/CELNoch keine Bewertungen

- Conveyor SafetyDokument18 SeitenConveyor Safetyshaik sakeemNoch keine Bewertungen

- RO-OP-SWP64 Removal of Heavy Earthmover TyresDokument4 SeitenRO-OP-SWP64 Removal of Heavy Earthmover Tyresammar aymanNoch keine Bewertungen

- Operation and Maintenance For Electrically OperatedDokument15 SeitenOperation and Maintenance For Electrically OperatedAbiodun IloriNoch keine Bewertungen

- Guidance For Carrying Out Rig ChecksDokument2 SeitenGuidance For Carrying Out Rig Checksargon39Noch keine Bewertungen

- Actuator & Test Procedure1Dokument11 SeitenActuator & Test Procedure1armin heidariNoch keine Bewertungen

- Inspection Form PM0007 Grader DailyDokument1 SeiteInspection Form PM0007 Grader DailyMalik RizwanNoch keine Bewertungen

- Control of Hazardous EnergyDokument67 SeitenControl of Hazardous Energymalik jahan100% (1)

- 25 Stab in Safety Valve and Gray ValveDokument5 Seiten25 Stab in Safety Valve and Gray ValveAli Mahgoub Ali TahaNoch keine Bewertungen

- Jsa For Piping Hydro Test, Pneumatic TestDokument8 SeitenJsa For Piping Hydro Test, Pneumatic Testsanath adhikaryNoch keine Bewertungen

- Grinding Operation JSA HSE ProfessionalsDokument4 SeitenGrinding Operation JSA HSE ProfessionalsYogisopian HadiNoch keine Bewertungen

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDokument5 SeitenInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNoch keine Bewertungen

- Centrifuge 4Dokument1 SeiteCentrifuge 4admin ptkmiNoch keine Bewertungen

- O&M Guidelines NPDokument6 SeitenO&M Guidelines NPPaldexNoch keine Bewertungen

- Desmontaje de La Torre de PerforacionDokument12 SeitenDesmontaje de La Torre de PerforacionMariana EndaraNoch keine Bewertungen

- 14.03.2018 Shuaiba/PSCJV/CCC See Note 4Dokument8 Seiten14.03.2018 Shuaiba/PSCJV/CCC See Note 4arun kumarNoch keine Bewertungen

- Procedimiento Psp-Inf09-02 Carguio Con RetroexcavadoraDokument3 SeitenProcedimiento Psp-Inf09-02 Carguio Con Retroexcavadorarosa luz herediaNoch keine Bewertungen

- Eot Crane Monthly ChecksheetDokument4 SeitenEot Crane Monthly ChecksheetAmit ThakurNoch keine Bewertungen

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsVon EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsBewertung: 3.5 von 5 Sternen3.5/5 (14)

- Emergency Planning PDFDokument2 SeitenEmergency Planning PDFCerón Niño SantiagoNoch keine Bewertungen

- Reach Assistance PDFDokument2 SeitenReach Assistance PDFCerón Niño SantiagoNoch keine Bewertungen

- Hydrablast Howco H02323 PDFDokument2 SeitenHydrablast Howco H02323 PDFCerón Niño SantiagoNoch keine Bewertungen

- Rig Evaluation Cover SheetDokument29 SeitenRig Evaluation Cover SheetCerón Niño SantiagoNoch keine Bewertungen

- ALASKA Aquifer Aeo6a PDFDokument4 SeitenALASKA Aquifer Aeo6a PDFCerón Niño SantiagoNoch keine Bewertungen

- CaraCara6B - Service ReportDokument3 SeitenCaraCara6B - Service ReportCerón Niño SantiagoNoch keine Bewertungen

- GRAVEL Packer Tool OperationDokument7 SeitenGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsDokument4 SeitenEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoNoch keine Bewertungen

- Rig Evaluation MiSWACO New-LogoDay 2Dokument72 SeitenRig Evaluation MiSWACO New-LogoDay 2Cerón Niño SantiagoNoch keine Bewertungen

- Effect of Well Control On Constrained Sparse Spike Seismic InversionDokument9 SeitenEffect of Well Control On Constrained Sparse Spike Seismic InversionCerón Niño SantiagoNoch keine Bewertungen

- 00 - IWCF - Equipment B&W PDFDokument19 Seiten00 - IWCF - Equipment B&W PDFCerón Niño SantiagoNoch keine Bewertungen

- IADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSDokument13 SeitenIADC Well Control Audit/Test Subcommittee: August 27, 2008 Joe Levine MMSCerón Niño SantiagoNoch keine Bewertungen

- Wild Well Control - Technical Date BookDokument57 SeitenWild Well Control - Technical Date Bookgabriel851007Noch keine Bewertungen

- Surface Stack Questions: IWCF Well Control Practice Test KeyDokument2 SeitenSurface Stack Questions: IWCF Well Control Practice Test KeyCerón Niño SantiagoNoch keine Bewertungen

- PETREVEN Eng PDFDokument1 SeitePETREVEN Eng PDFCerón Niño SantiagoNoch keine Bewertungen

- Spot Heavy MudDokument1 SeiteSpot Heavy MudCerón Niño SantiagoNoch keine Bewertungen

- Gavel Packer Technical GP Proposal Bengala 5 V1Dokument16 SeitenGavel Packer Technical GP Proposal Bengala 5 V1Cerón Niño SantiagoNoch keine Bewertungen

- Introduccion - W1 Lecture1 PDFDokument49 SeitenIntroduccion - W1 Lecture1 PDFCerón Niño SantiagoNoch keine Bewertungen

- Drilling Rig ComponentsDokument2 SeitenDrilling Rig ComponentsCerón Niño SantiagoNoch keine Bewertungen

- I) Typical Scenario Steps Under Normal ConditionsDokument10 SeitenI) Typical Scenario Steps Under Normal ConditionsCerón Niño SantiagoNoch keine Bewertungen

- df100 InstructionDokument20 Seitendf100 InstructionFranco SNoch keine Bewertungen

- Agrofarm 410 420 430 LP EN 02 12Dokument119 SeitenAgrofarm 410 420 430 LP EN 02 12Lacatusu Mircea100% (1)

- Compressed Air MonitoringDokument4 SeitenCompressed Air MonitoringRonak JoshiNoch keine Bewertungen

- of MotorvaneDokument3 Seitenof MotorvaneJeevan BabuNoch keine Bewertungen

- Thakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingDokument4 SeitenThakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingAshwini ChaurasiaNoch keine Bewertungen

- Foundation EngineeringDokument90 SeitenFoundation EngineeringAnonymous 2R2pCtCDNoch keine Bewertungen

- AGP PWT - WPM Presentation by AILLC (20th Sep 2022) - EngineeringDokument4 SeitenAGP PWT - WPM Presentation by AILLC (20th Sep 2022) - EngineeringsudsNoch keine Bewertungen

- Transducer: TypesDokument39 SeitenTransducer: Typestujuh belasNoch keine Bewertungen

- Welding Symbols and NomenclatureDokument17 SeitenWelding Symbols and Nomenclaturesa saNoch keine Bewertungen

- D77003 enDokument57 SeitenD77003 enzliangNoch keine Bewertungen

- Kohn-Sham Equations For DFTDokument15 SeitenKohn-Sham Equations For DFTRikardo Pino RiosNoch keine Bewertungen

- D399 AttachmentDokument50 SeitenD399 AttachmentNOUR ZAINNoch keine Bewertungen

- Euro IV BH117L Trans ManualDokument748 SeitenEuro IV BH117L Trans ManualOlga PlohotnichenkoNoch keine Bewertungen

- Crouse Hinds Form7 Catalog PageDokument8 SeitenCrouse Hinds Form7 Catalog PageFERNANDO RODRIGUEZNoch keine Bewertungen

- TRF InspectionDokument15 SeitenTRF InspectionSonny RaymundoNoch keine Bewertungen

- Well Rounded.: 360 CassetteDokument12 SeitenWell Rounded.: 360 Cassettetafadzwa simbiNoch keine Bewertungen

- Thermodynamics: AllenDokument9 SeitenThermodynamics: AllenronakNoch keine Bewertungen

- Geared Motor: Product ManualDokument178 SeitenGeared Motor: Product Manualsanjibkrjana100% (1)

- CAESAR II Expansion JointsDokument26 SeitenCAESAR II Expansion Jointskamal_md100% (4)

- Agma 9112 - A04Dokument41 SeitenAgma 9112 - A04FARIBA100% (2)

- Treadmill 93T-04 - THH100000 - PARTS LISTDokument19 SeitenTreadmill 93T-04 - THH100000 - PARTS LISTpowerliftermiloNoch keine Bewertungen

- Inertia and MassDokument4 SeitenInertia and MassTanNoch keine Bewertungen

- Superhero ExampleDokument8 SeitenSuperhero Exampleapi-343241309Noch keine Bewertungen

- A.C Lecture 2Dokument5 SeitenA.C Lecture 2mamnd tahaNoch keine Bewertungen

- Extensive Applications of PM Gears: FocusDokument4 SeitenExtensive Applications of PM Gears: FocusAAAHNoch keine Bewertungen

- RCCDokument101 SeitenRCCJay PatelNoch keine Bewertungen

- AGCO Power Gensets Land V2Dokument2 SeitenAGCO Power Gensets Land V2Tawfiq ZidanNoch keine Bewertungen

- Sharkbite Evopex Product Catalog 08 2020Dokument21 SeitenSharkbite Evopex Product Catalog 08 2020Arq Cesar Augusto Mejia GNoch keine Bewertungen

- ABB Water MotorDokument16 SeitenABB Water MotorHenry ChokieNoch keine Bewertungen

- 3 Cross Wheel LacingDokument41 Seiten3 Cross Wheel LacingbobNoch keine Bewertungen