Beruflich Dokumente

Kultur Dokumente

1 SM

Hochgeladen von

Ahmed Sherif CupoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 SM

Hochgeladen von

Ahmed Sherif CupoCopyright:

Verfügbare Formate

www.ccsenet.org/mas Modern Applied Science Vol. 5, No.

5; October 2011

Porous Layers Preparation for Solar Cells by Using Effect Etching

Process

Mohammed S.Mahmoud

Faculty of Engineering, University Of Malaya, Kuala Lumpur, Malaysia

Ali L. Abed

School of Applied Science, University of Technology, Baghdad –Iraq

Mohammad H. H

Center of Training and Work Shop Center, University of Technology, Baghdad -Iraq

Received: August 8, 2011 Accepted: August 26, 2011 doi:10.5539/mas.v5n5p165

Abstract

Recently, nanometer size semiconductors have been a topic of great interest. Electrochemical and /or chemical

etches of silicon produce P-Si layers have a strong link between the details of processing and the optical and

electronic properties of the resulting structure. This paper focuses on investigation different affecting parameters

on the surface morphology, etching rate, electrical properties. Good electrical properties (low resistivity and high

passing current) achieved by electrochemical etching when appropriate etching current density and short

etching time of 10 min.

Keywords: Nanometer size semiconductors, Solar cells, Effect etching process

1. Introduction

Nowadays, Solar cell technologies are an attractive option for clean and renewable energy generation in the form

of electricity. Several technologies have been developed since 1950s and many of them now reached to

commercialization stage. However, photovoltaic (PV) solar cells are not economically efficient yet when

compared to the ordinary grid power used nowadays. P-Si is not a new material. It was first reported over 40

years ago during electropolishing of Si in aqueous HF acid observed by Uhlir, but was basically a nuisance at

that time, since it supposed to be a Si sub oxide (D. P. Lasher, B. A. Decraff, and B. H. Augustin. 2000)(J. T.

Frederksen, P. G. Mecher, and E. Veje. 1998). P-Si are widely used in solar cell applications because of the

increase of the absorption coefficient with its energy and due to the simplicity of the fabrication so, solar cell

incorporating P-Si can be achieved at low cost (S. Bastide, A. Albu-Yaron, S. Strenlke, and C. Lévy-Clément.

1999). The most commonly P-Si production technique used is the electrochemical etching in which biasing is

required to initiate the chemical reaction which produce a well-controlled photoemission characteristics of

porous layer.

Recent studies (K.W. Kolasinski, A. Wallner, R. Neaendeorf, C. X. Pederson, and R. E. Palmer. 2001)( S.

Stolyarova, A. El-Bahar, and Y. Nemirovsky. 2000) have shown that certain electrochemical (EC) etching of Si

produce a microporous material (P-Si) Porous silicon is quickly becoming an increasingly important and

versatile electronic material in today's fabrication technology (R. L. Smith, and S. D. Collins. 1992). P-Si is a

complex network of pores separated by thin columns and contains nano-meter sized Si crystallites. The

relationship between fabrication conditions and the structural and electronic properties of P-Si was examined

extensively in subsequent work(V. Lehmann, and U. Gosele. 1991). The current density, HF acid concentration,

etching time, presence or absence of illumination during etching and, in particular, the doping type and

resistivity of the Si influence the morphology of porous layer(R. T. Collins, P. M. Fauchet, and M. A. Tisler.

1997).

The most common P-Si preparation method which transforms silicon to large-surface area material using

constant current densities in the range of 1-300 mA/cm2 in aqueous HF solutions (Z. C. Feng and R. Tsu, 1994).

Many researches have established the decrease of the density of the P-Si layer at increasing value of the anodic

current. The Si surface serves as the anode, while the cathode is made of platinum or any conducting

Published by Canadian Center of Science and Education 165

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 5; October 2011

HF-resistant material. The cell body itself is made of highly acid-resistant polymer such as plastic or Teflon(V.

Lehmann, and U. Gosele. 1991). HF is diluted in an aqueous solution (ethanol and DI water) with up to 50% of

HF. In fact, ethanoic solutions infiltrate the pores.

Nansheng et al. (Zh. Nansheng, M. Zhongquan, Zh. Chengyue and H. Bo. 2009) formed PS layer by

electrochemical etching in emitter layer of solar cell with very low reflectivity was obtained. The morphology

and reflectivity of PS layer are easily modulated by controlling the electrochemical condition (i.e. the current

density and etching time). It has been shown that the reflectivity of approximately 1.42% in the range

380-1100nm is realized by using optimized condition.

This paper focuses on investigation of the effect etching process to fabricate nanostructure solar cell by

electrochemical technique with different current density. Moreover, effects of the effective parameters on the

surface morphology and the device parameters can be used to determine the optimization preparation condition

on the solar cell conversion efficiency. The main results are in terms of minimization of the reflection losses and

reduction of the density of the surface states. More recently, the effects of using a PS layer on the front surface of

a crystalline Si solar cell have been extensively investigated (O. V. Brodovoy, V. A. Skryshevsky and V. A.

Brodovoy, 2006). The minimization of the optical losses has been obtained by electrochemically etching a 10μm

thick porous layer on Si substrates and treating it in a HF-based solution. In this manner, the achieved effect is

comparable to the best AR coating obtained depositing a double layer (ZnS+MgF2) on a pre-textured Si surface.

Specifically the integrated reflectance changes from 1.6% to 3.4% in the wavelength from 400 to 900nm.

However, when PS is formed on polycrystalline Si, the integrated reflectance in the 300-900 nm spectral region

is around 10%. In the same study, porous Si has been formed on the front surface of a point-contact Si solar cell

to increase the total amount of the light absorbed and improve the efficiency. But all the tested cells show a

degradation of the open-circuit voltage and of the short-circuit current density. The degradation of the cell

performances was explained by the increased surface recombination caused by the partial removal of the very

efficient front surface oxide layer(O. Nichiporuk, A. Kaminski, M. Lemiti, A. Fave, S. Litvinenko and V.

Skryshevsky, 2006).

2. Experimental Setup

PS layers with various porosities were fabricated by electrochemical etching of a highly doped p-type <100>

oriented silicon substrate with a resistivity of 0.01–0.02 Ω cm in the mixture of hydrofluoric acid and ethanol.

The set-up for the electrochemical etching consists of power supply as a current source, ammeter and HF acid in

plastic container. Fig. (1) shows a schematic diagram of the ECE set-up, crystalline silicon samples (c-Si) was

cut into small pieces with dimensions of (1x2 cm). The thicknesses of the wafers were nearly 500µm. The

samples were cleaned, then rinsed and mounted on a Teflon cell in such a way that current could only pass

between the faced surfaces of the silicon substrate and the platinum. The silicon was mounted as an anode and

completes the electrical by putting a platinum mesh as a cathode in a parallel way to achieve homogeneous

layers of P-Si. The HF acid should be diluted with ethanol to minimize the hydrogen bubbles during the etching

which starts within a few minutes. The process was carried out at acid concentration (40%), different etching

times (10-60min.),and different current densities (10-120mA/cm2). All these requirements were considered as

effective parameters in the ECE process. In this work the current density passes through only the immersed area

of the two electrodes to form a layer of P-Si. After that, samples were kept in a plastic container of ethanol to

prevent oxidation of P-Si layers. The thicknesses of the porous layers determined with an optical microscope

were in the range of 8–34 μm. The changes in surface morphology of three different PS samples were

investigated by using a scanning electron microscope (SEM) (EVO550, Carl Zeiss).

The current from the current generator was passed through the etchant solution. As the current moves from

anode to cathode, it provides a flow to ions in the solution toward the sample. The anodic ions release electrons

when they reach the surface of the substrate across the solution. The p-doped sample pushes these electrons into

its holes, depleted and combined with neighboring holes. It eventually creates an etched area around the pattern.

Each test was initiated by activating the time counter and the current source. The etched depth was varied by the

duration of etching.

3. Result and Discussion

The most important applications of porous silicon (PS) devices consisting silicon nanostructures is

optoelectronic and specifically solar cells. Porous silicon was produced by electrochemical etching process with

different anodization conditions were include current density and etching time at HF acid of 40 % concentration

to control the electrical properties and surface morphology of the prepared devices. These properties strongly

depend on the structure characteristics of the formed PS layer, SEM analysis indicates that etching times ranging

166 ISSN 1913-1844 E-ISSN 1913-1852

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 5; October 2011

from (10 - 60 min) yield a progression of P-Si layers morphologies. In general, etching times less than

approximately 20 min yield a ridged porous structure as shown in Fig. 1a. The porous morphology is

homogeneous across the entire wafer surface, although occasional pockets of varying degrees of porosity are

observed. Longer etch times (≈60 min) yield different morphologies, porosity results that is restricted to the

near-surface region. morphology results. As etching process proceeds, extra holes reach the surface leading for

further dissolving of the Si, and with more time the carriers will confined in the thin column leading for dissolve

these columns and excessive etching take place untill the carriers rearrange again on the whole surface and

initiate a new layer as show in (Fig. 1b). The key difference between the morphologies obtained at short and long

times appears in the lateral etching. At shorter etch times the etching occurs inhomogeneously in the plane, but is

largely directed perpendicular to the original surface. At longer times the etching develops more lateral structure

with etching proceeding to undercut some of the structures confined to the surface

The effect of the etching time also studied and the optimum layer thickness could be obtained at 60 minutes. As

the etching time proceeds, excessive etching leads to decrease the P-Si layer thickness since longer etching time

leads to remove the porous layer formed at early stage.

The porosity is defined as the fraction of void within the PS layer. which is strongly dependant on the

anodization conditions. From fig. (3), it is clear that the effect of etching time with the porosity of P-Si layer is

linear function when the etching time is increased some columns disappeared due to excessive etching was

observed. Average size of columns decreased with increasing etching time (10min to 50min) but the porosity

increased with increasing etching time.

The effect of current density on the PS formation was examined. the current density plays a significant role in

controlling the porous morphology which is considered as an important feature for nanostructured solar cells.

For small current density of 15mA/cm2, the surface of c-Si is converted into relatively rough surface but the

porous layer has small thickness. When the current density increased, new structure (column) would appear due

to more effective holes accumulation. Generally, increasing current density (50mA/cm2) leads to an increase in

the thickness of porous layer and the pillar width to about 24µm.Increasing the etching current density leads to a

reduction of pore diameters.

High current density increases the etching rate and the porous layer in the thickness direction leaving the pore

diameter slightly changed. As a result, the etching rate could be estimated as a function of current density and

etching time. The etching rate of electrochemical etching process has attracted a great attention since it describes

the etching process speed. The etching rate depends on the formation parameters and governed by the diffusion

rate and drift velocities of holes to the surface. One can easily recognize that the etching rate increases

exponentially with the current density for P-Si layers were prepared with HF acid of 40 % concentration for 60

minutes in Fig. (4), And this could be explained as follows; When the current density increased, the hole

accumulation becomes larger and then, holes consummation will be faster since the responsible chemical

reaction depends strongly on the supplied holes.

The Electrical Properties the nanostructured solar cells prepared at different conditions are presented in this

paper . In general, J-V characteristics was studied to examine its influence on the electrical properties the

forward bias current is originated from the transport of majority charge carriers. As the voltage is applied, the

majority charge carriers are injected, which in turn causes to lower the built-in potential and decrease the width

of depletion region, then the product of majority and minority charge carriers concentrations is larger than the

squared intrinsic carriers concentration (ni2<np). The current is responsible to accumulate holes while the

consumption is almost slow. At low etching current densities, the accumulation process is very slow and the

thickness of the formed porous layer is too small, i.e., the current flowing through the cell is small. Increasing

the etching current density will increase the density of the accumulated holes (collected) on the surface

consequently, a current is generated to get the balance back, This current is known as "recombination current"

and occurs at low voltages only.

4. Conclusions

Different preparation parameters are affecting the surface morphology of the nanostructured solar cell. Increase

of current density results in more porous silicon surface layer and the corresponding pores are deeper. At low

current density chemical etching prevails and pores shape is more complex and branched, Geometry of the pores

and etching anisotropy changes, when different current density is used. The optoelectronic properties could

determine the optimum preparation conditions which give higher conversion efficiency of the device. In addition

the small etching time (10min) and low current density are preferable to obtain porous layers of good electrical

properties and at very low current density (10mA/cm2) of the electrochemical etching, the conversion efficiency

Published by Canadian Center of Science and Education 167

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 5; October 2011

increases when it’s compared with that of the ordinary solar cell. Finally, the surface area increases with

increasing the preparation current density for p-type silicon

References

D. P. Lasher, B. A. Decraff, and B. H. Augustin. (2000). J. Chem. Educ. 77 (2000) 1201.

J. T. Frederksen, P. G. Mecher, and E. Veje. (1998). Phys. Rev. 58 (1998) 8020

K.W. Kolasinski, A. Wallner, R. Neaendeorf, C. X. Pederson, and R. E. Palmer. (2001). Laser for Science

Facility (2001) 134.

O. Nichiporuk, A. Kaminski, M. Lemiti, A. Fave, S. Litvinenko and V. Skryshevsky. (2006). “Passivation of the

surface of rear contact solar cells by porous silicon”, Thin Solid Films, 511 – 512, (2006), P.248 – 251.

O. V. Brodovoy, V. A. Skryshevsky and V. A. Brodovoy. (2006). “Recombination properties of electronic states

in porous silicon”, Solid state electronics 46, (2006), P.83-87.

R. L. Smith, and S. D. Collins. (1992). J. Appl. Phys. 71 (1992) R1.

R. T. Collins, P. M. Fauchet, and M. A. Tisler. (1997). Physics today, (1997), 24.

S. Bastide, A. Albu-Yaron, S. Strenlke, and C. Lévy-Clément. (1999). Solar energy Mat. of Solar cells, 57 (1999)

393-417.

S. Stolyarova, A. El-Bahar, and Y. Nemirovsky. (2000). J. Appl. Phys. 33 (2000) L90.

V. Lehmann, and U. Gosele. (1991). Appl. Phys. Lett. 58 (1991) 856.

V. Lehmann, and U. Gosele. (1991). Appl. Phys. Lett. 58 (1991) 856.

Z. C. Feng and R. Tsu. (1994). "Porous silicon" World Scientific, Singapore (1994).

Zh. Nansheng, M. Zhongquan, Zh. Chengyue and H. Bo. (2009). “Lower reflectivity and higher minority carrier

lifetime of hand-tailored porous silicon”, Journal of Semiconductors, 30, 7, 2009.

Table 1.

Preparation Time (min) P-Si thickness (μm)

10 8

20 12

30 20

60 34

168 ISSN 1913-1844 E-ISSN 1913-1852

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 5; October 2011

Figure 1. The electrochemical etching setup

Figure 2. SEM images of silicon surface etched with etching times (a) 10 minutes, (b) 50 minutes

Figure 3. The porosity as a function of etching time

Published by Canadian Center of Science and Education 169

www.ccsenet.org/mas Modern Applied Science Vol. 5, No. 5; October 2011

Figure 4. Etching rate versus the current density

Figure 5. The J-V characteristics of solar cells contain P-Si layers prepared at an etching time 20 min

170 ISSN 1913-1844 E-ISSN 1913-1852

Das könnte Ihnen auch gefallen

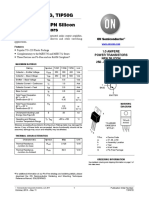

- MJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsDokument6 SeitenMJD47, NJVMJD47T4G, MJD50, NJVMJD50T4G High Voltage Power TransistorsAhmed Sherif CupoNoch keine Bewertungen

- Mosfet: Nttfs4C10N - Power, Single, N-Channel, m8FLDokument7 SeitenMosfet: Nttfs4C10N - Power, Single, N-Channel, m8FLAhmed Sherif CupoNoch keine Bewertungen

- NCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsDokument26 SeitenNCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsAhmed Sherif CupoNoch keine Bewertungen

- 60238Dokument8 Seiten60238Ahmed Sherif CupoNoch keine Bewertungen

- U1B, U1C, U1D: Vishay General SemiconductorDokument4 SeitenU1B, U1C, U1D: Vishay General SemiconductorAhmed Sherif CupoNoch keine Bewertungen

- SDoC PX53 2015Dokument1 SeiteSDoC PX53 2015Ahmed Sherif CupoNoch keine Bewertungen

- 1Smb59Xxbt3G Series, Sz1Smb59Xxt3G Series 3 Watt Plastic Surface Mount Zener Voltage RegulatorsDokument6 Seiten1Smb59Xxbt3G Series, Sz1Smb59Xxt3G Series 3 Watt Plastic Surface Mount Zener Voltage RegulatorsAhmed Sherif CupoNoch keine Bewertungen

- BuxDokument3 SeitenBuxAhmed Sherif CupoNoch keine Bewertungen

- Aluminium Housed Power Wirewound Resistor Style RFH 1000 & RFH 1400 & RFH 1900Dokument2 SeitenAluminium Housed Power Wirewound Resistor Style RFH 1000 & RFH 1400 & RFH 1900Ahmed Sherif CupoNoch keine Bewertungen

- SUD25N06-45L: Vishay SiliconixDokument5 SeitenSUD25N06-45L: Vishay SiliconixAhmed Sherif CupoNoch keine Bewertungen

- MMUN2214LT1Dokument17 SeitenMMUN2214LT1Ahmed Sherif CupoNoch keine Bewertungen

- 7062Dokument5 Seiten7062Ahmed Sherif CupoNoch keine Bewertungen

- TIP47G, TIP48G, TIP50G High Voltage NPN Silicon Power TransistorsDokument6 SeitenTIP47G, TIP48G, TIP50G High Voltage NPN Silicon Power TransistorsAhmed Sherif CupoNoch keine Bewertungen

- Power Schottky Rectifier: With Common CathodeDokument2 SeitenPower Schottky Rectifier: With Common CathodeAhmed Sherif CupoNoch keine Bewertungen

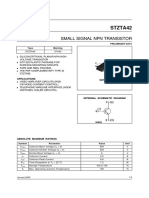

- Stzta42: Small Signal NPN TransistorDokument5 SeitenStzta42: Small Signal NPN TransistorAhmed Sherif CupoNoch keine Bewertungen

- Preventa Xps MP - Xps MC - Xps MCM - xpsmp11123pDokument6 SeitenPreventa Xps MP - Xps MC - Xps MCM - xpsmp11123pAhmed Sherif CupoNoch keine Bewertungen

- kst42, kst43 Fairchild PDFDokument6 Seitenkst42, kst43 Fairchild PDFAhmed Sherif CupoNoch keine Bewertungen

- KG6 04 PDFDokument4 SeitenKG6 04 PDFAhmed Sherif CupoNoch keine Bewertungen

- Vishay Semiconductors: FeaturesDokument4 SeitenVishay Semiconductors: FeaturesAhmed Sherif CupoNoch keine Bewertungen

- Portable Air CompressorsDokument3 SeitenPortable Air CompressorsAhmed Sherif CupoNoch keine Bewertungen

- (SMD) - DatasheetDokument4 Seiten(SMD) - DatasheetAhmed Sherif CupoNoch keine Bewertungen

- Taiwan Semiconductor Small Signal Product: FeaturesDokument4 SeitenTaiwan Semiconductor Small Signal Product: FeaturesAhmed Sherif CupoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- P 664Dokument10 SeitenP 664TomasNoch keine Bewertungen

- Mindray VS800 Users-ManualDokument74 SeitenMindray VS800 Users-ManualPercy De la CruzNoch keine Bewertungen

- Anexo IiDokument61 SeitenAnexo IihelberNoch keine Bewertungen

- IIP2-improved Frontend Receiver Using A Mismatch Compensation LNADokument8 SeitenIIP2-improved Frontend Receiver Using A Mismatch Compensation LNAwrite2arshad_mNoch keine Bewertungen

- Temperature Limiter, Temperature Monitor Nach Din en 14597: Jumo Safetym TB/TWDokument52 SeitenTemperature Limiter, Temperature Monitor Nach Din en 14597: Jumo Safetym TB/TWRazvanNoch keine Bewertungen

- Generation of High Voltages & CurrentsDokument79 SeitenGeneration of High Voltages & CurrentshamzaNoch keine Bewertungen

- Larson TED May2006Dokument11 SeitenLarson TED May2006lpuresearchNoch keine Bewertungen

- M4066BP Mitsubishi PDFDokument5 SeitenM4066BP Mitsubishi PDFDeivys VargasNoch keine Bewertungen

- Generator Relay SettingsDokument22 SeitenGenerator Relay SettingsKuntal Satpathi90% (10)

- Dual Broadband Cross Polarized 7752.00: Electrical SpecificationsDokument1 SeiteDual Broadband Cross Polarized 7752.00: Electrical SpecificationsCAMILO SEBASTIAN DAROCH PAQUIENNoch keine Bewertungen

- Manual DCM300GDokument40 SeitenManual DCM300GLuis SerranoNoch keine Bewertungen

- Motor Insulation Health Monitoring White Paper EnglishDokument13 SeitenMotor Insulation Health Monitoring White Paper EnglishFauzan Fakhrul ArifinNoch keine Bewertungen

- Space Vector Pulse Width ModulationDokument25 SeitenSpace Vector Pulse Width Modulationswathi_grenNoch keine Bewertungen

- BVM TechDokument22 SeitenBVM TechbalabhaviniNoch keine Bewertungen

- Nichrome Wire CalculationDokument7 SeitenNichrome Wire CalculationDilipSinghNoch keine Bewertungen

- The Transistor Astable Multi VibratorDokument6 SeitenThe Transistor Astable Multi VibratorTavleen KaurNoch keine Bewertungen

- Infrarrojos y UltrasónicosDokument81 SeitenInfrarrojos y UltrasónicosgdiliogNoch keine Bewertungen

- Esm-4450 Man Env11Dokument125 SeitenEsm-4450 Man Env11Cristian SerbanoiuNoch keine Bewertungen

- Electrostatic GeneratorDokument56 SeitenElectrostatic GeneratorPraveen KumarNoch keine Bewertungen

- Questions & Answers On Electromechanical Energy ConversionsDokument14 SeitenQuestions & Answers On Electromechanical Energy Conversionskibrom atsbhaNoch keine Bewertungen

- GDS FinalDokument1.317 SeitenGDS FinalRachad BachaNoch keine Bewertungen

- 785 Truck Electrical System: 8GB418-UPDokument2 Seiten785 Truck Electrical System: 8GB418-UPEdwin Ruiz VargasNoch keine Bewertungen

- DatasheetDokument13 SeitenDatasheetlizxcanoNoch keine Bewertungen

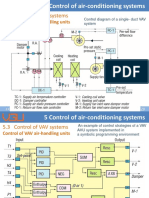

- Control of VAV Air-Handling UnitsDokument9 SeitenControl of VAV Air-Handling UnitsAnh Cao Minh NgocNoch keine Bewertungen

- Acme Orion (XP-260 Beam)Dokument28 SeitenAcme Orion (XP-260 Beam)Luis Antonio Hernandez CastroNoch keine Bewertungen

- 9100 User ManualDokument48 Seiten9100 User Manualหน่อง นพดล83% (35)

- Alphaled CatalogueDokument2 SeitenAlphaled CatalogueManoj Kumar PanigrahiNoch keine Bewertungen

- RRU5301 Technical Specifications: Supported Modes and Frequency BandsDokument7 SeitenRRU5301 Technical Specifications: Supported Modes and Frequency BandsMARCSTARSNoch keine Bewertungen

- EST Answer On BookmarkDokument26 SeitenEST Answer On Bookmarkjj012586100% (1)

- Physics Practical-5Dokument12 SeitenPhysics Practical-5www.jyotirmay1234Noch keine Bewertungen