Beruflich Dokumente

Kultur Dokumente

High Tensile Steel 4140

Hochgeladen von

Lazzarus Az GunawanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

High Tensile Steel 4140

Hochgeladen von

Lazzarus Az GunawanCopyright:

Verfügbare Formate

HIGH TENSILE STEEL – AISI 4140

AISI 4140 Chrome - Moly High Tensile CHEMICAL ANALYSIS

Carbon 0.40%

Steel, generally supplied hardened and

Silicon 0.25%

tempered to Condition “T” in sections

Manganese 0.85%

up to 100mm, with a tensile strength of

Chromium 1.00%

850 – 1000 MPa and aiming for this

Molybdenum 0.25%

strength range in larger sections. It

offers a very good balance of strength, RELATED SPECIFICATIONS:

toughness and wear-resistance. AS 1444-1996 4140

BS 970-3-1991 708M40 or 709M40

TYPICAL APPLICATIONS:

Axles, conveyor parts, crow bars, gears, logging BS 970-1955 EN 19A

parts, spindles, shafts, sprockets, studs, pinions, EN10083-1-1991 1.7225 42CrMo4

pump shafts, rams, ring gears etc.

JIS G 4105 SCM 440

SAE & UNS 4140 & G41400

.

Good through hardening properties with excellent toughness due to the low carbon and high alloy content, also

suitable for Nitriding.

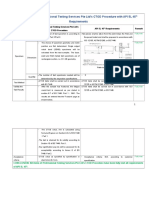

MECHANICAL PROPERTY REQUIREMENTS IN CONDITION “T” – to AS 1444-1996

Section 0.2% Proof Tensile Strength Elongation Impact Hardness

mm Stress MPa on 5.65√So Izod Charpy HB

MPa % J J

*up to 63 680 n 850 - 1000 14 - - 248 - 302

*up to 100 665 min 850 - 1000 15 54min 50min 248 - 302

*Applies only to bars bright drawn after hardening and tempering

TYPICAL MECHANICAL PROPERTIES – Hardened and tempered in section size listed

Section Yield Strength Tensile Strength Elongation Impact Izod Hardness

mm MPa MPa % J HB

50 770 930 17 90 275

100 710 920 15 70 270

200 570 850 14 60 250

Typical Mechanical Properties for guidance only

HIGH TENSILE STEEL – AISI 4140 - continued

WELDING:

Welding procedure:

Readily welded in the annealed condition but

Low hydrogen electrodes are recommended.

avoid when possible if hardened and tempered

Pre-heat at 200°C – 300°C and maintain during

due to the effect on the mechanical properties.

welding. Cool slowly in ashes or sand etc and

Welding in the nitrided, flame or induction

stress relieve if this is possible.

hardened condition is not recommended.

Welding details for guidance only

HEAT TREATMENT:

Forging: Flame and Induction Hardening:

Heat quickly to the required case depth at 860°C

Heat to 1150°C Hold till uniform

– 890°C and quench immediately in water or oil

Minimum forging temperature 850°C

Cool slowly in ashes or sand etc Carburise at 900°C – 950°C

Tempering at 150°C – 200°C will reduce stresses

Annealing: in the case with minimal effect on its hardness.

Heat to 830°C – 850°C

Cool in furnace All de-carburised surface material must first be

removed to ensure best results

Normalising:

Heat to 870°C – 900°C Nitriding:

Cool in furnace Heat to 500°C – 530°C and hold for sufficient time

to develop the depth of case required

Stress Relieving:

Annealed: Heat to 600°C – 650°C Parts should be pre-hardened and tempered as

Hardened: Heat to 500°C – 550°C required and also pre-machined leaving a small

Cool in still air grinding allowance only.

Hardening: Heat treatment details for guidance only

Heat to 830°C – 880°C

Cool in Oil or Polymer

Tempering:

Heat to 450°C – 700°C cool in still air

NB. Tempering within the range 200°C – 420°C

will result in temper brittleness and should be

avoided

Das könnte Ihnen auch gefallen

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceVon EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNoch keine Bewertungen

- ATA Heet: Marvac 250 VIM-VARDokument2 SeitenATA Heet: Marvac 250 VIM-VARspibluNoch keine Bewertungen

- Advances in Research on the Strength and Fracture of Materials: An OverviewVon EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinNoch keine Bewertungen

- Fatigue Analysis Problem Solution: Basquin's LawDokument13 SeitenFatigue Analysis Problem Solution: Basquin's LawAnonymous pmPNWGpNoch keine Bewertungen

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Dokument2 SeitenProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Special Alloys and Overmatched Welding Products SolveDokument14 SeitenSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryNoch keine Bewertungen

- Strength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985Von EverandStrength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985H. J. McQueenNoch keine Bewertungen

- Glen Allan Shocking Truths About WeldingDokument33 SeitenGlen Allan Shocking Truths About Weldingashlyjon1Noch keine Bewertungen

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNoch keine Bewertungen

- 4140Dokument7 Seiten4140Cristopher CastroNoch keine Bewertungen

- Cobalt Based Super AlloysDokument203 SeitenCobalt Based Super AlloysLou ParkerNoch keine Bewertungen

- Steel IndexDokument24 SeitenSteel IndexAnonymous AlhzFE9EVNNoch keine Bewertungen

- Effect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFDokument119 SeitenEffect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFBurag HamparyanNoch keine Bewertungen

- ADokument2 SeitenAMinh Vuong TranNoch keine Bewertungen

- A2.4-98 Standard Symbols, MarkDokument118 SeitenA2.4-98 Standard Symbols, MarkAngela WalkerNoch keine Bewertungen

- Calibration-Validation - Good ArticleDokument12 SeitenCalibration-Validation - Good ArticleVijay KumarNoch keine Bewertungen

- Revealing Prior-Austenite Grain Boundaries in Heat-Treated SteelsDokument5 SeitenRevealing Prior-Austenite Grain Boundaries in Heat-Treated Steelsmp87_ingNoch keine Bewertungen

- Ductile To Brittle Transition-Reason For The Failure of TitanicDokument2 SeitenDuctile To Brittle Transition-Reason For The Failure of TitanicVishnupriya AryabhumiNoch keine Bewertungen

- ISSF Martensitic Stainless SteelsDokument56 SeitenISSF Martensitic Stainless Steelsarjun prajapati100% (1)

- Aws WJ 202009Dokument78 SeitenAws WJ 202009Fernando Emmanuel BenitezNoch keine Bewertungen

- Graphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundDokument2 SeitenGraphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundMuhammad Noman ButtNoch keine Bewertungen

- Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelDokument5 SeitenEffect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelCường BéoNoch keine Bewertungen

- En 10140-2006Dokument14 SeitenEn 10140-2006KaanMertNoch keine Bewertungen

- Aluminum - Filler - Alloy - Selection - Chart Alcotec PDFDokument2 SeitenAluminum - Filler - Alloy - Selection - Chart Alcotec PDFAnonymous nw5AXJqjdNoch keine Bewertungen

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDokument11 SeitenWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNoch keine Bewertungen

- Heat Treatment of Commercial Steels For Engineering ApplicationsDokument34 SeitenHeat Treatment of Commercial Steels For Engineering ApplicationsmeNoch keine Bewertungen

- 101 Metal Repair Paste PS PDFDokument2 Seiten101 Metal Repair Paste PS PDFhemnNoch keine Bewertungen

- Tealsheets PDFDokument37 SeitenTealsheets PDFDee DeeNoch keine Bewertungen

- OSMB Technical Handbook Iss3Dokument92 SeitenOSMB Technical Handbook Iss3halder_kalyan9216Noch keine Bewertungen

- EN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215Dokument2 SeitenEN 12070 EN 12070 EN 12070 EN 12070: Exam Exam Exam Example Ple Ple Ple:::: TG 215 TG 215 TG 215 TG 215spaljeniNoch keine Bewertungen

- Specification Sheet: 2304: (UNS S32304)Dokument2 SeitenSpecification Sheet: 2304: (UNS S32304)Deepak TdNoch keine Bewertungen

- ASTM A 681-08 Standard Specification For Tool Steels AlloyDokument14 SeitenASTM A 681-08 Standard Specification For Tool Steels AlloyTeodoroNoch keine Bewertungen

- Brazing Filler Metal Selector Chart: NicrobrazDokument2 SeitenBrazing Filler Metal Selector Chart: NicrobrazathulpcucekNoch keine Bewertungen

- AMS 2263 E-2006 (2012) - Eng.Dokument5 SeitenAMS 2263 E-2006 (2012) - Eng.TetianaNoch keine Bewertungen

- ASME SA240 Stainless SteelDokument5 SeitenASME SA240 Stainless SteelAndaru MahayektiNoch keine Bewertungen

- Alloy Guide PDFDokument12 SeitenAlloy Guide PDFArjed Ali ShaikhNoch keine Bewertungen

- Cylinders Valve ConnectionsDokument4 SeitenCylinders Valve ConnectionsJavier LerinNoch keine Bewertungen

- Evolution of Super Austenitic Sainless SteelDokument20 SeitenEvolution of Super Austenitic Sainless SteelMidhun K ChandraboseNoch keine Bewertungen

- Aisi 4340 Alloy Steel (Uns g43400)Dokument4 SeitenAisi 4340 Alloy Steel (Uns g43400)JourdyPradityaNoch keine Bewertungen

- A1010 WeldingDokument20 SeitenA1010 WeldingCurious RajNoch keine Bewertungen

- Hydrogen Induced Corrosion: Material Science 112 Group Research PaperDokument8 SeitenHydrogen Induced Corrosion: Material Science 112 Group Research Paperz2aliNoch keine Bewertungen

- AL 6XN SourceBookDokument56 SeitenAL 6XN SourceBookdrbeyerNoch keine Bewertungen

- Manson Coffin BasquinDokument11 SeitenManson Coffin BasquineankiboNoch keine Bewertungen

- Team Pipe RepairDokument24 SeitenTeam Pipe RepairDavid Rios CruzNoch keine Bewertungen

- Bisalloy: Bunge Industrial Steels Pty. LimitedDokument65 SeitenBisalloy: Bunge Industrial Steels Pty. Limitedramaus100% (1)

- A1018 Hslas GR 50Dokument1 SeiteA1018 Hslas GR 50Claudio SampaioNoch keine Bewertungen

- Lab Description For Hardness Testing Procedures: Applicable StandardsDokument11 SeitenLab Description For Hardness Testing Procedures: Applicable StandardsJaymin PatelNoch keine Bewertungen

- New Galvanizing TechnologyDokument4 SeitenNew Galvanizing Technologywmaddoxmec100% (1)

- Weld CrackDokument3 SeitenWeld CrackHoangNoch keine Bewertungen

- 4.3. Residual Stresses and Distortion in WeldmentsDokument11 Seiten4.3. Residual Stresses and Distortion in WeldmentsprokulisNoch keine Bewertungen

- Great Minds of Carbon Equivalent - 1 PDFDokument3 SeitenGreat Minds of Carbon Equivalent - 1 PDFSiva SubramaniNoch keine Bewertungen

- Atlas Technical Handbook Rev Aug 2013Dokument49 SeitenAtlas Technical Handbook Rev Aug 2013Ahmed Mohamed SabriNoch keine Bewertungen

- WJ 2013 05Dokument128 SeitenWJ 2013 05Matija BušićNoch keine Bewertungen

- Module 07 - Distortion & Residual StressDokument46 SeitenModule 07 - Distortion & Residual Stresspanda33upNoch keine Bewertungen

- Metal AlloysDokument31 SeitenMetal AlloysAbie RexoMenNoch keine Bewertungen

- AWS Welding Journal October 2017Dokument225 SeitenAWS Welding Journal October 2017rony16novNoch keine Bewertungen

- Plastic Deformation, Flow Stress and FormabilityDokument35 SeitenPlastic Deformation, Flow Stress and FormabilityAnna100% (1)

- Alloy Chain Slings - Grade 100: Single Leg Slings - Vertical (90 Deg.)Dokument5 SeitenAlloy Chain Slings - Grade 100: Single Leg Slings - Vertical (90 Deg.)Lazzarus Az GunawanNoch keine Bewertungen

- Api 6d 2008Dokument332 SeitenApi 6d 2008Lazzarus Az GunawanNoch keine Bewertungen

- Crosby® Jaw & Jaw Galvanized TurnbucklesDokument7 SeitenCrosby® Jaw & Jaw Galvanized TurnbucklesLazzarus Az GunawanNoch keine Bewertungen

- Troubleshooting Guide ET CATDokument11 SeitenTroubleshooting Guide ET CATLazzarus Az Gunawan100% (1)

- Eyebolts & Eyenuts: How Should You Select The Right Bolt?Dokument4 SeitenEyebolts & Eyenuts: How Should You Select The Right Bolt?Lazzarus Az GunawanNoch keine Bewertungen

- Ames ProceduresDokument90 SeitenAmes ProceduresLazzarus Az GunawanNoch keine Bewertungen

- Engine Driven Welders PDFDokument13 SeitenEngine Driven Welders PDFLazzarus Az GunawanNoch keine Bewertungen

- 163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualDokument4 Seiten163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualLazzarus Az Gunawan100% (1)

- Break System Pneumatic LowboyDokument1 SeiteBreak System Pneumatic LowboyLazzarus Az Gunawan100% (1)

- 141 110 2 Falk Magnum Seals For Type A, AB, Y, YF, YB Drives Selection ManualDokument4 Seiten141 110 2 Falk Magnum Seals For Type A, AB, Y, YF, YB Drives Selection ManualLazzarus Az GunawanNoch keine Bewertungen

- Windrock 6320 Diesel BrochureDokument4 SeitenWindrock 6320 Diesel BrochureLazzarus Az GunawanNoch keine Bewertungen

- GEP 220-1 SpecDokument4 SeitenGEP 220-1 SpecLazzarus Az GunawanNoch keine Bewertungen

- Proto 108 - Pliers, Clamping, Cutting (p.739-788)Dokument50 SeitenProto 108 - Pliers, Clamping, Cutting (p.739-788)Lazzarus Az GunawanNoch keine Bewertungen

- Tabel Baja Profil WF PDFDokument7 SeitenTabel Baja Profil WF PDFErwin d'Adventura63% (19)

- 4799e SabbDokument2 Seiten4799e SabbLazzarus Az GunawanNoch keine Bewertungen

- 1103a 33GDokument8 Seiten1103a 33GahmedalgaloNoch keine Bewertungen

- Sugar and Ethanol Industry: Bearings and Units Seals Lubrication SystemsDokument2 SeitenSugar and Ethanol Industry: Bearings and Units Seals Lubrication SystemsLazzarus Az Gunawan100% (1)

- Catalogue 2 1Dokument6 SeitenCatalogue 2 1Lazzarus Az GunawanNoch keine Bewertungen

- Catalogue 2 1Dokument6 SeitenCatalogue 2 1Lazzarus Az GunawanNoch keine Bewertungen

- Manual Xgi Cpu Eng 2Dokument211 SeitenManual Xgi Cpu Eng 2Lazzarus Az GunawanNoch keine Bewertungen

- Shaft Alignment ReportDokument1 SeiteShaft Alignment ReportLazzarus Az GunawanNoch keine Bewertungen

- Sika Decap PDFDokument2 SeitenSika Decap PDFthe pilotNoch keine Bewertungen

- Abu Khader Group ProposalDokument5 SeitenAbu Khader Group ProposalChristine AghabiNoch keine Bewertungen

- Toro 006Dokument2 SeitenToro 006Eric CNoch keine Bewertungen

- Real-World Data Is Dirty: Data Cleansing and The Merge/Purge ProblemDokument29 SeitenReal-World Data Is Dirty: Data Cleansing and The Merge/Purge Problemapi-19731161Noch keine Bewertungen

- Soft-Starter: Programming ManualDokument162 SeitenSoft-Starter: Programming ManualThaylo PiresNoch keine Bewertungen

- The Ultimate Guide To The Gemba WalkDokument9 SeitenThe Ultimate Guide To The Gemba WalkĐan VũNoch keine Bewertungen

- DuffDokument44 SeitenDuffNikolai_Noch keine Bewertungen

- APTET 2014 Social Question Paper II With Solutions PDFDokument47 SeitenAPTET 2014 Social Question Paper II With Solutions PDFgayathriNoch keine Bewertungen

- Guidelines For The Oral Presentation Bands Singers e MusicDokument2 SeitenGuidelines For The Oral Presentation Bands Singers e Musicjuliusdelazare100% (1)

- Quickspecs: HP Probook 440 G2 Notebook PCDokument51 SeitenQuickspecs: HP Probook 440 G2 Notebook PCAseemSharanNoch keine Bewertungen

- Preparation of Giemsa Working SolutionDokument4 SeitenPreparation of Giemsa Working SolutionMUHAMMAD DIMAS YUSUF 1903031Noch keine Bewertungen

- Mazada Consortium LimitedDokument3 SeitenMazada Consortium Limitedjowila5377Noch keine Bewertungen

- High Low MethodDokument4 SeitenHigh Low MethodSamreen LodhiNoch keine Bewertungen

- Ball Valves PDFDokument34 SeitenBall Valves PDFThomasFrenchNoch keine Bewertungen

- Oracle SQL Developer User GuideDokument194 SeitenOracle SQL Developer User Guidesureshreddy_iNoch keine Bewertungen

- Questionnaire Supply ChainDokument4 SeitenQuestionnaire Supply ChainKshatriy'as ThigalaNoch keine Bewertungen

- BA427 Chapter 7Dokument11 SeitenBA427 Chapter 7Maloloy-on, JeromeNoch keine Bewertungen

- An Example of A Rating Scale To Q4Dokument4 SeitenAn Example of A Rating Scale To Q4Zeeshan ch 'Hadi'Noch keine Bewertungen

- Instructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Dokument6 SeitenInstructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Princess DumlaoNoch keine Bewertungen

- Arguments and FallaciesDokument18 SeitenArguments and FallaciesSarah Mae Peñaflor Baldon-IlaganNoch keine Bewertungen

- Validation of Analytical ProceduresDokument15 SeitenValidation of Analytical ProceduresildamonalisaNoch keine Bewertungen

- 82 - Engineering Mechanics Refresher SetDokument6 Seiten82 - Engineering Mechanics Refresher Setdevilene nayazakoNoch keine Bewertungen

- 3838-Article Text-7786-1-10-20230403Dokument8 Seiten3838-Article Text-7786-1-10-20230403Ramona Elena SpiridonNoch keine Bewertungen

- Electrical Service Minimum RequirmentDokument97 SeitenElectrical Service Minimum RequirmentachniajosiNoch keine Bewertungen

- One Page Mistake ProofingDokument1 SeiteOne Page Mistake Proofingtuan mai vanNoch keine Bewertungen

- Vedic Astrology - Marriage Star Matching Compatibility For Pooraadam Girl and Aayilyam BoyDokument1 SeiteVedic Astrology - Marriage Star Matching Compatibility For Pooraadam Girl and Aayilyam BoyRam GopalNoch keine Bewertungen

- The European Code of Conduct For Research IntegrityDokument24 SeitenThe European Code of Conduct For Research Integritytajsis100% (1)

- Multidisciplinary Research: EPRA International Journal ofDokument5 SeitenMultidisciplinary Research: EPRA International Journal ofMathavan VNoch keine Bewertungen

- Experiment 13 Ultrafiltration UnitDokument13 SeitenExperiment 13 Ultrafiltration UnitKishen NaniNoch keine Bewertungen

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Dokument11 SeitenCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesVon EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNoch keine Bewertungen

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeVon EverandThe Invisible Rainbow: A History of Electricity and LifeBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Practical Chemical Thermodynamics for GeoscientistsVon EverandPractical Chemical Thermodynamics for GeoscientistsNoch keine Bewertungen

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen