Beruflich Dokumente

Kultur Dokumente

AGV - Product Sheet - en - LD

Hochgeladen von

TienRienOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AGV - Product Sheet - en - LD

Hochgeladen von

TienRienCopyright:

Verfügbare Formate

HIGH-SPEED TRAINS

AGV

Avelia range

AGV high-speed train is GENERAL DESCRIPTION

designed to reduce operating AGV is part of the Avelia range, based on proven technology with more than 1,000 high

high-speed trains in service worldwide.

costs and in particular, Its articulated architecture provides enhanced safety and comfort at very high speed while

energy consumption. reducing energy consumption and maintenance costs.

Compared to standard single deck trains, the distributed traction of the AGV allows a higher

This innovative train offers capacity for a given platform length.

superior safety and travel

experience with elegant and

spacious interiors. CUSTOMER BENEFITS

Low life cycle costs Elegant and spacious interiors

AGV aerodynamic resistance has been Thanks to 11 passenger rooms, operators

reduced by 15% thanks to its front end can offer different types of atmosphere on-

design but also thanks to its articulated board. The low floor and closed gaps

architecture which improves drastically the between the platform and the train

air flow beneath the train. Combined with facilitate on-board circulation and

its low weight, Permanent Magnet Motors accessibility. A smooth ride thanks to

and braking energy recovery, the energy bogies placed between cars for less

consumption is 15% to 30% lower than vibrations and rolling noise. Furthermore,

non-articulated trains. As for maintenance, AGV offers spacious, bright, elegant and

fewer bogies thanks to articulation, and quiet interiors with large windows for the

design for serviceability, reduce by 10% well-being of passengers.

maintenance costs reduction.

Innovation and performance Optimal safety

Thanks to lower aerodynamic resistance AGV benefits from Alstom’s four decade

and greater specific power, AGV delivers experience in high-speed. Today, nearly

excellent residual acceleration at high 600 Avelia trains are running at speeds

speeds, nearly twice higher than other equal or over 300 km/h. Their articulated

trains. This ensures continuous high speeds architecture was specifically designed for

during the whole journey and reduces travel very high speeds and guarantees the

times. AGV maintains 80% to 83% of its highest safety. The rigidity of the trainset

power in case of breakdown (vs. 75% for prevents deformation and limits the risk of

other trains), a guarantee of unfailing tipping over in the event of derailment.

reliability.

HIGHLIGHTS

• Alstom Avelia technology:

used in 1/3 trains in service in

the world

• Energy consumption: 15% to

30% less energy consumption

than non-articulated trains

• Maintenance: Up to 10% lower

maintenance costs than non-

articulated trains

Avelia AGV/EN/09.2016 - Photo credits: ©ALSTOM SA / Arnaud Fevrier/ M. Sfreddo

© ALSTOM SA, 2016. All rights reserved. ALSTOM, the ALSTOM logo, all alternative versions and all mentioned trademarks of Alstom’s Transport Domain, are the brands and

trademarks of ALSTOM SA. The other names mentioned registered or not, belong to their respective owners. Technical and other forms of data contained in the present document

are given for the purposes of information only. ALSTOM reserves the right to reconsider or change this data at any time and without warning.

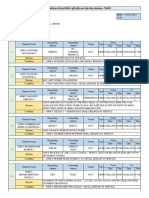

AGV

Technical specifications

Distributed traction

Architecture

Articulated

From 400 to 500 passengers (in 200 m version)

Capacity

The interior layout can be modified during the life cycle (30 years or more)

Service speed 360 km/h (depending on the chosen traction configuration)

11 cars - 200 m train

Length

Flexibility for other configurations (from 7 to 14 cars)

Width 2 995 mm

Power supply 25kV, 3kV - 15 kV, 1,5kV also available

Weight 380 t (vs. 450 t/460 t for non-articulated trains) V150 set the 574.8 km/h world speed

Axle load 17 t record in April 2007 with AGV motorized

Braking energy recovery Up to 8 MW for a 200 m train bogies and traction blocks.

12 bogies for a 200 m train (vs. 16 for non-articulated trains)

Bogies

3 m wheelbase

Passenger experience

• Interior width: 2 700 mm (100 mm wider than non-articulated trains)

• Quasi-static gangway in curves

• Floor located 1 155 mm above the rail (vs. 1260 mm for non-articulated trains) i.e. 2 steps

TSI from a 550 mm-high platform (vs. 3)

• Maximum distance between a seat and an access door: 9m (vs. 12 m)

• Each doors are separated by equivalent distance and accessible from 2 corridors

Environment

• Low energy consumption: 20% to 30% less than non-articulated trains

• Reduced carbon emissions: 0.4 l in oil equivalent per 100 km i.e. 3 times less than a bus, 8

times less than a car, 15 times less than an airplane

• Easily recyclable materials: aluminum, steel, copper and glass

• Enhanced aerodynamics and special brake pads to reduce external noise

For more information

please contact Alstom:

Alstom

48, rue Albert Dhalenne

93842 Saint-Ouen, Cedex France

Phone: +33 1 57 06 90 00

Visit us online: www.alstom.com

© ALSTOM SA, 2016. All rights reserved. ALSTOM, the ALSTOM logo, all alternative versions and all mentioned trademarks of Alstom’s Transport Domain, are the brands and

trademarks of ALSTOM SA. The other names mentioned registered or not, belong to their respective owners. Technical and other forms of data contained in the present document

are given for the purposes of information only. ALSTOM reserves the right to reconsider or change this data at any time and without warning.

Das könnte Ihnen auch gefallen

- Qcomm LTE Log Packet Information 80 VP457 5 C LTE LPID PDFDokument232 SeitenQcomm LTE Log Packet Information 80 VP457 5 C LTE LPID PDFMichał Ujma100% (1)

- X Trapolis Mega - Product Sheet - ENDokument2 SeitenX Trapolis Mega - Product Sheet - ENPTOIR FPTK UPINoch keine Bewertungen

- The Versatile Articulated Truck That Does It AllDokument16 SeitenThe Versatile Articulated Truck That Does It AllYakupovmm0% (1)

- Bell B30E Tech ManualDokument24 SeitenBell B30E Tech ManualSimon manoen50% (4)

- Avelia HorizonDokument2 SeitenAvelia HorizonIngenioerenNoch keine Bewertungen

- Ficha Tecnica Erp025-030vcDokument8 SeitenFicha Tecnica Erp025-030vcRAUL HERRERANoch keine Bewertungen

- Aptis Product Sheet March 17 v2Dokument2 SeitenAptis Product Sheet March 17 v2FWEFWEFWNoch keine Bewertungen

- Montacargas Electrico 10131518202530br-9 (Updated)Dokument14 SeitenMontacargas Electrico 10131518202530br-9 (Updated)luismdmjNoch keine Bewertungen

- WA95 EnglischDokument8 SeitenWA95 EnglischTamquadistu AlexNoch keine Bewertungen

- SY135C4Dokument12 SeitenSY135C4Vieira InvestidorNoch keine Bewertungen

- Alstom - English AgvDokument14 SeitenAlstom - English AgvRodrigo SampaioNoch keine Bewertungen

- Man TGS.: Consistently EfficientDokument19 SeitenMan TGS.: Consistently EfficientAntonio GasparNoch keine Bewertungen

- S1300 3Dokument22 SeitenS1300 3Bryson PlazosNoch keine Bewertungen

- Elphinstone 3900 Series SpecalogDokument24 SeitenElphinstone 3900 Series SpecalogMarkNoch keine Bewertungen

- Electric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBDokument12 SeitenElectric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBvictor laraNoch keine Bewertungen

- O5469v83 Hamm 3K EN 092009Dokument9 SeitenO5469v83 Hamm 3K EN 092009revelacopNoch keine Bewertungen

- The Crane Platform For Inland PortsDokument12 SeitenThe Crane Platform For Inland PortsGogyNoch keine Bewertungen

- 725 Truck ArticulatedDokument20 Seiten725 Truck ArticulatedForomaquinas100% (3)

- 8 - 12t XF Series IC ForkliftDokument6 Seiten8 - 12t XF Series IC ForkliftSrđan HamovićNoch keine Bewertungen

- Optare Electric Vehicles: Embracing The EnvironmentDokument4 SeitenOptare Electric Vehicles: Embracing The EnvironmentarrenNoch keine Bewertungen

- EKKE Single-Girder Overhead Travelling Cranes Up To 12.5 Tonnes - DemagcranesDokument1 SeiteEKKE Single-Girder Overhead Travelling Cranes Up To 12.5 Tonnes - Demagcranesadik andi rahmat hanafiNoch keine Bewertungen

- Chariot Elevateur Hyundai PDFDokument9 SeitenChariot Elevateur Hyundai PDFhocine gherbiNoch keine Bewertungen

- BR Aeam50 004 - 201210 PDFDokument16 SeitenBR Aeam50 004 - 201210 PDFSabahNoch keine Bewertungen

- BR Aeam50 004 - 201210Dokument16 SeitenBR Aeam50 004 - 201210SabahNoch keine Bewertungen

- Bell B30e5Dokument24 SeitenBell B30e5Robert grobler0% (1)

- Abb CRP AzipodDokument16 SeitenAbb CRP AzipodScott_B4U50% (2)

- HANGCHADokument6 SeitenHANGCHAFer PerezNoch keine Bewertungen

- Electric Bus For Airports enDokument4 SeitenElectric Bus For Airports enOne SpringNoch keine Bewertungen

- Powerboat Guide Engines and Accessories - Volvo Penta ServiceDokument36 SeitenPowerboat Guide Engines and Accessories - Volvo Penta ServicedanielNoch keine Bewertungen

- A Series 1.0-3.5T HANGCHADokument4 SeitenA Series 1.0-3.5T HANGCHAAndres Espinoza0% (1)

- WA75 Englisch PDFDokument8 SeitenWA75 Englisch PDFStephane BarilNoch keine Bewertungen

- SANY-PORT-Bro.-Reachstacker 4535G5 4540G5 ENDokument9 SeitenSANY-PORT-Bro.-Reachstacker 4535G5 4540G5 ENAcacio NetoNoch keine Bewertungen

- Multi Speed Transmission For ElectDokument4 SeitenMulti Speed Transmission For ElectHamza TAKTINoch keine Bewertungen

- Air-Ride Suspensions For 2-Axle & 3-Axle Bus & Motorcoach ApplicationsDokument8 SeitenAir-Ride Suspensions For 2-Axle & 3-Axle Bus & Motorcoach ApplicationsGreg PulidoNoch keine Bewertungen

- Vogele PavimentadorasRastos SUPER2100-3iDokument22 SeitenVogele PavimentadorasRastos SUPER2100-3iHighwayNoch keine Bewertungen

- Hyundai Heavy Industries: Electric Counterbalance TrucksDokument12 SeitenHyundai Heavy Industries: Electric Counterbalance TrucksDragan PilipovićNoch keine Bewertungen

- Skyline Pro E 9mDokument7 SeitenSkyline Pro E 9msanthoshvrptNoch keine Bewertungen

- A350 Special 2016 PDFDokument16 SeitenA350 Special 2016 PDFNick TsangNoch keine Bewertungen

- Ready For All Missions, Except Emissions.: The Man EtgeDokument7 SeitenReady For All Missions, Except Emissions.: The Man EtgeShashi TiwariNoch keine Bewertungen

- Jaguar: 900 Series 800 SeriesDokument16 SeitenJaguar: 900 Series 800 SeriesFerreira Anibal ParedesNoch keine Bewertungen

- Crown Platform Crown Battery Operated Pallet TruckDokument7 SeitenCrown Platform Crown Battery Operated Pallet Truckgaurav champawatNoch keine Bewertungen

- Bi Mode DampersDokument2 SeitenBi Mode DampersJitark DarjiNoch keine Bewertungen

- Powerboat Guide: Engines and AccessoriesDokument36 SeitenPowerboat Guide: Engines and Accessoriesankur.jade100% (2)

- Wa900 8R - Cen00855 00Dokument20 SeitenWa900 8R - Cen00855 00Ahmad Badawi100% (1)

- Catalogo - AMMNN ASC110 - VARIOS PDFDokument8 SeitenCatalogo - AMMNN ASC110 - VARIOS PDFDavid Apaza HurtadoNoch keine Bewertungen

- SUSPENSIÓNKW Pdfproducts01 PDFDokument8 SeitenSUSPENSIÓNKW Pdfproducts01 PDFmjdeleoncNoch keine Bewertungen

- AB TT Kom ENDokument40 SeitenAB TT Kom ENAnna PrzygodzkaNoch keine Bewertungen

- 308.8537.3.1-6 Explorer EN 3Dokument20 Seiten308.8537.3.1-6 Explorer EN 3gerald connollyNoch keine Bewertungen

- 1.5-3.8t X Series IC Forklift TruckDokument6 Seiten1.5-3.8t X Series IC Forklift TruckE Abadt DLNoch keine Bewertungen

- English LessonDokument20 SeitenEnglish Lessonlymeng porNoch keine Bewertungen

- Custom C500 People Mover: Features Benefits AGV OptionsDokument2 SeitenCustom C500 People Mover: Features Benefits AGV OptionsCoreconNoch keine Bewertungen

- Hiab XS 077 Range 6-8 TM: Product BrochureDokument4 SeitenHiab XS 077 Range 6-8 TM: Product BrochureDavidNoch keine Bewertungen

- Dynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700Dokument8 SeitenDynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700danielfbarradas1370Noch keine Bewertungen

- International LT SeriesDokument19 SeitenInternational LT SeriesArjun PrashanthNoch keine Bewertungen

- BB 1215R BrochureDokument7 SeitenBB 1215R BrochureVinit TyagiNoch keine Bewertungen

- Wheel Loader: Engine Gross Power Operating Weight Bucket CapacityDokument16 SeitenWheel Loader: Engine Gross Power Operating Weight Bucket CapacityAbo Achraf LaalawiNoch keine Bewertungen

- HYS0631 - C1L2P0 - Brochure Update Sept16 - Hyster J1.5-3.5GXDokument12 SeitenHYS0631 - C1L2P0 - Brochure Update Sept16 - Hyster J1.5-3.5GXMickNoch keine Bewertungen

- Lead The Change With: High Altitude PackageDokument9 SeitenLead The Change With: High Altitude PackagegaelNoch keine Bewertungen

- 1553263043NR NDR030 40daDokument6 Seiten1553263043NR NDR030 40dasebouellet77Noch keine Bewertungen

- Natural Stability and the Parachute Principle in AeroplanesVon EverandNatural Stability and the Parachute Principle in AeroplanesNoch keine Bewertungen

- Vehicle Engineering - ENOTRAC AGDokument2 SeitenVehicle Engineering - ENOTRAC AGTienRienNoch keine Bewertungen

- Biological Effect and Medical Applications of Electromagnetic EnergyDokument580 SeitenBiological Effect and Medical Applications of Electromagnetic EnergyTienRienNoch keine Bewertungen

- Wind ReliabilityDokument41 SeitenWind ReliabilityTienRienNoch keine Bewertungen

- Fabel - Enotrac AgDokument2 SeitenFabel - Enotrac AgTienRienNoch keine Bewertungen

- Ocean ThermalDokument10 SeitenOcean ThermalTienRienNoch keine Bewertungen

- Geothermal Review (Pertamina)Dokument15 SeitenGeothermal Review (Pertamina)TienRienNoch keine Bewertungen

- The AGV, Incorporating Cutting-Edge Technology: François LACÔTE - SVP TechnicalDokument16 SeitenThe AGV, Incorporating Cutting-Edge Technology: François LACÔTE - SVP TechnicalTienRienNoch keine Bewertungen

- TGV 01 - Presentation Alstom PDFDokument16 SeitenTGV 01 - Presentation Alstom PDFTienRienNoch keine Bewertungen

- TGV 01 - Presentation Alstom PDFDokument16 SeitenTGV 01 - Presentation Alstom PDFTienRienNoch keine Bewertungen

- UC XLPE CatalogueDokument63 SeitenUC XLPE CatalogueZafar BakhshNoch keine Bewertungen

- Alstom - English AgvDokument14 SeitenAlstom - English AgvRodrigo SampaioNoch keine Bewertungen

- (Prof. Dr.-Ing. Adolf J. Schwab (Auth.) ) Field TH PDFDokument233 Seiten(Prof. Dr.-Ing. Adolf J. Schwab (Auth.) ) Field TH PDFTienRienNoch keine Bewertungen

- Cable Catalogue PDFDokument174 SeitenCable Catalogue PDFjedi_pandaNoch keine Bewertungen

- HV Catalogue 0902Dokument64 SeitenHV Catalogue 0902Irving VitaliNoch keine Bewertungen

- Pei-Bai Zhou - Numerical Analysis of Electromagnetic FieldsDokument418 SeitenPei-Bai Zhou - Numerical Analysis of Electromagnetic FieldsTienRienNoch keine Bewertungen

- IEEE PQ Case-1Dokument33 SeitenIEEE PQ Case-1TienRienNoch keine Bewertungen

- Pei-Bai Zhou - Numerical Analysis of Electromagnetic FieldsDokument418 SeitenPei-Bai Zhou - Numerical Analysis of Electromagnetic FieldsTienRienNoch keine Bewertungen

- Module 7 CSS G11 2nd Sem Week 3 4 PDFDokument59 SeitenModule 7 CSS G11 2nd Sem Week 3 4 PDFKenkenNoch keine Bewertungen

- Rail and Safety ConceptDokument4 SeitenRail and Safety ConceptJoseNoch keine Bewertungen

- Unit 2: Introduction To The Engineering Profession: Engr. Roman M. Richard, MengDokument13 SeitenUnit 2: Introduction To The Engineering Profession: Engr. Roman M. Richard, MengRoman MarcosNoch keine Bewertungen

- Supply Chain - ABCDokument15 SeitenSupply Chain - ABCYulia Tri AngganiNoch keine Bewertungen

- Crocus SHDSL g703Dokument302 SeitenCrocus SHDSL g703Ahmed Sakr100% (1)

- Standards National Institute of Standards and TechnologyDokument2 SeitenStandards National Institute of Standards and Technologysundhar_vNoch keine Bewertungen

- Wordlist Unit 1 GOLD EXPERIENCE B1 PDFDokument112 SeitenWordlist Unit 1 GOLD EXPERIENCE B1 PDFmelisa collinsNoch keine Bewertungen

- ECE Black Box Testing Report PDFDokument12 SeitenECE Black Box Testing Report PDFMahyndra Reddy Chagam100% (1)

- Er Shutdown For 15.12.21 Rev1Dokument8 SeitenEr Shutdown For 15.12.21 Rev1Gitesh PatelNoch keine Bewertungen

- Type No. 430-211-011 Clubsport: Basic Unit Ags Family IiDokument4 SeitenType No. 430-211-011 Clubsport: Basic Unit Ags Family IibruceNoch keine Bewertungen

- Hardware Faults: Stäubli CorporationDokument3 SeitenHardware Faults: Stäubli CorporationJulio LiranzoNoch keine Bewertungen

- Tide Power Products50HzDokument22 SeitenTide Power Products50HzmaherNoch keine Bewertungen

- Inventory Database - All Parts Inc (8/20/20)Dokument2.368 SeitenInventory Database - All Parts Inc (8/20/20)All Parts Inc.0% (1)

- Learning Docker - Sample ChapterDokument24 SeitenLearning Docker - Sample ChapterPackt PublishingNoch keine Bewertungen

- Oracle Documentation - Do-060 User Reference ManualDokument11 SeitenOracle Documentation - Do-060 User Reference ManualAnbu ManoNoch keine Bewertungen

- 2nd Group Makalah of Letter of EnquiryDokument12 Seiten2nd Group Makalah of Letter of EnquiryInas Afifah ZahraNoch keine Bewertungen

- Elon Musk and Twitter - TBADokument11 SeitenElon Musk and Twitter - TBASibghatullah SiyalNoch keine Bewertungen

- V Ug Type ListDokument3 SeitenV Ug Type ListDanang BiantaraNoch keine Bewertungen

- Dell™ C1765nfw Color Multifunction Printer User's GuideDokument376 SeitenDell™ C1765nfw Color Multifunction Printer User's GuidesoxxxxNoch keine Bewertungen

- 09 ARUP SlimCity Urban MobilityDokument30 Seiten09 ARUP SlimCity Urban MobilitynbilicNoch keine Bewertungen

- Chapter 01Dokument62 SeitenChapter 01Rap JaviniarNoch keine Bewertungen

- Manual VsDokument44 SeitenManual VsMax WilsonNoch keine Bewertungen

- Siemens Bs 240 Bs 241 BrochureDokument4 SeitenSiemens Bs 240 Bs 241 Brochuremegamaster0987654321Noch keine Bewertungen

- 12 TriesDokument10 Seiten12 TriesNikhil 20528Noch keine Bewertungen

- Step-by-Step Guide To Enrolling Online: Ready To Enrol? Enrolment StepsDokument11 SeitenStep-by-Step Guide To Enrolling Online: Ready To Enrol? Enrolment Stepscrescentarian77Noch keine Bewertungen

- 2 Module No. 1 The Field of Engineering ManagementDokument4 Seiten2 Module No. 1 The Field of Engineering ManagementAdrian LequironNoch keine Bewertungen

- MIT5 and MIT10 Spec SheetDokument6 SeitenMIT5 and MIT10 Spec SheetArturo Calvo CNoch keine Bewertungen

- Megger Limited Mit330 en Megohmmeter DatasheetDokument4 SeitenMegger Limited Mit330 en Megohmmeter DatasheetCésar Ricardo Mamani RetamalesNoch keine Bewertungen

- 1st Quarter ICT ReviewerDokument5 Seiten1st Quarter ICT ReviewerazrielgenecruzNoch keine Bewertungen