Beruflich Dokumente

Kultur Dokumente

Lec05-Basic Steam Calculation

Hochgeladen von

Timotius Candra KusumaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lec05-Basic Steam Calculation

Hochgeladen von

Timotius Candra KusumaCopyright:

Verfügbare Formate

Lecture 5

Basic Steam Calculations

Lec05- 1 Utility Systems (2013)

Phase changes Pure substances

T OC

300

Superheated

vapour

100

Saturated

mixture

Compressed

20 liquid

Lec05- 2 Utility Systems (2013)

Property Diagram - Pure

Substances

T

Critical point

374ºC

220 bar

COMPRESSED

LIQUID

REGION

SUPERHEATED

VAPOUR

REGION

SATURATED

LIQUID + VAPOR

REGION

ν

Lec05- 3 Utility Systems (2013)

Idealised Vapour Cycle - Carnot

Cycle

T

● 1-2: Water is heated reversibly and

isothemally in a boiler

● 2-3: mixture is expanded isentropically

in a turbine

● 3-4: mixture condensed reversibly and

isothermally in a condenser

1 2 ● 4-1: mixture compressed isentropically

by compressor to initial state

4 3

Lec05- 4 Utility Systems (2013)

Idealised Vapour Cycle

Carnot Cycle (continued)

T

Impracticalities

● Maximum temperature limited - has to

be below critical point of 374OC (water)

● Isentropic expansion (2-3) achieved by

1 2 well designed turbine. But possibility

of liquid contamination of vapour

● Compression process (4-1) will involve

both liquid and vapour. Difficult to

consistently achieve state 4 and also

4 3

difficulty of designing compressor to

handle liquid/vapour mixture

S

Carnot Cycle difficult to achieve in practice

(not realistic with actual devices)

Lec05- 5 Utility Systems (2013)

Rankine Cycle

Most of the impracticalities of the Carnot Cycle

can be eliminated by superheating the steam

(vapour) in the boiler, and then condensing the

steam completely in the condenser.

Lec05- 6 Utility Systems (2013)

Rankine Cycle

T

● 1-2 Isentropic compression in

pump

● 2-3 Heat addition in boiler

3 (constant P)

qin wturb,out ● 3-4 Isentropic expansion in

turbine

● 4-1 Heat rejection in condenser

2 (constant P)

wpump,in 1

qout 4

Lec05- 7 Utility Systems (2013)

Rankine Cycle

qin

Boiler

3

wturb,out

2 Turbine

wpump,in

Pump 4

qout

Condenser

1

Lec05- 8 Utility Systems (2013)

Rankine Cycle – Energy Analysis

Pump (q = 0) Boiler (w = 0)

wpump,in = h2 - h1 qin = h3 - h2

or

wpump,in = v (P2 - P1)

Turbine (q = 0) Condenser (w = 0)

wturb,out = h3 - h4 qout = h4 - h1

wnet qout

Thermal efficiency (η) = q =1-

in qin

wnet = qin - qout = wturb,out - wpump,in

v = specific volume (kg/m3)

h = specific enthalpy (kJ/kg)

Lec05- 9 Utility Systems (2013)

Rankine Cycle Energy Analysis

Example qin

Boiler

30 bar

3 350°C

wturb,out

2 30 bar

Turbine

0.7 bar

4 qout

Pump

wpump,in

Condenser

1 0.7 bar

0.7 bar

Lec05- 10 Utility Systems (2013)

Example (continued)

T

350 3

1 4

wpump,in

S1 = S2 S3 = S4

S

Lec05- 11 Utility Systems (2013)

Example (continued)

Given a steam power plant operating on the simple Rankine cycle. Steam enters

the turbine at 30 bar and 350°C and is expanded to 0.7 bar. Determine the

efficiency of this cycle.

Assume that the pump and the turbine are isentropic. The steam exits the

condenser and enters the pump as saturated liquid at the condenser pressure.

(Using Steam Tables)

Step 1

Position 1 (sat.liq.): P1 = 0.7bar h1 = 377 kJ/k v 1 = 0.001036 m3/kg

Position 2: P2 = 30bar (s2 = s1)

wpump,in = v (P2 - P1)

= (0.001036) (30*100 - 0.7*100)

= 0.001036 (3000 - 70)

= 3.03 kJ/kg

where 1kJ = 1kPa.m3 then

h2 = h1 + wpump,in

= 377 + 3.03 kJ/kg

= 380.03 kJ/kg

Lec05- 12 Utility Systems (2013)

Example (continued)

Step 2

Position 3: P3 = 30bar h3 = 3117 kJ/kg

T3 = 350OC s3 = 6.744 kJ(kg.K)

Position 4: P4 = 0.7bar (s4 = s3)

s4 - sf

x4 = = 6.744 -1.192 = 0.88 (dryness fraction)

sfg 6.286

h4 = hf + x4hfg (saturated mixture)

= 377 + 0.88(2283) = 2386.04 kJ/kg

(if vapour at exit of turbine then h4 = hg = 2660 kJ/kg)

Lec05- 13 Utility Systems (2013)

Example (continued)

Step 3: Thermal efficiency

qin = h3 - h2 = 3117 - 380.03 = 2736.97 kJ/kg

qout = h4 - h1 = 2386.04 - 377 = 2009.04 kJ/kg

wturb,out = h3 - h4

= 3117 - 2386.04

= 730.96 kJ/kg

wnet = wturb,out - wpump,in = 730.96 - 3.03

= 727.93 kJ/kg

wnet 727.93

Thermal efficiency η = = = 0.27

qin 3117 - 380.03

Lec05- 14 Utility Systems (2013)

Rankine Cycle - Irreversibilities

T

● Pressure drops in boiler, condenser,

and piping

● Heat losses to surroundings

● Non-isentropic compression and

expansion in pump and turbine

3

Isentropic or Adiabatic efficiencies

ws h2s - h1

2a η pump = wa

=

h2a - h1

2s

wa h3 - h4a

1 η turb =

ws

=

4s 4a h3 - h4s

wpump,in a = actual

s = isentropic

S1 = S2 S3 = S4 S

Lec05- 15 Utility Systems (2013)

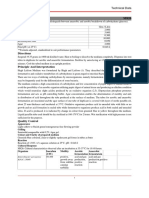

Example 2

A steam power plant operates as shown below. The isentropic efficiency of the turbine is

87%, and of the pump 85%. Determine the thermal efficiency of the cycle and the net

power output of the plant for a mass flow rate of 15 kg/s.

Changes in kinetic and potential energies are assumed to be negligible.

(Now losses in system included)

qin

159 bar 152 bar

35OC 625OC

Boiler

3 4 150 bar

5 600OC

wturb,out

2 160bar

Turbine

h = 0.87

0.1 bar

6

Pump

qout

wpump,in

1 0.095 bar Condenser

44.9OC

Lec05- 16 Utility Systems (2013)

Example 2 (continued)

Step 1

Position 1 (sat.liq.): P1 = 0.095 bar h1 = 188 kJ/kg

υ1 = 0.001010 m3/kg

Position 2: P2 = 160 bar (s2 = s1)

wpump,in = υ (P2 - P1)

= ((0.001010) (160*100- 0.095*100)) / η pump

= (0.001010 (16000 - 9.5)) / η pump

= 16.15 / 0.85 kJ/kg

= 19 kJ/kg

where 1kJ = 1kPa.m3

then

h2 = h1 + wpump,in

= 188 + 19 kJ/kg

= 207 kJ/kg

Lec05- 17 Utility Systems (2013)

Example 2 (continued)

Step 2

Position 5 (turbine inlet): P5 = 150bar h5 = 3581 kJ/kg T5 = 600°C

s5 = 6.677 kJ(kg.K)

Position 6 (turbine outlet): P4 = 0.1bar (s6 = s5)

s6 - s6f 6.677 - 0.649

x6 = = = 0.804 (dryness fraction)

s6fg 7.5

h6s = h6f + x6h6fg

= 192 + 0.804(2392) = 2115.2 kJ/kg

(if vapour at exit of turbine then h6 = hg = 2584 kJ/kg)

Lec05- 18 Utility Systems (2013)

Example 2 (continued)

Step 3: Turbine work output

wturb,out = ηturb (h5 - h6s)

= 0.87 (3581 - 2115.2)

= 1275.25 kJ/kg

Step 4: Boiler heat input

qin = h4 - h3 = (3644 - 147) kJ/kg (Boiler feedwater 35°C sat.liq.)

= 3497 kJ/kg

wnet = wturb,out - wpump,in = 1275.25 - 19 = 1256.25 kJ/kg

wnet 1256.25

Thermal efficiency η = qin = = 0.36

3497

The power produced by the power plant is then

Wnet = m (wnet) = 15 kg/s * 1256 .25kJ/kg = 18844kW

Lec05- 19 Utility Systems (2013)

Increasing efficiency of

Rankine cycle

● Lower the condenser pressure

● Superheat steam to a higher temperature

● Increase the boiler pressure (less heat required to

reach superheat temperature)

Lec05- 20 Utility Systems (2013)

Summary

• Carnot cycle provides ideal (and very approximate) operation

of power system

• Rankine cycle (with superheating of steam and full

condensation of expanded steam) provides more realistic

operation of power system

• Losses in the system should be taken into account

• Pumps, boilers, and turbines do not operate at 100% efficiency

• Limits to increasing efficiency by boiler pressure changes,

superheating of steam, and changing condensing pressure

Lec05- 21 Utility Systems (2013)

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Energy Conversion Technologies & HydrogenDokument18 SeitenEnergy Conversion Technologies & Hydrogenanon-530265100% (1)

- 2007 - Shellac in PolymerDokument43 Seiten2007 - Shellac in PolymerAnonymous x7VY8VF7Noch keine Bewertungen

- Porphyry DepositsDokument43 SeitenPorphyry DepositsVictor Valdivia100% (2)

- Calculation of Liquid Heat Capacity of Petroleum Distillate FuelsDokument3 SeitenCalculation of Liquid Heat Capacity of Petroleum Distillate Fuelsdennise8Noch keine Bewertungen

- ASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsDokument10 SeitenASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsAarón Escorza MistránNoch keine Bewertungen

- Pyro FormulasDokument121 SeitenPyro FormulasMichael Beasley100% (4)

- مستند بلا عنوانDokument4 Seitenمستند بلا عنوانHamzah A. LaftaNoch keine Bewertungen

- HY10 1630US 5 2012-Diaphragm AccumulatorsDokument6 SeitenHY10 1630US 5 2012-Diaphragm AccumulatorsAlejandro GilNoch keine Bewertungen

- Kurva SaprolDokument1 SeiteKurva SaprolTimotius Candra KusumaNoch keine Bewertungen

- Utility Systems: Course IntroductionDokument4 SeitenUtility Systems: Course IntroductionTimotius Candra KusumaNoch keine Bewertungen

- Reynolds Average Navier-Stokes EquationDokument108 SeitenReynolds Average Navier-Stokes EquationTimotius Candra KusumaNoch keine Bewertungen

- Recombinant DnaDokument23 SeitenRecombinant DnaTimotius Candra KusumaNoch keine Bewertungen

- Gasal 1718 (FIX)Dokument3 SeitenGasal 1718 (FIX)Timotius Candra KusumaNoch keine Bewertungen

- Accepted Manuscript: Journal of The Saudi Society of Agricultural SciencesDokument15 SeitenAccepted Manuscript: Journal of The Saudi Society of Agricultural SciencesTimotius Candra KusumaNoch keine Bewertungen

- Formulir Beasiswa YAGI - ITS PDFDokument4 SeitenFormulir Beasiswa YAGI - ITS PDFTimotius Candra KusumaNoch keine Bewertungen

- HiMedia Hugh Leifson Medium M826 Technical DatasheetDokument2 SeitenHiMedia Hugh Leifson Medium M826 Technical DatasheetTimotius Candra KusumaNoch keine Bewertungen

- Performance Test of Palm Fatty Acid Biodiesel On Compression Ignition EngineDokument9 SeitenPerformance Test of Palm Fatty Acid Biodiesel On Compression Ignition EngineTimotius Candra KusumaNoch keine Bewertungen

- Production of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesDokument13 SeitenProduction of X-RAYS Using X-RAY Tube: Journal of Physics: Conference SeriesATWIJUKIRE DICKENSNoch keine Bewertungen

- Admira Fusion - VC-84-002750-GB PDFDokument10 SeitenAdmira Fusion - VC-84-002750-GB PDFkomanjoeNoch keine Bewertungen

- Flange Sealing Guide - EN PDFDokument64 SeitenFlange Sealing Guide - EN PDFAli AlizadehNoch keine Bewertungen

- Petromole F GradesDokument4 SeitenPetromole F GradesmehrsaNoch keine Bewertungen

- Phosphorus Removal On DewateringDokument39 SeitenPhosphorus Removal On DewateringAlberto SemillánNoch keine Bewertungen

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Dokument13 SeitenPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahNoch keine Bewertungen

- Year 9 Study Guide ChemistryDokument15 SeitenYear 9 Study Guide Chemistryreem halawiNoch keine Bewertungen

- B.Tech. - R09 - ECE - Academic Regulations Syllabus PDFDokument186 SeitenB.Tech. - R09 - ECE - Academic Regulations Syllabus PDFnskprasad89Noch keine Bewertungen

- Mixtures and Separations-Lecture#1Dokument15 SeitenMixtures and Separations-Lecture#1victoria0% (1)

- Radio-Analytical TechniquesDokument30 SeitenRadio-Analytical TechniquesMohammad Zamir TaqwaNoch keine Bewertungen

- Lab 12 - Bunsen Burner Flame PDDokument2 SeitenLab 12 - Bunsen Burner Flame PDvictoria kairoo50% (2)

- BHGFGDokument11 SeitenBHGFGbsaimukeshreddy 820Noch keine Bewertungen

- 02 Torque and Socket OptimizeDokument26 Seiten02 Torque and Socket OptimizeANDI SETIAWANNoch keine Bewertungen

- Energy ChangesDokument13 SeitenEnergy ChangesLok Jun HaoNoch keine Bewertungen

- Complex Systems in Finance and EconometricsDokument19 SeitenComplex Systems in Finance and EconometricsJuliana TessariNoch keine Bewertungen

- LOVIBOND Reagents Suited For HachDokument6 SeitenLOVIBOND Reagents Suited For HachKacem BenaoumeurNoch keine Bewertungen

- TSC Lec Plan PCM - JEE MainDokument20 SeitenTSC Lec Plan PCM - JEE MainrajNoch keine Bewertungen

- WSS-M21P36 10-09-2014Dokument4 SeitenWSS-M21P36 10-09-2014Ronald AraujoNoch keine Bewertungen

- 4 BrickDokument31 Seiten4 BrickNardos GebruNoch keine Bewertungen

- Chemistry: NO CHODokument12 SeitenChemistry: NO CHOPrasann KatiyarNoch keine Bewertungen

- EVS UNIT 2 NotesDokument21 SeitenEVS UNIT 2 NotesNivashini VindhyaNoch keine Bewertungen

- Author's Accepted Manuscript: Physica B: Physics of Condensed MatterDokument29 SeitenAuthor's Accepted Manuscript: Physica B: Physics of Condensed MatteryassinebouazziNoch keine Bewertungen