Beruflich Dokumente

Kultur Dokumente

Spandrel Panel

Hochgeladen von

Stefan Jakovljevic0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten1 Seite12

Originaltitel

12

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden12

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten1 SeiteSpandrel Panel

Hochgeladen von

Stefan Jakovljevic12

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

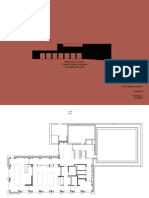

Construction details

1 2 14 Spandrel panel

3.3.12 Fair-face precast concrete

spandrel panel

3.3.13 Prefabricated sheet metal spandrel

panel

3 3.3.14 Precast reconstituted stone spandrel

4

panel

19

21

Vertical sections

8 scale 1:5

12

Three examples of spandrel panels based on

different architectural and constructional

approaches, as well as different materials are

shown here.

Fig. 3.3.12. The primary structure here is rein-

forced concrete. The spandrel panel is made

from a fair-face precast concrete element and

is thermally isolated from the reinforced con-

crete floor slab using insulated starter bars or

stainless steel brackets. The spandrel panel

must be insulated on the inside and a vapour

barrier – protected against damage – attached

to the inner face. Consequently, the heat stor-

age effect of the solid spandrel panel cannot

be used for the internal climate. The surface

1 finish of the spandrel panel is of fair-face qua-

3.3.12 lity. The facade bears on or is suspended from

1 2 14 each floor. Connections are accordingly either

rigid or flexible. Fixing is by means of a facade

rail attached to an insulated aluminium hollow

1 Double glazing

2 Aluminium facade rail

section with thermal break. Its position is

3 Plastic spacer block adjusted by means of steel plates fitted under-

4 Aluminium section,

3

neath, and it is fixed to the spandrel panel

insulated, with thermal using stainless steel bolts. To avoid galvanic

4

break

corrosion, an intermediate pad (e.g. EPDM)

5 Vapour barrier 5

6 Anodised aluminium must be placed between steel and aluminium.

sheet The connections must be permanently elastic

6 13

7 Steel angle as well as impervious to air and vapour diffu-

8 Thermal insulation sion. An alternative, popular solution makes

9 Cavity for ventilation

10 Vapour barrier

use of hollow section rails. Such facades are

11 Sheet aluminium, 20

usually fixed with facade posts.

1.5 mm Fig. 3.3.13. The primary structure here is rein-

12 Floor construction: forced concrete. In this example the facade

textile floor covering

12 post continues past the spandrel panel and the

floating screed 7

isolating membrane facade is free-standing. Load is transferred at

impact sound insulation the top of the spandrel panel via an insulated

13 Cast-in slotted channel aluminium hollow section with thermal break,

14 Window board on 8

steel angle and cast-in slotted channel in the

framing

15 Permanently elastic joint

solid spandrel panel. The upper connection

16 Stainless steel fixed fixes the facade horizontally and must be able

9

anchor to accommodate thermal expansion plus move-

17 Reconstituted stone ments due to wind loads and structural move-

panel

ments; it must also remain impervious to air

18 Stainless steel movable

anchor and vapour diffusion. The facade is fixed to the

19 Steel flat main structure via an insulated steel angle inte-

20 Solid spandrel panel, grated into the facade rail. Insulation is affixed

concrete or masonry to the outside of the spandrel panel. The

21 Precast reinforced

concrete element

vapour barrier must be correctly positioned

and the insulation protected against damp-

10 11 ness. An air gap behind the spandrel panel

3.3.13

188

Das könnte Ihnen auch gefallen

- 3.3 Architectural Details Flat Roof JunctionDokument1 Seite3.3 Architectural Details Flat Roof JunctionStefan JakovljevicNoch keine Bewertungen

- 038 Ajw 150109Dokument1 Seite038 Ajw 150109Soifern K.Noch keine Bewertungen

- WRMM Ll-A'Fhi RM: Indian StandardDokument22 SeitenWRMM Ll-A'Fhi RM: Indian StandardAjit P. SinghNoch keine Bewertungen

- Effect of Studs On The Heat Loss and Insulation Value of A WallDokument4 SeitenEffect of Studs On The Heat Loss and Insulation Value of A WallGreen Action Sustainable Technology GroupNoch keine Bewertungen

- Building Integrated Photovoltaics - p099Dokument1 SeiteBuilding Integrated Photovoltaics - p099arunghandwalNoch keine Bewertungen

- Improvements To Portal Frame Design Using Stressed Skin Action of Sandwich PanelsDokument13 SeitenImprovements To Portal Frame Design Using Stressed Skin Action of Sandwich Panelsmehdi_hoseineeNoch keine Bewertungen

- Component Catalogue For: Building Your Own HomeDokument28 SeitenComponent Catalogue For: Building Your Own HomeBasaraba DragosNoch keine Bewertungen

- Annotated Drawings of Britten Pears ArchiveDokument5 SeitenAnnotated Drawings of Britten Pears ArchiveDavid CaetanoNoch keine Bewertungen

- GTT Mark IIIDokument4 SeitenGTT Mark IIIiuliiulianNoch keine Bewertungen

- SECTION 07 22 00 Roof and Deck InsulationDokument14 SeitenSECTION 07 22 00 Roof and Deck InsulationRachel ButilNoch keine Bewertungen

- Concrete Article April 2010Dokument2 SeitenConcrete Article April 2010Carolina CordeiroNoch keine Bewertungen

- Door and Window FramesDokument27 SeitenDoor and Window FramesTisnaNoch keine Bewertungen

- Doors and FiitingsDokument27 SeitenDoors and FiitingsFello KimNoch keine Bewertungen

- DAI148 - PCANA0819 Rooftop Packaged Unit - LRDokument5 SeitenDAI148 - PCANA0819 Rooftop Packaged Unit - LRInventor SolidworksNoch keine Bewertungen

- Perdida de Calor en CañeriasDokument22 SeitenPerdida de Calor en CañeriasDiego GiovioNoch keine Bewertungen

- CIE 316 GlassDokument11 SeitenCIE 316 GlassinnocentNoch keine Bewertungen

- Tanza Village Park: Church: Outline SpecificationsDokument10 SeitenTanza Village Park: Church: Outline SpecificationsBobby BaybayNoch keine Bewertungen

- SECTION 07 21 13 Thermal InsulationDokument10 SeitenSECTION 07 21 13 Thermal Insulationtaghreed shabanNoch keine Bewertungen

- Flat Fiber-Cement Sheets: Standard Specification ForDokument4 SeitenFlat Fiber-Cement Sheets: Standard Specification ForGanesamoorthy kajavaranNoch keine Bewertungen

- ABB GOM 1ZSE 2750-108 en Rev 5 - Low ResDokument16 SeitenABB GOM 1ZSE 2750-108 en Rev 5 - Low ResDimitar MarkovNoch keine Bewertungen

- Proteção CatódicaDokument5 SeitenProteção CatódicaCarlos SandinoNoch keine Bewertungen

- Thermal Bridges in Wall Construction: TEK 6-13BDokument4 SeitenThermal Bridges in Wall Construction: TEK 6-13BgrahambrasicNoch keine Bewertungen

- Kingspan Kooltherm k108 Brochure en GBDokument13 SeitenKingspan Kooltherm k108 Brochure en GBTayeb KazemiNoch keine Bewertungen

- Cembrit CembonitDokument12 SeitenCembrit CembonitNicky LimNoch keine Bewertungen

- Astm C1516Dokument6 SeitenAstm C1516SilviaMonicaNoch keine Bewertungen

- ABM Panel Installation & Trim Guide: A B Martin A B MartinDokument14 SeitenABM Panel Installation & Trim Guide: A B Martin A B Martingleber_1Noch keine Bewertungen

- LS Classification of Interlaminar Insulation Coatings 8.18.20 08Dokument1 SeiteLS Classification of Interlaminar Insulation Coatings 8.18.20 08Alexis A. Illarramendi G.Noch keine Bewertungen

- SECTION 03 51 16 Gypsum Concrete Roof DecksDokument4 SeitenSECTION 03 51 16 Gypsum Concrete Roof DecksJuanPaoloYbañezNoch keine Bewertungen

- Aluminum Cladding Part 03Dokument7 SeitenAluminum Cladding Part 03Anonymous ELujOV3Noch keine Bewertungen

- KlimallcoDokument8 SeitenKlimallcoshahzad32552372Noch keine Bewertungen

- Ancon Thermal Break BK03Dokument2 SeitenAncon Thermal Break BK03NguyễnTúSơnNoch keine Bewertungen

- Annex E (Table 1, SZ No. (Xii) )Dokument1 SeiteAnnex E (Table 1, SZ No. (Xii) )SvapneshNoch keine Bewertungen

- Cap23 PDFDokument10 SeitenCap23 PDFCamila Ramos100% (1)

- Technical Bulletin TB-34: Steel House FramesDokument4 SeitenTechnical Bulletin TB-34: Steel House FramesRaymond WongNoch keine Bewertungen

- Wang-Salhab2009 Article StructuralBehaviourAndDesignOfDokument11 SeitenWang-Salhab2009 Article StructuralBehaviourAndDesignOfRodyShineNoch keine Bewertungen

- Play Safe With Stiff Interlayers - GPD 2023Dokument3 SeitenPlay Safe With Stiff Interlayers - GPD 2023Louis MoreauNoch keine Bewertungen

- Ennio Mognato - ShortDokument7 SeitenEnnio Mognato - ShortKhurshed Alam IndiaNoch keine Bewertungen

- First Floor Si No Description of Work Unit Qty Vitrified Tile Flooring Unit PriceDokument26 SeitenFirst Floor Si No Description of Work Unit Qty Vitrified Tile Flooring Unit PriceHasan JamalNoch keine Bewertungen

- UntitledDokument3 SeitenUntitledTyler NgNoch keine Bewertungen

- Polyboard PE: Polyethylene Joint Filler BoardDokument2 SeitenPolyboard PE: Polyethylene Joint Filler BoardaahtagoNoch keine Bewertungen

- Untitled 1Dokument1 SeiteUntitled 1JetjonNoch keine Bewertungen

- Vapour Aluminide Coating of Internal CooDokument6 SeitenVapour Aluminide Coating of Internal CooYavuz KeskinNoch keine Bewertungen

- Application of Direct-Applied Exterior Finish Systems: Standard Practice ForDokument6 SeitenApplication of Direct-Applied Exterior Finish Systems: Standard Practice ForKristian EspinozaNoch keine Bewertungen

- Glass Mat Gypsum Panels: Standard Specification ForDokument4 SeitenGlass Mat Gypsum Panels: Standard Specification ForAlejandroNoch keine Bewertungen

- Low 6.5 Ni: Fe C 20 CR 9 MN 0.28NDokument34 SeitenLow 6.5 Ni: Fe C 20 CR 9 MN 0.28NsunsirNoch keine Bewertungen

- 09 28 13 Cement Board CeilingsDokument6 Seiten09 28 13 Cement Board CeilingsWagih NabihNoch keine Bewertungen

- Stanely Induction HeatingDokument4 SeitenStanely Induction HeatingRaja Bharath DonthiNoch keine Bewertungen

- Standard Details For Metal Roofing & Siding: Post Frame and Residential StructuresDokument48 SeitenStandard Details For Metal Roofing & Siding: Post Frame and Residential Structurespierre_oosthuizenNoch keine Bewertungen

- Dynamic Characteristics of A Semi-Rigid Hanging Roof Structure Composed of Glulams and Steel PlateDokument16 SeitenDynamic Characteristics of A Semi-Rigid Hanging Roof Structure Composed of Glulams and Steel PlateLong Hin WongNoch keine Bewertungen

- 15-027 Goudarzi - MA16 PDFDokument15 Seiten15-027 Goudarzi - MA16 PDFMauricio Bustamante HuaquipaNoch keine Bewertungen

- Design of Prestressed Concrete Structures 15cese2005-1 PDFDokument2 SeitenDesign of Prestressed Concrete Structures 15cese2005-1 PDFvineela saiNoch keine Bewertungen

- Melissa Brown: Portfolio 2008 - 2009Dokument6 SeitenMelissa Brown: Portfolio 2008 - 2009MBrown35Noch keine Bewertungen

- Replacing Glaze Burned Insulators: Bureau of Reclamation Facilities Instructions, Standards, & Techniques Volume 3-18Dokument2 SeitenReplacing Glaze Burned Insulators: Bureau of Reclamation Facilities Instructions, Standards, & Techniques Volume 3-18José SánchezNoch keine Bewertungen

- FC PW 6 2015 Double Layer 15mm Gypsum Board Interior Wall PartitionDokument2 SeitenFC PW 6 2015 Double Layer 15mm Gypsum Board Interior Wall PartitionPsiko QuattroNoch keine Bewertungen

- SECTION 03 55 11 Gypsum Concrete Floor DecksDokument5 SeitenSECTION 03 55 11 Gypsum Concrete Floor DecksJuanPaoloYbañezNoch keine Bewertungen

- Construction DetailsDokument56 SeitenConstruction Detailsasingh400Noch keine Bewertungen

- Section 2. Metallic Sandwich Secondary Structure RepairsDokument5 SeitenSection 2. Metallic Sandwich Secondary Structure RepairsrobinyNoch keine Bewertungen

- Drywall Wood Framed Systems SA924Dokument24 SeitenDrywall Wood Framed Systems SA924bo cephusNoch keine Bewertungen

- Chester Jensen Ice BuildersDokument7 SeitenChester Jensen Ice BuildersBenito Antonio Formoso LouroNoch keine Bewertungen

- Facades: M Od U L A R Ho Us eDokument1 SeiteFacades: M Od U L A R Ho Us eStefan JakovljevicNoch keine Bewertungen

- Tsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Dokument1 SeiteTsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Stefan JakovljevicNoch keine Bewertungen

- 022Dokument1 Seite022Stefan JakovljevicNoch keine Bewertungen

- 022 PDFDokument1 Seite022 PDFStefan JakovljevicNoch keine Bewertungen

- Facades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Dokument1 SeiteFacades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Stefan JakovljevicNoch keine Bewertungen

- Facades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Dokument1 SeiteFacades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Stefan JakovljevicNoch keine Bewertungen

- 020Dokument1 Seite020Stefan JakovljevicNoch keine Bewertungen

- 022Dokument1 Seite022Stefan JakovljevicNoch keine Bewertungen

- Timber Construction Systems: Materials - ModulesDokument1 SeiteTimber Construction Systems: Materials - ModulesStefan JakovljevicNoch keine Bewertungen

- Residence and Studio at Gallina Canyon, New Mexico, USA: Built Examples 162Dokument1 SeiteResidence and Studio at Gallina Canyon, New Mexico, USA: Built Examples 162Stefan JakovljevicNoch keine Bewertungen

- 020Dokument1 Seite020Stefan JakovljevicNoch keine Bewertungen

- Chapter ThreeDokument1 SeiteChapter ThreeStefan JakovljevicNoch keine Bewertungen

- 1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Dokument1 Seite1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Stefan JakovljevicNoch keine Bewertungen

- 36.01 Site Plan 1:10000Dokument1 Seite36.01 Site Plan 1:10000Stefan JakovljevicNoch keine Bewertungen

- 04Dokument1 Seite04Stefan JakovljevicNoch keine Bewertungen

- Shape StackDokument1 SeiteShape StackStefan JakovljevicNoch keine Bewertungen

- 05Dokument1 Seite05Stefan JakovljevicNoch keine Bewertungen

- 35 Bennetts Associates Mint Hotel Tower of London City of London, UKDokument1 Seite35 Bennetts Associates Mint Hotel Tower of London City of London, UKStefan JakovljevicNoch keine Bewertungen

- Clamping PlateDokument1 SeiteClamping PlateStefan JakovljevicNoch keine Bewertungen

- 36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumDokument1 Seite36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumStefan JakovljevicNoch keine Bewertungen

- 02Dokument1 Seite02Stefan JakovljevicNoch keine Bewertungen

- 34 Becker Architekten Hydroelectric Power Station Kempten, GermanyDokument1 Seite34 Becker Architekten Hydroelectric Power Station Kempten, GermanyStefan JakovljevicNoch keine Bewertungen

- 02Dokument1 Seite02Stefan JakovljevicNoch keine Bewertungen

- Point Fixing in Drilled HoleDokument1 SeitePoint Fixing in Drilled HoleStefan JakovljevicNoch keine Bewertungen

- Joint at Unsupported EdgeDokument1 SeiteJoint at Unsupported EdgeStefan JakovljevicNoch keine Bewertungen

- Point Fixing Without Penetrating GlassDokument1 SeitePoint Fixing Without Penetrating GlassStefan JakovljevicNoch keine Bewertungen

- Clamp FixingDokument1 SeiteClamp FixingStefan JakovljevicNoch keine Bewertungen

- Profiled GlassDokument1 SeiteProfiled GlassStefan JakovljevicNoch keine Bewertungen

- Silver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDokument3 SeitenSilver Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNoch keine Bewertungen

- Bionic ArchitectureDokument45 SeitenBionic ArchitectureAllaNoch keine Bewertungen

- Astm A1078Dokument5 SeitenAstm A1078mmendez11333% (3)

- Supply Services Code (E)Dokument101 SeitenSupply Services Code (E)kasundp88Noch keine Bewertungen

- Surplus Parts WAU Items2022Dokument19 SeitenSurplus Parts WAU Items2022ray mojicaNoch keine Bewertungen

- ASP Catalogue 2018 WebDokument104 SeitenASP Catalogue 2018 WebRenzo ArangoNoch keine Bewertungen

- Chapter 2:-Reciprocating Pump 2.1: IntroducationDokument7 SeitenChapter 2:-Reciprocating Pump 2.1: IntroducationParth VyasNoch keine Bewertungen

- DENAIR Dry Oil Free PPT (DWW 55-315KW)Dokument15 SeitenDENAIR Dry Oil Free PPT (DWW 55-315KW)GrumetcomNoch keine Bewertungen

- Addis Ababa University School of CommerceDokument55 SeitenAddis Ababa University School of CommerceAbdilbasit HamidNoch keine Bewertungen

- Test Summary: Number ReleasedDokument3 SeitenTest Summary: Number ReleasedPaloma GarcíaNoch keine Bewertungen

- The Construction of Super High-Rise Composite Structures in Hong KongDokument98 SeitenThe Construction of Super High-Rise Composite Structures in Hong KongJevgenijs Kolupajevs100% (2)

- RD - PROTECTION WORKDokument34 SeitenRD - PROTECTION WORKMuthusamy ArumugamNoch keine Bewertungen

- 01 E4 - Auxilary Layout - Don Henricos - Second Floor Copy-Second Floor LevelDokument1 Seite01 E4 - Auxilary Layout - Don Henricos - Second Floor Copy-Second Floor LevelJean Cornelia DelubioNoch keine Bewertungen

- Fencing PermitDokument2 SeitenFencing PermitBernard BragaNoch keine Bewertungen

- Grounding GuidelinesDokument22 SeitenGrounding GuidelinesdraganbabicNoch keine Bewertungen

- Aqautherm Parts Guide PDFDokument57 SeitenAqautherm Parts Guide PDFmech_sahilNoch keine Bewertungen

- Chapter 13 Bridge Load Rating: WSDOT Bridge Design Manual M 23-50.20 Page 13-I September 2020Dokument26 SeitenChapter 13 Bridge Load Rating: WSDOT Bridge Design Manual M 23-50.20 Page 13-I September 2020HermanRomanNoch keine Bewertungen

- New NRLDDokument203 SeitenNew NRLDnlnmurthy28Noch keine Bewertungen

- Aimsite Display Printing Cost - 10.02.2023Dokument8 SeitenAimsite Display Printing Cost - 10.02.2023sayli pNoch keine Bewertungen

- Progressive Collapse Basics: R. Shankar NairDokument11 SeitenProgressive Collapse Basics: R. Shankar NairMr PolashNoch keine Bewertungen

- PDFDokument7 SeitenPDFZeeshanNoch keine Bewertungen

- Mirel Bakessov CVDokument3 SeitenMirel Bakessov CVMirelNoch keine Bewertungen

- Astm C216-10 (Bricks) PDFDokument13 SeitenAstm C216-10 (Bricks) PDFVasa100% (1)

- Catalog Custom Pergolas ChadsworthDokument44 SeitenCatalog Custom Pergolas ChadsworthEugen IliesiuNoch keine Bewertungen

- Intership ReportDokument20 SeitenIntership ReportAnchappu ansi67% (9)

- Rubber TireDokument5 SeitenRubber TireRajveer FandanNoch keine Bewertungen

- Giacomini - Modelo R850 Y R910 - Valvula EsfericaDokument14 SeitenGiacomini - Modelo R850 Y R910 - Valvula EsfericaDiego Francisco Ancajima CuevaNoch keine Bewertungen

- Work Method Statement - GYPSUM FALSE CEILINGDokument3 SeitenWork Method Statement - GYPSUM FALSE CEILINGSathish GowdaNoch keine Bewertungen

- Section 05120 Structural SteelDokument9 SeitenSection 05120 Structural SteelMØhãmmed ØwięsNoch keine Bewertungen

- Cable Current Carrying CapacitiesDokument3 SeitenCable Current Carrying CapacitiesZdravko OstrogonacNoch keine Bewertungen