Beruflich Dokumente

Kultur Dokumente

290147

Hochgeladen von

kannanmech87Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

290147

Hochgeladen von

kannanmech87Copyright:

Verfügbare Formate

Determination of coefficient

of friction from oscillations

under Coulomb friction

damping

R. VENKATACHALAM*, Professor of Mechanical Engineering,

Regional Engineering College, Warangal - 506 004, India.

〈chalamrv@yahoo.com〉

Received 6th January 2000

The oscillations of a vibrating system in the presence of Coulomb friction damping is well

known. In this paper, an attempt is made to use this concept, to measure the coefficient of

friction. For this purpose, a simple pendulum, whose hinge is not free from Coulomb

friction, is considered. An experimental set-up is designed and fabricated. Experiments are

performed with different materials and the coefficients of friction are determined. Satisfac-

tory results are obtained. The work described here may be incorporated as a laboratory

experiment in applied mechanics.

Key words: friction, damping, pendulum, free oscillations

1. NOMENCLATURE

L length of the pendulum

T, T1, T2 tensions

W1–2 work done between positions 1 and 2

d diameter of the rod, which is acting as a hinge for the pendulum

h1, h2 heights of the bob above the datum

m mass of the bob

∆KE and ∆PE change in kinetic and potential energies, respectively

α semi groove angle of a grooved pulley

β angle of wrap on a pulley

µ coefficient of friction

θ angular displacement of the pendulum measured from the vertical passing

through the hinge

*

Currently, on a temporary assignment, Associate Professor of Mechanical Engineering, Faculty of

Engineering, Garyounis University, P.O. Box 1308, Benghazi, Libya.

International Journal of Mechanical Engineering Education Vol 29 No 2

148 R. Venkatachalam

2. INTRODUCTION

In many engineering applications, friction is one of the important design criteria. There are

many situations in which the designer intends to reduce the friction; for instance, hinges,

sliding contact bearings, gears in mesh, etc. There are also occasions where the designer

intends to introduce friction, as in the case of rolling of objects, clutches, and brakes, etc.

The coefficient of friction is an important parameter in the mechanical engineering de-

signs whenever the application involves rubbing of surfaces. The coefficient of friction may

be determined directly by observing the amount of force required to move an object of

known weight, on a horizontal surface. It may also be determined, by measuring the mini-

mum angle of inclination at which the object slides on an inclined plane. Practical difficul-

ties are involved in these methods, owing to the fact that the kinetic coefficient of friction is

less than the static coefficient of friction.

The coefficient of friction may be determined by rotating one friction surface over

another under a known load and measuring the amount of torque required to rotate the

surface. Pal and Basu [1] used a method in which a normal force was applied through a small

friction surface resting on a horizontal rotating friction surface, by means of a cantilever

beam which had stiffness only in the horizontal plane. The bending of the beam in the

horizontal plane was caused by the friction force. The bending deflection of the beam was

measured, from which the friction force was estimated and thereby the coefficient of friction

was calculated.

Venkatachalam and Sitharamarao [2] proposed a method for determining the kinetic

coefficient of friction by generating self excited oscillations. The method involved

measuring the kinetic coefficient of friction from the period of oscillations of a beam kept on

two rotating discs. This method was further extended to measure the coefficient of friction

between two test surfaces, with respect to a standard pair of friction surfaces whose coeffi-

cient of friction was known. The pair of test surfaces was kept at one disc and the standard

pair of friction surfaces was kept at the other disc. With this arrangement, it was found

possible to measure the coefficient of friction from the amplitude of oscillations, instead of

the time period of oscillations. Venkatachalam and Sitharamarao [3] further suggested

another simple technique through which both the static and kinetic coefficients of friction

could be measured. This method involved observing the stick slip motion of a body kept on a

moving surface. The experimental measurements were only displacements and did not in-

volve any time measurements. This made the method more attractive.

In this paper an attempt is made to measure the kinetic coefficient of friction by observ-

ing the oscillations of a simple pendulum to which the friction is introduced at the hinge.

3. DESCRIPTION OF THE MODEL

Fig. 1 shows a schematic arrangement of the model considered. It consists of a fixed round

circular rod to act as a hinge. A wire bent in the for of a U is placed over the rod. The free

ends of the bent wire are fastened to a plate too which the pendulum wire is attached. The

bent wire, the plate, the pendulum wire and the bob together form the simple pendulum.

When it is oscillating, the U shaped wire rubs against the surface of the rod and experiences

the friction which tries to dampen the oscillations. The mass of the wires and the plate are

very small in comparison to the mass of the bob and hence the former is neglected in the

analysis to follow.

International Journal of Mechanical Engineering Education Vol 29 No 2

Oscillations under Coulomb friction damping 149

Fig. 1. Schematic arrangement of the model.

4. MATHEMATICAL DEVELOPMENT

If the hinge is frictionless and there are no other losses, then the pendulum exhibits simple

harmonic motion, the amplitude of oscillations remaining constant forever [4], as shown in

Fig. 2(a). But if there are losses, the amplitude θ1 on one side of oscillation reduces to θ2 on

the other side of the oscillation as shown in Fig. 2(b). In the model considered, the friction at

the hinge is dominating all the other losses such as the one that may arise due to the air drag.

Hence, the effect of friction alone is considered, neglecting all other losses.

International Journal of Mechanical Engineering Education Vol 29 No 2

150 R. Venkatachalam

(a) (b)

Fig. 2. Oscillations of the pendulum. (a) When there are no losses; (b) when losses exist.

In the analysis, the attention is focused on the decrease of the amplitude of oscillation

from θ1 to θ2. For this, the principle of work energy [5]

∆KE = ∆PE + W1–2 (1)

is applied between the positions 1 and 2 as shown in Fig. 3. Substituting

∆KE = 0 (2a)

∆PE = mg(h1 − h2 ) (2b)

and

W1− 2 = ( d 2) (T1 − T2 ) (θ1 + θ 2 ) (2c)

in equation (1), the work energy relation may be obtained as

0 = mg(h1 − h2 ) + ( d 2) (T1 − T2 ) (θ1 + θ 2 ) (3)

where T1 and T2 are the tensions in the bent wire, which are different because of the friction

between the wire and the rod.

For small oscillations, the heights from the datum

hi = L(1 − cosθ i ), i = 1, 2 (4)

may be approximated as

hi ≈ ( L 2)θ i2 , i = 1, 2 (5)

and the tensions T1 and T2 may be approximated as

T1 + T2 = T ≈ mg (6)

where T is the tension in the pendulum wire.

International Journal of Mechanical Engineering Education Vol 29 No 2

Oscillations under Coulomb friction damping 151

Fig. 3. Application of the work–energy principle.

Using equation (5) in equation (3), the decrease in the amplitude of oscillations may be

expressed as

∆θ = ( d L ) (T1 − T2 ) mg (7)

where

∆θ = θ1 − θ 2 (8)

The tensions T1 and T2 may be related as

T1 T2 = e µβ (9)

where µ is the coefficient of friction between the rod and the wire, and β is the angle of

contact of the wire on the rod, which may be taken as π in the present case.

Using equations (6) and (9) in equation (7), the decrease ∆θ may be re-expressed as

∆θ = ( d L ) (e µβ − 1) (e µβ + 1) (10)

Equation (10) gives the reduction in the amplitude in the half-cycle of oscillation. It also

shows that this reduction is constant. Therefore, the reduction in amplitude in one complete

oscillation will be 2∆θ, and in two oscillations will be 4∆θ, and so on, as illustrated in Fig. 4.

International Journal of Mechanical Engineering Education Vol 29 No 2

152 R. Venkatachalam

This idea of introducing Coulomb friction at the hinge of a simple pendulum to dampen the

oscillations is taken from reference [6].

Fig. 4. Oscillations of the pendulum under Coulomb friction damping.

5. EXPERIMENTATION

Equation (10) may be rewritten for convenience as

µβ = ln (1 + Z ) − ln (1 − Z ) (11)

where

Z = ∆θ ( L d ) (12)

In an experiment, if ∆θ could be measured, then by using equation (11) the coefficient of

friction µ may be calculated. However, if L∆θ ⭓ d, which refers to Z ⭓ 1, equation (11)

does not give any value for µ. This is because, the development of equation (10) is based on

the application of the work energy, equation (1), with an assumption that the pendulum

moves to the other side of the vertical static equilibrium position by an amount θ2 as shown

in Fig. 3.

A simple pendulum is constructed as shown in Fig. 1. A mild steel rod of diameter

d = 18 mm, is used to serve as a hinge. A groove is made on this rod in order to prevent the

slipping of the wire on the rod. The length of the pendulum L is chosen as 1 m. A mass of

1 kg is used for the bob. Provision is made to change the U shaped wire which sits on the

circular rod. With this arrangement, experiments may be performed with different materials.

International Journal of Mechanical Engineering Education Vol 29 No 2

Oscillations under Coulomb friction damping 153

The pendulum bob may be pulled to one side by an angle θ1 and released, allowing the

pendulum to swing to an angle θ2 on the other side. With these values of θ1 and θ2, the

coefficient of friction µ may be calculated using equation (11). However, in order to reduce

the experimental errors, the amplitude may be measured after two complete oscillations; that

is, θ1 and θ5 shown in Fig. 4 may be measured. As shown in Fig. 1, a circular scale is

provided near the bob. From the arc lengths recorded on this scale, the angular displacements

may be calculated with less errors.

6. RESULTS AND DISCUSSION

Experiments are performed with different wires and the coefficients of friction are calcu-

lated. One typical experimental observation is presented in Table 1.

Table 1. A typical experimental observation

Trials θ1 θ5 (θ1 – θ5) ∆θ = (θ1 – θ5)兾4

(degrees) (degrees) (degrees) (degrees)

1 30 28.0 2.0 0.50

2 20 17.9 2.1 0.52

3 10 8.0 2.0 0.50

It may be noticed that the value of ∆θ turned out to be same irrespective of the value of θ1.

The same trend has been observed in other experiments in which the wires of different

materials are tried. Table 2 presents the results of the other experiments.

Table 2. Results of the experiments with

different wires

Sample ∆θ 0 µ

Copper wire 0.6 0.42

Aluminium wire 0.5 0.34

Steel wire 0.45 0.30

Nylon wire 0.4 0.26

The values of the coefficients of friction obtained for different materials, presented in Table

2, appear to be more than the values available in the design data books. This may perhaps be

due to the groove made on the rod in which the wire slides. The effective coefficient of

friction, when a circular wire is in a grooved member is

µ effective = µ sin α (13)

where, α is the semi-groove angle. The coefficients of friction calculated with the present

experimental set-up must have already taken into account the effect of the groove angle.

International Journal of Mechanical Engineering Education Vol 29 No 2

154 R. Venkatachalam

7. CONCLUDING REMARKS

The significant conclusions that may be drawn on the basis of the present work may be

summarized as follows.

(i) An experimental method of determining the coefficient of friction is proposed.

(ii) The experimental set-up is very simple in construction, and the experimental observa-

tions are also very simple.

(iii) Experiments are performed with different materials and the coefficients of friction are

calculated.

(iv) The decrease in amplitude of oscillation is found to be constant, as predicted by the

mathematical analysis.

(v) The proposed method may be very useful in obtaining the coefficient of friction

between belt/rope and plane/grooved pulleys.

(vi) The experiments may be performed with different angles of wrap β.

(vii) The work presented in this paper involves the mathematical solutions of a physical

problem followed by experimental investigations. The work can be incorporated as a

laboratory experiment with a view to illustrating a simple principle mathematically

and experimentally.

ACKNOWLEDGEMENT

The author wishes to acknowledge the Department of Mechanical Engineering, Garyounis

University, Benghazi, Libya, for providing various facilities to carry out the work.

REFERENCES

[1] Pal, D. K. and Basu, S. K., ‘Hydrostatic lubrication of plastic guides’, Proceedings of Third All

India Machine Tool Design and Research Conference, The Indian Institute of Technology, Bombay,

India (1969).

[2] Venkatachalam, R. and Sitharamarao, T. L., ‘Determination of coefficient of friction by generating

self excited motion’, International Journal of Mechanical Engineering Education, 14(1), 23–30,

1986.

[3] Venkatachalam, R. and Sitharamarao, T. L., ‘Determination of static and kinetic coefficients of

friction by generating stick slip motion’, International Journal of Applied Engineering Education,

3(2), 131–137, (1987).

[4] Beer, F. P. and Johnson Jr., E. R., Vector Mechanics for Engineers—Dynamics, McGraw Hill Book

Company, New York, pp. 946–948, 1990.

[5] Meriam, J. L. and Kraige, L. G., Engineering Mechanics, Volume 2–Dynamics, 3rd edn. John Wiley

and Sons Inc., New York, pp. 460–465.

[6] Steidel Jr., R. F., An Introduction to Mechanical Vibrations, 3rd edn., John Wiley & Sons Inc., New

York, p. 194.

International Journal of Mechanical Engineering Education Vol 29 No 2

Das könnte Ihnen auch gefallen

- Valla DuraiDokument2 SeitenValla Duraikannanmech87Noch keine Bewertungen

- Recruitment of Sales Executives TLs ASM Processing Staff BFSLDokument6 SeitenRecruitment of Sales Executives TLs ASM Processing Staff BFSLTopRankersNoch keine Bewertungen

- Alternative Fuels & Bio - FuelsDokument8 SeitenAlternative Fuels & Bio - Fuelskannanmech87Noch keine Bewertungen

- AutoCAD 2013Dokument264 SeitenAutoCAD 2013panosscribd100% (1)

- Nano TechnologyDokument10 SeitenNano Technologykannanmech87100% (1)

- Sel CV I Ae Agri 2k17 ListDokument2 SeitenSel CV I Ae Agri 2k17 Listkannanmech87Noch keine Bewertungen

- NEW507179சூலை 2012 மாத இதழ்Dokument26 SeitenNEW507179சூலை 2012 மாத இதழ்David MayNoch keine Bewertungen

- KSR Institute For Engineering and Technology Department of Mechanical Engineering Mentoring Data SheetDokument2 SeitenKSR Institute For Engineering and Technology Department of Mechanical Engineering Mentoring Data Sheetkannanmech87Noch keine Bewertungen

- Course Objectives & Outcomes Undergraduate Program in Mechanical Engineering (ME) School of Engineering, College of Science & EngineeringDokument1 SeiteCourse Objectives & Outcomes Undergraduate Program in Mechanical Engineering (ME) School of Engineering, College of Science & Engineeringkannanmech87Noch keine Bewertungen

- Dept May2011gfDokument506 SeitenDept May2011gfkannanmech87Noch keine Bewertungen

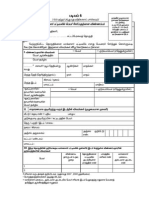

- பட்டா மாற்றத்திற்கான விண்ணப்படிவம்Dokument3 Seitenபட்டா மாற்றத்திற்கான விண்ணப்படிவம்Bakrudeen Ali AhamedNoch keine Bewertungen

- Dom QBDokument8 SeitenDom QBkannanmech87Noch keine Bewertungen

- TNPSC GKDokument415 SeitenTNPSC GKkannanmech87100% (2)

- இருப்பிட சான்றிதழுக்கான விண்ணப்பபடிவம்Dokument1 Seiteஇருப்பிட சான்றிதழுக்கான விண்ணப்பபடிவம்Bakrudeen Ali Ahamed0% (1)

- Fiscal Responsibility ActDokument9 SeitenFiscal Responsibility Actkannanmech87Noch keine Bewertungen

- குடும்ப அட்டை பெறுவதற்கான விண்ணப்ப படிவம்Dokument2 Seitenகுடும்ப அட்டை பெறுவதற்கான விண்ணப்ப படிவம்Bakrudeen Ali AhamedNoch keine Bewertungen

- Form 8 AtamilDokument3 SeitenForm 8 AtamilVijayabaskaran SundhareshwarNoch keine Bewertungen

- ST Forest Dwellers Act 2006 T 0Dokument3 SeitenST Forest Dwellers Act 2006 T 0kannanmech87Noch keine Bewertungen

- TNPSC Group 4 Model Question Paper 2Dokument20 SeitenTNPSC Group 4 Model Question Paper 2training2jobs100% (1)

- Model TestDokument21 SeitenModel Testanand_dec84Noch keine Bewertungen

- TNPSC Group 2 Model Question and AnswerDokument20 SeitenTNPSC Group 2 Model Question and Answeruit@Noch keine Bewertungen

- Answer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)Dokument1 SeiteAnswer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)kannanmech87Noch keine Bewertungen

- Answer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)Dokument1 SeiteAnswer All The Questions (9X2 18 Marks) Answer All The Questions (9X2 18 Marks)kannanmech87Noch keine Bewertungen

- TNPSC Model TamilDokument22 SeitenTNPSC Model Tamilபிரகாஷ் பாரிNoch keine Bewertungen

- Form 6 TamilDokument7 SeitenForm 6 Tamilapi-276452640Noch keine Bewertungen

- PhysResInt 10 341016Dokument10 SeitenPhysResInt 10 341016kannanmech87Noch keine Bewertungen

- RBI & IMF CompensationDokument3 SeitenRBI & IMF Compensationkannanmech87Noch keine Bewertungen

- Validation of A Vapour Compression Refrigeration System Design ModelDokument7 SeitenValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87Noch keine Bewertungen

- Jarme 3 1 2010Dokument8 SeitenJarme 3 1 2010kannanmech87Noch keine Bewertungen

- Validation of A Vapour Compression Refrigeration System Design ModelDokument7 SeitenValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- (Isaac Asimov) How Did We Find Out About AntarcticDokument24 Seiten(Isaac Asimov) How Did We Find Out About AntarcticDrBabu PSNoch keine Bewertungen

- Barrett Beyond Psychometrics 2003 AugmentedDokument34 SeitenBarrett Beyond Psychometrics 2003 AugmentedRoy Umaña CarrilloNoch keine Bewertungen

- A Literary Nightmare, by Mark Twain (1876)Dokument5 SeitenA Literary Nightmare, by Mark Twain (1876)skanzeniNoch keine Bewertungen

- RN42Dokument26 SeitenRN42tenminute1000Noch keine Bewertungen

- International Freight 01Dokument5 SeitenInternational Freight 01mature.ones1043Noch keine Bewertungen

- Zimbabwe - Medical - CPIN - v2.0 - GOV - UKDokument39 SeitenZimbabwe - Medical - CPIN - v2.0 - GOV - UKsammy redganjiNoch keine Bewertungen

- Benedict Anderson, Imagined CommunitiesDokument2 SeitenBenedict Anderson, Imagined CommunitiesMonir Amine0% (1)

- Riqas Ri RQ9142 11aDokument6 SeitenRiqas Ri RQ9142 11aGrescia Ramos VegaNoch keine Bewertungen

- Sap New GL: Document Splitting - Configuration: ChooseDokument3 SeitenSap New GL: Document Splitting - Configuration: ChooseChandra Sekhar PNoch keine Bewertungen

- At The Origins of Music AnalysisDokument228 SeitenAt The Origins of Music Analysismmmahod100% (1)

- PetrifiedDokument13 SeitenPetrifiedMarta GortNoch keine Bewertungen

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDokument10 SeitenAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiNoch keine Bewertungen

- Bioinformatics Computing II: MotivationDokument7 SeitenBioinformatics Computing II: MotivationTasmia SaleemNoch keine Bewertungen

- GCP Vol 2 PDF (2022 Edition)Dokument548 SeitenGCP Vol 2 PDF (2022 Edition)Sergio AlvaradoNoch keine Bewertungen

- Exponential Smoothing - The State of The ArtDokument28 SeitenExponential Smoothing - The State of The ArtproluvieslacusNoch keine Bewertungen

- Cipet Bhubaneswar Skill Development CoursesDokument1 SeiteCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiNoch keine Bewertungen

- CUBE Dealer Book 2009Dokument280 SeitenCUBE Dealer Book 2009maikruetzNoch keine Bewertungen

- Algorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzDokument6 SeitenAlgorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzGONGNoch keine Bewertungen

- Nfpa 1126 PDFDokument24 SeitenNfpa 1126 PDFL LNoch keine Bewertungen

- ET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsDokument5 SeitenET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsMichael LeungNoch keine Bewertungen

- Internship Format HRMI620Dokument4 SeitenInternship Format HRMI620nimra tariqNoch keine Bewertungen

- Refutation EssayDokument6 SeitenRefutation Essayapi-314826327Noch keine Bewertungen

- Data Network Unit 6 - UCDokument15 SeitenData Network Unit 6 - UCANISHA DONDENoch keine Bewertungen

- 35 Electrical Safety SamanDokument32 Seiten35 Electrical Safety SamanSaman Sri Ananda RajapaksaNoch keine Bewertungen

- Lesson 1: Composition: Parts of An EggDokument22 SeitenLesson 1: Composition: Parts of An Eggjohn michael pagalaNoch keine Bewertungen

- Unbound DNS Server Tutorial at CalomelDokument25 SeitenUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreNoch keine Bewertungen

- Camless EnginesDokument4 SeitenCamless EnginesKavya M BhatNoch keine Bewertungen

- Aribah Ahmed CertificateDokument2 SeitenAribah Ahmed CertificateBahadur AliNoch keine Bewertungen

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDokument2 SeitenFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoNoch keine Bewertungen

- Vygotsky EssayDokument3 SeitenVygotsky Essayapi-526165635Noch keine Bewertungen