Beruflich Dokumente

Kultur Dokumente

Teroson RB r2000 Hs

Hochgeladen von

Yosua Dimas Agus Sriyanto0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

138 Ansichten2 Seitenundercoating

Originaltitel

Teroson Rb r2000 Hs

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenundercoating

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

138 Ansichten2 SeitenTeroson RB r2000 Hs

Hochgeladen von

Yosua Dimas Agus Sriyantoundercoating

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Technical Data Sheet

TEROSON RB R2000 HS

July-2013

PRODUCT DESCRIPTION Layer thickness wet 1 mm

Skin formation time 2 to 4 hrs

TEROSON RB R2000 HS provides the following Curing through 24 to 48 hrs

characteristics: Abrasion resistance very high

Application temperature 10 to 25 °C

Technology Highly Abrasion Resistant Coating In service temperature -25 to 80 °C

Material for Underbody Coating, Road short exposure (up to 1h) 100 °C

Stone Anti-Chip, Sound Damping

Base Rubber / Resins

TEROSON RB R2000 HS is a solvent containing coating PRELIMINARY STATEMENT

material, free of bitumen, based on rubber/resins. After Prior to application it is necessary to read the Safety Data

complete drying, the coating exhibits a permanently elastic Sheet for information about precautionary measures and

corrosion protection with good aging characteristics and no safety recommendations. Also, for chemical products exempt

cracking at low temperatures, due to its combination of raw from compulsory labeling, the relevant precautions should

materials. The dry film adheres well to cleaned underbodies, always be observed.

also to painted surfaces and exhibits a very high abrasion-

resistance.

Painting with standard automotive paints (conventional and Pretreatment

water based) is possible under the Surfaces to be treated with TEROSON RB R2000 HS have to

following conditions: be cleaned well and rust must be removed. The areas must

- allow minimum 16 hours drying of the coating be dry and free of grease, dirt and to a great extent free of

- apply a fine paint mist prior to final painting dust. Areas not to be coated should be covered with masking

- final painting only after beginning of drying of the paper. In the case of new vehicles, protective wax must be

pre-paintingsubsequent oven drying at 60°C possible. steam-cleaned. If applied to older vehicles, watch out for

beginning of rust formation, which has to be removed with a

wire brush.

APPLICATION AREAS

TEROSON RB R2000 HS is suitable for repair work on the Application

underbody, wheel house, front and rear aprons, spoilers, door TEROSON RB R2000 HS is applied with the Teroson

sills, particularly as protection against road stones. The UBC-Gun from 1-l-cans; application pressure: 4 - 5 bar.

material is used as coating for painted parts or primer Shake the can well up side down for 1 minute before use.

surfaced metals on the underbody and for repair works on Opened containers must not be left open because the

coatings which are based on rubber/resins. TEROSON material will form a skin. On vertical surfaces, the underbody

RB R2000 HS is also suitable for sound damping of wheel coating can be applied in one step up to 1 mm layer thickness

houses and side walls, and for covering and sealing of repair (wet film). In order to avoid bare patches, the material should

jobs, welding seams and overlaps. be sprayed in criss-cross fashion. Under favourable weather

conditions, the vehicle is ready for use 2 - 4 hours after

application. For final drying 24 - 48 hours are necessary.

TECHNICAL DATA

(Typical Test Results)

Important

Do not spray on joints, engine, drive, cardan shaft, exhaust,

Colour black , grey, white catalyst and brake system. After use blow through Teroson-

Odour of petroleum spirit UBC Pistol and then purge with Teroson FL.

Consistency thick liquid Clogging of the pistol may cause the tin to burst.

Density approx. 1.22 g/cm³ Read instruction leaflet of the pistol!

Solids approx. 64 %

Sag resitance good

TEROSON RB R2000 HS Revision 1 Page 1 of 2

Technical Data Sheet

TEROSON RB R2000 HS

July-2013

Finishing Treatment warranties of merchantability or fitness for a particular purpose, arising

from sale or use of Henkel Corporation’s products. Henkel Corporation

Remove excess spray immediately with benzine or Teroson specifically disclaims any liability for consequential or incidental

FL. damages of any kind, including lost profits. The discussion herein of various

processes or compositions is not to be interpreted as representation that they

are free from domination of patents owned by others or as a license under any

Henkel Corporation patents that may cover such processes or compositions.

STORAGE We recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one

or more United States or foreign patents or patent applications.

Frost sensitive no

Recommended 10 to 25 °C Trademark usage

storage temperature Except as otherwise noted, all trademarks in this document are trademarks of

Shelf life 18 months in original packaging Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

registered in the U.S. Patent and Trademark Office.

Disclaimer Henkel AG & Co. KGaA

Note: D-40191 Düsseldorf. Germany

The information provided in this Technical Data Sheet (TDS) including the Phone: +49-211-797-0

recommendations for use and application of the product are based on our www.henkel.com

knowledge and experience of the product as at the date of this TDS. The

product can have a variety of different applications as well as differing Henkel Central Eastern Europe GmbH

application and working conditions in your environment that are beyond our

control. Henkel is, therefore, not liable for the suitability of our product for the

A-1030 Wien. Austria

production processes and conditions in respect of which you use them, as well Phone: +43-1711-040

as the intended applications and results. We strongly recommend that you www.henkel.com

carry out your own prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any Henkel & Cie AG

other written or oral recommendation(s) regarding the concerned product is CH-4133 Pratteln. Switzerland

excluded, except if otherwise explicitly agreed and except in relation to death or

personal injury caused by our negligence and any liability under any applicable

Phone: +41-61-825-7000

mandatory product liability law. www.henkel.com

In case products are delivered by Henkel Belgium NV, Henkel Electronic

Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

Henkel France SA please additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal ground,

Henkel’s liability will in no event exceed the amount of the concerned delivery.

In case products are delivered by Henkel Colombiana, S.A.S. the

following disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. Henkel is,

therefore, not liable for the suitability of our product for the production

processes and conditions in respect of which you use them, as well as the

intended applications and results. We strongly recommend that you carry out

your own prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any

other written or oral recommendation(s) regarding the concerned product is

excluded, except if otherwise explicitly agreed and except in relation to death or

personal injury caused by our negligence and any liability under any applicable

mandatory product liability law.

In case products are delivered by Henkel Corporation, Resin Technology

Group, Inc., or Henkel Canada Corporation, the following disclaimer is

applicable:

The data contained herein are furnished for information only and are believed

to be reliable. We cannot assume responsibility for the results obtained by

others over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods

mentioned herein and to adopt such precautions as may be advisable for the

protection of property and of persons against any hazards that may be involved

in the handling and use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied, including

TEROSON RB R2000 HS Revision 1 Page 2 of 2

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- GMW14671 - Organic Coating UnderbodyDokument4 SeitenGMW14671 - Organic Coating UnderbodyYosua Dimas Agus SriyantoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Volvo EC160Dokument25 SeitenVolvo EC160superbludnik100% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- BrosurAllProduct 2018 ENGDokument1 SeiteBrosurAllProduct 2018 ENGYosua Dimas Agus SriyantoNoch keine Bewertungen

- Organic Coat GMW 14670 PDFDokument4 SeitenOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNoch keine Bewertungen

- UndercoatDokument2 SeitenUndercoatYosua Dimas Agus SriyantoNoch keine Bewertungen

- 8 Seater at PDFDokument1 Seite8 Seater at PDFYosua Dimas Agus SriyantoNoch keine Bewertungen

- Cyclic Corrosion Test - GMW14872 PDFDokument21 SeitenCyclic Corrosion Test - GMW14872 PDFYosua Dimas Agus SriyantoNoch keine Bewertungen

- Colby - Sapac BrochureDokument16 SeitenColby - Sapac Brochureshogun billings100% (1)

- First Part Lab ManualDokument6 SeitenFirst Part Lab ManualInfo EsocketNoch keine Bewertungen

- LNG Ships: by F. R. ChowdhuryDokument6 SeitenLNG Ships: by F. R. ChowdhuryThusitha DalpathaduNoch keine Bewertungen

- NPSH - Net Positive Suction HeadDokument5 SeitenNPSH - Net Positive Suction HeadSutrisno KlsNoch keine Bewertungen

- ST101 Kiln Over-Temperature TripDokument2 SeitenST101 Kiln Over-Temperature TripDave WalkerNoch keine Bewertungen

- 2013 Marine Air PricebookDokument111 Seiten2013 Marine Air Pricebooknwmarineair2869Noch keine Bewertungen

- CO2 Arc Welding ProcessDokument4 SeitenCO2 Arc Welding ProcessHari krishnan100% (1)

- Split Tensile Strength of ConcreteDokument9 SeitenSplit Tensile Strength of Concreteabhineet srivastavaNoch keine Bewertungen

- Material Selection Guide - MILD STEELDokument1 SeiteMaterial Selection Guide - MILD STEELlouis donyNoch keine Bewertungen

- The effect of temperature on the rate of a catalyzed reactionDokument5 SeitenThe effect of temperature on the rate of a catalyzed reactionRabia RafiqueNoch keine Bewertungen

- 2 PerformanceofflowingwellsDokument16 Seiten2 PerformanceofflowingwellsnciriNoch keine Bewertungen

- 07 - Balancing Redox in Acid or BasicDokument5 Seiten07 - Balancing Redox in Acid or BasicSupriyanto Bin PraptoutomoNoch keine Bewertungen

- Standard Specification For GB 700Dokument12 SeitenStandard Specification For GB 700Ma'arif Nuzul AddibNoch keine Bewertungen

- Sedimentation and Sedimentation TanksDokument43 SeitenSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Xypec Catalog B UVC A MS 9106 R0 DraftDokument94 SeitenXypec Catalog B UVC A MS 9106 R0 DraftJusron MasjhudaNoch keine Bewertungen

- prEN 15229 hEN Manholes & Chamb UAP VD 211005Dokument16 SeitenprEN 15229 hEN Manholes & Chamb UAP VD 211005NezarKakhiNoch keine Bewertungen

- Quartz ToleranceDokument36 SeitenQuartz Tolerancenick10686Noch keine Bewertungen

- Chapter 11-Refrigeration CyclesDokument24 SeitenChapter 11-Refrigeration CyclesAbas S. AcmadNoch keine Bewertungen

- MICRO-M-3: Microelectronic Operation and Unit TroubleshootingDokument32 SeitenMICRO-M-3: Microelectronic Operation and Unit TroubleshootinghanamanNoch keine Bewertungen

- SY35U PART FILTER PERIODICAL SERVICEDokument2 SeitenSY35U PART FILTER PERIODICAL SERVICEIman SantosaNoch keine Bewertungen

- OMEGA AIR-Process and Sterile Filtration - EN - 950119Dokument12 SeitenOMEGA AIR-Process and Sterile Filtration - EN - 950119Junaid AhmedNoch keine Bewertungen

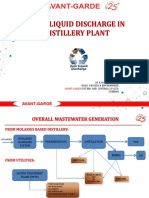

- Avant-Garde Mr. K Mohan KumarDokument46 SeitenAvant-Garde Mr. K Mohan KumarSivakumar SelvarajNoch keine Bewertungen

- Virtualengine Brochure 2016 Web 20160401Dokument2 SeitenVirtualengine Brochure 2016 Web 20160401Vusumzi MzimvubuNoch keine Bewertungen

- Ben's Presentation 2 PDFDokument65 SeitenBen's Presentation 2 PDFAiza BensNoch keine Bewertungen

- AQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDokument2 SeitenAQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDEVANDRAN A/L MOHAN MoeNoch keine Bewertungen

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDokument1 SeiteTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariNoch keine Bewertungen

- Leaflet Uniswitch CBCDokument2 SeitenLeaflet Uniswitch CBCFahmi CumiNoch keine Bewertungen

- Imsbc CodeDokument2 SeitenImsbc CodeBBluningningNoch keine Bewertungen

- PVC Sch40 - Sch80 Industrial Pipe COC 042017Dokument1 SeitePVC Sch40 - Sch80 Industrial Pipe COC 042017Hector RojasNoch keine Bewertungen