Beruflich Dokumente

Kultur Dokumente

In-Situ Stabilization of Road Base Using Cement

Hochgeladen von

nagy_andor_csongorOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

In-Situ Stabilization of Road Base Using Cement

Hochgeladen von

nagy_andor_csongorCopyright:

Verfügbare Formate

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/29454029

In-Situ Stabilization of Road Base Using

Cement - A Case Study in Malaysia

Article

Source: OAI

CITATIONS READS

3 396

3 authors:

Gary Chai Erwin Oh

Griffith University Griffith University

60 PUBLICATIONS 89 CITATIONS 94 PUBLICATIONS 363 CITATIONS

SEE PROFILE SEE PROFILE

Arumugam Balasubramaniam

Griffith University

284 PUBLICATIONS 2,020 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Bangkok Blue line MRT View project

Assessment and Modelling Deterioration of Flood-affected Pavements View project

All content following this page was uploaded by Erwin Oh on 15 July 2014.

The user has requested enhancement of the downloaded file.

In-Situ Stabilization of Road Base Using Cement - A Case Study in Malaysia

G. W. K. Chai, E. Y. N. Oh and A. S. Balasubramaniam

School of Engineering, Griffith University Gold Coast Campus,

Gold Coast, Queensland 9726, Australia.

the construction of concrete and flexible composite pavements. The

ABSTRACT terminology used to describe the cement bound aggregate may differ

internationally. In the United Kingdom, the term “cement-bound

Cement stabilization is one of the most common techniques for material” or “CBM” (British Standards Institution, 1990) is for

stabilizing recycled road base material, and offers a longer pavement mixtures from gravel-sand, a washed or processed granular material,

life. With the cement effect, the increase in stiffness of the stabilized crushed rock, all-in-aggregate, blast-furnace or any combination of

layer would provide better load transfer to the pavement foundation. these. Austroads (2004) gives a simple description as “cemented

The recycling method provides an environmental friendly option as the material”. In Malaysia, the common terminology is “cement stabilized

existing road base materials will not be removed. This paper presents a base” or “CTB” (PLUS, 2001).

case study at a trial section along the North-South Expressway in

Malaysia, where the Falling Weight Deflectometer (FWD) was adopted This paper describes the field test carried out using FWD on a flexible

to determine the in situ stiffness of the cement stabilized road base composite pavement test section on the Southbound Carriageway of the

material. The FWD would assess the compressive strength and the North-South Expressway in West Malaysia. The pavement

material stiffness of the cement stabilized layer. The improvement in rehabilitation involved in-situ stabilization of the existing road base

the stiffness of the stabilized base layer was monitored, and samples material using cement. The pavement works involved, milling of the

were tested during the trial. FWD was found to be useful for the existing bituminous layers to a depth of about 175mm, in-situ cement

structural assessment of the cement stabilized base layer prior to the stabilization of the road base to a thickness of 200mm, and overlay with

placement of asphalt layers. Results from the FWD were also used to 230mm asphalt concrete. Field and laboratory tests were carried out on

verify the assumed design parameters for the pavement. Using the the cement stabilized base (CTB), and core sampling was part of the

FWD, an empirical relationship between the deflection and the stiffness testing work.

modulus of the pavement foundation is proposed in this paper.

The trial section was 100m in length and 3.65m (one lane) width. The

KEY WORDS: Falling weight deflectometer, pavement, cement purpose of the trial was to assess the suitability of the construction

stabilization. procedure for cement stabilization. Monitoring works carried out

during the trial will allow any initial problems to be identified and

INTRODUCTION rectified before commencing full scale stabilization works. Field and

laboratory tests were conducted on the recycled material from the trial

Falling Weight Deflectometer (FWD) has been widely accepted as a area. The test results were to verify the mix design, and to demonstrate

non-destructive device for evaluating the condition of pavements in compliance with the specification. The use of FWD during the trial

Malaysia. FWD has been used during pavement construction for enabled the stiffness modulus of the existing base layer to be verified

assessing the performance of the pavement foundations along an before recycling. Further, the trial was intended to demonstrate that the

expressway in West Malaysia. Chai and Faisal (2000) demonstrated design parameters such as the in-situ effective stiffness of the CTB

that, when FWD tests are performed on the pavement foundation, layer are achieved on site. Thus, based on the actual in-situ properties

information can be gathered from the FWD deflection basin. The FWD of the pavement, the expected design life could be determined.

deflection measurements can be used directly to verify the design

assumptions, such as the level of compaction and the recommended CEMENT STABILISATION WORKS

material stiffness. This approach may also serve to provide a

supplementary performance specification to sub-grade construction in The first operation involved in the in-situ recycling was milling the

highway projects. existing 175mm bituminous materials using a “Wirtgen-W1000”. The

in-situ aggregate moisture content was determined by drying a sample

The practice of cement bound aggregate is recognized in Malaysia for of aggregate in a pan at the verge of the road located next to the paved

shoulder. The balance water content (the difference of the optimum and cores were transported to the laboratory where the recycled thickness

in-situ aggregate moisture contents) was then calculated. Cement was was checked. In addition to the thickness measurement, the cores were

then manually spread on the surface of the existing road base material, tested for in-situ compressive strength. 12 cube specimens were also

and the rate of cement spreading was based on the mix design prepared from the recycled CTB on the day of construction. The

requirements. A summary of the design parameters adopted in the CTB samples of the recycled CTB were taken before compaction from four

design is as follows: locations along the length of the trial area. Cubes were prepared and

tested in the laboratory for compressive strength.

1. Design water content within 4.5+0.5% of the dry mass of

aggregate and cement. RESULTS FROM TRIAL SECTION

2. Design cement content was 3.5% (by mass of the dry

aggregate). The cement content was decided based on the The in-situ cube compressive strength was determined from the

targeted compressive strength (4 MPa to 8 MPa). In this prepared cube specimens taken at 3, 7, and 28 days after CTB

case, the cement content of 3.5% achieve desired construction and tested on the subsequent day. The results are

compressive strength specified in the specification summarized in Table 1, which indicate that the average compressive

3. A minimum effective stiffness modulus of 1000MPa to be cube strength of the CTB at 7-days was 6.00MPa, which was within the

achieved after 28 days of curing. specified requirements of 4.0 to 8.0MPa. The results of in-situ

4. The average 7-days compressive strength determined from a compressive strength measured from the prepared core samples are also

group of 5 cubes of the CTB road-base shall be between 4 summarized in Table 1. The results show that an average of the 7-day

and 8MPa. compressive strength obtained from the core samples is 6.0MPa which

5. The average in-situ wet density shall not be less than 94% of is equivalent to the in-situ compressive strength obtained from the cube

the average wet density of the corresponding group of 5 specimens.

cubes.

Table 1. Compressive strength of the CTB layer

The in-situ recycling was then performed to a depth of 200mm using a

“Caterpillar-CAT 350” stabilizer machine. The aggregate and cement Age at In-situ compressive strength In-situ compressive strength

were mixed in the mixing chamber of the stabilizer machine. The CTB test (MPa) from core samples (MPa) from cube specimens

was then leveled using a motor grader. The measurements allowed the (days)

thickness of asphalt to be determined. Compaction of the recycled base 1 - 3

layer was then carried out using a “Dynapac” vibratory. After a curing 3 - 5.5

period of 7-days, bituminous materials to a nominal thickness of 190 4 4.5 -

mm were laid over the CTB base. 7 - 6.0

8 6.0 -

FIELD MONITORING PROGRAM 29 7.5 -

A testing program was prepared for the purpose of monitoring the The FWD data obtained from the field test were normalized to a

quality and performance of the stabilized pavement at various stages, pressure 200, 350 and 700 kPa for the testing performed on the existing

during and after the CTB construction. The testing comprised density granular road base, CTB and completed asphalt surfaces, respectively.

measurements, FWD, and laboratory tests on the CTB cores and cube The seven normalized deflection readings were measured by geophones

specimens prepared during construction. Density measurements were at distances (0, 300mm, 600mm, 900mm, 1200mm, 1500mm and

made shortly after the CTB had been compacted using sand 2100mm) from the centre of the loading plate.

replacement test. The density results were used to ensure the CTB layer

had achieved the minimum 94% relative density during the stabilization FWD test carried out on the existing road base gave a centre deflection

work. reading of 900 micron at 85 percentile value. For tests performed on the

CTB, the deflections were observed to decrease between 3 and 7 days

FWD test was performed at 5m spacing along two runs, which were due to curing of the CTB base. The FWD centre deflection value at 85

positioned approximately 0.7m from both edges of the trial area. FWD percentile for the 3 and 7 days are 500 micron and 400 micron,

loading used at the various stages of the FWD test were computed as respectively. For the 28-days, FWD centre deflection at 85 percentile

those expected from a standard axle loading on a completed pavement. gives a value of 300 micron. The profiles of the centre deflection

The contact pressures adopted were 200, 350 and 700kPa for testing parameter before and after the stabilization have been plotted against

performed on the existing granular road base, CTB and completed chain-age and are shown in Fig. 1.

asphalt surfaces respectively. For stage 1, FWD testing on the granular

road base surface just before recycling was carried out to determine the The FWD data were back-analyzed using ELSYM5 (1986) computer

initial condition of the granular road. In Stage 2 and 3, FWD tests on program to determine the effective stiffness after each stage of testing.

the CTB after 3-days of curing and 7-days of curing were carried out to A three-layer pavement structure was used to model the CTB base,

monitor the increase in stiffness of the CTB layer. FWD test was also granular sub-base and sub-grade layers for the 3 and 7-days strength

carried out on the asphalt layer surface at 28-days after the CTB evaluation. For the 28-days, a 4-layer model was used for the asphalt,

construction. The tests on the completed pavement layers would enable CTB base, granular sub-base and sub-grade layers. The effective

the effective stiffness of each of the various pavement layers to be stiffness modulus at 85 percentile values for the various pavement

determined and the assumed design parameters to be verified. layers at different stages of construction are presented in Table 2. The

stiffness of the CTB layer increased from 700 MPa at 3-days to 1350

A total of 12 cores were taken from the trial section. 4 cores were taken MPa at 28-days after curing. It was also noted that, the stiffness of the

from the CTB pavement after a curing period of 3-days, 5 cores at 7- CTB is greater than the adopted design stiffness of 1000MPa, and the

days and 3 cores through the combined thickness of bituminous and CTB stiffness value had been achieved on site.

CTB layers at 28-days, at various locations of the test site. The CTB

From the compressive strength (after 28 days) and FWD deflection data

gathered at the test site, a relationship between the compressive Based on the empirical relationship shown in Fig. 3, another useful

strength-deflection (D1) can be derived. Statistical regression analyses engineering relationship between the stiffness modulus and

have been performed to establish the empirical relationship (as shown compressive strength of CTB is proposed, and is shown in Eq. 2.

in Figs. 2 and 3). The relationship for compressive strength and FWD

deflection is illustrated in Eq. 1. (2)

E = 381 Su 0.6047

Su = 7.4543 ln( D1) + 51.002 (1)

Where, E is the back-calculated stiffness modulus (MPa)

Where, Su is compressive strength of CTB (MPa), and D1 is the 10

reading from FWD deflection sensor (micron).

1000

Compressive Strength (MPa)

8

800

4

FWD Deflection (micron)

600

0

100 200 300 400 500 600 700 800 900 1000

FWD Deflection (micron)

Fig. 2 Compressive strength and deflection D1 relationship from FWD.

400

10

Compressive Strength (MPa)

After cement stabilisation (3 days) 8

After cement stabilisation (7 days)

Before cement stabilisation 6

200

0 20 40 60 80 100 4

Chainage (m)

Fig. 1(a) FWD centre deflection profiles before and after cement

stabilization (3 and 7 days) 2

1000

0

0 300 600 900 1200 1500

Stiffness Modulus (MPa)

Fig. 3 Stiffness modulus and compressive strength relationship from

800 field test.

FWD Deflection (micron)

Table 2. Effective stiffness modulus of the CTB layer

Test stages Effective stiffness modulus (MPa)

600 at 85 percentile values

Pavement Layers CTB Road base

Granular Road base 280

Before Recycling

CTB after 3 days 700 -

400 CTB after 7 days 1150 -

Asphalt Surface after 1350 -

28 days

After cement stabilisation (28 days)

CONCLUSIONS

Before cement stabilisation

200

A pavement section of 100m in length on the Southbound Carriageway

0 20 40 60 80 100

Chainage (m)

of the North-South Expressway (West Malaysia) has been rehabilitated

Fig. 1(b) FWD centre deflection profiles before and after cement by strengthening the existing granular road base using cement

stabilization (28 days) stabilization. The performance of the completed pavement was

investigated through FWD and laboratory testing. For tests performed

on the CTB, the deflections were observed to decrease between 3 and 7 Centralab are greatly appreciated.

days due to curing of the CTB base. The use of cement stabilized base

leads to a significant improvement in the structural capacity of the REFERENCES

pavement. An empirical relationship between the in situ compressive

strength and the deflection of the CTB layer has been proposed. Austroads (2004). Pavement Design – A Guide to the Structural Design

Further, the study illustrated an empirical relationship between the of Road Pavements, Pub. No. AP-G17/04, Austroads, Sydney,

stiffness modulus and the in-situ compressive strength of the CTB. Australia.

These two engineering relationships can be useful for the monitoring British Standards Institution (1990). Methods of test for Cement-

the performance of the CTB layer when stabilization is in progress. The Stabilized and lime-stabilized materials (BS 1924: Part 2: 1990),

significant finding from the trial test showed that, the use of FWD will Stabilized Materials for Civil Engineering Purposes, London, UK.

verify design parameters such as the in-situ effective stiffness modulus Chai, G. W. K., and Faisal. H. A., (2000). “Determination of Stiffness

of the CTB layer. FWD test can also be used to demonstrate that the Modulus and Density of Pavement Foundation using Falling Weight

required compressive strength and stiffness modulus of the CTB had Deflectometer during Pavement Construction,” Proceedings of 10th

been achieved on site. Thus, the expected design life, based on the REAAA Conference, Tokyo, Japan, pp 24-29.

actual in-situ properties of the pavement, could be determined in ELSYM5, (1986). Manual of Computer Program for Determining

greater confidence. Stresses and Strains in a Multiple-layer Asphalt Pavement System,

Institute of Transportation and Traffic Engineering, University of

ACKNOWLEDGMENT California at Berkeley, U.S.A.

PLUS, (2001). Specification for Highway Works, North-South

The authors wish to thank PLUS (Projek Lebuhraya Utara-Selatan Interurban Toll Expressway and New Klang Valley Expressway,

Berhad) for granting the permission to publish the data presented in this Technical Report, Projek Lebuhraya Utara-Selatan Berhad, Kuala

paper. Technical contributions from Pengurusan Lebuhraya Berhad Lumpur, Malaysia.

(PLB), UE Construction/Scott Wilson Pavement Engineering, and Soil

View publication stats

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Inclinare I2Dokument1 SeiteInclinare I2nagy_andor_csongorNoch keine Bewertungen

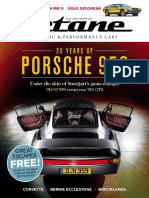

- Octane UK January 2018Dokument284 SeitenOctane UK January 2018nagy_andor_csongor0% (1)

- Tensile Strength Rammed Earth MaterialsDokument16 SeitenTensile Strength Rammed Earth Materialsnagy_andor_csongorNoch keine Bewertungen

- Enzo Independent Ferrari Magazine Spring 2018Dokument148 SeitenEnzo Independent Ferrari Magazine Spring 2018nagy_andor_csongorNoch keine Bewertungen

- United States Patent (19) : (45) Date of Patent: Dec. 8, 1998Dokument6 SeitenUnited States Patent (19) : (45) Date of Patent: Dec. 8, 1998nagy_andor_csongorNoch keine Bewertungen

- DECGE 2018 Abstract Nagy AndorDokument1 SeiteDECGE 2018 Abstract Nagy Andornagy_andor_csongorNoch keine Bewertungen

- Octane - June 2016Dokument284 SeitenOctane - June 2016nagy_andor_csongor100% (1)

- Stabilization of Dispersive Soil by Blending PolymDokument4 SeitenStabilization of Dispersive Soil by Blending Polymnagy_andor_csongorNoch keine Bewertungen

- Octane UK Issue 166 April 2017Dokument328 SeitenOctane UK Issue 166 April 2017nagy_andor_csongor0% (1)

- Isle Ro 2015Dokument12 SeitenIsle Ro 2015nagy_andor_csongorNoch keine Bewertungen

- Iih2i Octane December 2015Dokument300 SeitenIih2i Octane December 2015nagy_andor_csongorNoch keine Bewertungen

- D 1635 - 00 - Rde2mzuDokument3 SeitenD 1635 - 00 - Rde2mzunagy_andor_csongorNoch keine Bewertungen

- Scribd, Fuck You, I Already Uploaded, You Denied Me ADokument1 SeiteScribd, Fuck You, I Already Uploaded, You Denied Me Anagy_andor_csongorNoch keine Bewertungen

- WeggjskjgdlkslshşlsşlgtrştgrfşDokument1 SeiteWeggjskjgdlkslshşlsşlgtrştgrfşnagy_andor_csongorNoch keine Bewertungen

- Catalog UXGGDokument5 SeitenCatalog UXGGnagy_andor_csongorNoch keine Bewertungen

- Vortrag Carbon FootprintDokument13 SeitenVortrag Carbon Footprintnagy_andor_csongorNoch keine Bewertungen

- STAS8942 PlacaDokument12 SeitenSTAS8942 PlacaAni AlexandruNoch keine Bewertungen

- Octane Magazine October 2014Dokument336 SeitenOctane Magazine October 2014nagy_andor_csongorNoch keine Bewertungen

- The Construction of Super High-Rise Composite Structures in Hong KongDokument98 SeitenThe Construction of Super High-Rise Composite Structures in Hong KongJevgenijs Kolupajevs100% (2)

- Oc - UK - February 2015Dokument296 SeitenOc - UK - February 2015nagy_andor_csongorNoch keine Bewertungen

- Case Study On Ground Improvement by High Pressure Jet GroutingDokument6 SeitenCase Study On Ground Improvement by High Pressure Jet Groutingnagy_andor_csongorNoch keine Bewertungen

- Vibratii MasiniDokument10 SeitenVibratii Masininagy_andor_csongorNoch keine Bewertungen

- Admitere DoctoratDokument11 SeitenAdmitere Doctoratnagy_andor_csongorNoch keine Bewertungen

- Structura Drum.a3Dokument1 SeiteStructura Drum.a3nagy_andor_csongorNoch keine Bewertungen

- GFASDokument110 SeitenGFASnagy_andor_csongorNoch keine Bewertungen

- Performance-Related Product Specification Tensar Triax Tx160 GeogridDokument2 SeitenPerformance-Related Product Specification Tensar Triax Tx160 Geogridnagy_andor_csongorNoch keine Bewertungen

- Octane Magazine UK 2013. 06.Dokument268 SeitenOctane Magazine UK 2013. 06.nagy_andor_csongor100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- (AB-ANI) Program SpecificationDokument8 Seiten(AB-ANI) Program SpecificationMycah EvangelistaNoch keine Bewertungen

- Introduction To Rhetorical Analysis: Week 1Dokument16 SeitenIntroduction To Rhetorical Analysis: Week 1Will KurlinkusNoch keine Bewertungen

- ZTE V4 RNC Commissioning and Integration TrainingDokument2 SeitenZTE V4 RNC Commissioning and Integration TrainingBeena SinghNoch keine Bewertungen

- Template 3 - MATH 3-REGULAR-DIAGNOSTICDokument2 SeitenTemplate 3 - MATH 3-REGULAR-DIAGNOSTIClailanie CervantesNoch keine Bewertungen

- Online Preboard Math PDFDokument4 SeitenOnline Preboard Math PDFmarkos0% (1)

- Critique of Violence - Walter BenjaminDokument14 SeitenCritique of Violence - Walter BenjaminKazım AteşNoch keine Bewertungen

- One Plan Student 1Dokument7 SeitenOne Plan Student 1api-465826207Noch keine Bewertungen

- Casio AT 1 Service ManualDokument28 SeitenCasio AT 1 Service ManualMario Gabriel MoralliNoch keine Bewertungen

- PreNav - Pitch - Customers Wind SiDokument20 SeitenPreNav - Pitch - Customers Wind SiKaterinaLiNoch keine Bewertungen

- Chapter 01 Fundamental and Derived QuantitiesDokument7 SeitenChapter 01 Fundamental and Derived QuantitiesAlicia WilliamsNoch keine Bewertungen

- Inglês - Degrees of ComparisonDokument4 SeitenInglês - Degrees of ComparisonVersehgi IINoch keine Bewertungen

- Module 3: Literature Review and CitationDokument3 SeitenModule 3: Literature Review and CitationLysss EpssssNoch keine Bewertungen

- Systematic Literature Review SvenskaDokument6 SeitenSystematic Literature Review Svenskafihum1hadej2100% (1)

- Fuses f150Dokument7 SeitenFuses f150ORLANDONoch keine Bewertungen

- SPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESDokument17 SeitenSPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESPranavBalarajuNoch keine Bewertungen

- Instruction Manual: Slit Lamp Bon SL-EDokument20 SeitenInstruction Manual: Slit Lamp Bon SL-EVladimir LevchenkoNoch keine Bewertungen

- The Aerodynamics of ParachutesDokument78 SeitenThe Aerodynamics of Parachutesstevehuppert50% (2)

- (Prestressed Concrete) Lecture 05 Dr. ZubairDokument62 Seiten(Prestressed Concrete) Lecture 05 Dr. ZubairAhmed RiadNoch keine Bewertungen

- NIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationDokument6 SeitenNIELIT Recruitment For Scientist and Technical Assistants 2017 Official NotificationKshitija100% (1)

- Ground Architecture (Mourad Medhat)Dokument146 SeitenGround Architecture (Mourad Medhat)Aída SousaNoch keine Bewertungen

- Q1 Practical Research 2 - Module 1bDokument15 SeitenQ1 Practical Research 2 - Module 1bRhea Mae MacabodbodNoch keine Bewertungen

- Staad 4Dokument37 SeitenStaad 4saisssms9116100% (2)

- Prof Ed 9-A - Module 6 - Tumacder, DHMLDokument6 SeitenProf Ed 9-A - Module 6 - Tumacder, DHMLDanica Hannah Mae TumacderNoch keine Bewertungen

- UnitPlan (P.E) Grade 6Dokument13 SeitenUnitPlan (P.E) Grade 6Lou At CamellaNoch keine Bewertungen

- An Introduction To EFTDokument24 SeitenAn Introduction To EFTkunjammuNoch keine Bewertungen

- Pepperl KFD2 STC4 EX1.20 DatasheetDokument2 SeitenPepperl KFD2 STC4 EX1.20 DatasheetAhmed HusseinNoch keine Bewertungen

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDokument5 SeitenFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNoch keine Bewertungen

- PP in Ii 001Dokument15 SeitenPP in Ii 001Dav EipNoch keine Bewertungen

- Effect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaDokument6 SeitenEffect of Liquidity Risk On Performance of Deposit Money Banks in NigeriaEditor IJTSRDNoch keine Bewertungen

- Empowerment TechnologyDokument15 SeitenEmpowerment Technologysxhan gwenNoch keine Bewertungen