Beruflich Dokumente

Kultur Dokumente

4 Surface Finish Measurement P3

Hochgeladen von

Sandip BarikCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4 Surface Finish Measurement P3

Hochgeladen von

Sandip BarikCopyright:

Verfügbare Formate

Methods of Measuring Surface Finish

19

Scratch Inspection:

The materials like lead, plastics rubbed on surface are inspected by this method. The

impression of this scratches on the surface produced is then visualized.

Micro-Interferometer

Optical flat is placed on the surface to be inspected and illuminated by a

monochromatic source of light.

Surface Photographs

Magnified photographs of the surface are taken with different types of illumination.

The defects like irregularities are appear as dark spots and flat portion of the surface

appears as bright.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

20

Reflected light Intensity

A beam of light is projected on the surface to be inspected and the light

intensity variation on the surface is measured by a photocell and this

measured value is calibrated

Wallace surface Dynamometer:

It consists of a pendulum in which the testing shoes are clamped to a

bearing surface and a pre determined spring pressure can be applied and

then, the pendulum is lifted to its initial starting position and allowed to

swing over the surface to be tested.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

21

Direct instrument measurements

Direct methods enable to determine a numerical value of the surface finish of

any surface. These methods are quantitative analysis methods and the output is

used to operate recording or indicating instrument. Direct Instruments are

operated by electrical principles. These instruments are classified into two types

according to the operating principle. In this is operated by carrier-modulating

principle and the other is operated by voltage-generating principle, and in the

both types the output is amplified.

Some of the direct measurement instruments are

1. Stylus probe instruments.

2. Tomlinson surface meter.

3. Profilometer.

4. Taylor-Hobson

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

22

Stylus probe type instrument

Principle

When the stylus is moved over the surface which is to be measured, the

irregularities in the surface texture are measured and it is used to assess the

surface finish of the work piece.

Working

The stylus type instruments consist of skid, stylus, amplifying device and

recording device. The skid is slowly moved over the surface by hand or by

motor drive. The skid follows the irregularities of the surface and the stylus

moves along with skid. When the stylus moves vertically up and down and the

stylus movements are magnified, amplified and recorded to produce a trace.

Then it is analyzed by automatic device.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

23

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

24

Advantage

Any desired roughness parameter can be recorded.

Disadvantages

1. Fragile material cannot be measured.

2. High initial cost.

3. Skilled operators are needed to operate.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

25

Tomlinson Surface meter

This instrument uses mechanical-cum-optical means for magnification.

Construction

In this the diamond stylus on the surface finish recorder is held by spring

pressure against the surface of a lapped cylinder. The lapped cylinder is

supported one side by probe and other side by rollers. The stylus is also attached

to the body of the instrument by a leaf spring and its height is adjustable to

enable the diamond to be positioned and the light spring steel arm is attached to

the lapped cylinder. The spring arm has a diamond scriber at the end and

smoked glass is rest on the arm.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

26

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Methods of Measuring Surface Finish

27

Working

When measuring surface finish the body of the instrument is moved across the

surface by a screw rotation. The vertical movement of the probe caused by the

surface irregularities makes the horizontal lapped cylinder to roll. This rolling

of lapped cylinder causes the movement of the arm. So this movement is

induces the diamond scriber on smoked glass. Finally the movement of scriber

together with horizontal movement produces a trace on the smoked glass plate

and this trace is magnified by an optical projector.

Lecture (4) – Mechanical Measurements – 2nd year – Industrial.

Das könnte Ihnen auch gefallen

- 4-Surface Finish Measurement-P2Dokument9 Seiten4-Surface Finish Measurement-P2Bahiru BelachewNoch keine Bewertungen

- Surface Finish MeasurementDokument6 SeitenSurface Finish MeasurementsathiaNoch keine Bewertungen

- Surface Finish MeasurementDokument45 SeitenSurface Finish MeasurementMuraliNoch keine Bewertungen

- Analysis of Surface Traces Till 28 Slide-1Dokument30 SeitenAnalysis of Surface Traces Till 28 Slide-1Rayon 9Noch keine Bewertungen

- Analysis of Surface Finishing Processes A Review Research JournalDokument22 SeitenAnalysis of Surface Finishing Processes A Review Research JournalAtharv KhadatareNoch keine Bewertungen

- CH 5 - Surface Roughness Assessment-P2Dokument15 SeitenCH 5 - Surface Roughness Assessment-P2Omar GamalNoch keine Bewertungen

- Metrology 2nd Year 23.04.2020Dokument2 SeitenMetrology 2nd Year 23.04.2020NAZMEPS23984SUBHAM LAYEKNoch keine Bewertungen

- Chapter-1: 1.1 Surface RoughnessDokument50 SeitenChapter-1: 1.1 Surface RoughnessJohnson Bandaru100% (1)

- Surface Finish MeasurementDokument14 SeitenSurface Finish MeasurementRaghu Krishnan100% (1)

- Milling IndexingDokument25 SeitenMilling IndexingJeevanantham KannanNoch keine Bewertungen

- 2022 PPT 06Dokument8 Seiten2022 PPT 06jemsNoch keine Bewertungen

- Metrology Lab ManualDokument39 SeitenMetrology Lab ManualNivedh Vijayakrishnan0% (1)

- 1 - Introduction To SurveyingDokument35 Seiten1 - Introduction To SurveyingSarah Gwyneth CabungcalNoch keine Bewertungen

- M & IDokument12 SeitenM & INenu Na RakshasiNoch keine Bewertungen

- BTM2133-Chapter 8 Surface MeasurementDokument46 SeitenBTM2133-Chapter 8 Surface MeasurementAswaja313Noch keine Bewertungen

- Me3581 Metrology and Dynamics Lab Manual R2021actDokument133 SeitenMe3581 Metrology and Dynamics Lab Manual R2021actmarakamadhu800Noch keine Bewertungen

- ME334 Manufacturing Technology Laboratory - IIDokument5 SeitenME334 Manufacturing Technology Laboratory - IInandan144Noch keine Bewertungen

- 5.measurment of Form ErrorsDokument22 Seiten5.measurment of Form ErrorsRaj PatelNoch keine Bewertungen

- Jambeswar Module 7Dokument93 SeitenJambeswar Module 7Aayush KNoch keine Bewertungen

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Dokument27 SeitenLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNoch keine Bewertungen

- Mechanical Measurement and Metrology: Prepared by - Navroz NavodiaDokument20 SeitenMechanical Measurement and Metrology: Prepared by - Navroz NavodiaengrodeNoch keine Bewertungen

- Iare NDT PPTDokument137 SeitenIare NDT PPTMohan RajNoch keine Bewertungen

- Lecture 1 Survey 1Dokument35 SeitenLecture 1 Survey 1m saadullah khanNoch keine Bewertungen

- Subject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IDokument2 SeitenSubject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IMech DeptNoch keine Bewertungen

- Manufacturing Process 1 (Surface Finish (B.eng) - 02092014Dokument63 SeitenManufacturing Process 1 (Surface Finish (B.eng) - 02092014bananaNoch keine Bewertungen

- Metrology and Surface EngineeringDokument2 SeitenMetrology and Surface EngineeringnvemanNoch keine Bewertungen

- Topographic SurveyDokument27 SeitenTopographic SurveyKenny Jose100% (1)

- SPH1318Dokument145 SeitenSPH1318ControlSI PeruNoch keine Bewertungen

- QIPV 10 - Surface Roughness MetrologyDokument18 SeitenQIPV 10 - Surface Roughness MetrologyMPD19I004 MADDUKURI SRINoch keine Bewertungen

- Surface Roughness by Taly SurfaceDokument11 SeitenSurface Roughness by Taly Surfaceshantanu kumarNoch keine Bewertungen

- Lecture Note Engineering Surveying: Under RevisionDokument78 SeitenLecture Note Engineering Surveying: Under Revisionnaresh snowNoch keine Bewertungen

- Weatherability and Light Resistance Test Methods For Synthetic Resin PartsDokument32 SeitenWeatherability and Light Resistance Test Methods For Synthetic Resin PartsjenwitbunjongsatNoch keine Bewertungen

- Chapter 2 - METROLOGY-Main NotesDokument25 SeitenChapter 2 - METROLOGY-Main NotesyamadaNoch keine Bewertungen

- 12 - Types of Survey InstrumentsDokument11 Seiten12 - Types of Survey InstrumentsFarouq EngNoch keine Bewertungen

- NDTDokument51 SeitenNDTMuraliManohar100% (1)

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDokument4 SeitenMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNoch keine Bewertungen

- Metalurgical Lab MannuelDokument6 SeitenMetalurgical Lab Mannuelmritunjay1987Noch keine Bewertungen

- 5.EMM Lab ManualDokument38 Seiten5.EMM Lab ManualRakeshkumarcegNoch keine Bewertungen

- Fab 03 Non - Destructive TestingDokument25 SeitenFab 03 Non - Destructive TestingRaghu vamshiNoch keine Bewertungen

- Elementary SurveyingDokument269 SeitenElementary SurveyingWingel hope Ramping64% (11)

- M&M Lesson Plan and SyllabusDokument5 SeitenM&M Lesson Plan and Syllabuschandrasekhar reddyNoch keine Bewertungen

- Elementary SurveyingDokument268 SeitenElementary SurveyingmarvinmagdulaNoch keine Bewertungen

- Jambeswar MetrologyDokument119 SeitenJambeswar MetrologyAayush KNoch keine Bewertungen

- ME6504 - Metrology & Measurements Unit 4 - Form MeasurementDokument45 SeitenME6504 - Metrology & Measurements Unit 4 - Form MeasurementarunpdcNoch keine Bewertungen

- Metrology Lab ManualDokument33 SeitenMetrology Lab ManualRachit_Goyal25_10Noch keine Bewertungen

- Department of Mechanical Engineering: Experiment No. 12Dokument7 SeitenDepartment of Mechanical Engineering: Experiment No. 12zakibrant23Noch keine Bewertungen

- Water Jet Procedd PDFDokument788 SeitenWater Jet Procedd PDFVijendraAgar100% (1)

- MachineToolTesting MechDokument87 SeitenMachineToolTesting MechAnkit SharmaNoch keine Bewertungen

- Principle and Operation of Stylus and Probe InstrumentsDokument19 SeitenPrinciple and Operation of Stylus and Probe InstrumentsSatyam Singh100% (5)

- Surveying For Cotm RevisedDokument118 SeitenSurveying For Cotm RevisedTarekegnNoch keine Bewertungen

- Metrology and Measurements Lab Manual: V Semester Mechanical Engineering Rajalakshmi Engineering CollegeDokument30 SeitenMetrology and Measurements Lab Manual: V Semester Mechanical Engineering Rajalakshmi Engineering CollegeSanju JohnNoch keine Bewertungen

- Inspection MethodsDokument20 SeitenInspection MethodsturboconchNoch keine Bewertungen

- Serveying Assignment 1Dokument3 SeitenServeying Assignment 1Anania TashomeNoch keine Bewertungen

- Development of A Desktop Universal Testing Machine With A Full-Field Optical ExtensometerDokument12 SeitenDevelopment of A Desktop Universal Testing Machine With A Full-Field Optical ExtensometerDaniel Alejandro La ValleNoch keine Bewertungen

- NDI and Roll MovementDokument17 SeitenNDI and Roll MovementJose Luis GrajedaNoch keine Bewertungen

- Wenhan Zeng - AMTDokument18 SeitenWenhan Zeng - AMTsubhromondal2017Noch keine Bewertungen

- Module 1Dokument15 SeitenModule 1GaniNoch keine Bewertungen

- Engineering Surveying: Theory and Examination Problems for StudentsVon EverandEngineering Surveying: Theory and Examination Problems for StudentsBewertung: 4.5 von 5 Sternen4.5/5 (24)

- Topics On Optical and Digital Image Processing Using Holography and Speckle TechniquesVon EverandTopics On Optical and Digital Image Processing Using Holography and Speckle TechniquesNoch keine Bewertungen

- Applied Metrology for Manufacturing EngineeringVon EverandApplied Metrology for Manufacturing EngineeringBewertung: 5 von 5 Sternen5/5 (1)

- Cengel Heat Transfer Errata SheetDokument55 SeitenCengel Heat Transfer Errata SheetDINESH KUMARNoch keine Bewertungen

- Thermal Analysis of Fin Using Ansys: BY (ADMISSION NO. 19MT0337)Dokument19 SeitenThermal Analysis of Fin Using Ansys: BY (ADMISSION NO. 19MT0337)Sandip BarikNoch keine Bewertungen

- Mechanical Engineering (Objecctive Type) Paper-I: DO NOT Write Anything Else On The Test BookletDokument19 SeitenMechanical Engineering (Objecctive Type) Paper-I: DO NOT Write Anything Else On The Test BookletRanjeethNoch keine Bewertungen

- 1 Test Booklet: Mechanical EngineeringDokument48 Seiten1 Test Booklet: Mechanical EngineeringSandip BarikNoch keine Bewertungen

- Avg Power Vs WDokument1 SeiteAvg Power Vs WSandip BarikNoch keine Bewertungen

- IES Mechanical Engineeering 2015Dokument48 SeitenIES Mechanical Engineeering 2015sanjibkrjanaNoch keine Bewertungen

- Course Structure For M.Tech in Mechanical Engineering: Specialization: Machine DesignDokument10 SeitenCourse Structure For M.Tech in Mechanical Engineering: Specialization: Machine DesignSandip BarikNoch keine Bewertungen

- MMDokument29 SeitenMMSandip BarikNoch keine Bewertungen

- Kaplan Turbine I: NtroductionDokument3 SeitenKaplan Turbine I: NtroductionSandip BarikNoch keine Bewertungen

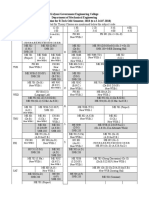

- 2nd 3rd 4th Yr Routine ME Odd Sem 2018-19 - Google Docs 2Dokument2 Seiten2nd 3rd 4th Yr Routine ME Odd Sem 2018-19 - Google Docs 2Sandip BarikNoch keine Bewertungen

- Uribapplicationform 74446631 PDFDokument1 SeiteUribapplicationform 74446631 PDFzaheedhusainNoch keine Bewertungen

- The Mechanics of Mind ReadingDokument5 SeitenThe Mechanics of Mind ReadingSandip BarikNoch keine Bewertungen

- Compressor TypesDokument35 SeitenCompressor TypesSaju SebastianNoch keine Bewertungen

- Specifications:-: Major Commands Used During The Stress Analysis of Ni-Cr Steel BeamDokument1 SeiteSpecifications:-: Major Commands Used During The Stress Analysis of Ni-Cr Steel BeamSandip BarikNoch keine Bewertungen

- Reading People's Minds From Emotion Expressions in Interdependent Decision MakingDokument51 SeitenReading People's Minds From Emotion Expressions in Interdependent Decision MakingSadineni Vinay KumarNoch keine Bewertungen

- Major Commands Used During The Stress Analysis of NiDokument1 SeiteMajor Commands Used During The Stress Analysis of NiSandip BarikNoch keine Bewertungen

- Major Commands Used During The Stress Analysis of NiDokument1 SeiteMajor Commands Used During The Stress Analysis of NiSandip BarikNoch keine Bewertungen

- 0 Placement 17Dokument1 Seite0 Placement 17Sandip BarikNoch keine Bewertungen

- Mechanical Engineering - Stanford UniversityDokument44 SeitenMechanical Engineering - Stanford UniversitySandip BarikNoch keine Bewertungen

- Grinding PDFDokument5 SeitenGrinding PDFshuklahouseNoch keine Bewertungen

- Chapter6 - Wind Loads PDFDokument40 SeitenChapter6 - Wind Loads PDFtatarce0% (1)

- Pavement Design Class NotesDokument42 SeitenPavement Design Class NotesAzaz Ahmed100% (1)

- Paper Surface Testing ApplicationDokument12 SeitenPaper Surface Testing ApplicationKristina ivanovicNoch keine Bewertungen

- TR 066 Design Post Installed Shear Connection 2concrete Layer 2019 04Dokument15 SeitenTR 066 Design Post Installed Shear Connection 2concrete Layer 2019 04phamducquangNoch keine Bewertungen

- Tol and Fits PDFDokument39 SeitenTol and Fits PDFjason RodricksNoch keine Bewertungen

- E402 PDFDokument226 SeitenE402 PDFDavi PxhxcNoch keine Bewertungen

- Rock Engineering Rock Engineering Practice & Design Practice & DesignDokument36 SeitenRock Engineering Rock Engineering Practice & Design Practice & DesignVictor Pangihutan SinagaNoch keine Bewertungen

- Surface Finish DefinitionsDokument2 SeitenSurface Finish DefinitionsAntonioNoch keine Bewertungen

- Micromachines 08 00264Dokument9 SeitenMicromachines 08 00264HarshaDesuNoch keine Bewertungen

- Preparing Holes For FasteningDokument9 SeitenPreparing Holes For Fasteningolegprikhodko2809100% (1)

- Bs en 10228 2 2016Dokument16 SeitenBs en 10228 2 2016Daryna KupriianovaNoch keine Bewertungen

- Sa 388.sa 388MDokument8 SeitenSa 388.sa 388MWagner Renato AraújoNoch keine Bewertungen

- Honda Monkey z50j Workshop ManualDokument276 SeitenHonda Monkey z50j Workshop ManualKeith Romanowski100% (3)

- Lecture 11 Surface TextureDokument2 SeitenLecture 11 Surface TextureDhaneshNoch keine Bewertungen

- Hybrid Sol-Gel Coatings Based On Silanes-Amino Acids For Corrosion Protection of AZ91 Magnesium Alloy - Electrochemical and DFT InsightsDokument12 SeitenHybrid Sol-Gel Coatings Based On Silanes-Amino Acids For Corrosion Protection of AZ91 Magnesium Alloy - Electrochemical and DFT InsightsJerson Javier Chaparro PlataNoch keine Bewertungen

- Assesment of Surface Texture (BS - 1134-1 - 1988)Dokument35 SeitenAssesment of Surface Texture (BS - 1134-1 - 1988)Yan LucienNoch keine Bewertungen

- ASME B46 - PT32 Functional Standards CollectionDokument21 SeitenASME B46 - PT32 Functional Standards CollectionCristhian CoariteNoch keine Bewertungen

- Surface Free Energy Dental MaterialsDokument10 SeitenSurface Free Energy Dental MaterialsMartin AdriazolaNoch keine Bewertungen

- GDand TDokument83 SeitenGDand TJitendra BagalNoch keine Bewertungen

- Module 4. Lubricant & Lubrication PDFDokument65 SeitenModule 4. Lubricant & Lubrication PDFarcee coinNoch keine Bewertungen

- An Experimental Study On Scale Effects in Rock Mass Joint StrengthDokument14 SeitenAn Experimental Study On Scale Effects in Rock Mass Joint StrengthTen FreireNoch keine Bewertungen

- Hydraulic Data For Pump ApplicationDokument28 SeitenHydraulic Data For Pump ApplicationedwinramonNoch keine Bewertungen

- 2018 Hastings Catalog 2Dokument412 Seiten2018 Hastings Catalog 2NOE LUGO100% (3)

- Cat 3600 Series and c280 Series Diesel Engine Fluids RecDokument24 SeitenCat 3600 Series and c280 Series Diesel Engine Fluids Recical iculNoch keine Bewertungen

- Industrial Training ReportDokument42 SeitenIndustrial Training ReportShubham SatheNoch keine Bewertungen

- 6.1 Rock Stabilisation MethodsDokument28 Seiten6.1 Rock Stabilisation Methodsxdhrts54 yNoch keine Bewertungen

- Hs ManualDokument73 SeitenHs Manualuchiiha_camiNoch keine Bewertungen

- Study of Turbine Blade RoughnessDokument118 SeitenStudy of Turbine Blade RoughnessSIVA KAVYANoch keine Bewertungen