Beruflich Dokumente

Kultur Dokumente

Zinc Hi-Ten g450-450s Steel

Hochgeladen von

Purnomo MbangunOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zinc Hi-Ten g450-450s Steel

Hochgeladen von

Purnomo MbangunCopyright:

Verfügbare Formate

Coated Steel – Metallic

Data Sheet

December 2017. This literature supersedes all previous issues

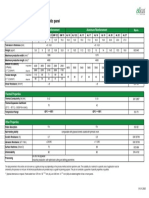

ZINC HI-TEN® steel

G450 / G450S

General Description Typical uses Australian and International Standards

ZINC HI-TEN® G450 steel is a hot-dipped zinc- Purlins, structural decking, scaffolding. AS/NZS 1365:1996

coated structural steel with a spangled surface AS 1397:2011

and guaranteed minimum yield strength of ISO 9001 Quality System certified

450MPa. Suitable for roll-forming to a 4t

minimum internal diameter.

ZINC HI-TEN® G450S steel is skin passed to

improve surface quality. This skin passed

product is only available up to 2mm thick.

Guaranteed properties of steel base

Mechanical properties Guaranteed minimum

Yield Strength, MPa (longitudinal tensile) 450

Tensile Strength, MPa (longitudinal tensile) 480

Elongation on 80mm (≥ 0.60mm) % 9

180° Transverse Bend 4t

Chemical composition of steel base

Chemical properties Guaranteed maximum %

Carbon - C 0.20

Manganese - Mn 1.20

Phosphorus - P 0.040

Sulphur - S 0.030

Metal coating adhesion – 180° bend test

Coating class Result

Z100 0t

Z200 1t

Z275 2t

Z450 2t

Z600 3t

Where t = the diameter of mandrel in terms of thickness of product.

Dimensional capabilities

Thickness range (mm) Width range (mm)

1.50 – 1.600 700 – 1525

1.61 – 2.000 700 – 1350

2.01 – 3.000 700 – 1225

3.01 – 3.200 700 – 1200

3.30 – 3.500 700 – 1000

Notes: Not every combination of thickness and width may be available. Supply conditions may be subject to dimensional restrictions and are subject to

BlueScope Sales and Marketing confirmation. Slitting and shearing available on request from BlueScope Sales Offices. For requirements outside the

standard product range please contact your local Sales Office. To determine maximum mill edge width available, subtract 30mm from the maximum width.

Resistance to fire

Index Range Result

Ignitability Index 0 - 20 0

Spread of Flame Index 0 - 10 0

Heat Evolved Index 0 - 10 0

Smoke Developed Index 0 - 10 0

National Construction Code Non-Combustible Material *

*According to National Construction Code, Building Code of Australia, Volume1: Part C1.12.e, and Volume 2: Part 3.7.1.2.e.

Supply conditions

Attribute Normal Optional

Coating Class Z275 Z200, Z450, Z600

Surface Condition Spangled Minimised Spangle

Surface Treatment Passivated -

Branding Branded -

Tolerance - Dimensions Class A -

Tolerance - Flatness Class A -

Important Notes: Optional supply conditions may be subject to dimensional restrictions

Fabricating performance

Method Rating

Bending 3

Drawing NR

Pressing NR

Roll Forming 4

Welding (design must allow for some strength reduction near welds) 5

Painting Pre-treatment 5

Where: 1 = Limited to 5 = Excellent or NR = Not Recommended.

The ratings in this table are general indicators only, given as a guide to fabricating performance.

Important information

Skin-passing will generally give a marginally higher yield strength and marginally reduced % elongation.

Material should be used promptly (within six months) to avoid the possibility of a storage related corrosion. For selection of the most appropriate metallic coated steel, please

refer to technical bulletins TB1a, TB1b, CTB21 and CTB22. For storage, rollforming lubricants and other information please refer to the Technical Bulletins

steel.com.au 1800 064 384

To learn more about this product For more information call Steel Direct 9 320075 086961

The information contained in this datasheet is provided by way of general information about this product only, and has not been prepared with your specific needs in mind. We recommend that you

seek BlueScope’s advice as to the suitability of this product for the purpose(s) for which you propose to use it. To contact BlueScope for advice about your proposed use of this product, please

contact Steel Direct. ZINC HI-TEN ®, BlueScope and the BlueScope brand mark are registered trade marks of BlueScope Steel Limited.

© 2017 BlueScope Steel Limited ABN 16 000 011 058.

Das könnte Ihnen auch gefallen

- Ammonium Chloride Corrossion in RefineryDokument12 SeitenAmmonium Chloride Corrossion in RefinerySudarshan GopalNoch keine Bewertungen

- PDFDokument6 SeitenPDFNinaNoch keine Bewertungen

- Work Instruction (Used Drill Pipe Coating) - NOVDokument17 SeitenWork Instruction (Used Drill Pipe Coating) - NOVYadi Kusmayadi100% (1)

- Lecture 20 Sodium ThiosulfateDokument5 SeitenLecture 20 Sodium ThiosulfateVarsha Kankani100% (1)

- LiposomesDokument58 SeitenLiposomesBharath ChinnaNoch keine Bewertungen

- Electrochemical Cells Worksheet AnswersDokument3 SeitenElectrochemical Cells Worksheet AnswersNurul Hana Omar100% (2)

- Bill of Quantities (R0) : FlashingDokument2 SeitenBill of Quantities (R0) : FlashingRakesh SharmaNoch keine Bewertungen

- VRSDokument8 SeitenVRSCNoch keine Bewertungen

- CrystalDokument2 SeitenCrystalAduchelab AdamsonuniversityNoch keine Bewertungen

- Galvaspan G450Dokument2 SeitenGalvaspan G450khurshedlakhoNoch keine Bewertungen

- Galvaspan G550Dokument2 SeitenGalvaspan G550eli abdul rohimNoch keine Bewertungen

- EI ServicesDokument2 SeitenEI ServicesAnonymous P8Bt46mk5INoch keine Bewertungen

- TRUECORE® Steel G550 Datasheet Aug 2019Dokument2 SeitenTRUECORE® Steel G550 Datasheet Aug 2019Julio de Andrade WerkNoch keine Bewertungen

- Zincalume® G550 Technical Datasheet MalaysiaDokument2 SeitenZincalume® G550 Technical Datasheet MalaysiaJeffrey RonquilloNoch keine Bewertungen

- Zincalume Ultra Activate Technical Data Sheet Rev2 151221Dokument4 SeitenZincalume Ultra Activate Technical Data Sheet Rev2 151221Nam Hoàng HảiNoch keine Bewertungen

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDokument1 SeiteZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Zincalume G300 Steel: Metallic Coated - MC Structural - SDokument2 SeitenZincalume G300 Steel: Metallic Coated - MC Structural - SPranatia Wisnu HeryudaNoch keine Bewertungen

- ZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCDokument3 SeitenZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCEwo50 NewNoch keine Bewertungen

- ZINCALUME® Steel G250 Datasheet May 2023Dokument3 SeitenZINCALUME® Steel G250 Datasheet May 2023a0931474125Noch keine Bewertungen

- Zincform G300 G300SDokument2 SeitenZincform G300 G300SBaziNoch keine Bewertungen

- Datasheet Zincalume G550Dokument2 SeitenDatasheet Zincalume G550adihindNoch keine Bewertungen

- Zincalume G550 G550S PDFDokument2 SeitenZincalume G550 G550S PDFkartikkeyyanNoch keine Bewertungen

- GALVSTEEL® G300 SteelDokument2 SeitenGALVSTEEL® G300 SteelTulus Ztx ZaputroNoch keine Bewertungen

- Metallic Coated MC Structural S Zincalume G300 Steel G300S SteelDokument2 SeitenMetallic Coated MC Structural S Zincalume G300 Steel G300S SteelEwo50 NewNoch keine Bewertungen

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDokument2 SeitenDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNoch keine Bewertungen

- Metal-Coated - Galvsteel: Data SheetDokument2 SeitenMetal-Coated - Galvsteel: Data SheetjcvalenciaNoch keine Bewertungen

- GALVABOND_G2_G2S_Dokument2 SeitenGALVABOND_G2_G2S_Michael ChongNoch keine Bewertungen

- CA3SN-G Cold Rolled SteeDokument2 SeitenCA3SN-G Cold Rolled SteeFaizan QadirNoch keine Bewertungen

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDokument2 SeitenCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNoch keine Bewertungen

- Powders: Technical, Application & Safety DataDokument7 SeitenPowders: Technical, Application & Safety DataphuongNoch keine Bewertungen

- Powders: Technical, Application & Safety DataDokument8 SeitenPowders: Technical, Application & Safety DataphuongNoch keine Bewertungen

- Zincform ASTM A653 Grade 50/1: General Description: Normal / Optional Supply ConditionsDokument1 SeiteZincform ASTM A653 Grade 50/1: General Description: Normal / Optional Supply ConditionsmuathNoch keine Bewertungen

- Anti-Seize Stainless GBDokument3 SeitenAnti-Seize Stainless GBKarinaNoch keine Bewertungen

- Hot-Rolled - Plate: Data SheetDokument2 SeitenHot-Rolled - Plate: Data SheetRichard Vica CalvoNoch keine Bewertungen

- m705 grn360 Kv20series20flyDokument2 Seitenm705 grn360 Kv20series20flyKek Siang MingNoch keine Bewertungen

- New Technology Mechanical Face Seal ManufacturingDokument21 SeitenNew Technology Mechanical Face Seal ManufacturingRavi MirzaNoch keine Bewertungen

- Hot Rolled HR Formable F HA3 Steel: General Description Typical UsesDokument2 SeitenHot Rolled HR Formable F HA3 Steel: General Description Typical UsesBaziNoch keine Bewertungen

- Stainless Steel Data Sheet Explains Grades, Properties and ApplicationsDokument2 SeitenStainless Steel Data Sheet Explains Grades, Properties and ApplicationsGoNoch keine Bewertungen

- Typical Chemical Composition (Weight %)Dokument3 SeitenTypical Chemical Composition (Weight %)strip1Noch keine Bewertungen

- Details - Aspx Coating Details: The Following Is A List of The Various Coating PropertiesDokument6 SeitenDetails - Aspx Coating Details: The Following Is A List of The Various Coating PropertiesToolgripNoch keine Bewertungen

- ANTI-SEIZE Stainless - GBDokument3 SeitenANTI-SEIZE Stainless - GBHasan RazaNoch keine Bewertungen

- Colorbond Ultra Datasheet New V8Dokument2 SeitenColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNoch keine Bewertungen

- Rule No. 1Dokument64 SeitenRule No. 1Albert AliminNoch keine Bewertungen

- COLORBOND Spectrum Series Datasheet New V8Dokument2 SeitenCOLORBOND Spectrum Series Datasheet New V8eng.ahmadrihawiNoch keine Bewertungen

- 1 5736Dokument2 Seiten1 5736solidwormNoch keine Bewertungen

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Dokument4 SeitenSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNoch keine Bewertungen

- TDC 09 - R1 - S690 QL & Weldox 700Dokument2 SeitenTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNoch keine Bewertungen

- RC1005F561CSDokument2 SeitenRC1005F561CSDarwin SipayungNoch keine Bewertungen

- AS 3678 STEEL GRADE 350Dokument3 SeitenAS 3678 STEEL GRADE 350gsoaresrj80Noch keine Bewertungen

- Technical Characteristics 2020 ENDokument1 SeiteTechnical Characteristics 2020 ENezzularabNoch keine Bewertungen

- SMB Catalogue Index: Contact Details Numbering SystemDokument60 SeitenSMB Catalogue Index: Contact Details Numbering SystemIgorNoch keine Bewertungen

- Velosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportDokument1 SeiteVelosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportAli TahirNoch keine Bewertungen

- Powders: Technical, Application & Safety DataDokument7 SeitenPowders: Technical, Application & Safety DataphuongNoch keine Bewertungen

- Flat Steel SpecsDokument8 SeitenFlat Steel SpecscuongdcNoch keine Bewertungen

- Durability: Hot Dip Galvanised Steel Sheet & CoilDokument8 SeitenDurability: Hot Dip Galvanised Steel Sheet & CoilDin TcmNoch keine Bewertungen

- ISO 3506 stainless steel designation system breakdownDokument3 SeitenISO 3506 stainless steel designation system breakdownPaulo Henrique NascimentoNoch keine Bewertungen

- Bolt Depot - Bolt Grade Markings and Strength ChartDokument2 SeitenBolt Depot - Bolt Grade Markings and Strength ChartSundar KumarNoch keine Bewertungen

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDokument3 SeitenData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNoch keine Bewertungen

- Colorbond XRW Datasheet New V8Dokument2 SeitenColorbond XRW Datasheet New V8Gireesh Krishna KadimiNoch keine Bewertungen

- SSAB Domex 420MC: General Product DescriptionDokument2 SeitenSSAB Domex 420MC: General Product DescriptionpeterNoch keine Bewertungen

- Grooving ToolsDokument8 SeitenGrooving ToolsAngad BankarNoch keine Bewertungen

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDokument3 SeitenTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNoch keine Bewertungen

- PLANCHA RF 15.9mm - GYPLACDokument4 SeitenPLANCHA RF 15.9mm - GYPLACGERALDINE GREYCI MEDRANO PONCENoch keine Bewertungen

- Stainless Steel Data - Fuller Metric Parts LTDDokument3 SeitenStainless Steel Data - Fuller Metric Parts LTDchitopeNoch keine Bewertungen

- Benteller Pipe Cataloque PDFDokument2 SeitenBenteller Pipe Cataloque PDFGarry Bernard NelsonNoch keine Bewertungen

- FN MTW W M R W Rmi A.N. Kapoldajiiet O: Java FDokument1 SeiteFN MTW W M R W Rmi A.N. Kapoldajiiet O: Java FPurnomo MbangunNoch keine Bewertungen

- Ijazah AriDokument7 SeitenIjazah AriPurnomo MbangunNoch keine Bewertungen

- Kop Pt. Sumber Bayak KreasiDokument1 SeiteKop Pt. Sumber Bayak KreasiPurnomo Mbangun100% (1)

- Mohamad KholilDokument3 SeitenMohamad KholilPurnomo MbangunNoch keine Bewertungen

- RAB Pek. Pengadaan Upgrade Lampu Penerangan Gd. B Kemtan - NPMDokument5 SeitenRAB Pek. Pengadaan Upgrade Lampu Penerangan Gd. B Kemtan - NPMPurnomo MbangunNoch keine Bewertungen

- 376 728 1 PB PDFDokument12 Seiten376 728 1 PB PDFPurnomo MbangunNoch keine Bewertungen

- Sujk WikanuDokument2 SeitenSujk WikanuPurnomo MbangunNoch keine Bewertungen

- 376 728 1 PB PDFDokument12 Seiten376 728 1 PB PDFPurnomo MbangunNoch keine Bewertungen

- 376 728 1 PB PDFDokument12 Seiten376 728 1 PB PDFPurnomo MbangunNoch keine Bewertungen

- Pra RK3K 2012Dokument5 SeitenPra RK3K 2012Purnomo MbangunNoch keine Bewertungen

- Acs Macromol 8b02148Dokument10 SeitenAcs Macromol 8b02148Đỗ Thị Vi ViNoch keine Bewertungen

- Biomolecules Chemistry AssignmentDokument19 SeitenBiomolecules Chemistry AssignmentLEGEND CjNoch keine Bewertungen

- In Dice 2003Dokument110 SeitenIn Dice 2003Liliana LazoNoch keine Bewertungen

- Granodiorite - WikipediaDokument7 SeitenGranodiorite - Wikipediashalom napoleonNoch keine Bewertungen

- Ceramic MaterialsDokument14 SeitenCeramic MaterialsVivekNoch keine Bewertungen

- The mosaic model explains membrane structure and functionDokument25 SeitenThe mosaic model explains membrane structure and functionDianna WattNoch keine Bewertungen

- A1 Alcohols Ws 1Dokument21 SeitenA1 Alcohols Ws 1GyaanNoch keine Bewertungen

- PEEK vs Acetal Resin: Comparing Material Properties for Dental ApplicationsDokument3 SeitenPEEK vs Acetal Resin: Comparing Material Properties for Dental ApplicationsMahmoud Gamal El FeelNoch keine Bewertungen

- P Block EquationsDokument10 SeitenP Block EquationsFarha Sh67% (9)

- EESB15 Sedimentary Rock Classification Chart Used (Guide)Dokument1 SeiteEESB15 Sedimentary Rock Classification Chart Used (Guide)Kristika RaguthasNoch keine Bewertungen

- Alcohol Oxidation NotesDokument11 SeitenAlcohol Oxidation Notesapi-281589298Noch keine Bewertungen

- Concentration of SolutionsDokument15 SeitenConcentration of SolutionsswamyforuNoch keine Bewertungen

- Hydrolysis DNA RNA Test IdentificationDokument39 SeitenHydrolysis DNA RNA Test Identificationdansuper50% (2)

- Tips Nanotechnology PDFDokument2.664 SeitenTips Nanotechnology PDFDario Bejarano RojasNoch keine Bewertungen

- "Chemical Pulping" Edited by Johan Gullichsen and Carl-Johan FogelholmDokument15 Seiten"Chemical Pulping" Edited by Johan Gullichsen and Carl-Johan FogelholmrdLuis1Noch keine Bewertungen

- 2019 - Super Moisture-Absorbent Gels For All-Weather PDFDokument7 Seiten2019 - Super Moisture-Absorbent Gels For All-Weather PDFDanh TruongNoch keine Bewertungen

- Reaction of CationsDokument4 SeitenReaction of CationsAshley JohnsNoch keine Bewertungen

- Polybond 3150 TDSDokument1 SeitePolybond 3150 TDSjai_dceNoch keine Bewertungen

- 1. Etcing And Bonding PPT - CopyDokument43 Seiten1. Etcing And Bonding PPT - Copy002Kadek Adinda Chantika OktaviaNoch keine Bewertungen

- Fundamental Understanding of Carbon Black Feedstock (CBFS)Dokument31 SeitenFundamental Understanding of Carbon Black Feedstock (CBFS)SDawNoch keine Bewertungen

- Synthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical AlloyingDokument5 SeitenSynthesis and Charecterization of Alfecrni Four Component High Entropy Alloy by Mechanical Alloyingvsraju2Noch keine Bewertungen

- Properties of NanomaterialsDokument44 SeitenProperties of NanomaterialsSNEHNoch keine Bewertungen

- AP '84 Multiple ChoiceDokument19 SeitenAP '84 Multiple ChoiceMatt FerrariNoch keine Bewertungen