Beruflich Dokumente

Kultur Dokumente

EN

Hochgeladen von

Suvranil BanerjeeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EN

Hochgeladen von

Suvranil BanerjeeCopyright:

Verfügbare Formate

Steps of progressing in Electromechanical component:

Process design → HFD (Hydraulic Flow Diagram) → layout, plant operation and control philosophy → P&ID

(Piping and Instrumentation Diagram: covers duty parameters of mechanical equipment) → Load list (of

electrical equipment) → SLD (Single Line Diagram preparation: electrical) → SLD single line diagram of plant

with component ratings, Lighting layout, Earthing layout, Cable layout, Preparation of electrical requirement

data sheet → Requirement data sheet → Floating enquiry → Purchase order → Obtaining QAP →

BEP: Basic Engineering Package: constitutes all the above.

KUIDFC Dept.: Generally document of DPR consists of three nos. of volumes:

Volume I: Report

Volume II: Designs

Volume III: Estimate (Process Design)

Note: all the three volumes may be included in one document and depends on size or otherwise three volumes

are separated.

Sluice Gates Data Notes:

1. No sluice gates at:

Single gate for Inlet chamber and Bypass chamber at SPS.

Outlets at Mech. coarse screen chambers at SPS,

Inlets of Distribution chamber,

2. Details of values of Water Levels: IL of Chamber (Invert Level) and Opening, Water Level on Seating

and Unseating Side (Flow Top Level) (Size of Sluice Gate i.e. size of opening to be maintained at

vertical wall of chamber may be determined to suit designed flow or difference between water level

and seating side and invert level of chamber), Platform Level (of chamber where person stands for

operating wheel of Sluice Gate), Mounting Wall Thickness, Platform Thickness are shown in GAD

(General arrangement Drawing of PTU at STP and in Architecture and Section Plan of SPS (Sewage

Pumping Station) and Wet Well.

3. Platform Level at Inlet side of Chamber remains higher than that of outlet side.

4. Size of Sluice Gate (i.e. size of opening to be maintained at vertical wall of chamber) of Inlet side

remains higher than that of outlet side for inlets of Mech. coarse screen chamber at SPS and Fine

screen chambers of STP.

5. In Ilkal case, a. values of Water Levels: IL (Invert Level) of Chamber /Opening are identical.

6. Values of Invert Level of chamber are values of invert level of previous chamber/inflow side.

7. Values of seating level at inlet are top water level of previous structure i.e. of inlet side/ inflow side.

8. Values of Unseating level at outlet are dropped top water level towards next structure i.e. of outlet

side/outflow side.

9. In Ilkal case, Values of Water Level on a. Seating and b. Unseating Side (Flow Top Level),

a. Are identical for Inlet/Bypass/ Inlets of coarse screen, chambers of SPS.

b. Values of unseating side are lower than that of seating side at inlets of Mech. and Manual fine

screen chambers by 200 mm. at STP.

c. Values of unseating side and that of seating side at outlets of Mech. and Manual fine screen

chambers at STP, are identical.

d. Values of unseating side are lower than that of seating side at inlets of Grit chamber by 200 mm.

at STP.

e. Values of unseating side and that of seating side at outlets of Grit chamber at STP, are identical.

f. Values of unseating side are lower than that of seating side at inlets of Grease Trap chamber by

300 mm. at STP.

g. Values of unseating side are higher than that of seating side at outlets of Grease Trap chamber

by 20 mm. at STP

h. Values of unseating side are lower than that of seating side at outlets of Distribution chamber by

500 mm. at STP

10. Value of Platform level is inclusive/exclusive of platform thickness.

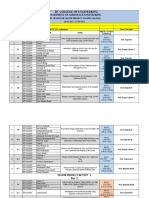

Site Sub- Name of Chamber Provision of Sluice

Work Gate at

Inlet of Outlet of

Chamber Chamber

Ilkal SPS Inlet chamber √ X

Bypass chamber √ X

Mech. Coarse Screen √ X

STP Mech. Fine Screen √ √

Manual Fine Screen √ √

Grit Chamber √ √

Grease Trap √ √

Distribution Chamber X √

Letter No.: UPLEEL/ILKAL/288/Dated: 07-10-2015

To,

Project Manager/Executive Engg.,

NKUSIP, Belgaum Division,

KUIDFC, Belgaum.

Subject: HFD (Hydraulic Flow Diagram) and P&ID (Piping and Instrumentation Diagram).

Ref.: 1. Balance works of construction of sewerage network and FAL type STP of 8 mld capacity in Ilkal city

Municipal Council and improvements to Urban drainage system in Ilkal CMC, Bagalkot District. Contract

Package No. 02 ILK 02, Agreement No.: CMC / ADB / KUIDFC-NKUSIP / Contract Agreement Reg. No. 729

/2013-14 / Dated 24-03-2014.

Respected Sir,

Please issue drawings of following,

1. Piping and Instrument Diagram (consisting duty parameters of mechanical

equipment, All the Instruments involved in the project, Mechanical equipment details in the

equipment schedule etc.)

2. Hydraulic Flow Diagram (consisting layout, plant operation and control

philosophy, etc.)

3. (SLD) Single Line Diagram of plant with component ratings,

4. Lighting layout,

5. Earthing layout,

6. Cable layout

Please provide,

a. Operation and control philosophy of the plant.

b. GAD for all the units.

c. Mechanical GAD for screens, Pumps, Valves & Gates.

For proceeding further, we request you to provide following clarification/information,

1. Mechanical equipment details in the equipment schedule.

2. Missing Pipe line sizes/Channel Sizes.

3. All the Instruments involved in the project to be shown in P&ID. Isolation & Drain valves for

PG. Apart from PG and DLS no other instrument is shown. Level Instrument not shown

anywhere not even in the wet well.

4. Trapped Grease and Grit disposal part is not clear so as to where to be disposed and by

whom.

5. Valve type in the Valve schedule is not provided.

6. Blower and Air line in the grit chamber not shown.

7. As per BOQ there are 16.0 Nos. of sluice gates whereas recently issued drawings propose

21.0 nos. GT-20 and GT-21 doesn't exist instead there is an isolation valve of 450 mm dia

with valve pit, please confirm.

8. Valve numbering and listing in the valves schedule has been missed out some valves some of

them are the drain valves from FAL. Please clarify

9. Alarm list is incomplete. Alarm AL 01 and AL 02 are not clear.

10. Apart from this issued document, we need the GAD for all the units.

11. Mechanical GAD for screens, Pumps, Valves & Gates would be provided by us after the

receipt from supplier.

12. Please provide Operation and control philosophy of the plant

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Sub.: Housing Loan Sanctioned For Flat No. 1802, BLDG - No.1, Highland Park, Dhokali Road, BalkumDokument1 SeiteSub.: Housing Loan Sanctioned For Flat No. 1802, BLDG - No.1, Highland Park, Dhokali Road, BalkumSuvranil BanerjeeNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Sai Consulting Engineers Pvt. LTD.: Clearance FormDokument2 SeitenSai Consulting Engineers Pvt. LTD.: Clearance FormSuvranil BanerjeeNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Names of Co-Owners Cell No. E-Mail ID Flat No. Bldg. No.: Other Family MemberDokument2 SeitenNames of Co-Owners Cell No. E-Mail ID Flat No. Bldg. No.: Other Family MemberSuvranil BanerjeeNoch keine Bewertungen

- Properties Around Pune, Satara, Wai, Pachagani, MahabaleshwarDokument1 SeiteProperties Around Pune, Satara, Wai, Pachagani, MahabaleshwarSuvranil BanerjeeNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Satara AgentsDokument1 SeiteSatara AgentsSuvranil BanerjeeNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Flat No. BLDG - No. Names of Co-Owners Cell No. E-Mail ID Re-Sale Agreement DetailsDokument2 SeitenFlat No. BLDG - No. Names of Co-Owners Cell No. E-Mail ID Re-Sale Agreement DetailsSuvranil BanerjeeNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Staad File Reg: Reply All Download Save To Onedrive - Upl LimitedDokument2 SeitenStaad File Reg: Reply All Download Save To Onedrive - Upl LimitedSuvranil BanerjeeNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 16-12-2014-Meeting AgendaDokument1 Seite16-12-2014-Meeting AgendaSuvranil BanerjeeNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Sr. Node No Length UGL UIL DIL Pipe Pipe WC Bc/2H L/2H WSC C/s WW Total Pipe Load Type No From TO Dia. THK Cutting Soil (S.I. L) Area (Water) Load Strength Factor of Bedding H/B C CDokument3 SeitenSr. Node No Length UGL UIL DIL Pipe Pipe WC Bc/2H L/2H WSC C/s WW Total Pipe Load Type No From TO Dia. THK Cutting Soil (S.I. L) Area (Water) Load Strength Factor of Bedding H/B C CSuvranil BanerjeeNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 18 12 2014 Meeting MinutesDokument4 Seiten18 12 2014 Meeting MinutesSuvranil BanerjeeNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- From Receipt Total To Issue Balance Receipt Date Date of Issue Total IssueDokument12 SeitenFrom Receipt Total To Issue Balance Receipt Date Date of Issue Total IssueSuvranil BanerjeeNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Doubts 1Dokument4 SeitenDoubts 1Suvranil BanerjeeNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Hardness of Rock - Unit - UCS - Unconfined Compressive Strength in KG/CM /mPA MOH - 3 To 4 For Depth Up To 36 Mtr. For Mahm ShaftDokument1 SeiteHardness of Rock - Unit - UCS - Unconfined Compressive Strength in KG/CM /mPA MOH - 3 To 4 For Depth Up To 36 Mtr. For Mahm ShaftSuvranil BanerjeeNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Yield of ConcreteDokument19 SeitenYield of ConcreteSuvranil BanerjeeNoch keine Bewertungen

- 90m3/shift@rs.16000/day ÷ 90 m3 90m3/shift@rs.16000/day ÷ 90 m3Dokument1 Seite90m3/shift@rs.16000/day ÷ 90 m3 90m3/shift@rs.16000/day ÷ 90 m3Suvranil BanerjeeNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Bearing Capacity of MHDokument1 SeiteBearing Capacity of MHSuvranil BanerjeeNoch keine Bewertungen

- WeightsDokument4 SeitenWeightsSuvranil BanerjeeNoch keine Bewertungen

- Thermally Curable Polystyrene Via Click ChemistryDokument4 SeitenThermally Curable Polystyrene Via Click ChemistryDanesh AzNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Module 1: Overview of Applied Behaviour Analysis (ABA)Dokument37 SeitenModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaNoch keine Bewertungen

- PMP Question BankDokument3 SeitenPMP Question BankOmerZiaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- CEE Annual Report 2018Dokument100 SeitenCEE Annual Report 2018BusinessTech100% (1)

- QP December 2006Dokument10 SeitenQP December 2006Simon ChawingaNoch keine Bewertungen

- Rockaway Times 11818Dokument40 SeitenRockaway Times 11818Peter J. MahonNoch keine Bewertungen

- Review1 ScheduleDokument3 SeitenReview1 Schedulejayasuryam.ae18Noch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Elements of ArtDokument1 SeiteElements of Artsamson8cindy8louNoch keine Bewertungen

- SHCDokument81 SeitenSHCEng Mostafa ElsayedNoch keine Bewertungen

- LetrasDokument9 SeitenLetrasMaricielo Angeline Vilca QuispeNoch keine Bewertungen

- AlpaGasus: How To Train LLMs With Less Data and More AccuracyDokument6 SeitenAlpaGasus: How To Train LLMs With Less Data and More AccuracyMy SocialNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Shostack ModSec08 Experiences Threat Modeling at MicrosoftDokument11 SeitenShostack ModSec08 Experiences Threat Modeling at MicrosoftwolfenicNoch keine Bewertungen

- Organization and Management Module 3: Quarter 1 - Week 3Dokument15 SeitenOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoNoch keine Bewertungen

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDokument19 SeitenHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraNoch keine Bewertungen

- Space Hulk - WDDokument262 SeitenSpace Hulk - WDIgor Baranenko100% (1)

- RTDM Admin Guide PDFDokument498 SeitenRTDM Admin Guide PDFtemp100% (2)

- .Urp 203 Note 2022 - 1642405559000Dokument6 Seiten.Urp 203 Note 2022 - 1642405559000Farouk SalehNoch keine Bewertungen

- School of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1Dokument2 SeitenSchool of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1STEM Education Vung TauNoch keine Bewertungen

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderDokument7 SeitenThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoNoch keine Bewertungen

- WebLMT HelpDokument12 SeitenWebLMT HelpJoão LopesNoch keine Bewertungen

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Dokument4 SeitenLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Objective & Scope of ProjectDokument8 SeitenObjective & Scope of ProjectPraveen SehgalNoch keine Bewertungen

- CX Programmer Operation ManualDokument536 SeitenCX Programmer Operation ManualVefik KaraegeNoch keine Bewertungen

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDokument9 SeitenStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoNoch keine Bewertungen

- Networker Performance Tuning PDFDokument49 SeitenNetworker Performance Tuning PDFHarry SharmaNoch keine Bewertungen

- Crown WF-3000 1.2Dokument5 SeitenCrown WF-3000 1.2Qirat KhanNoch keine Bewertungen

- Laboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)Dokument76 SeitenLaboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)gyanendraNoch keine Bewertungen

- Excon2019 ShowPreview02122019 PDFDokument492 SeitenExcon2019 ShowPreview02122019 PDFSanjay KherNoch keine Bewertungen

- SMC 2D CADLibrary English 1Dokument590 SeitenSMC 2D CADLibrary English 1Design IPGENoch keine Bewertungen

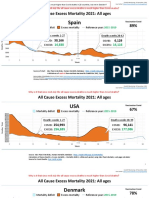

- Countries EXCESS DEATHS All Ages - 15nov2021Dokument21 SeitenCountries EXCESS DEATHS All Ages - 15nov2021robaksNoch keine Bewertungen

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)