Beruflich Dokumente

Kultur Dokumente

Formulation Development of CR Oflaxacin Matrix Tablet and Their In-Vitro Evaluation

Hochgeladen von

Baru Chandrasekhar RaoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Formulation Development of CR Oflaxacin Matrix Tablet and Their In-Vitro Evaluation

Hochgeladen von

Baru Chandrasekhar RaoCopyright:

Verfügbare Formate

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1219957

Available online at: http://www.iajps.com Research Article

FORMULATION DEVELOPMENT OF CR OFLAXACIN

MATRIX TABLET AND THEIR IN-VITRO EVALUATION

Sana mubeen1, Ghulam Razaque1, Noman ul haq1, Nisar ahmed1, G. Mustafa Shahwani1,

Zarmeena khan1, Aqeel Nasim1, M. Zeeshan Danish2.

1

Faculty of Pharmacy & Health Sciences, University of Balochistan, Quetta

2

College of Pharmacy, Punjab University, Lahore.

Abstract:

Among the all sophisticated drug deliveries oral drug delivery is known as safest and most convenient rout of

administration. DDS are formulated for rapid release, for CDD (Controlled Drug delivery and release) and for

targeted drug delivery. Controlled delivery system is the system which deliver the active ingredient at a

predetermined rate and time for the local or systemic effect for a definite period of time. Formulation and

development of CR made possible by the polymers i.e is synthetic polymers and natural polymers. Eudragit is an

Synthetic amorphous polymer, which is non absorbable, non-biodegradable, and non-toxic polymers. Ofloxacin is

a synthetic antibiotic of the fluoroquinolone drug considered to be a second generation flouroquinolone.(12) (13)

ofloxacin is approved for the treatment of bacterial infection like chronic bronchitis, community acquired

pneumonia, acute pelvic inflammatory disease complicated urinary tract infection. In this study CR drug

formulated of Ofloxacin by adding Xanthan Gum and Eudragit RL100 polymers with direct compression method.

Pre-formulation studies were conducted which all were according to the standards. Three different drug and

polymers ratios were incorporated of two different polymers i.e. 10.3, 10.4, 10.5. Invitro dissolution studies were

also conducted, the %age release was enhanced in all formulation. The formulation 10.3 in both formulations

enhanced the release rate more than the other formulations. These polymers can also be used in other drug

preparations and also suitable for development of CR formulations which may extended the drug release.

Corresponding author:

Sana Mubeen, QR code

Faculty of Pharmacy and Health Sciences,

University of Balochistan,

Quetta.

Please cite this article in Sana Mubeen et al., Formulation Development of CR Oflaxacin Matrix Tablet and

Their In-Vitro Evaluation, Indo Am. J. P. Sci, 2018; 05(04).

www.iajps.com Page 2572

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

INTRODUCTION:

Among the drug deliveries the most widely used drug is to increase the drug therapy, to protect the

delivery is oral drug delivery which is easily degradation of drug and to improve the patient

delivered, handled and less unwanted effects. Almost compliance (5). Formulation and development of CR

the oral rout can deliberated the most natural, made possible by the polymers i.e is synthetic

suitable, nontoxic and safest due to easily polymers and natural polymers. Eudragit is a

administration, patient compliance and the less cost Synthetic amorphous polymer, which is non-

of manufacturing process. Pharma products which are absorbable, non-biodegradable, and non-toxic

designed for oral rout are mostly immediate released polymers (6). Eudragit RL100 is swell able and

type or conventional type of drug delivery systems, permeable polymer and xantane gum is a natural

which are formulated for rapid release of the drug for polymer (7). Both Polymer are suitable for

their rapid absorption (1, 2). These rapid release formulation of matrix tablets. A natural polymer,

formulations have some limits such as the Drugs Xanthane Gum is best retarders in CR formulation.

have short half-life which requires frequent As the property of Xanthane Gum is concern it is a

administration, also increases chances of the missing hetropolysaccharide and biopolymer, which is

of the dose for unaffordable patient and their produced by the fermentation from the bacteria (08).

compliance. Ofloxacin is a synthetic antibiotic of the

fluoroquinolone drug considered to be a second

The DD is a process of drug administration or a drug generation flouroquinolone.(12) (13) ofloxacin is

compound to attain the needed therapeutic effect (3). approved for the treatment of bacterial infection like

DDS are formulated for rapid release, for CDD chronic bronchitis, community acquired pneumonia,

(Controlled Drug delivery and release) and for acute pelvic inflammatory disease complicated

targeted drug delivery. Controlled delivery system is urinary tract infection. Ofloxacin is effected against

the system which deliver the active ingredient at a the aerobic gram-positive or gram negative bacteria

predetermined rate and time for the local or systemic (14).The elimination half-life of Ofloxacin is 4-5

effect for a definite period of time (4). The basic aim hours.

2. MATERIAL AND METHODS:

2.1 Materials

2.1.1 Chemicals:

Different following analytical grade chemical were used.

No. Material Made in/by

1 Monobasic Potassium Phosphate China

2 Ofloxacin Zafa Pharmaceuticals Karachi

3 Eudragit RS 100 China

6 Xanthan Gum China

9 Mg-Stearate China

10 Starch China

2.1.2 Instruments:

The following many apparatuses which were used in this research work of CR Ofloxacin development. All of

these apparatuses were standardized before use;

No. Instruments Made in/by

1 Friabilator Germany

2 Dissolution apparatus Germany

3 Beakers, Test tubes and volumetric flask Japan

4 PH-Meter USA

5 Vernier Caliper Germany

6 UV-Visible spectrophotometer Japan

7 Syringes Pakistan

8 Tableting machine Germany

9 Electronic Balance Japan

10 Hardness Tester Germany

www.iajps.com Page 2573

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

2.2: Preformulation studies

These studies were conducted as per prescribed

procedures, these Preformulation tests which were contained 0.5mg per ml Ofloxacin, third dilution

included and were done contained 0.25mg per ml Ofloxacin, forth dilution

1. Solubility studies, contained 0.0125mg per ml and the fifth dilution

2. Standard curve, which contained 0.00625mg per ml.

3. Bulk density, 2.2.5 Spectrophotometric analysis of stock

4. Compatibility study, solutions

5. Hausner’s ratio, These five different dilutions of Ofloxacin were

6. Tapped density, and further analyzed with the help of UV- Visible

7. Angle of repose all these tests were done for the spectroscopy at 294 nm, the readings of absorbance

Ofloxacin (active drug). were noted.

2.2.6. Solubility studies of Ofloxacin.

2.2.1. Standard Curve of Ofloxacin Solubility studies of Ofloxacin were performed by

First of all phosphate buffer was prepared before using distilled water with different temperatures at pH

construction of standard curve. 5 (diverse) dilutions 1.2 for 24 hours. 100 mg of Ofloxacin was added in

were prepared from the stock solution accordingly as hundred ml solvent in a volumetric flask and kept in

mentioned in the standards and then analyzed the shaker. The shaker temperatures were kept

absorbance spectrophotometrically. accordingly according to the condition. Five ml

2.2.2 Phosphate buffer solution sample were took and analyzed by spectrophotometer

1.2 pH Phosphate buffer was made by adding 200 ml at 294 nm wavelength.

according to the standard procedures. 2.3: Preparation of CR

2.2.3. Stock solution Preparation Ofloxacin Tablets:

Prepared 100 ml of Ofloxacin stock solution by CR tablets contained Ofloxacin were developed by

adding of 20 mg Ofloxacin in pH 1.2 phosphate the method of direct compression a n d used

buffer in a volumetric flask (100 ml) and volume was variable concentrations of polymers, Mg stearate

made 100ml up to the mark which contained 0.2mg and filler were incorporated shown in table No 2.1

per ml of active ingredient Ofloxacin. and 2.2.

All the ingredients were weight accurately and

2.2.4. Preparation Ofloxacin different dilutions were passed through the sieve size no 60 mesh.

With the help of original stock solution 5 different Before, mixing uniformly all ingredients except

dilutions were made by adding 50ml stock solution Talc and Mg stearate were mixed togather with

and added 50 ml buffer of 1.2 pH solution to make the help of mortar and pestle for fifteen

that solution up to the mark i.e. 100 ml and repeated minutes. After through mixing of active ingredient

this for five different dilutions making 100 ml with the other excipient, 1% Talc & Mg stearate

solutions from every next dilution. First dilution were added, as post lubricant. These all

contained 0.1mg per ml of Ofloxacin, second dilution components were mixed again for 2- 3 minutes.

The blended mixture was then compressed with the

help of single tableting machine.

www.iajps.com Page 2574

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

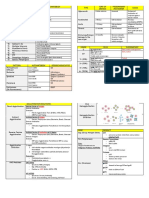

Table. 2.1 Designing of 100mg Ofloxacin Matrix CR tablet by adding the polymers (Xanthan

Gum)

Drug and the Ofloxacin Polymers (Mg St. 0.5%) Starch

Polymer Ratio

Xanthan Gum

10:3 (F1) 50 mg 15mg 0.5mg 34.5mg

10:4 (F2) 50 mg 20mg 0.5mg 29.5mg

10:5 (F3) 50 mg 25mg 0.5mg 24.5mg

Table No. 2.2 Designing of 100mg Ofloxacin Matrix CR tablet by adding the polymers (Eudragit RL 100)

Drug and the Ofloxacin Polymers (Mg St. 0.5%) Starch

Polymer Ratio

Eudragit RL 100

10:3 (F4) 50 mg 15mg 0.5mg 34.5mg

10:4 (F5) 50 mg 20mg 0.5mg 29.5mg

10:5 (F6) 50 mg 25mg 0.5mg 24.5mg

2.4.. PHYSICOCHEMICAL PARAMETERS

2.4.1: Hardness of the formulation HCl at 1.2 buffer pH and that solution was filtered

To evaluate the hardness of the CR Ofloxacin over 0.45µ filter membranes. Each of the tablet

hardness tester both manual and electronic extracts were appropriately diluted and then theses

were used to avoid any error of the compressed were examined spectrophotometrically at 294 nm.

tablets and results were tabulated.

2.5: In-vitro dissolution evaluation

2.4.2: Friability This study was carried out by using dissolution

20 CR Ofloxacin tablets were selected and then apparatus .In-vitro release studies were examined,

weighed accurately after weighing those 20 tablets each vessel was filled up to 900 ml of 0.N HCl the

were placed in friabilator which was operated for pH was maintained 1.2 and temperature was set

100 revolutions per minute for four minutes. After on 37±0.5 oC ,the rotations were kept 50 per

that tablets were weight again and the loss in minute. At different time intervals 5ml samples

weight were noted and tabulated. were collected up to 24 hrs and as this 5ml were

replaced with same pH solution. The %age release

2.4.3: Weight variation were noted and tabulated using statistical

For this test randomly 20 of the formulated CR equations and interpreted (16).

tablets of Ofloxacin were selected and individually

tablets were weighed to check any weight variation 2.6. DRUG RELEASE KINETICS

among these formulated tablets (15). To investigate the mechanism of the CR Ofloxacin

2.4.4: Drug content: release rate kinetics, all the data obtained from

For determination of drug contents 5 tablets of CR these formulations developed were fitted into zero

Ofloxacin were grinded and powdered with the order, Higuchi model ,first order and Korsmeyer’s

help of mortar & pestle. An exact weighed 100mg equation release models (17,18).

quantity of that powdered was extracted in 0.1N

www.iajps.com Page 2575

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

3. RESULTS AND DISCUSSION:

Table No 3.1. Standard graph for the estimation of Ofloxacin

Concentration(µg/ml) Absorbance (nm)

10 0.08

12 0.23

14 0.429

16 0.588

18 0.799

20 0.99

Figure 3.1. Calibration curve for the estimation of Ofloxacin

3.1. Pre-formulation Experiments accordingly. The results of the Compressibility

Results of the Angle of repose, compressibility index showed the limits raged in between 12.13%

and Hausner’s ration were done for formulation and 14.21% that indicated the powder has the

F1 to F6 are shown in Table 3.2. necessary flow properties for tablet formulation as

All values of angle of repose were found in this wet granulation. While the Hausner ratio also

research work with in the acceptable limits ranged found within the limits which ranged between

from 24º.96´ to 26º.43´. This shows that these 1.110 to1.122.

powders flow properties were good and were

www.iajps.com Page 2576

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

Table 4.2: Pre-compression evaluation parameters

S.No Angle of Compressibility Hausner’s

repose Index ratio

(θ) (%)

F1 24.96±0.03 13.29±0.014 1.119

F2 25.39±0.05 12.13±0.020 1.110

F3 26.43±0.06 14.2110.023 1.122

F4 25.33±0.05 13.55±0.021 1.115

F5 26.13±0.05 12.95±0.124 1.131

F6 26.52±0.04 13.36±0.016 1.116

Table 3.3. Physical Characteristics of Ofloxacin CR Tablets

Formulati Hardness Weight Variation Friability Thickness Drug Content

on Kg/cm2 (n=3) (mg) (n=20) (%) (n=10) (n=3) (%) (n=3)

Mean±SD Mean±SD Mean±SD

F1 5.7±0.3 669±3.0 0.16 3.2±0.102 250.6±0.5

F2 5.6±0.2 678±3.0 0.14 3.4±0.112 249.8±0.3

F3 5.5±0.3 711±1.0 0.17 4.1±0.111 248.2±0.5

F4 5.6±0.2 677±2.0 0.17 4.0±0.105 250.0±0.2

F5 5.6±0.3 712±2.0 0.13 3.6±0.113 250.4±0.5

F6 5.9±0.1 711±1.0 0.15 4.2±0.108 251.9±0.2

All the formulations of Ofloxacin CR tablets were limits and ranged from 0.13 to 0.17% these results

physically analyzed, their hardness, thickness, of friability shows that all the tablets values were

friability, weight variation and drug content and below the recommended standards i.e. 1%. So this

were matched with standard specifications. These result show resistance from any mechanical abrasion

CR Ofloxacin showed hardness in the limits and and shock and also indicates good compatibility of

ranged from 5.5±0.3 to 5.9±0.1 kg/cm2 these the tablets. The thicknesses of those formulations

results indicate that all the CR formulations of were checked accordingly and it showed that the

Ofloxacin were within the limits and having tablets are within the limits ranged from 3.2±0.102

mechanical strength. Weight variations of the CR to 4.2±0.108mm. The %age contents of those

Ofloxacin formulations were within the limits formulations were showed within the limits it ranged

specified in the Pharmacopeia and ranged from from 248.2±0.5 to 251.9±0.2 %.( table No 3.3).

69±3.0 to 712±2.0. The friability tests of these

formulation done and the results were within the

www.iajps.com Page 2577

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

Table 3.4. Drug Release Profile of CR Ofloxacin Matrix Tablets

Time 0 1 2 4 6 8 10 12 16 20 24

(hrs)

Cumulat F1 0 3.23 17.22 29.11 40.01 48.12 53.23 63.48 72.87 85.11 97.01

ive %

Drug F2 0 5.34 21.22 33.51 42.13 52.20 59.17 69.01 78.05 88.89 94.62

Released

F3 0 12.22 23.17 36.10 44.15 50.11 58.23 68.22 73.09 82.22 92.02

F4 0 10.31 24.52 41.12 48.56 56.22 63.56 73.00 82.23 87.25

98.20

F5 0 13.10 19.06 31.02 36.51 42.23 56.20 61.20 73.25 81.20 92.20

F6 0 9.23 23.00 32.02 39.23 43.25 53.22 62.25 74.32 81.52 91.02

anomalous non fickian mechanism but both

In-vitro Dissolution Studies:

Dissolution In-vitro studies of all C R Ofloxacin

formulations were performed in 0.1 N HCl. The formulations of Ofloxacin with Xanthan Gum and

dissolution studies and the study was performed for Eudragit RL100 polymers at 10:3 releases the drug

24 hrs, and the accumulative drug percentage by non fickian diffusion or it showed near to zero-

releases were noted at different time intervals after order release kinetics. It was also observed and

that the results of dissolution were tabulated of each confirmed that Eudragit RL100 is by nature a

of the formulation F1 to F6 (Shown in table 4.4). hydrophobic polymer and it may retarded the

The drug release % age verses Time in hours for all medium of dissolution by penetrating into the

formulations (F1 to F3) were shown in Figure No matrices which exhibited in prolonged the drug

4. 2 and formulation (F4 to F6) were shown in release profile and it also indicated which increased

figure No 4.3. As the quantity of the polymers the molecular volume of these hydrated polymer

increases the % age release of the drug indicated with a decreased in free space as microspore are

decrease. As the amount of polymer quantity is less existing (Kan and Zhu, 1999, Rehman et al., 2013).

with drug combination the %age release showed

increase in %age. Two different polymers were CONCLUSION:

used in different ratios Ofloxacin with polymer The conclusion of this study work is that the

Xanthan Gum used as (F1 to F3) 10:3, 10:4 and polymers used Xanthan Gum and Eudragit RL100

10:5, subsequently Ofloxacin with polymer both were showed extended results up to 24 hours.

Eudragit RL 100 (F4 to F6) with same ratio as in All these Ofloxacin CR formulations indicated that

Xanthan Gum. In formulation F1 the ratio of drug when Ofloxacin drug is combined with polymer the

and polymer was 10.3 which showed increased decrease in polymer ratio increases the drug release

drug release 97.10%, as in formulation F2 and F3 where the polymer ratio increases it decreases the

where polymer ratio increased 10.4 and 10.5 and drug release and these results showed that in F1 and

the %age release of drug were 94.32% and 92.02% F4 where the drug and polymer ratio were 10.3

in 24 hours. Where the same drug and polymer increased the drug release in both polymers. These

ratio were incorporated as Ofloxacin and polymer polymers can also be used in other drug preparations

Eudragit RL 100 in formulations F4, F5, and F6, as and also suitable for development of CR formulations

10.3, 10.4, and 10.5 it also gave good results in which may give results and extended the drug

10.3 formulation 98.20% as compare to the F5 and release. In these CR formulation developments it

F6 92.20 and 91.02%. These results of all improves the patient compliance and also cost of

formulations confirms that all formulations were these formulation will be very low.

www.iajps.com Page 2578

IAJPS 2018, 05 (04), 2572-2579 Sana mubeen et al ISSN 2349-7750

Campylobacter species and the withdrawal of

fluoroquinolones from use in poultry: a public

REFERENCES: health success story". Clin Infect Dis 44 (7):

1. Brahmankar D.M. and Jaiswal S.B. (1995): “Bio 977–80.doi:10.1086/512369. PMID 17342653.

pharmaceutics and Pharmacokinetics” a Treatise. 10. Jump up^ Kawahara, S. (December 1998).

Vallabh Prakashan, First Edition; 336-337. "[Chemotherapeutic agents under

2. Lachman Leon, Lieberman Herbert A., Kanig study]". Nippon Rinsho 56 (12): 3096–

Joseph L. (1996) “The theory and practice of 9. PMID 9883617.

industrial pharmacy” Second edition, Varghese 11. Sato K, Matsuura Y, Inoue M, Une T, Osada Y,

publishing house; Bombay, 171-196. Ogawa H, Mitsuhashi S; Matsuura; Inoue; Une;

3. Satish ummadi,B Shravani,N. G. Raghavendra Osada; Ogawa; Mitsuhashi (October 1982). "In

Rao,M.Srikanth Reddy, B.Sanjeev Nayak (2013) vitro and in vivo activity of DL-8280, a new

Overview on Controlled Release Dosage Form oxazine derivative". Antimicrob. Agents

International Journal of Pharma Sciences Vol. 3, Chemother. 22 (4): 548-53. doi: 10. 1128/aac.

No. 4 258-269 22.4.548. PMC183791.PMID 6960805 548.

4. King, D.H. (1988) Gennaro, 1995) History, Retrieved 2014-09-28.

pharmacokinetics, and pharmacology of 12. Higuchi, T., & K.A. connor (1965). Adv. Anal.

acyclovir. J. Am. Acad.Dermatol., 18, 176–179 Chem. Instrum. 4: 117.

5. 5. Colin. 2007; McGavin and Goa., 2001 Design 13. Ritger R. L., & N.S. Peppas (1987) J. Control

and development of Nano sized ocular drug Release. 5: 37- 42.

delivery system Jamia Hamdard. Opie L. H., & 14. Gohal, M.C., & M.K. Panchal (2002). Drug.

F.H. Messerli (1995). Nifedipine and mortality. Dev. Ind. Pharm. 28: 77-87.

Circulation. 92: 1068-1073. 15. Lachman L; Liberman HA; Kanig JL

6. Chowdary, K.P.R., K.V. Satyanarayana, S. S. D. (1991). The theory and practice of

Kumar & D. Y. Priya (2011). Int. J. Pharma. industrial pharmacy. 3rd ed. Varghese

1(1): 34-39. publication house, 300.

7. 7. Zsoter TI', Church JG. (1983). Calcium 16. Gohel MC; Mehta PR; Dave PK;

antagonists. Pharmacodynamic effects and Bariya NH (2005). Dissolution tech,

mechanism of action. Drugs; 25: 93-112. 11: 22-5.

8. Xu, G.J., & H. Sanda (1995). Chem. Pharm. 17. Higuchi T. J Pharm Sci, (1963). 52: 1145-1149.

Bull. 43: 483-487. 18. Korsmeyer RW; Gunny R; Peppas NA (1983).

9. Nelson, JM.; Chiller, TM.; Powers, JH.; Angulo, Int J Pharm,15: 25-35.

FJ. (Apr 2007). "Fluoroquinolone-resistant

www.iajps.com Page 2579

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDokument6 SeitenDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoNoch keine Bewertungen

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDokument4 SeitenRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoNoch keine Bewertungen

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDokument9 SeitenFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoNoch keine Bewertungen

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDokument11 SeitenDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNoch keine Bewertungen

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDokument6 SeitenAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoNoch keine Bewertungen

- A Brief Review On YawsDokument7 SeitenA Brief Review On YawsBaru Chandrasekhar RaoNoch keine Bewertungen

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDokument8 SeitenAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNoch keine Bewertungen

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Dokument5 SeitenGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoNoch keine Bewertungen

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDokument6 SeitenSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoNoch keine Bewertungen

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDokument13 SeitenNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoNoch keine Bewertungen

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDokument7 SeitenGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNoch keine Bewertungen

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDokument4 SeitenRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNoch keine Bewertungen

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDokument8 SeitenKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNoch keine Bewertungen

- Preparation of Silver Nanoparticles From Herbal PlantDokument9 SeitenPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoNoch keine Bewertungen

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDokument8 SeitenThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoNoch keine Bewertungen

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDokument12 SeitenNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoNoch keine Bewertungen

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDokument4 SeitenAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoNoch keine Bewertungen

- Review On: Inventory ManagementDokument8 SeitenReview On: Inventory ManagementBaru Chandrasekhar RaoNoch keine Bewertungen

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDokument6 SeitenAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoNoch keine Bewertungen

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDokument5 SeitenC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoNoch keine Bewertungen

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDokument7 SeitenPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNoch keine Bewertungen

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDokument7 SeitenAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNoch keine Bewertungen

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDokument4 SeitenDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNoch keine Bewertungen

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Dokument8 SeitenIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoNoch keine Bewertungen

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDokument6 SeitenAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoNoch keine Bewertungen

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Dokument6 SeitenStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoNoch keine Bewertungen

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDokument4 SeitenAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoNoch keine Bewertungen

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDokument8 SeitenA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoNoch keine Bewertungen

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDokument11 SeitenThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNoch keine Bewertungen

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDokument10 SeitenOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fatigue: Symptom Tiredness Lethargy SleepDokument10 SeitenFatigue: Symptom Tiredness Lethargy Sleepjohnjoseph4069Noch keine Bewertungen

- MEDICAL ABBREVIATIONS AND BLOOD KNOWLEDGEDokument12 SeitenMEDICAL ABBREVIATIONS AND BLOOD KNOWLEDGEShania Kate Ledesma ManabatNoch keine Bewertungen

- Roles and Responsibilities of ASHADokument3 SeitenRoles and Responsibilities of ASHAmohanpskohli8310Noch keine Bewertungen

- Gerd JournalDokument12 SeitenGerd JournalxtineNoch keine Bewertungen

- Typhoid Fever and Cure Well VersedDokument1 SeiteTyphoid Fever and Cure Well Versedscope 3901Noch keine Bewertungen

- Varaha Mihira's Sarvato Bhadra ChakraDokument59 SeitenVaraha Mihira's Sarvato Bhadra ChakraRohith6Noch keine Bewertungen

- Drug StudyDokument8 SeitenDrug StudyMaria Charlene Orpilla0% (1)

- ENT Anatomy of NoseDokument10 SeitenENT Anatomy of NoseMahesh ShresthaNoch keine Bewertungen

- The Relationship Between Dietary Patterns and Nutritional Knowledge With The Nutritional Status of Bajo Tribe Pregnant Women in Duruka District, Muna RegencyDokument5 SeitenThe Relationship Between Dietary Patterns and Nutritional Knowledge With The Nutritional Status of Bajo Tribe Pregnant Women in Duruka District, Muna RegencytreesNoch keine Bewertungen

- Pancreatic HEad MassDokument17 SeitenPancreatic HEad MassNolan CabralNoch keine Bewertungen

- Yoga and Total Health August 2016Dokument32 SeitenYoga and Total Health August 2016kumarNoch keine Bewertungen

- Pcare Sakit Apr 2019Dokument80 SeitenPcare Sakit Apr 2019puskesmas ngkeranNoch keine Bewertungen

- The Future of Health and Wellbeing in The WorkplaceDokument15 SeitenThe Future of Health and Wellbeing in The WorkplaceSalim MuftahNoch keine Bewertungen

- ICD-9-CM Morphology of Neoplasms GuideDokument17 SeitenICD-9-CM Morphology of Neoplasms GuideMaju_kasusNoch keine Bewertungen

- Good Afternoon Everybody My Name Is Farahita and IDokument2 SeitenGood Afternoon Everybody My Name Is Farahita and Iwhite blackNoch keine Bewertungen

- Hancock County Comprehensive Health AssessmentDokument169 SeitenHancock County Comprehensive Health AssessmentGenna FreedNoch keine Bewertungen

- Relationship Between Cigarette Smoking and Novel Risk Factors For Cardiovascular DiseaseDokument4 SeitenRelationship Between Cigarette Smoking and Novel Risk Factors For Cardiovascular DiseaseInternational Medical PublisherNoch keine Bewertungen

- Philippine Guidelines on Clinical Management of COVID-19Dokument41 SeitenPhilippine Guidelines on Clinical Management of COVID-19Athan Antonio100% (1)

- AUTOIMMUNE DISEASES AND ASSOCIATED AUTOANTIBODIESDokument8 SeitenAUTOIMMUNE DISEASES AND ASSOCIATED AUTOANTIBODIESLynx EemanNoch keine Bewertungen

- Nephrolithiasis - NCPDokument9 SeitenNephrolithiasis - NCPAia Javier83% (6)

- Best Practice Diagnostic Guidelines For Patients Presenting With Breast Symptoms PDFDokument60 SeitenBest Practice Diagnostic Guidelines For Patients Presenting With Breast Symptoms PDFfauziafahmi95Noch keine Bewertungen

- Writing Project 3-5Dokument10 SeitenWriting Project 3-5api-456365943Noch keine Bewertungen

- Scribe America Final, Emergency DepartmentDokument41 SeitenScribe America Final, Emergency DepartmentJulio CastilloNoch keine Bewertungen

- Daftar Pustaka FixDokument2 SeitenDaftar Pustaka FixAlmira Shabrina SaraswatiNoch keine Bewertungen

- Minor Disorders of N.B FinalDokument26 SeitenMinor Disorders of N.B Finalsanthiyasandy67% (3)

- Applied Part of Kulliyat With Reference To Venesection (Fasd) : A ReviewDokument4 SeitenApplied Part of Kulliyat With Reference To Venesection (Fasd) : A ReviewDebby Adhila ShanahanNoch keine Bewertungen

- SITXFSA201 Participate in Safe Food Handling PracticesDokument42 SeitenSITXFSA201 Participate in Safe Food Handling PracticesJasmeet Bindra67% (3)

- RashiDokument14 SeitenRashiajay khandelwalNoch keine Bewertungen

- Lesson PlanDokument11 SeitenLesson Planpraneet waghmare100% (2)

- Ill Effects of CrackersDokument3 SeitenIll Effects of Crackersnagpal3Noch keine Bewertungen