Beruflich Dokumente

Kultur Dokumente

Visio-Belt Rip Installation Instructions PDF

Hochgeladen von

MikiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Visio-Belt Rip Installation Instructions PDF

Hochgeladen von

MikiCopyright:

Verfügbare Formate

8 7 6 5 4 3 2 1

INSTALLATION INSTRUCTIONS

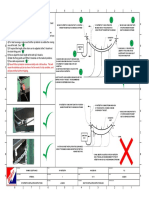

Your Belt Rip Detector is best installed by two persons. 1 2 3

H 1) Follow isolating procedures and make sure that the belt is isolated and H

MOVE RIP DETECTOR FIXING POINT IN TO A POSITION RIP DETECTOR TO BE OUTSIDE THE MOVE CHAIN FIXING POINT IN TO

safe to work on. WHERE THE BEST BELT COVERAGE IS OBTAINED MOVING AREA OF THE CONVEYOR IN A POSITION WHERE THE BEST

2) Fit the pin into its locking position inside the rip detector ORDER TO GET THE BEST BELT COVERAGE BELT COVERAGE IS OBTAINED

3) With one person on the one side,” 1 “ of the conveyor and another

person on the other side,” 3 “ of the conveyor, hang the chain so that you

CONVEYOR

get an even clearance between the chain and the belt. See: “ 5 “ BELT

4) For best coverage, make sure that the rip detector is outside the moving 6

G area of the belt. See: “ 2 “ G

JUNCTION

5) If required the length of the chain can be adjusted at the D shackle at BOX

CHAIN SLACK. IF REQUIRED THE

LENGTH OF THE CHAIN CAN BE

the chain fixing point. “ 6 “

6) Never adjust the chain length at the belt rip D shackle. 4 AJUSTED WITH THE D SHACKLE AT

THE CHAIN FIXING POINT

4) Mark the fixing points and fit the D shackles on the marked positions. 1)ALWAYS USE A HIGH QUALITY FLEXIBLE CABLE.

5) See cable requirements. “ 4 “ 2) ALWAYS LEAVE ENOUGH SLACK TO ALLOW THE

8) Never fit the rip detector enclosure solidly onto a flat surface. This will RIP DETECTOR TO SWING FREELY INTO ANY

DIRECTION

F cause the stainless pull pin to sheer of in the event of a trip condition, and 3) USE THE CORRECT SIZE OF CABLE FOR THE

F

will prevent the belt from tripping. GLAND IN THE RIP DETECTOR 5

CHAIN

AJUST CHAIN TO HAVE AN EVEN CLEARANCE OVER THE

ENTIRE CURVE OF THE BELT. THE RECOMMENDED

CLEARANCE IS BETWEEN 50 AND 100 mm.

E E

RIP DETECTOR FIXING POINT IS NOT IN A POSITION RIP DETECTOR IS INSIDE THE MOVING AREA

WHERE THE BEST BELT COVERAGE IS OBTAINED OF THE CONVEYOR, CAUSING UN EAVEN

D COVERAGE OF THE BELT.

MOVE CHAIN FIXING POINT IN TO D

A POSITION WHERE THE BEST

BELT COVERAGE IS OBTAINED

CONVEYOR

BELT

C C

JUNCTION CHAIN

BOX

DUE TO INCORRECT INSTALLATION THE CLEARANCES

ARE NOT THE SAME CAUSING UNEFECTIVE PROTECTION

AGAINST BELT RIPS

B CHAIN LENGTH IS AJUSTED ON THE RIP DETECTOR B

SIDE. THIS WILL AD EXCESIVE WEIGHT TO THE RIP

DETECTOR AND COULD CAUSE NUINSANCE TRIP[PING

COMPANY TITLE DRAWING No DRAWN BY

BRAMCO ELECTRONICS RIP DETECTOR AM 1259 BRC F.S

CUSTOMER REVISION PAGE DATE

A INTERNAL 1 1 OF 1 4/12/2010 A

PROJECT REVISED FILENAME APPROVED BY

RIP DETECTOR INSTALLATION INSTRUCTIONS 4/12/2010 BELT RIP INSTALLATION INSTRUCTIONS.VSD

8 7 6 5 4 3 2 1

Das könnte Ihnen auch gefallen

- Webley Omega ManualDokument5 SeitenWebley Omega ManualPhil Stevenson100% (1)

- 2du-8847 Epirb Final 00Dokument68 Seiten2du-8847 Epirb Final 00Виктор СуворовNoch keine Bewertungen

- Assembly / Installation Instructions: For Canadian Installations Please Refer To Page 2Dokument3 SeitenAssembly / Installation Instructions: For Canadian Installations Please Refer To Page 2dayshift5Noch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument3 SeitenAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Assembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Reeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuideDokument5 SeitenReeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuidealiNoch keine Bewertungen

- Is WC1915Dokument1 SeiteIs WC1915dayshift5Noch keine Bewertungen

- Automatic Transmission Parking Lock Pawl Removal & InstallationDokument1 SeiteAutomatic Transmission Parking Lock Pawl Removal & InstallationRoberoNoch keine Bewertungen

- Clipper Duet Manual 19 PDFDokument16 SeitenClipper Duet Manual 19 PDFcarylangleyNoch keine Bewertungen

- Hyd Cylinder Details Jyo MakeDokument4 SeitenHyd Cylinder Details Jyo MakeAnna BhosadikeNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument3 SeitenAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Dans Manual 1Dokument19 SeitenDans Manual 1Fabrii Magnus LodbrókNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Assembly / Installation Instructions:: Chain-Hung MountingDokument1 SeiteAssembly / Installation Instructions:: Chain-Hung MountingA_tenksNoch keine Bewertungen

- Notes:: Engineering StandardsDokument33 SeitenNotes:: Engineering Standardsahong100Noch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- 501 453 Universal ColdFlowDokument2 Seiten501 453 Universal ColdFlowRavi VarmaNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Foundation Design - 1. Soil Exploration - 6!1!2015Dokument3 SeitenFoundation Design - 1. Soil Exploration - 6!1!2015Aman Raj VermaNoch keine Bewertungen

- Naik Sir GSK PDFDokument19 SeitenNaik Sir GSK PDFLance RodriguesNoch keine Bewertungen

- Instruction Sheet Is Rvz5006 - Style Number Rvz5006Cs:: Package ContentsDokument4 SeitenInstruction Sheet Is Rvz5006 - Style Number Rvz5006Cs:: Package Contentsdayshift5Noch keine Bewertungen

- South Bend Taper AttachmentDokument6 SeitenSouth Bend Taper AttachmentMikeNoch keine Bewertungen

- Deep-Water-Black-Box-Retrieval - PINGERDokument4 SeitenDeep-Water-Black-Box-Retrieval - PINGERLuana MarchioriNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- 501/453 UNIVERSAL: Cable Gland Selection TableDokument2 Seiten501/453 UNIVERSAL: Cable Gland Selection TableManikandan ShriNoch keine Bewertungen

- Assembly / Installation Instructions:: Refer DETAIL1 and DETAIL2 For AssemblyDokument1 SeiteAssembly / Installation Instructions:: Refer DETAIL1 and DETAIL2 For Assemblydayshift5Noch keine Bewertungen

- Astm d6230 - Part 2Dokument4 SeitenAstm d6230 - Part 2leegoon82Noch keine Bewertungen

- Instruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package ContentsDokument4 SeitenInstruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package Contentsdayshift5Noch keine Bewertungen

- Fitting Guide Dml26Wb: Kit Contents 3. Coaxial Cable ConnectionDokument1 SeiteFitting Guide Dml26Wb: Kit Contents 3. Coaxial Cable ConnectionM100S2Noch keine Bewertungen

- EAG WL SWI Rope Socket Assembly GuideDokument3 SeitenEAG WL SWI Rope Socket Assembly GuideJose Antonio Acosta100% (1)

- Cable and Harness Solder SleevesDokument2 SeitenCable and Harness Solder SleeveslheriaufrancoisNoch keine Bewertungen

- Underground Settler Design InvestigationDokument21 SeitenUnderground Settler Design InvestigationGlenn NyirendaNoch keine Bewertungen

- Is Vesl1506Dokument1 SeiteIs Vesl1506dayshift5Noch keine Bewertungen

- Caution - Risk of Shock - Disconnect Power at The Main Circuit Breaker Panel or Main Fuse Box Before Starting and During The InstallationDokument1 SeiteCaution - Risk of Shock - Disconnect Power at The Main Circuit Breaker Panel or Main Fuse Box Before Starting and During The InstallationSohil KhanNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Rocket Science and Technology: Parachute ReefingDokument3 SeitenRocket Science and Technology: Parachute ReefingRohan PolNoch keine Bewertungen

- JJJJJLKLLDokument5 SeitenJJJJJLKLLsubodhasinghNoch keine Bewertungen

- Legend: General Notes & SpecificationDokument1 SeiteLegend: General Notes & SpecificationShaunjay Dela CalzadaNoch keine Bewertungen

- Notice 5500003Dokument43 SeitenNotice 5500003cruzetNoch keine Bewertungen

- Raystar 125 - 81247 - 3Dokument8 SeitenRaystar 125 - 81247 - 3CARDONNoch keine Bewertungen

- JSA Manual Excavation and Cable LayingDokument3 SeitenJSA Manual Excavation and Cable Layingimran100% (1)

- Criteria For Design of Lifting BeamsDokument10 SeitenCriteria For Design of Lifting BeamsFseha GideyNoch keine Bewertungen

- EzoBord - Ceiling Baffle - Installation InstructionsDokument3 SeitenEzoBord - Ceiling Baffle - Installation InstructionsMEPNoch keine Bewertungen

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Dokument9 SeitenV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612pablo7890Noch keine Bewertungen

- Back Off String ShotDokument16 SeitenBack Off String ShotChoayb Seller100% (1)

- Elf Assembly Version 1-5 PDFDokument15 SeitenElf Assembly Version 1-5 PDFDaiben SulitNoch keine Bewertungen

- Assembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Dokument1 SeiteAssembly / Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5Noch keine Bewertungen

- Assembly / Installation Instructions:: Note There Are 2 Kinds of CRYSTALS Please Refer To The Illustration To Locate ThemDokument1 SeiteAssembly / Installation Instructions:: Note There Are 2 Kinds of CRYSTALS Please Refer To The Illustration To Locate Themdayshift5Noch keine Bewertungen

- CABLE GLAND SERIES PROVIDES FLAMEPROOF AND DUST PROTECTIONDokument2 SeitenCABLE GLAND SERIES PROVIDES FLAMEPROOF AND DUST PROTECTIONsedcNoch keine Bewertungen

- Instruction Sheet Is-Srd1911 Style Number: Srd1911K: Package ContentsDokument5 SeitenInstruction Sheet Is-Srd1911 Style Number: Srd1911K: Package Contentsdayshift5Noch keine Bewertungen

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDokument12 SeitenYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenNoch keine Bewertungen

- Dismantling Joints: Pioneers in Pipe SolutionsDokument8 SeitenDismantling Joints: Pioneers in Pipe SolutionsMohamed TarekNoch keine Bewertungen

- Parking BrakeDokument42 SeitenParking BrakeMirceaNoch keine Bewertungen

- De AnleitungDokument42 SeitenDe AnleitungLucas GabrielNoch keine Bewertungen

- Constrain LinerDokument12 SeitenConstrain LinerAgung TristyantoNoch keine Bewertungen

- ED - Engine Hood DoorDokument57 SeitenED - Engine Hood DoorCarlos MafudNoch keine Bewertungen

- Shearing Blind Rams SBRDokument8 SeitenShearing Blind Rams SBRDavid OrtegaNoch keine Bewertungen

- DS-1 Training-Drill Pipe InspectionDokument180 SeitenDS-1 Training-Drill Pipe InspectionSara Marzouk83% (6)

- Mechanical Seal Installation GuideDokument3 SeitenMechanical Seal Installation GuidekiranNoch keine Bewertungen

- Antennas in Inhomogeneous Media: International Series of Monographs in Electromagnetic WavesVon EverandAntennas in Inhomogeneous Media: International Series of Monographs in Electromagnetic WavesNoch keine Bewertungen

- Coal Deposits Figure 1Dokument1 SeiteCoal Deposits Figure 1MikiNoch keine Bewertungen

- Bt2000 Belt Tear and Spillage Detector 0Dokument2 SeitenBt2000 Belt Tear and Spillage Detector 0MikiNoch keine Bewertungen

- Software DocumentationDokument19 SeitenSoftware Documentationamitkk100% (4)

- Visio-Belt Rip Installation InstructionsDokument1 SeiteVisio-Belt Rip Installation InstructionsMikiNoch keine Bewertungen

- Bt2000 Belt Rip and Spillage Detector Installation and Instruction ManualDokument7 SeitenBt2000 Belt Rip and Spillage Detector Installation and Instruction ManualMikiNoch keine Bewertungen

- Belt Tear Detector.20160126Dokument4 SeitenBelt Tear Detector.20160126MikiNoch keine Bewertungen

- Brc1 Belt Rip Detector Rev1Dokument2 SeitenBrc1 Belt Rip Detector Rev1MikiNoch keine Bewertungen

- Frederick County Fire Sprinkler ChecklistDokument3 SeitenFrederick County Fire Sprinkler Checklistdewi100% (1)

- ET Subsea Ball ValvesDokument9 SeitenET Subsea Ball ValvesAndrew BaileyNoch keine Bewertungen

- Main Pump Major ComponentsDokument7 SeitenMain Pump Major ComponentsElmanxd Proh100% (2)

- TM 80 Daily and Weekly Inspection and Maintenance TasksDokument25 SeitenTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNoch keine Bewertungen

- Carrier air conditioner installation guideDokument15 SeitenCarrier air conditioner installation guideArvin TabunotNoch keine Bewertungen

- Key Features Boilermaker Proven, Legendary ReliabilityDokument2 SeitenKey Features Boilermaker Proven, Legendary ReliabilityManuel Cantoral CortazarNoch keine Bewertungen

- Pricelistsalitems (Steel Pipes & Fittings)Dokument10 SeitenPricelistsalitems (Steel Pipes & Fittings)Anis MohdNoch keine Bewertungen

- Body Control System: SectionDokument80 SeitenBody Control System: Sectionwilder0l0pezNoch keine Bewertungen

- Wiring DiagramDokument12 SeitenWiring DiagramÁlvaro TorrellasNoch keine Bewertungen

- Lab Manual 1Dokument3 SeitenLab Manual 1elizabeth shaw gonzalezNoch keine Bewertungen

- INV Trouble Shootguide (Engver.)Dokument108 SeitenINV Trouble Shootguide (Engver.)Yohanes Triatmojo100% (1)

- Barrel Coupling PDFDokument1 SeiteBarrel Coupling PDFRajendra PagarNoch keine Bewertungen

- Kioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019Dokument19 SeitenKioti Daedong EX50, EX55, EX5310, EX5810 Tractors Service Manual 04-2019LisakolyNoch keine Bewertungen

- HY-P Leaflet (ENG) PDFDokument8 SeitenHY-P Leaflet (ENG) PDFEdwin RodríguezNoch keine Bewertungen

- 20180716082859681Dokument2 Seiten20180716082859681Paul Abi NajemNoch keine Bewertungen

- Alternator InspectionDokument2 SeitenAlternator Inspectionshahg9948Noch keine Bewertungen

- NR D513XZDokument5 SeitenNR D513XZaderloch100% (1)

- Scania P, G, R, T Series Workshop Manual - Removing The Radiator Part 4Dokument10 SeitenScania P, G, R, T Series Workshop Manual - Removing The Radiator Part 4musharrfNoch keine Bewertungen

- Power Distribution StandardsV1Dokument35 SeitenPower Distribution StandardsV1ajalbornozNoch keine Bewertungen

- M-900iB360 280L 280 Operator Manual (B-83684EN 03)Dokument154 SeitenM-900iB360 280L 280 Operator Manual (B-83684EN 03)Sakura ChangNoch keine Bewertungen

- MDO Transfer PumpDokument1 SeiteMDO Transfer PumpsuranovoleksandrNoch keine Bewertungen

- Cable Ladder Weight Calculation SheetsDokument46 SeitenCable Ladder Weight Calculation SheetsSadique Shaikh100% (1)

- WT-150II: Nakamura-TomeDokument4 SeitenWT-150II: Nakamura-Tomet.goncalvesNoch keine Bewertungen

- HI 800 357 E Device H7201Dokument3 SeitenHI 800 357 E Device H7201kailasamvvNoch keine Bewertungen

- Type Test Reports for 420 kV 10kA Class-II Polymer Surge ArrestersDokument1 SeiteType Test Reports for 420 kV 10kA Class-II Polymer Surge ArrestersVamsi SwapnaNoch keine Bewertungen

- Service Manual: Microwave Oven TC 2250/WHDokument8 SeitenService Manual: Microwave Oven TC 2250/WHTóth LászlóNoch keine Bewertungen

- Wincc Flexible Projekttransfer eDokument28 SeitenWincc Flexible Projekttransfer ewendelreis19746883Noch keine Bewertungen

- Electrical BoqDokument29 SeitenElectrical BoqPaulthiyagaraj SNoch keine Bewertungen

- KD 200-60 P Series: Cutting Edge TechnologyDokument2 SeitenKD 200-60 P Series: Cutting Edge TechnologyEmmanuel Entzana HdzNoch keine Bewertungen

- Street Photography Short Guide by Kent DufaultDokument22 SeitenStreet Photography Short Guide by Kent DufaultMilorad RadenovicNoch keine Bewertungen