Beruflich Dokumente

Kultur Dokumente

JSA - Sand Blasting and Paintng

Hochgeladen von

JohnOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JSA - Sand Blasting and Paintng

Hochgeladen von

JohnCopyright:

Verfügbare Formate

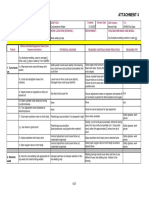

PROJECT: FIELD ERECTION OF 15000 BBLs TANK (IK-

2545) F O R M S

Job Safety Analysis Doc. Level IV Doc. Version: 00

Sand Blasting and Painting

Doc. No.: HSE-FRM-43 W.e.f: 20-3-2012

JSA Date: 10-06-2012 JSA NO:

Assessment Team: Yasin Rind, M.Waqas Farooq, Ahmad Bilal, M. Altaf

PPE's Required: Safety Helmet, Safety Shoes, Gloves, Glasses, and Dust Mask, Blasting

PTW NO.

Hood, Ear Muffs, Coverall

Step

No: Hazard Description &

Description of Task Step Controls Measures Residual Risk Controls

Effect

Ensure blasting equipment and compressor are not

Incorrect or defective defective . Compressor should be third party certified. Proper Inspection and color coding of power tools

material / Equipment Shicago couplings, whip guards and dead man switch (if applicable) and hand held tools.

must be ensured.

1 Mobilization of equipment.

Ensure workers involved in sand blasting are trained Conduction of tool box meeting before

Unskilled workers

and competant to carry out the job safely. commencement of job.

Follow PTW system. Proper PPE's shall be ensured for

workers who involved in sand blasting. Dust Mask and

Exposure of dust, noise Safety signs for sand blasting to be installed.

ear plugs shall be used. Sand blasting area should be

enclosed with green mesh.

2 Sand Blasting

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 1 Of 8

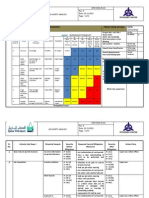

PROJECT: FIELD ERECTION OF 15000 BBLs TANK (IK-

2545) F O R M S

Job Safety Analysis Doc. Level IV Doc. Version: 00

Sand Blasting and Painting

Doc. No.: HSE-FRM-43 W.e.f: 20-3-2012

JSA Date: 10-06-2012 JSA NO:

Assessment Team: Yasin Rind, M.Waqas Farooq, Ahmad Bilal, M. Altaf

PPE's Required: Safety Helmet, Safety Shoes, Gloves, Glasses, and Dust Mask, Blasting

PTW NO.

Hood, Ear Muffs, Coverall

Step

No: Hazard Description &

Description of Task Step Controls Measures Residual Risk Controls

Effect

2 Sand Blasting

Do not leave blasting equipment un-attended with air

Injury due to mishandling supply on. Ensure that blast gun is fitted with Prohibition of unauthorized personnel to stay in

blasting equipment emergency release handle (Dead man's handle) and it affected area.

is functional.

Shicago couplings and whip guard shall be ensured. Safety valve and dead man switch should be

Pressure Explosion

Hose fittings need to be secured properly. ensured.

Presence of blastinfg supervisor shall be ensured in the Conduction of tool box meeting before

Lack of communication area. A watchman shall be present to communicate with commencement of job. Safety signs for sand

blaster in case of emergency. blasting to be installed.

Sand Blasting

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 2 Of 8

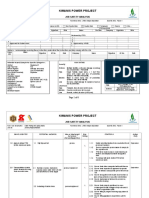

PROJECT: FIELD ERECTION OF 15000 BBLs TANK (IK-

2545) F O R M S

Job Safety Analysis Doc. Level IV Doc. Version: 00

Sand Blasting and Painting

Doc. No.: HSE-FRM-43 W.e.f: 20-3-2012

JSA Date: 10-06-2012 JSA NO:

Assessment Team: Yasin Rind, M.Waqas Farooq, Ahmad Bilal, M. Altaf

PPE's Required: Safety Helmet, Safety Shoes, Gloves, Glasses, and Dust Mask, Blasting

PTW NO.

Hood, Ear Muffs, Coverall

Step

No: Hazard Description &

Description of Task Step Controls Measures Residual Risk Controls

Effect

Sand Blasting

Fire extinguisher shall be present at the

location.Conduction of tool box meeting before

commencement of job.Continuous Monitoring of

flamable contents with LEL Meter. Maintain log

Fire Hazard Stop air compressor when fueling. sheet for LEL monitoring. Safety signs for sand

blasting to be installed.

Conduction of tool box meeting before

Proper sand blasting hood should be used for sand

Suffocation commencement of job. Safety signs for sand

blaster with proper supply of breathing air.

blasting to be installed.

Ensure proper recovery of material and house keeping.

Ensure the tidiness of area. Dust mask shall be used

3 House Keeping Scattered material for house keeping.

Conduction of tool box meeting before

Inhalation of paint and lungs Wear dust mask and other PPE's that are mentioned

commencement of job. Display MSDS in working

damage on MSDS.

area.

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 3 Of 8

4 Paint work

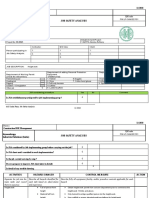

PROJECT: FIELD ERECTION OF 15000 BBLs TANK (IK-

2545) F O R M S

Job Safety Analysis Doc. Level IV Doc. Version: 00

Sand Blasting and Painting

Doc. No.: HSE-FRM-43 W.e.f: 20-3-2012

JSA Date: 10-06-2012 JSA NO:

Assessment Team: Yasin Rind, M.Waqas Farooq, Ahmad Bilal, M. Altaf

PPE's Required: Safety Helmet, Safety Shoes, Gloves, Glasses, and Dust Mask, Blasting

PTW NO.

Hood, Ear Muffs, Coverall

Step

No: Hazard Description &

Description of Task Step Controls Measures Residual Risk Controls

Effect

Wear safety goggles and hand gloves recommended in Conduction of tool box meeting before

Skin and eye irritation

MSDS. commencement of job.

4 Paint work

Fire extinguisher shall be present at the

No hot work shall be allowed near painting job.

location.Conduction of tool box meeting before

Bulk storage shall not be allowed in working area.

commencement of job.Continuous Monitoring of

Fire Hazard MSDS shall be present at site before the start of work.

flamable contents with LEL Meter. Maintain log

Contaminated rags shall be desposed of properly in

sheet for LEL monitoring. Safety signs for sand

designated waste drums.

blasting to be installed.

Prepared By: Reviewd By: Approved By:

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 4 Of 8

R M S

Doc. Version: 00

W.e.f: 20-3-2012

Risk Controls

color coding of power tools

held tools.

meeting before

asting to be installed.

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 5 Of 8

R M S

Doc. Version: 00

W.e.f: 20-3-2012

Risk Controls

ized personnel to stay in

man switch should be

meeting before

Safety signs for sand

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 6 Of 8

R M S

Doc. Version: 00

W.e.f: 20-3-2012

Risk Controls

be present at the

ool box meeting before

Continuous Monitoring of

LEL Meter. Maintain log

g. Safety signs for sand

meeting before

Safety signs for sand

meeting before

Display MSDS in working

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 7 Of 8

R M S

Doc. Version: 00

W.e.f: 20-3-2012

Risk Controls

meeting before

be present at the

ool box meeting before

Continuous Monitoring of

LEL Meter. Maintain log

g. Safety signs for sand

Controlled annd Confidential @ IKAN Engineering Services (Pvt.) Limited Page 8 Of 8

Das könnte Ihnen auch gefallen

- Risk Assesment For Sand Blasting and PaintingDokument6 SeitenRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (10)

- SCAT OriginalDokument4 SeitenSCAT OriginalChinmiholic100% (3)

- Jobs Safety Analysis (JSA)Dokument8 SeitenJobs Safety Analysis (JSA)uttam mishra100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDokument17 SeitenSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Working Safely Powerpoint PresentationDokument60 SeitenWorking Safely Powerpoint PresentationHAFIZ IMRAN AKHTER100% (1)

- JSA For Welding in Boiler PDFDokument2 SeitenJSA For Welding in Boiler PDFSravan Dasari100% (3)

- Rammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksDokument1 SeiteRammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksJohn75% (4)

- Surtec 650V MsdsDokument7 SeitenSurtec 650V MsdsjkljNoch keine Bewertungen

- Hazard Identification Plan (HIP) HaradhDokument29 SeitenHazard Identification Plan (HIP) HaradhAsif Khanzada63% (8)

- Manual Tig Welding (RRC) - Job ProcedureDokument3 SeitenManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA For Painting Works-Hazards ControlDokument4 SeitenJSA For Painting Works-Hazards Controlkaleem0% (2)

- JSA Template 2017-05-31 Cable Tray InstallationDokument19 SeitenJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNoch keine Bewertungen

- Risk Assess JSA Derrick Flare Structure Installation Erection 018Dokument11 SeitenRisk Assess JSA Derrick Flare Structure Installation Erection 018Abdeldjalil Ferhati100% (3)

- JHA Scaffolding ErectionDokument12 SeitenJHA Scaffolding ErectionChayank TiwariNoch keine Bewertungen

- JSA For Fabrication WorksDokument11 SeitenJSA For Fabrication Workssurendra behera100% (3)

- Scaffolding JSA (General)Dokument5 SeitenScaffolding JSA (General)Panchdev KumarNoch keine Bewertungen

- R1937-JSA-004 Job Safety Analysis For Pipe PullDokument3 SeitenR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNoch keine Bewertungen

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDokument18 SeitenJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- JHA Valve Leak Test and RepairDokument16 SeitenJHA Valve Leak Test and Repairrosevelvet100% (1)

- JSA - Paintng in Confined SpaceDokument6 SeitenJSA - Paintng in Confined SpaceJohnNoch keine Bewertungen

- JSA - Paintng in Confined SpaceDokument6 SeitenJSA - Paintng in Confined SpaceJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Human Resources BudgetDokument8 SeitenHuman Resources BudgetzidraveNoch keine Bewertungen

- 069909Dokument356 Seiten069909carolinasluggaNoch keine Bewertungen

- Final Report - September 7, 2017 Incident InvestigationDokument4 SeitenFinal Report - September 7, 2017 Incident InvestigationDan Lehr100% (1)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Dokument6 SeitenJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNoch keine Bewertungen

- JSA G20 Scaffolding Erection DismantlingDokument4 SeitenJSA G20 Scaffolding Erection DismantlingemmyNoch keine Bewertungen

- JSA Machinal PipingDokument7 SeitenJSA Machinal PipingNaitik Desai48100% (1)

- Jsa For Civil WorkDokument6 SeitenJsa For Civil WorkMuhammad Umar GondalNoch keine Bewertungen

- JSA - Blasting & PaintingDokument11 SeitenJSA - Blasting & PaintingRajuNoch keine Bewertungen

- JSA Earthpit Construction GeneralDokument4 SeitenJSA Earthpit Construction Generalmukka88Noch keine Bewertungen

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDokument5 Seiten1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliNoch keine Bewertungen

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokument4 SeitenJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Job Safety Analysis - Clinker StorageDokument4 SeitenJob Safety Analysis - Clinker StorageMohammed MinhajNoch keine Bewertungen

- JHA Scaffolding - ApprovedDokument15 SeitenJHA Scaffolding - ApprovedLuqman OsmanNoch keine Bewertungen

- Jsa-Jha For Using of Hand ToolsDokument2 SeitenJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA For HDPE SLEEVING DEL 89Dokument3 SeitenJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- JSA-055 Hydro-TestDokument24 SeitenJSA-055 Hydro-TestOmar Dhieb100% (7)

- Job Hazard Analysis Welding Operations: Attachment 4Dokument3 SeitenJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063Noch keine Bewertungen

- Crane JSADokument5 SeitenCrane JSAPungky Tri WijayaNoch keine Bewertungen

- PaintingDokument1 SeitePaintingReynaldo PesqueraNoch keine Bewertungen

- QP Blasting JSADokument6 SeitenQP Blasting JSAMohammed Mujahid100% (1)

- JSA #19 Grinding, Welding, Gas CuttingDokument2 SeitenJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- Sand Blasting ProceduresDokument2 SeitenSand Blasting Proceduressarge18100% (2)

- JSA For Piping-Hydro TestDokument10 SeitenJSA For Piping-Hydro TestMuthu AlaguRajNoch keine Bewertungen

- Mig Welding Work JSA HSE ProfessionalsDokument2 SeitenMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- Jsa For Cutting, Grinding and Welding For GulfconDokument3 SeitenJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- Job Hazard Analysis FOR Grinding WorkDokument6 SeitenJob Hazard Analysis FOR Grinding WorkMAHA LINGAMNoch keine Bewertungen

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDokument4 SeitenPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNoch keine Bewertungen

- JSA Cable Pulling and Laying WorksDokument6 SeitenJSA Cable Pulling and Laying Workskabir100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDokument4 SeitenThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNoch keine Bewertungen

- JSA GC-5 Mobile ScaffoldingDokument6 SeitenJSA GC-5 Mobile Scaffoldinggrande100% (2)

- JSA For Chimney Works 17.09.2021Dokument2 SeitenJSA For Chimney Works 17.09.2021Brenden PalanithangamNoch keine Bewertungen

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokument1 SeiteJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JSA PaintingDokument1 SeiteJSA PaintingjonesNoch keine Bewertungen

- Injury & Illness Prevention Program: Job Safety Analysis FormDokument2 SeitenInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokument4 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNoch keine Bewertungen

- JSA-Construction Right of WayDokument3 SeitenJSA-Construction Right of Wayfrancis_e_tan100% (6)

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDokument3 SeitenRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNoch keine Bewertungen

- 11 - Job Safety Analysis ProcedureDokument11 Seiten11 - Job Safety Analysis ProcedureMohammed MinhajNoch keine Bewertungen

- JSA For Painting Inside TankDokument2 SeitenJSA For Painting Inside TankDilshad aliNoch keine Bewertungen

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDokument2 SeitenRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Jsa For Piping and Erection RevisedDokument1 SeiteJsa For Piping and Erection RevisedDr AnwarNoch keine Bewertungen

- 003-JSA Pipe Loading and OffloadingDokument8 Seiten003-JSA Pipe Loading and OffloadingMoaatazz NouisriNoch keine Bewertungen

- Job Safety AnalysisDokument4 SeitenJob Safety AnalysisDedi Apriadi71% (7)

- SOP Erection TC PDFDokument3 SeitenSOP Erection TC PDFRashidi RahmanNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument7 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDokument4 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDokument9 SeitenJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNoch keine Bewertungen

- Store & Dispatch Swot: StrengthsDokument1 SeiteStore & Dispatch Swot: StrengthsJohnNoch keine Bewertungen

- Maintenance SWOTDokument1 SeiteMaintenance SWOTJohnNoch keine Bewertungen

- Accident Investigation 1Dokument51 SeitenAccident Investigation 1JohnNoch keine Bewertungen

- Proposal Swot: StrengthsDokument1 SeiteProposal Swot: StrengthsJohnNoch keine Bewertungen

- Fixed Assets SWOTDokument1 SeiteFixed Assets SWOTJohnNoch keine Bewertungen

- Environmental Lead ExposureDokument10 SeitenEnvironmental Lead ExposureJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (2)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument7 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument4 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDokument4 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- Barytes SDS 12 04INT19 03Dokument5 SeitenBarytes SDS 12 04INT19 03Shola EshoNoch keine Bewertungen

- Improving Patient and Worker SafetyDokument171 SeitenImproving Patient and Worker SafetylaggantigganNoch keine Bewertungen

- CSHPDokument4 SeitenCSHPYanna YóøNoch keine Bewertungen

- Premala Hse ManualDokument7 SeitenPremala Hse ManualLuqman Osman100% (1)

- ImistDokument33 SeitenImistprakashNoch keine Bewertungen

- ByDesign Z359Special Fall2007 PDFDokument7 SeitenByDesign Z359Special Fall2007 PDFA. C. V.Noch keine Bewertungen

- JOY, Jim GRIFFITHS, Derek. National Minerals Industry Safety and Health Risk Assessment Guideline. Version 3, March, MCA and MISHC, Australia, (2011), Retrieved August 2013 at Www. Pla PDFDokument164 SeitenJOY, Jim GRIFFITHS, Derek. National Minerals Industry Safety and Health Risk Assessment Guideline. Version 3, March, MCA and MISHC, Australia, (2011), Retrieved August 2013 at Www. Pla PDFAender FerreiraNoch keine Bewertungen

- Ergonomics For Restaurant and Hotel WorkersDokument33 SeitenErgonomics For Restaurant and Hotel WorkersZamfir SachelarescuNoch keine Bewertungen

- Searchable Text2Dokument547 SeitenSearchable Text2ChrisNoch keine Bewertungen

- Updated Fru Magdalene CV Jan 2015Dokument3 SeitenUpdated Fru Magdalene CV Jan 2015Lovis NKNoch keine Bewertungen

- Meguiar's M49 - Super Duty Fiberglass Cleaner: Motor ActiveDokument12 SeitenMeguiar's M49 - Super Duty Fiberglass Cleaner: Motor Activejeanada phillipsNoch keine Bewertungen

- Opti Tower Health and Safety File Oct 12Dokument387 SeitenOpti Tower Health and Safety File Oct 12Pieter HerbstNoch keine Bewertungen

- Proposal To Cancel Occupational SeriesDokument3 SeitenProposal To Cancel Occupational SeriesFedSmith Inc.100% (1)

- CV Marjan Petrovski APAVE Rev 2Dokument3 SeitenCV Marjan Petrovski APAVE Rev 2mac1677Noch keine Bewertungen

- Department of Labor: 99 107Dokument12 SeitenDepartment of Labor: 99 107USA_DepartmentOfLaborNoch keine Bewertungen

- Institut Keselamatan Dan Kesihatan Pekerjaan Negara National Institute of Occupational Safety and Health Kurikulum Kursus Course Curriculum TEL: 03 - 8769 2100 FAX: 03 - 8926 2900 URLDokument3 SeitenInstitut Keselamatan Dan Kesihatan Pekerjaan Negara National Institute of Occupational Safety and Health Kurikulum Kursus Course Curriculum TEL: 03 - 8769 2100 FAX: 03 - 8926 2900 URLSeindahNyaNoch keine Bewertungen

- CE462 Chapter2Dokument60 SeitenCE462 Chapter2fth52Noch keine Bewertungen

- SuprafitDokument8 SeitenSuprafitWan MichaelNoch keine Bewertungen

- Nadopod 2004Dokument21 SeitenNadopod 2004Jin Yi LimNoch keine Bewertungen

- Environment, Health and Safety Supplement To The TOE Guidebook - English PDFDokument180 SeitenEnvironment, Health and Safety Supplement To The TOE Guidebook - English PDFJohn RajeshNoch keine Bewertungen

- Manual COMPRESOR DEWALT PDFDokument56 SeitenManual COMPRESOR DEWALT PDFJorgeBrambilaNoch keine Bewertungen

- NASCDokument16 SeitenNASCbalasubramaniamNoch keine Bewertungen

- IRP 4 2009 Well Testing and Fluid HandlingDokument151 SeitenIRP 4 2009 Well Testing and Fluid HandlingAndy RosenerNoch keine Bewertungen