Beruflich Dokumente

Kultur Dokumente

Prob #1: Check For Slenderness of Column

Hochgeladen von

Aman Raj VermaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prob #1: Check For Slenderness of Column

Hochgeladen von

Aman Raj VermaCopyright:

Verfügbare Formate

{Strictly for students of CE372A at IIT Kanpur, 2018}

Prob #1

b 350 mm D 350 mm fy 415 MPa fck 25 MPa Es 200000 MPa

Lo 5 m clear cover to ties tc 40mm

π 2 2

Reinforcement n 4 d b 20mm d bt 10mm Ab d b 314.159 mm

4

db

d c t c d bt 60 mm d D d c 290 mm

2

3 2

Asc

Asc n Ab 1.257 10 mm ρ 1.026 %

b D

Pu 400kN M u 100kN m

Check for slenderness of column

Column is pin supported, hence, effective length factor K 1 and Le K Lo 5 m

Le

14.286 more than 12

D

So it's a slender column

Additional moment due to slenderness of column

2

Le

Pu D

M a 14.286kN

m [For single curvature bending and M1 =M2 ]

2000 D

Total Moment

M t M u M a 114.286kN

m

Pu Mt

0.131 0.107

fck b D 2

fck b D

dc

0.171

D

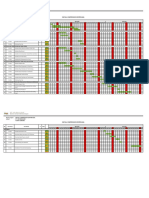

Use chart 33 and chart 34 amd interpolate for dc/D=0.171

Chart 33 (for dc /D=0.15) Chart 34 (for dc /D=0.2)

fck fck

ρ1 0.05 % 1.25 % ρ2 0.06 % 1.5 %

MPa MPa

Interpolate for dc/D=0.171

ρ2 ρ1

ρreqd ρ1 ( 0.171 0.15) 1.355 %

0.2 0.15

Since provided ρ < ρreqd , column is not safe under given loading conditions. Needs to be revised.

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

Prob #2

fy 415 MPa fck 25 MPa Es 200000 MPa

b b 300 mm Db 450 mm b c 450mm Dc 450mm

2

Lo.AB 8 m Lo.B 6m Lo.C 4 m Ag b c Dc 0.203m

Factored Column Forces

Column AB (Single curvature bending)

Pu.DL 750 kN M A.DL 75 kN m M B.DL 75 kN m

Pu.LL 900 kN M A.LL 100 kN m M B.LL 80 kN m

3

Pu Pu.DL Pu.LL 1.65 10 kN

M A M A.DL M A.LL 175 kN m

M B M B.DL M B.LL 155 kN m

Compute Effective Length Factors:

Column AB:

Top End at A is elastic

4

Dc 9 4

IgAB 3.417 10 mm

Column AB 12

4

Dc 9 4

IgC 3.417 10 mm

Column above and below AB 12

3

b b Db 9 4

Beams IgB 2.278 10 mm

12

IgAB IgC

Lo.AB Lo.C

β1 0.771

IgAB IgC IgB

L

o.AB Lo.C Lo.B

Bottom End at B is also elastic

β 2 will be same as β 1

β2 β1

Using Wood Chart of Fig. 26 (No Sway case)

KAB 0.83

Effective length of column AB

Le.AB KAB Lo.AB Db 6.266m

[Use unsupported length]

Are columns slender?

Le.AB

13.926 more than 12

Dc

Therefore column AB is slender

Max. slenderness permissible by limiting the unsupported column height to 60 b c 27 m [Cl. 25.3.1 , OK]

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

Check whether the moments are less than the minimum.

Lo.AB Dc Lo.AB Dc

emin max 20 mm 31 mm 31 mm

500. 30 500. 30

M min emin Pu 51.15 kN m

M AB min M A M B 155 kN m

M AB

3.03

M min [Actual moments are 3 times larger than minimum moment]

Compute additional moment

Assume consevative k =1, for the first trial

2

Le.AB

Pu Dc

M a 71.993 kN m

2000

Dc

Compute design moment

Single curvature bending M 1 M B 155 kN m

Initital Primary moment in the column M 2 M A 175 kN m

M i max 0.4 M 1 0.6 M 2 0.4 M 2 167 kN m 0.4 M 1 0.6 M 2 167 kN m

M u max M 2 M i M a 238.993 kN m

The secition of max. moment remains at the bottom end, B

Design Forces

3

Pu 1.65 10 kN M u 238.993 kN m

Select the reinforcement

Assume Clear cover t c 40 mm

π 2 2

Dia. of long. bar d b 25 mm Area of long. bar Ab d b 490.874 mm

4

Dia. of tie bar d bt 8 mm

db dc

d c tc d bt 60.5 mm 0.134 d Dc d c 389.5 mm

2 Dc

Non dimensnal parameters

Pu Mu

p u 0.326 mu 0.105

fck b c Dc 2

fck b c Dc

From Chart 33, Fe415 and d'/D=0.15

fck

ρ 0.07 % 1.75 %

MPa

3 2

Asc

Asc ρ b c Dc 3.544 10 mm n 7.219

Ab

Provide 8#25mm bars

3 2

Asc.provided 8 Ab 3.927 10 mm

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

Shear Design

M2 M1

Vu 2.5 kN

Design shear force Lo.AB

Asc.provided

2.24 %

b c d

τc 0.85MPa [IS 456 , Table 19]

Increase shear strength due to axial compression

3 Pu

δ min 1 1.5 1.5

Ag fck

Vc δ τc b c d 223.476 kN

0.5Vc 111.738 kN

Vu

0.022 hence, shear reinf. is not reqd.

0.5Vc

So provide min transverse reinforcement as in Cl. 26.5..3.2c

Min. dia. of bar reqd. for lateral ties

db

d t max 6 mm 6.25 mm Provide 8mm dia ties

4

Min. pitch of ties

p min Dc 16 d b 300 mm 300 mm

Provide 8mm lateral ties @300mm c/c

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

Prob #3

fy 415 MPa fck 25 MPa Es 200000 MPa

b b 300 mm Db 450 mm b c 450mm Dc 450mm

2

Lo.AB 8 m Lo.B 6m Lo.C 4 m Ag b c Dc 0.203 m

Factored Column Forces

Column AB

M A.DL 75 kN m M B.DL 75 kN m

Pu.DL 750 kN

Pu.LL 900 kN M A.LL 100 kN m M B.LL 80 kN m

Column will bend in double curvature and assuming moments only

change sign and not the magnitude.

3

Pu Pu.DL Pu.LL 1.65 10 kN

M A M A.DL M A.LL 175 kN m

M B M B.DL M B.LL 5 kN m

Compute Effective Length Factors:

Top End at A is elastic

4

Dc 9 4

Column AB IgAB 3.417 10 mm

12

4

Dc 9 4

Column above and below AB IgC 3.417 10 mm

12

3

b b Db 9 4

IgB 2.278 10 mm

Beams 12

IgAB IgC

Lo.AB Lo.C

β1 0.771

IgAB IgC IgB

L L

o.AB Lo.C

o.B

Bottom End at B is also elastic

β 2 will be same as β 1

β2 β1

Using Wood Chart of Fig. 27 (Sway case)

KAB 2.247

Effective length of column AB

Le.AB KAB Lo.AB Db 16.965 m

[Use unsupported length]

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

Are columns slender?

Le.AB

37.7 more than 12

Dc

Therefore column AB is slender

Max. slenderness permissible by limiting the unsupported column height to 60 b c 27 m [Cl. 25.3.1 , OK]

Check whether the moments are less than the minimum.

Lo.AB Dc Lo.AB Dc

emin max 20 mm 31 mm 31 mm

500. 30 500. 30

M min emin Pu 51.15 kN m

M AB min M A M B 5 kN m

That is, moment at end B should be taken as Mmin

M B M min 51.15 kN m

Compute additional moment

Assume consevative k =1, for the first trial

2

Le.AB

Pu Dc

M a 527.645 kN m

2000

Dc

Compute design moment

Initital Primary moment in the column

M 1 M B 51.15 kN m

M 2 M A 175 kN m

M u max M 1 M 2 M a 702.645 kN m

The secition of max. moment remains at the Top end, A

Design Forces

3

Pu 1.65 10 kN M u 702.645 kN m

Select the reinforcement

Assume Clear cover t c 40 mm

π 2 3 2

Dia. of long. bar d b 36 mm Area of long. bar Ab d b 1.018 10 mm

4

Dia. of tie bar d bt 10 mm

db dc

d c tc d bt 68 mm 0.151 d Dc d c 382 mm

2 Dc

Non dimensional strength parameters

Pu Mu

p u 0.326 mu 0.308

fck b c Dc 2

fck b c Dc

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

{Strictly for students of CE372A at IIT Kanpur, 2018}

From Chart 33, Fe415 and d'/D=0.15

fck ρmax 6%

ρ 0.245 % 6.125 % which is more than allowed max. limit [NG]

MPa

Revise using high grade steel Fe500 and higher grade concrete M35

fck 35 MPa

Non dimensional strength parameters

Pu Mu

p u 0.233 mu 0.22

fck b c Dc 2

fck b c Dc

From Chart 37, Fe500 and d'/D=0.15

fck

ρ 0.13 % 4.55 % which is about the practical limit of 4%. The better

MPa design option is to increse the column size.

3 2 Asc

Asc ρ b c Dc 9.214 10 mm n b 9.052

Ab

Provide 10#36mm bars

4 2

Asc.provided 10 Ab 1.018 10 mm

Shear design

M1 M2 Ma

Vu 94.224 kN

Design shear force Lo.AB

Asc.provided

5.921 %

b c d

τc 0.92MPa [IS 456 , Table 19]

Increase shear strength due to axial compression

3 Pu

δ min 1 1.5 1.5

Ag fck

Vc δ τc b c d 237.222 kN

0.5Vc 118.611 kN

Vu

0.794 hence, shear reinf. is not reqd.

0.5Vc

So provide min transverse reinforcement for columns as in Cl. 26.5..3.2c

Min. dia. of bar reqd. for lateral ties

db

d t max 6 mm 9 mm Provide 10 mm dia ties

4

Min. pitch of ties

p min Dc 16 d b 300 mm 300 mm

Provide 10mm lateral ties @300mm c/c (one close link and a close tie for 450 mm wide column)

CE372A/RC Design/Dr Durgesh Rai/IIT Kanpur/2018

Das könnte Ihnen auch gefallen

- Structural Calculation Sheet: P&T Consultants Pte LTDDokument2 SeitenStructural Calculation Sheet: P&T Consultants Pte LTDLordM00nNoch keine Bewertungen

- Gulariya MC L 5m, B 4mDokument9 SeitenGulariya MC L 5m, B 4mrashmi bhailaNoch keine Bewertungen

- Excell Sheet Slab DesignDokument20 SeitenExcell Sheet Slab DesignMohammad tarequl AlamNoch keine Bewertungen

- RCC54 Circular Column ChartingDokument13 SeitenRCC54 Circular Column Chartingali billNoch keine Bewertungen

- Design Calculation For Hexadecagonal Pole: L W W T FDokument3 SeitenDesign Calculation For Hexadecagonal Pole: L W W T FsaravqwertyNoch keine Bewertungen

- 1000 The Stiffness MethodDokument23 Seiten1000 The Stiffness MethodSarah Sullivan100% (1)

- Centre of Stiffness Calculation: Ground FloorDokument91 SeitenCentre of Stiffness Calculation: Ground FloorPoshan DhunganaNoch keine Bewertungen

- Chapter 5 Torsion BucklingDokument68 SeitenChapter 5 Torsion BucklingMalik Rehan SyedNoch keine Bewertungen

- Slab Design of Partially Fixed Circular SlabDokument4 SeitenSlab Design of Partially Fixed Circular SlabBithika DattaNoch keine Bewertungen

- Deflection of T BeamDokument3 SeitenDeflection of T BeamMayoo LaxmanNoch keine Bewertungen

- Seismic AnalysisDokument34 SeitenSeismic AnalysisCarla OrbetaNoch keine Bewertungen

- Anna University Wind and CycloneDokument12 SeitenAnna University Wind and CycloneAbinaya FoundationsNoch keine Bewertungen

- Design of StaircaseDokument4 SeitenDesign of StaircaseahmedNoch keine Bewertungen

- Beams - ASD NSCP 2001 FlowchartDokument1 SeiteBeams - ASD NSCP 2001 FlowchartDavid Nelson AngiwanNoch keine Bewertungen

- Woodlands Health Campus P4 - Struc Calc For Single Arm Monitor - Rev 0 (25.01.21)Dokument68 SeitenWoodlands Health Campus P4 - Struc Calc For Single Arm Monitor - Rev 0 (25.01.21)Herschell Vergel De DiosNoch keine Bewertungen

- Solving Indeterminate Structures - CompatibilityDokument24 SeitenSolving Indeterminate Structures - CompatibilityY SAHITHNoch keine Bewertungen

- Design of Beams - PPT SONAMDokument111 SeitenDesign of Beams - PPT SONAMLovely Mae Cruza GawinganNoch keine Bewertungen

- 2-Design For Action Effects - M & N (2014)Dokument15 Seiten2-Design For Action Effects - M & N (2014)george santiagoNoch keine Bewertungen

- Direct Stiffness MethodDokument14 SeitenDirect Stiffness MethodMutiara Puspahati CripstyaniNoch keine Bewertungen

- Selender For Regtangular ColDokument3 SeitenSelender For Regtangular Colsaddamalsayadi38100% (1)

- Ch#2 Stiffness MethodDokument24 SeitenCh#2 Stiffness MethodMegaPradiptaFainallaziNoch keine Bewertungen

- Beam Design (SSB)Dokument6 SeitenBeam Design (SSB)Er Sai KiranNoch keine Bewertungen

- 1 Centre of MassDokument18 Seiten1 Centre of MassAashique100% (1)

- Plane Frame With Steel Design - Staad ProDokument11 SeitenPlane Frame With Steel Design - Staad ProScarlet ShweNoch keine Bewertungen

- DBR How To MakeDokument15 SeitenDBR How To Maketanmay271100% (1)

- Foundation Calculation Sheet: Title DescriptionDokument26 SeitenFoundation Calculation Sheet: Title Descriptionsalman alfarisyNoch keine Bewertungen

- 1.1 BackgroundDokument34 Seiten1.1 BackgroundAnish NeupaneNoch keine Bewertungen

- Defence ReportDokument137 SeitenDefence ReportSushrutNoch keine Bewertungen

- HES2125 10S2 Revision01Dokument4 SeitenHES2125 10S2 Revision01Roberto RizzoNoch keine Bewertungen

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dokument7 SeitenEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINoch keine Bewertungen

- Column Design of 300x400Dokument24 SeitenColumn Design of 300x400karthik100% (1)

- CE2011 - Structural Analysis IDokument10 SeitenCE2011 - Structural Analysis IRashmiNoch keine Bewertungen

- Base Shear ComputationDokument5 SeitenBase Shear ComputationAmante MorenoNoch keine Bewertungen

- Shell Forces Stresses FormDokument4 SeitenShell Forces Stresses Formaungps_sone82Noch keine Bewertungen

- Staad Result Pass or Fail 1Dokument136 SeitenStaad Result Pass or Fail 1Renzo Ray M. OlivarNoch keine Bewertungen

- 13 271 147400929156 58 PDFDokument4 Seiten13 271 147400929156 58 PDFmujeebNoch keine Bewertungen

- CIV 4235 ExamDokument9 SeitenCIV 4235 Exammalumius100% (2)

- Dr. Ali TayehDokument32 SeitenDr. Ali TayehvijaykumarzNoch keine Bewertungen

- Two Dimensional Analysis of Frame StructuresDokument54 SeitenTwo Dimensional Analysis of Frame StructuresFrank PuchiNoch keine Bewertungen

- Raft FoundationDokument12 SeitenRaft FoundationAasif ShaikNoch keine Bewertungen

- Structural Notes PDFDokument40 SeitenStructural Notes PDFEnrico luis EscobarNoch keine Bewertungen

- Member Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFDokument98 SeitenMember Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFlau lauNoch keine Bewertungen

- Example 1 (Adopt From Hibbler Ex15-4, PG 578) : Lecture Note: Beam Analysis by Stiffness MethodDokument11 SeitenExample 1 (Adopt From Hibbler Ex15-4, PG 578) : Lecture Note: Beam Analysis by Stiffness Methoddixn__Noch keine Bewertungen

- Mathcad - 05-Design of Doubly Reinforced BeamsDokument4 SeitenMathcad - 05-Design of Doubly Reinforced BeamsMrAlittle Finger100% (1)

- Foundation Analysis: Ultimate Bearing Capacity: Shallow FoundationDokument21 SeitenFoundation Analysis: Ultimate Bearing Capacity: Shallow FoundationShiela Marie Cruz100% (1)

- Steady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDDokument19 SeitenSteady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDErick WanduNoch keine Bewertungen

- RCC41 Continuous Beams (A & D)Dokument26 SeitenRCC41 Continuous Beams (A & D)Jhondy TibubosNoch keine Bewertungen

- Module B: Tension MembersDokument21 SeitenModule B: Tension MembersFerdz PequiroNoch keine Bewertungen

- 4 Numerical Example On Design of 3 or More Span Cont. BeamDokument21 Seiten4 Numerical Example On Design of 3 or More Span Cont. BeamAshok Kumar RajanavarNoch keine Bewertungen

- Ultimate Strength Design USD of BeamDokument15 SeitenUltimate Strength Design USD of BeamJohn Carl Salas100% (1)

- CVL312 Lecture 1Dokument22 SeitenCVL312 Lecture 1Jay100% (1)

- 13 ZA DC F 83 RC Structural Design Review ChecklistDokument2 Seiten13 ZA DC F 83 RC Structural Design Review ChecklistMohammed AminNoch keine Bewertungen

- Center of Gravity Vs Center of MassDokument25 SeitenCenter of Gravity Vs Center of Massguptafamily1992Noch keine Bewertungen

- Beams Curved in PlanDokument4 SeitenBeams Curved in PlanJincy JohnsonNoch keine Bewertungen

- Problem1 - Solution 1 - Design of SRCBDokument5 SeitenProblem1 - Solution 1 - Design of SRCBRey Joseph IglesiaNoch keine Bewertungen

- 14 2042015Assignment01Solution PDFDokument4 Seiten14 2042015Assignment01Solution PDFNaNoch keine Bewertungen

- Problem1 - Solution 2 - Design of SRCBDokument5 SeitenProblem1 - Solution 2 - Design of SRCBRey Joseph IglesiaNoch keine Bewertungen

- Mathcad - 14-Design of Short Column (Rectangular)Dokument4 SeitenMathcad - 14-Design of Short Column (Rectangular)MrAlittle FingerNoch keine Bewertungen

- Mathcad - 18-2-Design of ColumnDokument7 SeitenMathcad - 18-2-Design of ColumnSok RaksaNoch keine Bewertungen

- Calculation Sketch: 1-Way Slab Design: Aci 2005Dokument7 SeitenCalculation Sketch: 1-Way Slab Design: Aci 2005Francisco DeLos Angeles IIINoch keine Bewertungen

- Six StoryBldg Rear Side ElevationDokument1 SeiteSix StoryBldg Rear Side ElevationAman Raj VermaNoch keine Bewertungen

- Six StoryBldg Left Side ElevationDokument1 SeiteSix StoryBldg Left Side ElevationAman Raj VermaNoch keine Bewertungen

- Six StoryBldg Right Side ElevationDokument1 SeiteSix StoryBldg Right Side ElevationAman Raj VermaNoch keine Bewertungen

- Six StoryBldg Front Side ElevationDokument1 SeiteSix StoryBldg Front Side ElevationAman Raj VermaNoch keine Bewertungen

- Six StoryBldg Basement PlanDokument1 SeiteSix StoryBldg Basement PlanAman Raj VermaNoch keine Bewertungen

- KeyCE372AHW062018Rev PDFDokument8 SeitenKeyCE372AHW062018Rev PDFAman Raj VermaNoch keine Bewertungen

- Homework #7:: Design of RC Slender Columns - Limit State MethodDokument1 SeiteHomework #7:: Design of RC Slender Columns - Limit State MethodAman Raj VermaNoch keine Bewertungen

- Foundation Design - 1. Soil Exploration - 6!1!2015Dokument3 SeitenFoundation Design - 1. Soil Exploration - 6!1!2015Aman Raj VermaNoch keine Bewertungen

- Homework #6:: Design of RC Short Columns - Limit State MethodDokument1 SeiteHomework #6:: Design of RC Short Columns - Limit State MethodAman Raj VermaNoch keine Bewertungen

- CE 352A Home Assignment IVDokument1 SeiteCE 352A Home Assignment IVAman Raj Verma100% (1)

- Flare Boom Engineering - Failure - DrillSafeDokument11 SeitenFlare Boom Engineering - Failure - DrillSafeAndrey RogozhaNoch keine Bewertungen

- Estimate For Samsipora RUB RampDokument1 SeiteEstimate For Samsipora RUB Rampapi-3823524Noch keine Bewertungen

- Design Analysis and Optimization of Offshore ModuleDokument116 SeitenDesign Analysis and Optimization of Offshore ModuleMirceaNoch keine Bewertungen

- Associated Flow RulesDokument10 SeitenAssociated Flow RulesShahram AbbasnejadNoch keine Bewertungen

- Schedule Install Compressor CentrifugalDokument2 SeitenSchedule Install Compressor CentrifugalredharereNoch keine Bewertungen

- 2.5 Cross Section Classification: 2.7.1 Shear BucklingDokument7 Seiten2.5 Cross Section Classification: 2.7.1 Shear Bucklingmn4webNoch keine Bewertungen

- Installation Mantainance ManualFan CoilYEKN YGKNDokument19 SeitenInstallation Mantainance ManualFan CoilYEKN YGKNJavier SosaNoch keine Bewertungen

- Incremental Launch Method For Steel Truss Bridge ErectionDokument11 SeitenIncremental Launch Method For Steel Truss Bridge ErectionaapennsylvaniaNoch keine Bewertungen

- 40rr 2pDokument12 Seiten40rr 2pAlejandro Castillo100% (1)

- Shallow Foundation and Deep FoundationDokument43 SeitenShallow Foundation and Deep FoundationWei Siong95% (21)

- Spata Vol. 1Dokument94 SeitenSpata Vol. 1Paul50% (2)

- Environmental System DesignDokument25 SeitenEnvironmental System DesignTeweldeNoch keine Bewertungen

- Passive Design Guidebook Designed 2015-12-31 0Dokument48 SeitenPassive Design Guidebook Designed 2015-12-31 0YasminRamirezValenzuelaNoch keine Bewertungen

- 1 Composite Floor SystemDokument27 Seiten1 Composite Floor SystemBertNoch keine Bewertungen

- Khaleeq PaperDokument125 SeitenKhaleeq Papervikas chawlaNoch keine Bewertungen

- CONCRETE (Material Science & Metallurgy)Dokument26 SeitenCONCRETE (Material Science & Metallurgy)Shuvas KhanalNoch keine Bewertungen

- GeostudioDokument12 SeitenGeostudioEarly BirdNoch keine Bewertungen

- Tumang Residence - Structural CalculationsDokument56 SeitenTumang Residence - Structural Calculationsjohn vincent musngiNoch keine Bewertungen

- Building Technology I: 1. Mortars and PlastersDokument11 SeitenBuilding Technology I: 1. Mortars and PlastersAN NENoch keine Bewertungen

- Kalahari Deposits at Ghaghoo Diamond Mine 020191128185514017Dokument15 SeitenKalahari Deposits at Ghaghoo Diamond Mine 020191128185514017BBBBBBNoch keine Bewertungen

- Assignment 2 - New PDFDokument2 SeitenAssignment 2 - New PDFprasadNoch keine Bewertungen

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsDokument2 SeitenStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3Noch keine Bewertungen

- Ice Breaker and Acceleration Record SelectionDokument5 SeitenIce Breaker and Acceleration Record SelectionAdriansyah SiregarNoch keine Bewertungen

- Ae Lab1Dokument4 SeitenAe Lab1Ali SagırNoch keine Bewertungen

- Hardinge Bridge To Padma BridgeDokument23 SeitenHardinge Bridge To Padma BridgeBridge WingNoch keine Bewertungen

- CE 2203 Construction Techniques, Equipment & Practices ABBREVIATIONS # Expansion Unit 1Dokument11 SeitenCE 2203 Construction Techniques, Equipment & Practices ABBREVIATIONS # Expansion Unit 1Rajha RajeswaranNoch keine Bewertungen

- Part - I: Chapter 2 - Piping ComponentsDokument8 SeitenPart - I: Chapter 2 - Piping ComponentsAshish PatelNoch keine Bewertungen

- Hydrology 06Dokument16 SeitenHydrology 06Mica L. SanoNoch keine Bewertungen

- Technical Guidance Notes (Level 1) - ContentsDokument1 SeiteTechnical Guidance Notes (Level 1) - ContentsEduard KovalevskijNoch keine Bewertungen

- SIE 2002 Tutorial 3Dokument4 SeitenSIE 2002 Tutorial 3lightsoul91Noch keine Bewertungen