Beruflich Dokumente

Kultur Dokumente

EPS Data Sheet

Hochgeladen von

ajoilhamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EPS Data Sheet

Hochgeladen von

ajoilhamCopyright:

Verfügbare Formate

EPS Insulation

Dyplast manufactures high-quality expanded Dyplast Products is the preeminent manufacturer of

EPS Insulation

polystyrene rigid foam insulation. Dyplast EPS is a polyisocyanurate and expanded polystyrene rigid foam

closed cell, light-weight, resilient rigid foam providing a products, and also distributes a variety of

host of unique properties. When insulation or protection complementary products. With new world-class

is the goal, rely on EPS insulation to lead the way. No production facilities in Miami, Florida, Dyplast

other product within this cost structure provides the Products offers its customers unsurpassed technology,

thermal efficiency, temperature range, damage and responsiveness, wide-ranging product configurations,

moisture control, flammability rating, or moisture vapor and state-of-the-art quality control. Our

permeability characteristics. Our product’s excellent customer-focused staff, combined with our sound

workability characteristics make it easy to handle, shape, financial footing, ensure we deliver incomparable value

and install. In addition, our GeoFoam soil substitute to our customers far into the future. For information

exceeds all requisite standards. on Dyplast Products or additional technical data on

this product, visit our website at: www.dyplast.com.

A wide range of core thickness and densities is available

for residential, commercial, industrial, or cold storage

applications. The high-quality rigid foam is free of voids COMPLIANCES AND APPROVALS

and cavities. Available in panels, blocks, tapered board, EPS insulation products have been tested and found to

custom shapes, and loose fill, EPS excels in an array of meet the requirements of the specifications listed below.

applications. With its high R-values, the resulting lower A Dyplast Products representative can provide you the

energy costs can significantly lower energy costs. Wood, assistance in determining the suitability of these and any

metal, and/or FRP skins can be readily added, unlisted specifications.

improving maintenance, strength, and integrity • ASTM C578-10

characteristics. With available compressive strengths • ASTM D6817: GeoFoam re: EPS 22 and EPS 29

from 10 to 35 lb/in², the vast majority of construction • FM 4450

applications can be accommodated. • Miami-Dade County, Florida Product Control No.

07-1107.08

UL Report BRYX.R4812

VERSATILE APPLICATIONS • ICC-ES Evaluation Report No. 2052

Where energy efficiency and cost-effectiveness are U.S. Army Corp of Engineers

primary design considerations, architects, constructors,

and homeowners have made EPS the dominant thermal

insulation. EPS is not susceptible to thermal aging, so its

R-value of up to 4.35/in does not deteriorate over time.

Applications include:

Building construction (roof, wall, and foundation)

- Cavity wall and drywall base insulation

- Exterior and interior foundation wall insulation

- Roof applications (tapered panel and Holey-Board)

Refrigeration

- Building and transportation applications

- Perfect for walk-in coolers, tanks, vessels SUSTAINABILITY

- Will not absorb odors Concerned about the environment? So is Dyplast

Transportation Products! That’s why all our products are manufactured

- Refrigerated rail and truck in a CFC/HCFC-free environment. EPS rigid foam

Facility construction: pharmaceutical, petrochemical, insulation is an inert, organic material produced from

liquid natural gas, and other facilities petroleum and natural gas by-products. This product

Marine and Maritime does not contain chlorofluorocarbons (CFC’s) or

hydro-chlorofluorocarbons (HCFC’s). It provides no

WARNING nutritive value to plants, animals or micro-organisms. It

This product will burn and should not be exposed to fire will not rot, is highly resistant to mildew, and is

or flame. Cover with an ignition barrier. recyclable.

Rev. EPS 0514

EPS 15 or EPS 19 or EPS 22 or EPS 29 or

“TYPE I” “TYPE VIII” “TYPE II” “TYPE IX”

Compressive Strength (10% deformation) D-1621 lb/in 10 - 14 13 - 18 15 - 21 25 - 33

20

300

Surface Burning Characteristics: E84 UL Rating:

Flame Spread 6 inch max. 20 20 20 20

Smoke Developed 300 300 300 300

1. These are nominal values obtained from representative samples, subject to normal manufacturing variances. For additional ranges and specifications, contact Dyplast Products.

2. Installed in a thickness or stored in an effective thickness, as indicated, for a density of 1.0 to 2.0 lb/ft3.

3. All types meet Class 1 UL Classified.

4. “Minimum” per ASTM D6817 for GeoFoam.

FABRICATION AND INSTALLATION LIMITATIONS AND DISCLAIMER OF WARRANTIES AND

EPS insulation is easily fabricated after manufacture to meet LIABILITIES

specific design and dimensional requirements. Further, because of Characteristics, properties, performance of materials, and applica-

its light weight it is easily stored, handled, and installed on the job tion specifications herein described are based on data obtained

site. It can be cut with ordinary tools to ensure tight joints, thus under controlled conditions. Information is supplied on the

eliminating heat loss. condition that the persons receiving same will make their own

determination as to its suitability for their purposes prior to use.

COST EFFICIENCY Dyplast makes no implied warranties of any type, including

EPS insulation typically costs less than other rigid board insulants without limitation, any warrant of merchantability or fitness for

when compared on the basis of R-value. When evaluating the cost purpose. In no event will Dyplast be responsible for damages of

efficiency of rigid insulations, compare prices based on R-value any nature whatsoever resulting from the use of or reliance upon

per inch of thickness for comparable length and widths. this information or the product to which the information refers. No

agent, sales representative, or employee is empowered to change,

OTHER EPS PRODUCTS alter, or amend this provision, unless approved in writing by an

Visit www.dyplast.com for other EPS products. Additional EPS authorized officer of Dyplast.

products include:

• Holey-Board roof insulation for lightweight concrete roof

applications

• Architectural shapes for decorative and architectural applica-

tions; an excellent alternative to wood or concrete

• GeoFoam, a lower-cost alternative to soil fills

• Concrete Forms

Das könnte Ihnen auch gefallen

- Sustainable Masonry: Stability and Behavior of StructuresVon EverandSustainable Masonry: Stability and Behavior of StructuresNoch keine Bewertungen

- Foam Sandwich Construction: How To Build A Foam Sandwich Composite BoatDokument24 SeitenFoam Sandwich Construction: How To Build A Foam Sandwich Composite BoatPhong TuanNoch keine Bewertungen

- Effect of Basalt Fibers On The Flexural Behavior of Concrete Beams Reinforced With BFRP Bars PDFDokument12 SeitenEffect of Basalt Fibers On The Flexural Behavior of Concrete Beams Reinforced With BFRP Bars PDFAyan HussainNoch keine Bewertungen

- Comet Cat 37Dokument7 SeitenComet Cat 37Roberto SaraviaNoch keine Bewertungen

- Lifting Anchor BrochureDokument48 SeitenLifting Anchor BrochureJacob ChirayilNoch keine Bewertungen

- Design of Rigid Pavement CC Road With M25Dokument5 SeitenDesign of Rigid Pavement CC Road With M25pravincs_007Noch keine Bewertungen

- Container - Intermodal Container TestDokument61 SeitenContainer - Intermodal Container Testgavsta007Noch keine Bewertungen

- Tyco UhpDokument6 SeitenTyco UhpalokNoch keine Bewertungen

- Adding Value To ConcreteDokument16 SeitenAdding Value To ConcreteFrancois KokNoch keine Bewertungen

- MHS DigitalbookletDokument6 SeitenMHS DigitalbookletNelson HillNoch keine Bewertungen

- Timber Code CheckDokument17 SeitenTimber Code Checkmargitorsi0% (1)

- Ferro Cement 2Dokument22 SeitenFerro Cement 2Abhishek DorugadeNoch keine Bewertungen

- LiteDeck Book 2013-1 WebDokument48 SeitenLiteDeck Book 2013-1 WebGonzalo Gomez CastilloNoch keine Bewertungen

- Residental ConstructionDokument10 SeitenResidental ConstructionUmange RanasingheNoch keine Bewertungen

- Mission 3 - FCM - Drainage & Stormwater Calculations (Nov7, 0Dokument60 SeitenMission 3 - FCM - Drainage & Stormwater Calculations (Nov7, 0Muttiah YathindraNoch keine Bewertungen

- Analysis of Pier Structures Supported On Battered Piles Using MotemsDokument27 SeitenAnalysis of Pier Structures Supported On Battered Piles Using MotemsJaymin PatilNoch keine Bewertungen

- FerroDokument129 SeitenFerrosureshrakesh0% (1)

- (2012) Innovative Interlocking BlocksDokument10 Seiten(2012) Innovative Interlocking BlocksbhavanaNoch keine Bewertungen

- Prefab House ProfileDokument25 SeitenPrefab House ProfilespellbindguyNoch keine Bewertungen

- Cellular Light Weight Concrete Manufacturing Process & Properties Full DetailsDokument4 SeitenCellular Light Weight Concrete Manufacturing Process & Properties Full Detailskinley dorjee100% (1)

- Part Five - Chemical Soil Stabilization - Application and Design-MinDokument16 SeitenPart Five - Chemical Soil Stabilization - Application and Design-Minsazwan2Noch keine Bewertungen

- Hambro Joist Typical DetailsDokument27 SeitenHambro Joist Typical DetailsjgjgNoch keine Bewertungen

- Hybrid Concrete Masonry Design: TEK 14-9ADokument8 SeitenHybrid Concrete Masonry Design: TEK 14-9AMega EstructurasNoch keine Bewertungen

- Precast EnvelopeDokument70 SeitenPrecast Envelopesdutta2591Noch keine Bewertungen

- Grouts Standards and TestingDokument12 SeitenGrouts Standards and TestingmithileshNoch keine Bewertungen

- Timber Roof DetailingsDokument91 SeitenTimber Roof DetailingsUbong Etok100% (2)

- Structural Analysis of Basalt Fiber Reinforced Plastic Wind Turbine Blade PDFDokument5 SeitenStructural Analysis of Basalt Fiber Reinforced Plastic Wind Turbine Blade PDFTohidNoch keine Bewertungen

- 6 Gravity Platforms PDFDokument42 Seiten6 Gravity Platforms PDFmctimlimNoch keine Bewertungen

- 3 Dreamland Margate SC Dreamland Business PlanDokument171 Seiten3 Dreamland Margate SC Dreamland Business PlanrajawaqasNoch keine Bewertungen

- Accidental DamageDokument29 SeitenAccidental Damagestan80Noch keine Bewertungen

- BuchananDokument8 SeitenBuchananbintnNoch keine Bewertungen

- Offshore Solutions For Wind Turbine Supporting StructuresDokument41 SeitenOffshore Solutions For Wind Turbine Supporting StructuresyapicoshinuraNoch keine Bewertungen

- WhatIsKSS PDFDokument8 SeitenWhatIsKSS PDFابو احمدNoch keine Bewertungen

- HSC Part 3 E-Feb14Dokument255 SeitenHSC Part 3 E-Feb14cupidkhhNoch keine Bewertungen

- A Review To Develop New Correlations For GeotechniDokument23 SeitenA Review To Develop New Correlations For GeotechniChinchu CherianNoch keine Bewertungen

- Cavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarDokument30 SeitenCavity Walls: Presented by - Aishwarya Deshmukh Aniket Late Tejas Joshi Dhananjay Marda Priti PawarTejas JoshiNoch keine Bewertungen

- 5-Prefabrication Group 103Dokument165 Seiten5-Prefabrication Group 103jimmyNoch keine Bewertungen

- KAQ KEW TechnicalBrochure en LRDokument64 SeitenKAQ KEW TechnicalBrochure en LRHylkeNoch keine Bewertungen

- Geoplast Slabs Solution English BrochureDokument52 SeitenGeoplast Slabs Solution English BrochureMohamedNoch keine Bewertungen

- Experiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateDokument8 SeitenExperiment-3 Using The Weighing in Water Method To Determine Particle Density and Water Absorption of Coarse AggregateanushaNoch keine Bewertungen

- Saudi Arabian Oil Company: NotesDokument1 SeiteSaudi Arabian Oil Company: NotesJohn Philip BuntalesNoch keine Bewertungen

- Disctrict SurveyorsDokument10 SeitenDisctrict Surveyorsanon_636232257Noch keine Bewertungen

- Floating Structures 2020Dokument45 SeitenFloating Structures 2020shorouk moahmedNoch keine Bewertungen

- Connection Details: 264 Reynoldsdale Road, Bedford, PA 15522-7401 Phone: 814-623-8125Dokument7 SeitenConnection Details: 264 Reynoldsdale Road, Bedford, PA 15522-7401 Phone: 814-623-8125Cancio FlorezNoch keine Bewertungen

- What Ails Structural Engineers?Dokument3 SeitenWhat Ails Structural Engineers?jithinraj1993Noch keine Bewertungen

- Determining Wind Actions in Kenya According To The EurocodesDokument7 SeitenDetermining Wind Actions in Kenya According To The Eurocodespatrick chegeNoch keine Bewertungen

- A Seminar On Bubble Deck Slab Technology: by Devesh Deshmukh TE Civil Engineering (T150020015) Guided by Prof G.S. IngleDokument39 SeitenA Seminar On Bubble Deck Slab Technology: by Devesh Deshmukh TE Civil Engineering (T150020015) Guided by Prof G.S. IngleDevesh DeshmukhNoch keine Bewertungen

- Easy FlashDokument2 SeitenEasy FlashunionewNoch keine Bewertungen

- 02 Bayset Sec2.WaterproofingmembrainsDokument39 Seiten02 Bayset Sec2.WaterproofingmembrainsKha PhucNoch keine Bewertungen

- Architectural Catalogue RenukootDokument103 SeitenArchitectural Catalogue Renukootprchoudharykp100% (2)

- Ultra High Performance Concrete Panels For Prefabricated Wall AssembliesDokument22 SeitenUltra High Performance Concrete Panels For Prefabricated Wall AssembliesDebasish DeyNoch keine Bewertungen

- Straw Bale Construction Front 1Dokument6 SeitenStraw Bale Construction Front 1Melvin Mathew VargheseNoch keine Bewertungen

- AWC DES413 1 ShearWallExamples 1hr 140822Dokument30 SeitenAWC DES413 1 ShearWallExamples 1hr 140822Dow JonesNoch keine Bewertungen

- Everdure Waterstop - Page1Dokument1 SeiteEverdure Waterstop - Page1Jefferd AlicanNoch keine Bewertungen

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDokument20 SeitenGypwall 3.2: General Purpose Metal Stud Partition SystemA CNoch keine Bewertungen

- GRCA Specification PDFDokument15 SeitenGRCA Specification PDFrencydNoch keine Bewertungen

- Geotechnical: TO EngineeringDokument6 SeitenGeotechnical: TO EngineeringxioNoch keine Bewertungen

- ScienceDirect - Quay WallsDokument15 SeitenScienceDirect - Quay WallsYayoi IshikawaNoch keine Bewertungen

- Promotion of Bamboo Housing System & Recent Developments: Shri K.Shyamasundar and Jagadish VengalaDokument12 SeitenPromotion of Bamboo Housing System & Recent Developments: Shri K.Shyamasundar and Jagadish VengalaPranav DarakhNoch keine Bewertungen

- Lamp IranDokument1 SeiteLamp IranajoilhamNoch keine Bewertungen

- UIN Format1-A, 1-B RoHS Compliant Products Guarantee and Non-Use GuaranteeDokument5 SeitenUIN Format1-A, 1-B RoHS Compliant Products Guarantee and Non-Use GuaranteeajoilhamNoch keine Bewertungen

- CFR 2011 Title21 Vol3 Sec175 105Dokument16 SeitenCFR 2011 Title21 Vol3 Sec175 105ajoilhamNoch keine Bewertungen

- Fill OutDokument20 SeitenFill OutajoilhamNoch keine Bewertungen

- Dry Fast Foam ChinaDokument2 SeitenDry Fast Foam ChinaajoilhamNoch keine Bewertungen

- BOM1Dokument473 SeitenBOM1ajoilhamNoch keine Bewertungen

- Manutti BelgiumDokument25 SeitenManutti BelgiumajoilhamNoch keine Bewertungen

- Australian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesDokument8 SeitenAustralian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesajoilhamNoch keine Bewertungen

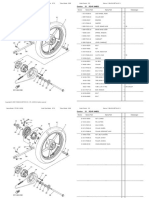

- Fz150 V-Ixion Rear WheelDokument2 SeitenFz150 V-Ixion Rear Wheelajoilham100% (1)

- E 010920Dokument22 SeitenE 010920ajoilhamNoch keine Bewertungen

- Pyrotek - SIVEX - Ceramic FoamDokument2 SeitenPyrotek - SIVEX - Ceramic FoamajoilhamNoch keine Bewertungen

- Ad 1041960Dokument14 SeitenAd 1041960ajoilhamNoch keine Bewertungen

- Summarization of EG Production OctDokument2 SeitenSummarization of EG Production OctajoilhamNoch keine Bewertungen

- Antistatic Agent KEMI 74 0331 80VDokument1 SeiteAntistatic Agent KEMI 74 0331 80VajoilhamNoch keine Bewertungen

- Ajac 2014022113435228Dokument6 SeitenAjac 2014022113435228ajoilhamNoch keine Bewertungen

- Us20120322903 ADokument17 SeitenUs20120322903 AajoilhamNoch keine Bewertungen

- FM 2015 Adrian BeardDokument26 SeitenFM 2015 Adrian BeardajoilhamNoch keine Bewertungen

- How Importance of Cell Structure For Viscoelastic Foams PolyuretgabDokument13 SeitenHow Importance of Cell Structure For Viscoelastic Foams PolyuretgabajoilhamNoch keine Bewertungen

- Technical Data Sheet Loctite 5438 UnderDokument2 SeitenTechnical Data Sheet Loctite 5438 UnderajoilhamNoch keine Bewertungen

- MSDS Loctite 5438Dokument7 SeitenMSDS Loctite 5438ajoilhamNoch keine Bewertungen

- FFR FinalDokument832 SeitenFFR FinalajoilhamNoch keine Bewertungen

- Dry Fast Foam ChinaDokument2 SeitenDry Fast Foam ChinaajoilhamNoch keine Bewertungen

- S707-60HF LT GB 2016-01-18Dokument3 SeitenS707-60HF LT GB 2016-01-18ajoilhamNoch keine Bewertungen

- 3040 Thickeners and Rheology GuideDokument7 Seiten3040 Thickeners and Rheology GuideajoilhamNoch keine Bewertungen

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDokument6 SeitenSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingajoilhamNoch keine Bewertungen

- MERCK Use Information Sheet: Exposure Driving Use DescriptorsDokument2 SeitenMERCK Use Information Sheet: Exposure Driving Use DescriptorsajoilhamNoch keine Bewertungen

- En 13501 5 PDFDokument31 SeitenEn 13501 5 PDFajoilhamNoch keine Bewertungen

- DoP CE W-T-S707-60HF v3-GB-ENDokument2 SeitenDoP CE W-T-S707-60HF v3-GB-ENajoilhamNoch keine Bewertungen

- Data Sheet TimbercoatDokument2 SeitenData Sheet TimbercoatajoilhamNoch keine Bewertungen

- LR Weld Certification Guide v1.3 SubscribeDokument24 SeitenLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoNoch keine Bewertungen

- BOQ Ductile IronDokument2 SeitenBOQ Ductile IronAshraf SalehNoch keine Bewertungen

- Fuel Types and Firing SystemsDokument80 SeitenFuel Types and Firing SystemsIrshad HussainNoch keine Bewertungen

- Applications of High Strength Concrete For Highway BridgesDokument30 SeitenApplications of High Strength Concrete For Highway Bridgesaji raNoch keine Bewertungen

- Le Châtelier's PrincipleDokument7 SeitenLe Châtelier's PrincipleBob AbramsNoch keine Bewertungen

- CHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture ADokument2 SeitenCHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture Aroven desuNoch keine Bewertungen

- Magnetic Refrigeration AssignmentDokument8 SeitenMagnetic Refrigeration AssignmentAwais Asghar KhanNoch keine Bewertungen

- Awareness Poster of Pesticides Waste Management (AlZaShaNi)Dokument1 SeiteAwareness Poster of Pesticides Waste Management (AlZaShaNi)Mohammad Bin OthmanNoch keine Bewertungen

- Particular SpecificationsDokument8 SeitenParticular SpecificationsmoumitaNoch keine Bewertungen

- Press Release PHBYC - Flood Prone LGU Builds Flood BoatsDokument4 SeitenPress Release PHBYC - Flood Prone LGU Builds Flood BoatsRoy EspirituNoch keine Bewertungen

- Lista MateriałówDokument7 SeitenLista MateriałówVanessa KowalskaNoch keine Bewertungen

- Loss of Prestressed Due To ANCHORAGEDokument38 SeitenLoss of Prestressed Due To ANCHORAGEKimberly Shawn Nicole SantosNoch keine Bewertungen

- Experiment 1 Tensile Testing (Universal Tester) : RD THDokument23 SeitenExperiment 1 Tensile Testing (Universal Tester) : RD THShangkaran RadakrishnanNoch keine Bewertungen

- Chemistry: Classifying MatterDokument3 SeitenChemistry: Classifying MatterMa. Filipina AlejoNoch keine Bewertungen

- Shear Walls-Frame DesignDokument150 SeitenShear Walls-Frame Designsaikiran100% (5)

- Effect of The Interaction Between An Ionic Surfactant and Polymer On The Dissolution of A Poorly Soluble DrugDokument9 SeitenEffect of The Interaction Between An Ionic Surfactant and Polymer On The Dissolution of A Poorly Soluble DrugDesi Rahma PrihandiniNoch keine Bewertungen

- GRP BoqDokument44 SeitenGRP BoqMikuNoch keine Bewertungen

- MSDS PPCPDokument4 SeitenMSDS PPCPSivakumar AmbikapathyNoch keine Bewertungen

- CEM-3 Material Generation in PCB Board ManufacturingDokument2 SeitenCEM-3 Material Generation in PCB Board ManufacturingpcbboardszNoch keine Bewertungen

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDokument10 SeitenDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaNoch keine Bewertungen

- Photo-Conversion and Photo-Catalytic Efficiency of Hydrothermally Treated Anatase-Tio Films and NanoparticlesDokument8 SeitenPhoto-Conversion and Photo-Catalytic Efficiency of Hydrothermally Treated Anatase-Tio Films and NanoparticlesPatricia BarreraNoch keine Bewertungen

- GoldyDokument1 SeiteGoldyAniket DubeNoch keine Bewertungen

- SA Ch01Dokument9 SeitenSA Ch01Mohd AsmawiNoch keine Bewertungen

- BOQ For Plumbing Sanitary WorksDokument6 SeitenBOQ For Plumbing Sanitary WorksHavoc KumarNoch keine Bewertungen

- Carpentry and MasonryDokument81 SeitenCarpentry and MasonryCassandra Noreen Pacayra SantosNoch keine Bewertungen

- Solid Waste Management Opportunities Challenges GujaratDokument14 SeitenSolid Waste Management Opportunities Challenges GujaratRahul Kumar AwadeNoch keine Bewertungen

- G40 Ready Mix Data Sheet: PropertiesDokument4 SeitenG40 Ready Mix Data Sheet: Propertieswadi ajanaNoch keine Bewertungen

- Stoichiometry FinalDokument54 SeitenStoichiometry FinalPrabhakar BandaruNoch keine Bewertungen

- Excel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioDokument3 SeitenExcel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioJohn Anthony YumulNoch keine Bewertungen

- Chemical Analysis of Sodium Chloride Test Methods For E534 PDFDokument6 SeitenChemical Analysis of Sodium Chloride Test Methods For E534 PDFafifatul jannahNoch keine Bewertungen

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyVon EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyBewertung: 4 von 5 Sternen4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyVon EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyBewertung: 4 von 5 Sternen4/5 (1)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Power Electronics Diploma Interview Q&A: Career GuideVon EverandPower Electronics Diploma Interview Q&A: Career GuideNoch keine Bewertungen

- Real Life: Construction Management Guide from A-ZVon EverandReal Life: Construction Management Guide from A-ZBewertung: 4.5 von 5 Sternen4.5/5 (4)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEVon EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEBewertung: 4 von 5 Sternen4/5 (1)

- Construction Project Management 101: For Beginners & New GraduatesVon EverandConstruction Project Management 101: For Beginners & New GraduatesNoch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsVon EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNoch keine Bewertungen