Beruflich Dokumente

Kultur Dokumente

Metal Forming Process

Hochgeladen von

tadele0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

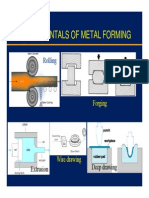

21 Ansichten5 SeitenThis presentation discusses fundamentals of metal forming processes. It covers an overview of metal forming techniques including bulk deformation processes like rolling, forging, and extrusion as well as sheet metalworking. It also examines factors that influence metal forming like material properties, temperature, strain rate sensitivity, and friction/lubrication. Temperature is a particularly important variable as it affects the strength, ductility, and formability of metals.

Originalbeschreibung:

metall

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis presentation discusses fundamentals of metal forming processes. It covers an overview of metal forming techniques including bulk deformation processes like rolling, forging, and extrusion as well as sheet metalworking. It also examines factors that influence metal forming like material properties, temperature, strain rate sensitivity, and friction/lubrication. Temperature is a particularly important variable as it affects the strength, ductility, and formability of metals.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten5 SeitenMetal Forming Process

Hochgeladen von

tadeleThis presentation discusses fundamentals of metal forming processes. It covers an overview of metal forming techniques including bulk deformation processes like rolling, forging, and extrusion as well as sheet metalworking. It also examines factors that influence metal forming like material properties, temperature, strain rate sensitivity, and friction/lubrication. Temperature is a particularly important variable as it affects the strength, ductility, and formability of metals.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

http://slideplayer.

com/slide/8344539/

"FUNDAMENTALS OF METAL FORMING"— Presentation transcript:

FUNDAMENTALS OF METAL FORMING

Overview of Metal Forming

Material Behavior in Metal Forming

Temperature in Metal Forming

Strain Rate Sensitivity

Friction and Lubrication in Metal Forming Department of Mechanical Engineering

2 Department of Mechanical Engineering

Metal Forming Large group of manufacturing processes in which plastic deformation is used to

change the shape of metal workpieces The tool, usually called a die, applies stresses that exceed

yield strength of metal The metal takes a shape determined by the geometry of the die

Department of Mechanical Engineering

3 Stresses in Metal Forming

Stresses to plastically deform the metal are usually compressive Examples: rolling, forging,

extrusion However, some forming processes Stretch the metal (tensile stresses) Others bend the

metal (tensile and compressive) Still others apply shear stresses Department of Mechanical

Engineering

4 Material Properties in Metal Forming

Desirable material properties: Low yield strength and high ductility These properties are affected

by temperature: Ductility increases and yield strength decreases when work temperature is raised

Other factors: Strain rate and friction Department of Mechanical Engineering

5 Bulk Deformation Processes

Characterized by significant deformations and massive shape changes "Bulk" refers to workparts

with relatively low surface area-to-volume ratios Starting work shapes include cylindrical billets

and rectangular bars Department of Mechanical Engineering

6 Figure 18.2 – Basic bulk deformation processes: (a) rolling

Department of Mechanical Engineering

7 Figure 18.2 – Basic bulk deformation processes: (b) forging

Department of Mechanical Engineering

8 Figure 18.2 – Basic bulk deformation processes: (c) extrusion

Department of Mechanical Engineering

9 Figure 18.2 – Basic bulk deformation processes: (d) drawing

Department of Mechanical Engineering

10 Department of Mechanical Engineering

Sheet Metalworking Forming and related operations performed on metal sheets, strips, and coils

High surface area-to-volume ratio of starting metal, which distinguishes these from bulk

deformation Often called pressworking because presses perform these operations Parts are called

stampings Usual tooling: punch and die Department of Mechanical Engineering

11 Figure 18.3 - Basic sheet metalworking operations: (a) bending

Department of Mechanical Engineering

12 Figure 18.3 - Basic sheet metalworking operations: (b) drawing

Department of Mechanical Engineering

13 Figure 18.3 - Basic sheet metalworking operations: (c) shearing

Department of Mechanical Engineering

14 Material Behavior in Metal Forming

Plastic region of stress-strain curve is primary interest because material is plastically deformed In

plastic region, metal's behavior is expressed by the flow curve: where K = strength coefficient;

and n = strain hardening exponent Stress and strain in flow curve are true stress and true strain

Department of Mechanical Engineering

15 Department of Mechanical Engineering

Flow Stress For most metals at room temperature, strength increases when deformed due to

strain hardening Flow stress = instantaneous value of stress required to continue deforming the

material where Yf = flow stress, that is, the yield strength as a function of strain Department of

Mechanical Engineering

16 Department of Mechanical Engineering

Average Flow Stress Determined by integrating the flow curve equation between zero and the

final strain value defining the range of interest where = average flow stress; and = maximum

strain during deformation process Department of Mechanical Engineering

17 Temperature in Metal Forming

For any metal, K and n in the flow curve depend on temperature Both strength and strain

hardening are reduced at higher temperatures In addition, ductility is increased at higher

temperatures Department of Mechanical Engineering

18 Temperature in Metal Forming

Any deformation operation can be accomplished with lower forces and power at elevated

temperature Three temperature ranges in metal forming: Cold working Warm working Hot

working Department of Mechanical Engineering

19 Department of Mechanical Engineering

Cold Working Performed at room temperature or slightly above Many cold forming processes

are important mass production operations Minimum or no machining usually required These

operations are near net shape or net shape processes Department of Mechanical Engineering

20 Advantages of Cold Forming vs. Hot Working

Better accuracy, closer tolerances Better surface finish Strain hardening increases strength and

hardness Grain flow during deformation can cause desirable directional properties in product No

heating of work required Department of Mechanical Engineering

21 Disadvantages of Cold Forming

Higher forces and power required Surfaces of starting workpiece must be free of scale and dirt

Ductility and strain hardening limit the amount of forming that can be done In some operations,

metal must be annealed to allow further deformation In other cases, metal is simply not ductile

enough to be cold worked Department of Mechanical Engineering

22 Department of Mechanical Engineering

Warm Working Performed at temperatures above room temperature but below recrystallization

temperature Dividing line between cold working and warm working often expressed in terms of

melting point: 0.3Tm, where Tm = melting point (absolute temperature) for metal Department of

Mechanical Engineering

23 Advantages of Warm Working

Lower forces and power than in cold working More intricate work geometries possible Need for

annealing may be reduced or eliminated Department of Mechanical Engineering

24 Department of Mechanical Engineering

Hot Working Deformation at temperatures above recrystallization temperature Recrystallization

temperature = about one-half of melting point on absolute scale In practice, hot working usually

performed somewhat above 0.5Tm Metal continues to soften as temperature increases above

0.5Tm, enhancing advantage of hot working above this level Department of Mechanical

Engineering

25 Department of Mechanical Engineering

Why Hot Working? Capability for substantial plastic deformation of the metal - far more than

possible with cold working or warm working Why? Strength coefficient is substantially less than

at room temperature Strain hardening exponent is zero (theoretically) Ductility is significantly

increased Department of Mechanical Engineering

26 Advantages of Hot Working vs. Cold Working

Workpart shape can be significantly altered Lower forces and power required Metals that usually

fracture in cold working can be hot formed Strength properties of product are generally isotropic

No strengthening of part occurs from work hardening Advantageous in cases when part is to be

subsequently processed by cold forming Department of Mechanical Engineering

27 Disadvantages of Hot Working

Lower dimensional accuracy Higher total energy required (due to the thermal energy to heat the

workpiece) Work surface oxidation (scale), poorer surface finish Shorter tool life Department of

Mechanical Engineering

28 Strain Rate Sensitivity

Theoretically, a metal in hot working behaves like a perfectly plastic material, with strain

hardening exponent n = 0 The metal should continue to flow at the same flow stress, once that

stress is reached However, an additional phenomenon occurs during deformation, especially at

elevated temperatures: Strain rate sensitivity Department of Mechanical Engineering

29 Department of Mechanical Engineering

What is Strain Rate? Strain rate in forming is directly related to speed of deformation v

Deformation speed v = velocity of the ram or other movement of the equipment Strain rate is

defined: where = true strain rate; and h = instantaneous height of workpiece being deformed

Department of Mechanical Engineering

30 Evaluation of Strain Rate

In most practical operations, valuation of strain rate is complicated by Workpart geometry

Variations in strain rate in different regions of the part Strain rate can reach 1000 s-1 or more for

some metal forming operations Department of Mechanical Engineering

31 Effect of Strain Rate on Flow Stress

Flow stress is a function of temperature At hot working temperatures, flow stress also depends

on strain rate As strain rate increases, resistance to deformation increases This effect is known as

strain-rate sensitivity Department of Mechanical Engineering

32 Department of Mechanical Engineering

Figure 18.5 - (a) Effect of strain rate on flow stress at an elevated work temperature. (b) Same

relationship plotted on log-log coordinates Department of Mechanical Engineering

33 Strain Rate Sensitivity Equation

where C = strength constant (similar but not equal to strength coefficient in flow curve equation),

and m = strain-rate sensitivity exponent Department of Mechanical Engineering

34 Department of Mechanical Engineering

Figure 18.6 - Effect of temperature on flow stress for a typical metal. The constant C in Eq.

(18.4), indicated by the intersection of each plot with the vertical dashed line at strain rate = 1.0,

decreases, and m (slope of each plot) increases with increasing temperature Department of

Mechanical Engineering

35 Observations about Strain Rate Sensitivity

Increasing temperature decreases C, increases m At room temperature, effect of strain rate is

almost negligible Flow curve is a good representation of material behavior As temperature

increases, strain rate becomes increasingly important in determining flow stress Department of

Mechanical Engineering

36 Friction in Metal Forming

In most metal forming processes, friction is undesirable: Metal flow is retarded Forces and

power are increased Wears tooling faster Friction and tool wear are more severe in hot working

Department of Mechanical Engineering

37 Lubrication in Metal Forming

Metalworking lubricants are applied to tool-work interface in many forming operations to reduce

harmful effects of friction Benefits: Reduced sticking, forces, power, tool wear Better surface

finish Removes heat from the tooling Department of Mechanical Engineering

Das könnte Ihnen auch gefallen

- Applied Welding Engineering: Processes, Codes, and StandardsVon EverandApplied Welding Engineering: Processes, Codes, and StandardsNoch keine Bewertungen

- Fundamental of Metal FormingDokument38 SeitenFundamental of Metal Formingkuba DefaruNoch keine Bewertungen

- Lec 7Dokument38 SeitenLec 7Romany AdelNoch keine Bewertungen

- Chapter 18-Fundamentals Metal FormingDokument32 SeitenChapter 18-Fundamentals Metal FormingZaka UllahNoch keine Bewertungen

- Metal Forming - FundamentalDokument35 SeitenMetal Forming - FundamentalR ChannelNoch keine Bewertungen

- 1 Fundamentals of Metal FormingDokument43 Seiten1 Fundamentals of Metal Formingdawitdafe4Noch keine Bewertungen

- Fundamentals of Metal FormingDokument38 SeitenFundamentals of Metal FormingAd Man GeTigNoch keine Bewertungen

- ManufProc 4 BulkFormingDokument96 SeitenManufProc 4 BulkFormingHannan yusuf KhanNoch keine Bewertungen

- Chapter 18-Fundamentals Metal FormingDokument33 SeitenChapter 18-Fundamentals Metal Formingdrbasit93Noch keine Bewertungen

- Proses Manufaktur - Fundamental of Metal FormingDokument35 SeitenProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeNoch keine Bewertungen

- Pertemuan 2 Material Behavior in Metal FormingDokument37 SeitenPertemuan 2 Material Behavior in Metal FormingMayonkFound ationNoch keine Bewertungen

- ManufacTechLecture 2aDokument83 SeitenManufacTechLecture 2aNawaz KhanNoch keine Bewertungen

- Fundamental of Metal FormingDokument31 SeitenFundamental of Metal FormingHusain AliNoch keine Bewertungen

- Plastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesDokument102 SeitenPlastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesEbrahim AliNoch keine Bewertungen

- Amr Shehata FayedDokument29 SeitenAmr Shehata FayeddpksobsNoch keine Bewertungen

- Fundamentals of Metal Forming Processes: Amr Shehata FayedDokument29 SeitenFundamentals of Metal Forming Processes: Amr Shehata FayedErick Maza MartinezNoch keine Bewertungen

- UntitledDokument7 SeitenUntitledKondwani NguletiNoch keine Bewertungen

- RJ - METAL FORMING PROCESS - NotesDokument16 SeitenRJ - METAL FORMING PROCESS - NotesAnshul YadavNoch keine Bewertungen

- Solutions Ch18 Spring08Dokument2 SeitenSolutions Ch18 Spring08hzeem50% (2)

- Unit V Metal Forming Process MTDokument10 SeitenUnit V Metal Forming Process MTShivakumarNoch keine Bewertungen

- 2.1 Overview of Metal FormingDokument8 Seiten2.1 Overview of Metal FormingWillykateKairuNoch keine Bewertungen

- Metals FormingDokument34 SeitenMetals FormingBilisuma SeyoumNoch keine Bewertungen

- Handout-8a-Metal Forming BasicDokument23 SeitenHandout-8a-Metal Forming BasicAmardhianaNoch keine Bewertungen

- Metal Forming & Shaping Processes: Topic 3Dokument37 SeitenMetal Forming & Shaping Processes: Topic 3afnanhananyNoch keine Bewertungen

- Rolling, Forging, Extrusion & DrawingDokument13 SeitenRolling, Forging, Extrusion & DrawingMuhammad Ali AbroNoch keine Bewertungen

- Unit-I Chapter-1 Introduction and Concepts: by Ravichandran G Assistant Professor Dept. of Mech - Engg. CUFE, BengaluruDokument38 SeitenUnit-I Chapter-1 Introduction and Concepts: by Ravichandran G Assistant Professor Dept. of Mech - Engg. CUFE, BengaluruRavichandran GNoch keine Bewertungen

- Metal Forming Technology 1601913164Dokument12 SeitenMetal Forming Technology 1601913164jesssepinkman03Noch keine Bewertungen

- Metal Forming-RollingDokument50 SeitenMetal Forming-RollingMuhammad Alsi AdharyNoch keine Bewertungen

- 05 Ch3 ForgingDokument26 Seiten05 Ch3 ForgingKamil BudimanNoch keine Bewertungen

- Fundamentals of Metal Forming: RollingDokument26 SeitenFundamentals of Metal Forming: RollingAyush BhadauriaNoch keine Bewertungen

- Hapter: MetalsDokument55 SeitenHapter: Metalsbedo39Noch keine Bewertungen

- Flow Stress or True StressDokument7 SeitenFlow Stress or True StressRajshekar NagarajNoch keine Bewertungen

- Chapter 3-Fundamentals of Metal FormingDokument6 SeitenChapter 3-Fundamentals of Metal FormingG. Dancer GhNoch keine Bewertungen

- Metal FormingDokument4 SeitenMetal Formingolyad ahmedinNoch keine Bewertungen

- CH 15Dokument34 SeitenCH 15ACC SHNoch keine Bewertungen

- FormingDokument10 SeitenFormingYashwanth D RNoch keine Bewertungen

- Unit 11 NotesDokument7 SeitenUnit 11 NotesarunkumarnoolaNoch keine Bewertungen

- Metal Forming Processes Unit-IDokument9 SeitenMetal Forming Processes Unit-IDimas Mahendra P BozerNoch keine Bewertungen

- Manufacturing Engineering Forming: Chapter 3: MetalDokument98 SeitenManufacturing Engineering Forming: Chapter 3: MetalnunuNoch keine Bewertungen

- Fundamentals of Metal FormingDokument22 SeitenFundamentals of Metal Formingelmar waruwuNoch keine Bewertungen

- Fundamentals of Metal Forming: RollingDokument26 SeitenFundamentals of Metal Forming: RollingamitNoch keine Bewertungen

- Mme 431 CH14Dokument15 SeitenMme 431 CH14Khalid WaleedNoch keine Bewertungen

- Part B: Principles of Major Manufacturing Processes and Bulk FormingDokument49 SeitenPart B: Principles of Major Manufacturing Processes and Bulk FormingsivaenotesNoch keine Bewertungen

- 6 Unit 2 - Metal Forming ProcessesDokument27 Seiten6 Unit 2 - Metal Forming ProcessesAditya KumarNoch keine Bewertungen

- Metal FormingDokument80 SeitenMetal FormingIbrahim Mehkri100% (1)

- Metal Forming FundamentalsDokument6 SeitenMetal Forming FundamentalsRupak KumarNoch keine Bewertungen

- Metal Forming Processes Classification Questions and Answers - SanfoundryDokument3 SeitenMetal Forming Processes Classification Questions and Answers - SanfoundryrahmaNoch keine Bewertungen

- Wrought Alloy Processing: ReferencesDokument30 SeitenWrought Alloy Processing: ReferencesDirajen PMNoch keine Bewertungen

- Chapter 4Dokument113 SeitenChapter 4girma workuNoch keine Bewertungen

- Forming Process ReportDokument4 SeitenForming Process ReportAqib ZamanNoch keine Bewertungen

- Casting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingDokument44 SeitenCasting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingRaj PatelNoch keine Bewertungen

- Defects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarDokument22 SeitenDefects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarKarun PeriyasamyNoch keine Bewertungen

- Mechanical Working of MetalsDokument76 SeitenMechanical Working of MetalsPradip GuptaNoch keine Bewertungen

- Lecture 32 - Introduction To Metal FormingDokument23 SeitenLecture 32 - Introduction To Metal Formingkunal gargNoch keine Bewertungen

- Fundamentals of Metal FormingDokument38 SeitenFundamentals of Metal FormingriyannnNoch keine Bewertungen

- Solid State Welding ProcessDokument17 SeitenSolid State Welding Processrajfmc100% (1)

- Chapter 18-Fundamentals of Metal FormingDokument33 SeitenChapter 18-Fundamentals of Metal FormingMuhammad Qasim QureshiNoch keine Bewertungen

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysVon EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNoch keine Bewertungen

- Dynamic Damage and FragmentationVon EverandDynamic Damage and FragmentationDavid Edward LambertNoch keine Bewertungen

- Ceramic Disc BrakeDokument16 SeitenCeramic Disc BrakesachinNoch keine Bewertungen

- Moisture and Fire Resistant Gypsum Board (WRFR)Dokument3 SeitenMoisture and Fire Resistant Gypsum Board (WRFR)burakNoch keine Bewertungen

- Serma LonDokument1 SeiteSerma LonIrwanzNoch keine Bewertungen

- Economics For Structural Steel Plate GirdersDokument10 SeitenEconomics For Structural Steel Plate Girdersthomas kilianNoch keine Bewertungen

- Gas Processing Fundamentals Manual1Dokument12 SeitenGas Processing Fundamentals Manual1Ahmed Khamees ShatlaNoch keine Bewertungen

- Schematic Diagram of Qualitative Tests For Elements in Organic CompoundsDokument5 SeitenSchematic Diagram of Qualitative Tests For Elements in Organic CompoundsChristine DomingoNoch keine Bewertungen

- Mild Steel Hollow Section - Square, Rectangular, Circular - MetaDokument10 SeitenMild Steel Hollow Section - Square, Rectangular, Circular - MetaAshebir AjemaNoch keine Bewertungen

- First Law of ThermodynamicsDokument7 SeitenFirst Law of Thermodynamics1155016764Noch keine Bewertungen

- Chem Project Kanishka KhamkarDokument10 SeitenChem Project Kanishka KhamkarKanishka P KhamkarNoch keine Bewertungen

- Cupola Malleable Iron: Standard Specification ForDokument4 SeitenCupola Malleable Iron: Standard Specification ForHenriqueNoch keine Bewertungen

- Manufacturing Process SyllabusDokument4 SeitenManufacturing Process SyllabusRAMAKANT RANANoch keine Bewertungen

- Alcohols, Phenols and Ethers - MCQs Test - 3Dokument3 SeitenAlcohols, Phenols and Ethers - MCQs Test - 3Prasant KumarNoch keine Bewertungen

- High Performance SeriesDokument8 SeitenHigh Performance SeriesRonCarNoch keine Bewertungen

- Twistlock TestingDokument44 SeitenTwistlock Testingkandahar_specNoch keine Bewertungen

- Outline SpecsDokument171 SeitenOutline Specsmohamed fawzyNoch keine Bewertungen

- Mullion Transom Connector BS-EN-1991-1-1 V2.0Dokument2 SeitenMullion Transom Connector BS-EN-1991-1-1 V2.0Giri DharanNoch keine Bewertungen

- 8 - Monographie Pyridoxine-Hydrochloride-1631Dokument1 Seite8 - Monographie Pyridoxine-Hydrochloride-1631asmae.labindusNoch keine Bewertungen

- Engineering Thermodynamics - QBDokument13 SeitenEngineering Thermodynamics - QBInduPalanisamyNoch keine Bewertungen

- Buffer Solutions .Docx 1Dokument8 SeitenBuffer Solutions .Docx 1H.M. AriyanNoch keine Bewertungen

- Resourceful Mock Ii Examinations 2017Dokument8 SeitenResourceful Mock Ii Examinations 2017Baguma MichaelNoch keine Bewertungen

- Wps Ausa Gtaw Smaw 002 2018 Ok RDokument2 SeitenWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- College Presentation On Highway ConstructionDokument34 SeitenCollege Presentation On Highway ConstructionNiTiN dHiMaNNoch keine Bewertungen

- Homework 4 NewDokument4 SeitenHomework 4 NewnooraNoch keine Bewertungen

- Tenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsDokument31 SeitenTenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsSudish Bhat100% (1)

- Phosphorus, Reactive (Orthophosphate) : Molybdovanadate Method Method 8114 1.0 To 100.0 MG/L PO (HR) Test N Tube VialsDokument6 SeitenPhosphorus, Reactive (Orthophosphate) : Molybdovanadate Method Method 8114 1.0 To 100.0 MG/L PO (HR) Test N Tube VialsOudah AliNoch keine Bewertungen

- InSituTesting WebsiteDokument38 SeitenInSituTesting Websiteag_007Noch keine Bewertungen

- Sheet MetalDokument46 SeitenSheet Metalpreetham shekarNoch keine Bewertungen

- Proiect Constructii Civile 2Dokument45 SeitenProiect Constructii Civile 2Lazurca Augustin100% (1)

- Theoretical Framework: Compressive Strength TestDokument11 SeitenTheoretical Framework: Compressive Strength TestqwertasdfgNoch keine Bewertungen

- 175 026510Dokument2 Seiten175 026510Abu Anas M.SalaheldinNoch keine Bewertungen