Beruflich Dokumente

Kultur Dokumente

Intelligent Optimal Tool Selections For CNC Programming of Machine Tools

Hochgeladen von

Agus GunawanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Intelligent Optimal Tool Selections For CNC Programming of Machine Tools

Hochgeladen von

Agus GunawanCopyright:

Verfügbare Formate

Afrim Gjelaj

Joze Balič

Mirko Fičko

ISSN 1333-1124

eISSN 1849-1391

INTELLIGENT OPTIMAL TOOL SELECTIONS FOR CNC

PROGRAMMING OF MACHINE TOOLS

UDC 621.9.02:658.5.018.2

Summary

The aim of this paper is to improve CNC programming of machine tools and to

minimize the need for human intervention or manual inputs. The proposed optimization

method for tool selection is based on a genetic algorithm. Experimental approval is done by

using the Matlab environment and it has been shown that the proposed method is useful for

the optimization of cutting tool selection. The reason for developing this method is to reduce

human resources during the machining process, and at the same time to decrease the cost of

the product, to save time and to achieve higher efficiency. This approach is called intelligent

way of CNC programming.

Key words: machine tools, intelligent, optimization of tool selection, CNC

programming, Matlab

1. Introduction

The rapid development of computer technology, the employing of CNC machines in

particular, has significantly contributed to the improvement of the quality and quantity of

production programmes in modern manufacturing industries. The use of an interface, which

makes it possible to connect a computer to a CNC machine, directly influences the increasing

capacities and accuracies of production programmes when compared to the earlier

conventional CNC machines.

Nowadays, intelligent methods are being developed for use within several real

applications in manufacturing industries, such as turning CNC machine tools, milling

machine tools, etc. [1, 2]. The goal of this paper was to develop an algorithm for tool selection

that would integrate a conventional CNC machine. In order for the intelligent method to be as

reasonable as possible, the path and tool selection of the CNC machine would be optimized

by the application of a Genetic Algorithm (GA). Optimizations of tool selection play an

important role both for CNC machine tools or within CAD/CAM systems. Different options

offered by CAD/CAM systems for tool selection are used (e.g. based on the processing

method used for lathe, milling and HSC machines, tool data, tool types, tool geometries,

length and diameter of tools, etc.). During machining processes, the CAD/CAM system

enables quick choices regarding desired tools for manufacturing workpieces. On the other

TRANSACTIONS OF FAMENA XXXVII-3 (2013) 31

A. Gjelaj, J. Balič Intelligent Optimal Tool Selections for

M. Fičko CNC Programming of Machine Tools

hand, without CAD/CAM systems, it is very difficult to programme CNC machines for

complex geometries of workpieces.

The following describes a procedure for the selection of tools for the tool charger of a

lathe and a milling machine. The procedure of selection is carried out from one tool to another

but not within the range of the tool number. The developed intelligent method, which will be

integrated into conventional CNC machines, enables us to select machine tools depending on

the geometry of the workpiece and the commands received from the computer [3].

Chen et al. [1] presented an automatic cutting tool selection method for rough turning

operations on CNC lathe machines. Their method for selecting a cutting tools procedure is

made from an appropriate tool library. In order to reduce the operation time, a heuristic

method is employed. This procedure ignores any request for an exhaustive operation library

and the final results are very fast and efficient.

Car et.al [2] introduced optimization parameters for machining turning processes based

on artificial intelligence. In order to find optimal cutting parameters, the Genetic Algorithm

(GA) is used as an optimal solution. The proposed model is combined by employing the GA,

and the implementation is done by using binary linear programming. The main advantages are

the ability to perform the multi-object optimization and the minimizing of machining time and

production costs, whilst being constrained by the technological processes and materials.

Ahmad et al. [3] describe sequences of tool selection as an important activity during

process planning for milling which has a great bearing on the cost of machining. The GA

formulation is used to find optimal tool sequences. Two types of selection mechanisms, i.e.

“elitist selection” and “roulette method” were tested. It was found that the GA formulation

generates near optimal solutions whilst reducing computation time by up to 30 % compared to

the graph formulation. Their research also extended to effects of tool holders.

Balic et al. [4] applied artificial intelligence during the production process. Their

concept was employed in turning operations for cutting tool selection that enabled the

selection of the optimal cutting tool set on the basis of a 3D CAD model. Furthermore, an

intelligent CNC programming method included a neural network (NN) and a GA was carried

out. However, their system has been improved, accuracy, speed and flexibility are increased

and at the same time full autonomy is reached.

Oral et al. [5] developed an optimum operation and tool sequences that are used in

generative process planning systems for rotational parts. Their method is characterized by a

minimum number of tool changes and minimum tool-travel time.

This paper is organized as follows: Section 1 discusses the tool selection system for

turning and milling machines. Section 2 introduces an intelligent method for tool selection

based on the geometry of the workpiece and crucial time of machining. Section 3 discusses

the optimization by using a Genetic Algorithm. Section 4 provides conclusions.

2. Tool selection system of CNC machine tools for a turret lathe and a milling machine

This tool selection system includes the selection, management and organization of tools

by CNC machines as well as all the issues concerning geometries of tools. Before the arrival

of the new generation of conventional CNC machines, the operator was required to manually

programme all cutting tools depending on the process of manfuacturing the workpiece. This

programming was hard and often boring, and a predictive complex geometry of the workpiece

was difficult to achieve.

With the application of the CAM software package it is easy to determine and

programme a cutting tool based on the geometry of the workpiece. The CAD/CAM systems

offer some possibilities for the solving of tool-type selection, tool path-length, type material

of work-piece, type of CNC machine tools etc.

32 TRANSACTIONS OF FAMENA XXXVII-3 (2013)

Intelligent Optimal Tool Selections for A. Gjelaj, J. Balič.

CNC Programming of Machine Tools M. Fičko

Tool selection by the CAD/CAM software is one of the more important activities of

CNC programming. Recently, intelligent methods have been developed which automatically

select cutting tools from a tool magazine. Various systems have been developed, but they

have never completely replaced the human resource (machine operator).

2.1 Tool system of a turret lathe and a milling machine

An orientation method for selecting cutting tools in the shortest time from a tool

magazine to the workpiece needs to be developed. For each manufacturing process such as

turning and milling machining [7], it is necessary to choose the cutting tool for predictive

geometry during the modelling of a workpiece.

In addition, there are mainly three kinds of tool changers available within the field of

CNC machine tools: 1 – Tool change system with gripper arms, 2 – Tool change system

magazine with chain magazine, and 3 – Tool change system with a disc magazine. The tool

selection systems for milling and lathe CNC machines are presented in Fig.1.

Fig. 1 Tool system: for a turret lathe (left) and for a milling machine (right) (catalogue Juraform E.K Germany)

The rotation of the tool magazine (ω - angular velocity) within the tool selection system

(T) should be run in the clockwise direction. The operation of the tool magazine is graphically

presented in Fig. 2.

a) b)

Fig. 2 a) Tool number positions during magazine tool and reserve tools selection, b) Tool selection and

describing the path from one to another

The selection of a tool for the turret lathe and the total number in the magazine can be

optimized based on the geometry and shape of the part. A mathematical model is generally

formed for tool selection in the case of milling and lathe CNC machines, as given by the

expression:

TRANSACTIONS OF FAMENA XXXVII-3 (2013) 33

A. Gjelaj, J. Balič Intelligent Optimal Tool Selections for

M. Fičko CNC Programming of Machine Tools

Tch T1 Tn1 (1)

where (T1) denotes the first cutting tool and (Tn+1) is given as the latest tool selected. The

angular angles between the cutting tools for each tool can be determined by the equation:

360

(2)

NT

where NT denotes the number of cutting tools.

In order to calculate the positions of each cutting tool determined by the angular angle,

it is necessary to know the number of cutting tools (NT). If this number is NT = 30, then the

angular angle φ = 12° denotes the angle between each tool.

Fig. 2 b) presents both the path (L) and the angular angle (φ) of the tool selections (T).

The determinations of the path and velocity of the magazine tool are derived from Fig. 2 b),

given by the expressions:

L r (3)

v r (4)

When differentiating between equations (3) and (4) as functions of the angular angle

(φ), and the angular velocity (ω), respectively, the equation of motion now takes this form:

dL r d (5)

dv r d (6)

Expressions (5) and (6) represent the equation of motion for the magazine tool.

The crucial time during production, based on the geometry and tool selection, is given

by the expression (Tm) of the magazine tool and cutting tool as follows:

Di d i 1

Tm PLi NT Tch (7)

2

where Tm is the crucial time, PL is the path length of the workpiece, Di denotes the first

diameter, di-1 variety diameter of the workpiece, Tch denotes the tool selections of the

magazine and cutting tools, respectively.

The target for the optimization of the tool selection is to minimize the auxiliary time and the

crucial time as well as the machining time in general. The total machining time depends on the

tool path length, the numbers of tools, the feed rate, the cutting speed, the depth of cutting, etc.

In order to clarify the method of intelligent tool selection during the machining

operation in the cases of milling and lathe machine tools that directly influence the

machinability, Table 1 below presents the application of the tool selection based on the

machining process.

Table 1 Characteristics and types of tools

Tool list Diameter/bxh [mm] Radius [mm] Tool type

T1 10 0.1 End mill

T5 15x15 2 Turn

T6 8 0.5 Ball end mill

T10 12 0.5 Drilling

T3 20x20 0.5 External

T8 16x16 - Threading

T13 20x25 1.2 Internal

34 TRANSACTIONS OF FAMENA XXXVII-3 (2013)

Intelligent Optimal Tool Selections for A. Gjelaj, J. Balič.

CNC Programming of Machine Tools M. Fičko

The tool list in this table refers to the number of tools, the diameter or bxh, the tool

holders for lathe and milling machine tools, the radius of the tool and the tool type during

machining operations, such us milling and lathe machining processes.

3. Intelligent method for tool selection for CNC machine tools

The method proposed for the intelligent tool selection will depend on certain

parameters, based on the geometries of workpieces (linear, circular and spline interpolation),

so that the best tool for the case of turning operation is selected and the operation is at the

same time independent from the human. The application of the intelligent method for

selecting the cutting tool will be based on the geometry of the workpiece (trajectory of the

workpiece) for the rotational part [11].

Depending on the design of the workpiece, it can be concluded that the presented

intelligent system for the cutting tool selection could be used for various shapes and for

generating the tool path using CNC machines [12, 13]. The selection of cutting tool

conditions is an important factor during metal cutting processes, as in the cases of lathe and

milling machine tools, etc. However, direct monitoring of tool selection systems is difficult to

implement because the tool selection method requires the application of the engineering

methods such as Artificial Intelligence (AI).

The intelligent method depends on tool selection but could be utilized for lathe and

milling machining, as shown in Fig. 3.

Fig. 3 Method of intelligent tool selection

The optimal tool selection by applying the method for intelligent systems for rotational

and square workpieces with complex geometry is analysed as shown in Fig. 3. In order to

operate the intelligent systems nowadays, it is necessary to optimize them by using artificial

intelligence. During the development of the tool selection method, the tool path and crucial

time of machining are analyzed as well.

Based on the tool selection method, the tool path trajectory is presented below, where

the tool path for rough machining is presented with a red line, and the blue line represents

TRANSACTIONS OF FAMENA XXXVII-3 (2013) 35

A. Gjelaj, J. Balič Intelligent Optimal Tool Selections for

M. Fičko CNC Programming of Machine Tools

final machining. The presented tool paths for rough and finished machining were done within

the environments of Matlab, see Fig. 4.

Fig. 4 Tool path based on intelligent tool selection

The tool path length depends on the tool selection method and cutting parameters. The

tools are selected for 3D rotational and prismatic workpieces in order to optimize the

trajectory of the path length, such as presented in the Figure above [10, 11].

4. Genetic algorithms

The genetic algorithm (GA) is one of the artificial techniques for analysis, which was

invented by John Holland [9, 15]. Genetic algorithms are global search methods that are based

on the evolutionary principle of natural election and genetic modifications. The work of

genetic algorithms (GAs) is very popular when resolving problem optimization.

The definition of a Genetic Algorithm is that this is a stochastic method, the overall

research of which mimics the natural biological metaphors of evolution. GA operates on a

population of possible solutions on the principle of the survival of those individuals who are

able to produce (hopefully) the best solutions possible.

Genetic algorithm is proposed for the machining process and optimization model for

tool selection methodology. However, this model depends on the machining parameters and

the design of the workpiece. To achieve this optimized model of tool selection, it is necessary

to know the knowledge base of the machining (technological process, types of tools, etc.) as

well as to find the best solutions for the machining process and tool selection. Fig. 5 presents

a model for tool selection and its optimization.

Fig. 5 Optimization process using intelligent tool selection

36 TRANSACTIONS OF FAMENA XXXVII-3 (2013)

Intelligent Optimal Tool Selections for A. Gjelaj, J. Balič.

CNC Programming of Machine Tools M. Fičko

In each generation, improvements are made based on the selections of individuals

according to the degree of adaptability within the field of the problem and their propagation

between them, through operators borrowed from natural genetics. This process has a key role

in the evolution of individual populations that are the most appropriate in their environments,

the populations of which they are themselves created, the same as in natural adaptation.

A Genetic Algorithm [6] can include three operations as follows:

selection,

crossover and

mutation.

The genetic algorithm selection is the process of determining the number of tests, the

individuals selected for reproduction, and the number of individuals posterity will produce for our

case of research. The basic operator during the production of new chromosomes in GAs is called

the 'crossover'. Similarly to nature, the crossover produces new individuals who have some

genetic similarities with both parents. The simplest form of crossover is single – point – crossover.

Fig. 6 Genetic operator (mutation and crossover)

In natural evolution, mutation is a random process when a gene is replaced with another

gene, thus providing a new genetic structure. Therefore, it can be concluded that the methods

for optimizing complex systems based on GAs are methods suitable for the optimization of

parameters of tool path lengths.

Table 2 presents the results from the Genetic Algorithm after three runs. For each run of

the Genetic Algorithm different results are obtained and these results will never be similar. As

the global optimization method GA makes it possible to put two or more functions at the same

time for some complexity problem and the best solution in the machining operation can be

found.

TRANSACTIONS OF FAMENA XXXVII-3 (2013) 37

A. Gjelaj, J. Balič Intelligent Optimal Tool Selections for

M. Fičko CNC Programming of Machine Tools

Table 2 Optimal results achieved from Genetic Algorithm results for three independent runs

Optimal value by GA

Machining parameters Initial values

Run 1 Run 2 Run 3

a [mm] 0.2 0.1 0.1 0.1

f [mm] 0.4 0.2 0.2 0.2

v [m/s] 2.8 2.305 2.3 2.302

Number of generation - 52 51 51

After the optimizations for each of the three runs, the best fitness values based on the

number of generations and the numbers of current iteration are obtained similarly.

Today, intelligent programming is defined as a function of artificial intelligence [8]. Basic

knowledge, such as intelligent programming is a procedure carried out without human

resources. Nowadays, intelligent programming plays an important role because of high market

demands, and customers also require advanced technology for their needs. The presented

work applies artificial intelligence such as Genetic Algorithms to finding the best solutions

regarding tool selections for CNC machine tools. Genetic Algorithms are search algorithms

based on the mechanism of natural selection and natural genetics. For our case, a general form

of the genetic evolution method is presented for tool selection from magazine tool data. The

program for solving equations regarding crucial time and tool selection is performed within

the Matlab environment. The flowchart is presented in Fig. 7.

Fig. 7 Flowchart of the evaluation process using GAs for tool selection

38 TRANSACTIONS OF FAMENA XXXVII-3 (2013)

Intelligent Optimal Tool Selections for A. Gjelaj, J. Balič.

CNC Programming of Machine Tools M. Fičko

The program starts by reading the machining parameters, tool selections, the number of

input and output variables, initial conditions, and the number of iterations.

In order to implement the optimization of the crucial time and tool selection for lathe

machining (Figure 7), three parameters are selected as optimization variables: feed rate (f),

depth of cutting (a) and cutting speed (v). The lower and upper bound optimization of the

parameters (constrains) are given as follows:

f min f f max (8)

amin a amax (9)

vmin v vmax (10)

The optimization procedure for GA starts by reading the boundaries of variables and

initializing the machining parameters: feed rate (f), depth of cut (a), and cutting speed (v) [13].

Furthermore, the main machining parameters are passed into the turning operation model for

the rotational part in order to find more near optimal solutions during the crucial time. These

values are substituted within a GA process to calculate the fitness function the objective

function. The GA process is repeated and stops when the optimal solution is obtained.

5. Conclusions

In this paper, cutting tool selection was carried out by using a conventional CNC

machine and by applying the method of an intelligent system for the geometry of a workpiece,

such as turning and milling. The following conclusions have been reached.

The tool path length was presented based on an intelligent tool selection method as well

as the complexities of the workpiece geometries. Also, the tool path for the rotational part is

described by the application of the Matlab software (Fig. 4). In our case, two cutting tools

were used for rough and final machining, the crucial time was carried out within the Matlab

environment and described in relation to tool selection and machining parameters which had a

direct influence on the optimizations of the machining processes.

GAs were utilized except for the tool selection method and at the same time the crucial

times for rough and finished tool path of the turret CNC machine tools are optimized. The red

line shows the tool path for rough machining, and the blue line shows the tool path for final

machining (see above). The tool path length was carried out within the environment of the

Matlab software. Fig. 5 presents the optimization process for the tool selection model. The

analysis of the crucial time and tool selection was performed by estimations of the machining

parameters and the tool paths for rough and final machining processes. The results are

presented in Table 2 for each run for the lower and upper bounds, the number of iterations, as

well as the initial values. The optimum results for our case have shown only one from three

results for the first case, with 52 current iterations, and the best value based on the objective

function value was obtained: 12.469034886859806.

ACKNOWLEDGEMENTS

The first author is profoundly grateful to the Slovene Human Resources Development

and Scholarship Fund, University of Maribor and University of Prishtina for their continuous

support.

Special thanks are dedicated to the P2-0157 (C) Dynamic, Intelligent, and Integrated

Technological Systems and Devices (DIP-TSN).

TRANSACTIONS OF FAMENA XXXVII-3 (2013) 39

A. Gjelaj, J. Balič Intelligent Optimal Tool Selections for

M. Fičko CNC Programming of Machine Tools

REFERENCES

[1] S.J. Chen, S. Hinduja, G. Barrow. Automatic tool selection for rough turning operations. International

Journal of Machine Tools and Manufacture Volume 29, Issue 4, 1989, p. 535-553

[2] Zaryab Ahmad, Keyvan Rahmani, Roshan M. D’Souza. Applications of genetic algorithms in process

planning: tool sequence selection for 2.5-axis pocket machining. Journal of Intelligent Manufacturing

(2010) 21:461–470, DOI 10.1007/s10845-008-0201-6

[3] Z. Car ; B. Barisic; M. Ikonic. GA based CNC turning center exploitation process parameters

optimization. Directory of Open Acess Journals Metallurgy (2009) 48(1) 47-50, ISSN 0543-5846

[4] Joze Balic, Franc Cus, Bostjan Vupatic. Intelligent automatic cutting-tool selection for turning

operations. ICGST AIML – 11 Conference Dubai, UAE, 12-14 April (2011) p. 1-7.

[5] Ali Oral, M. Cemal Cakir. Automated cutting tool selection and cutting tool sequence optimization for

rotational parts. Robotics and Computer-Integrated Manufacturing 20 (2004) p. 127–141.

[6] Joze Balic, Miha Kovacic, Bostjan Vaupotic. Intelligent programming of CNC turning operations using

genetic algorithm. Journal of Intelligent Manufacturing (2006) 17:331–340

[7] S.H. Suh “Architecture and implementation of a shop-floor programming system for STEP-compliant

CNC” Computer-Aided Design 35 (2003) 1069–1083,

[8] Wolfgang Ertel “Introduction to Artificial Intelligence” 2009, ISBN 978-0-85729-298-8

[9] Jones M. Tim, “Artificial Intelligence: An system approach” 2008, ISBN: 978-0-9778582-3-1, Publisher:

David Pallai,

[10] Wang, Jun and Andrew Kusiak, “Computational intelligence in manufacturing handbook” 2000, ISBN 0-

8493-0592-6

[11] ČUŠ, Franc, ŽUPERL, Uroš. Real-time cutting tool condition monitoring in milling. Journal of Stroj.

vestn., Feb. 2011, vol. 57, no. 2, p. 142-150.

[12] T. Tamizharasan, N. Senthil Kumar. Optimization of Cutting Insert Geometry Using DEFORM-3D:

Numerical Simulation and Experimental Validation. International Journal of Simulation Modelling,

Vol. 11, No. 2, 2012, p. 65-76.

[13] KLANČNIK, Simon, BALIČ, Jože, ČUŠ, Franc. Intelligent prediction of milling strategy using neural

networks. Control Cybern., 2010, vol. 39, no. 1, p. 9-22.

[14] YAO Yunping et al. “Optimize CNC Milling Parameters On-line” International Conference on Measuring

Technology and Mechatronics Automation China 2010.

[15] J. H. Holland. Adaptation in Natural and Artificial Systems. The University of Michigan Press, Ann

Arbor, MI, 1975.

Submitted: 10.3.2013 Afrim Gjelaj

Faculty of applied Technical Science

Accepted: 10.10.2013 University of Prishtina,

St. Battery Factory, Mitrovica,

40 000, Kosovo

afrim.gjelaj@uni-pr.edu

afrimgjelaj@yahoo.de

Joze Balič

Faculty of Mechanical Engineering,

University of Maribor,

St. Smetanova, 17, Maribor,

2000, Slovenia

Mirko Fičko

Faculty of Mechanical Engineering,

University of Maribor

St. Smetanova, 17, Maribor,

2000, Slovenia

40 TRANSACTIONS OF FAMENA XXXVII-3 (2013)

Das könnte Ihnen auch gefallen

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingVon EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNoch keine Bewertungen

- Finding Targets PDFDokument9 SeitenFinding Targets PDFSteve TangNoch keine Bewertungen

- CNC and NC MachineDokument36 SeitenCNC and NC MachineShaaf AmjadNoch keine Bewertungen

- Powerplant QuestionsDokument19 SeitenPowerplant QuestionsAshok KumarNoch keine Bewertungen

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Von EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Bewertung: 5 von 5 Sternen5/5 (1)

- Kunst 1600 Case AnalysisDokument3 SeitenKunst 1600 Case AnalysisrakeshNoch keine Bewertungen

- Computer Aided ManufacturingDokument28 SeitenComputer Aided ManufacturingSheik AbdullahNoch keine Bewertungen

- Machining Time Estimation by Experimental Method Using NC CAm Software Focusing CNC MachineDokument3 SeitenMachining Time Estimation by Experimental Method Using NC CAm Software Focusing CNC MachineSuresh RajagopalNoch keine Bewertungen

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDokument33 SeitenSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- Second Periodical Test in Organization and Management SY 2018-2019Dokument3 SeitenSecond Periodical Test in Organization and Management SY 2018-2019Merida BravoNoch keine Bewertungen

- CNC LAB Manual PDFDokument33 SeitenCNC LAB Manual PDFrajee10133% (3)

- CNC Milling ReportDokument15 SeitenCNC Milling ReportStarscream Aisyah78% (37)

- Design and Implementation of 3 Axis CNC Milling MachineDokument7 SeitenDesign and Implementation of 3 Axis CNC Milling Machineအောင် ချစ်သူNoch keine Bewertungen

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDokument7 SeitenTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesseventhsensegroupNoch keine Bewertungen

- Optimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodDokument11 SeitenOptimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodAllaboyinamahidharNoch keine Bewertungen

- L-23 (SM) (Ia&c) ( (Ee) Nptel)Dokument23 SeitenL-23 (SM) (Ia&c) ( (Ee) Nptel)Jayesh BaldotaNoch keine Bewertungen

- Virtual High Performance MachiningDokument7 SeitenVirtual High Performance MachiningGonçalo MiguelNoch keine Bewertungen

- 1709-Article Text-3215-1-10-20210224Dokument6 Seiten1709-Article Text-3215-1-10-20210224Seshank SubuNoch keine Bewertungen

- Journal of Advanced Mechanical Design, Systems, and ManufacturingDokument11 SeitenJournal of Advanced Mechanical Design, Systems, and ManufacturingManisha AryaNoch keine Bewertungen

- Cam Lab 1Dokument40 SeitenCam Lab 1Madhusudhan Rao KNoch keine Bewertungen

- Automatic Generation of CNC Codes Based On Machining FeaturesDokument5 SeitenAutomatic Generation of CNC Codes Based On Machining FeaturesSalehNoch keine Bewertungen

- Osama Sawafiri (CNC Machine)Dokument5 SeitenOsama Sawafiri (CNC Machine)Rahaf ZawNoch keine Bewertungen

- Implementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessDokument8 SeitenImplementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessRay SaNoch keine Bewertungen

- 1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Dokument38 Seiten1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Madhu SudhanNoch keine Bewertungen

- EP3 Aung Chit Thu (Term Paper)Dokument7 SeitenEP3 Aung Chit Thu (Term Paper)အောင် ချစ်သူNoch keine Bewertungen

- Tech Ascend CNC Student ManualDokument42 SeitenTech Ascend CNC Student ManualabyzenNoch keine Bewertungen

- Assignment-1 Computer Aided Manufacturing ME-418Dokument21 SeitenAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79Noch keine Bewertungen

- Introduction To CNC MachinesDokument15 SeitenIntroduction To CNC Machinespranjal priyeNoch keine Bewertungen

- Optimization of Machining Time Using Feature Based Process PlanningDokument7 SeitenOptimization of Machining Time Using Feature Based Process PlanningSuresh Rajagopal100% (1)

- Unit - Iv Part A 16.08Dokument19 SeitenUnit - Iv Part A 16.08Mohd InayathNoch keine Bewertungen

- EML2322L-CNC Machining PDFDokument17 SeitenEML2322L-CNC Machining PDFIvan JarebNoch keine Bewertungen

- CNC Lab Manual 2023 Med 3102Dokument66 SeitenCNC Lab Manual 2023 Med 3102G. RajeshNoch keine Bewertungen

- Notas 2 CNC MACHINE TOOLSDokument5 SeitenNotas 2 CNC MACHINE TOOLSArmandoNoch keine Bewertungen

- Fin Irjmets1652476781Dokument11 SeitenFin Irjmets1652476781yash matondkarNoch keine Bewertungen

- Minor PublicationsDokument20 SeitenMinor Publications20-311 AkhilNoch keine Bewertungen

- CNC MillingDokument18 SeitenCNC MillingShegs Jefferson JosephNoch keine Bewertungen

- APEM1 1 - 13 22 AIbased Cam:cncDokument10 SeitenAPEM1 1 - 13 22 AIbased Cam:cncTahir AbbasNoch keine Bewertungen

- Machining of Steam Turbine Blade On 5-Axis CNC Machine: SciencedirectDokument7 SeitenMachining of Steam Turbine Blade On 5-Axis CNC Machine: SciencedirectMido MoussaNoch keine Bewertungen

- 254464.1 Car Mikac VezaDokument6 Seiten254464.1 Car Mikac VezaengrodeNoch keine Bewertungen

- Protótipo de Uma Máquina CNC de Baixo Custo - Gabriel BatistaDokument12 SeitenProtótipo de Uma Máquina CNC de Baixo Custo - Gabriel BatistaGabriel BatistaNoch keine Bewertungen

- Cad, CamDokument16 SeitenCad, CamRakhi Mol BVNoch keine Bewertungen

- ME 408.01 - Computer Aided Manufacturing - Lab ManualDokument24 SeitenME 408.01 - Computer Aided Manufacturing - Lab ManualOMKAR MUSHRIFFNoch keine Bewertungen

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDokument8 SeitenTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesODEH ABU YAHIANoch keine Bewertungen

- Sensors: Automatic Identification of Tool Wear Based On Convolutional Neural Network in Face Milling ProcessDokument17 SeitenSensors: Automatic Identification of Tool Wear Based On Convolutional Neural Network in Face Milling ProcessAmine SassiNoch keine Bewertungen

- Cad Pace 2 57-68Dokument12 SeitenCad Pace 2 57-68Kazimir KozulNoch keine Bewertungen

- Title Objective: Figure 1: Hitachi Seiki Hitec-Turn20SiiDokument11 SeitenTitle Objective: Figure 1: Hitachi Seiki Hitec-Turn20SiiSilang KataNoch keine Bewertungen

- Modelo Radio EsquinasDokument7 SeitenModelo Radio EsquinasRich PetersonNoch keine Bewertungen

- Optimization of Surface Roughness Parameters in Dry TurningDokument7 SeitenOptimization of Surface Roughness Parameters in Dry TurningVijay KumarNoch keine Bewertungen

- CNC Lab ManualDokument40 SeitenCNC Lab ManualPavaniNoch keine Bewertungen

- New DOCX DocumentDokument39 SeitenNew DOCX DocumentPavaniNoch keine Bewertungen

- Virtual Cutting Tool Management System For Milling ProcessDokument6 SeitenVirtual Cutting Tool Management System For Milling ProcessshadowizardNoch keine Bewertungen

- 1 s2.0 S2214785322059521 MainDokument9 Seiten1 s2.0 S2214785322059521 MainfelipeNoch keine Bewertungen

- 06mel77 - Cim - AutoDokument79 Seiten06mel77 - Cim - AutoPraveen KumarNoch keine Bewertungen

- CNC Facts (Summary of CNC Machining Notes) : EML2322L - Design & Manufacturing LaboratoryDokument2 SeitenCNC Facts (Summary of CNC Machining Notes) : EML2322L - Design & Manufacturing LaboratoryAjay Kumar AgarwalNoch keine Bewertungen

- Automatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineDokument7 SeitenAutomatic Automatic Generating CNC-Code For Milling MachineGenerating CNC Code For Milling MachineVikas Singh SisodiaNoch keine Bewertungen

- AKINDokument15 SeitenAKINAjilosun Media AgapeNoch keine Bewertungen

- Design and Modelling of A Universal CNC MachineDokument12 SeitenDesign and Modelling of A Universal CNC MachineАндэрь ЗорьгNoch keine Bewertungen

- CNC Program and Programming of CNC MachiDokument5 SeitenCNC Program and Programming of CNC Machicjjeus9Noch keine Bewertungen

- Jit, Jimma University: Computer Aided Engineering AssignmentDokument8 SeitenJit, Jimma University: Computer Aided Engineering AssignmentGooftilaaAniJiraachuunkooYesusiinNoch keine Bewertungen

- CNC by AsfiDokument4 SeitenCNC by AsfiMuhaimenul SaschoNoch keine Bewertungen

- Cad/Cam: NC, CNC, DNC TechnologiesDokument37 SeitenCad/Cam: NC, CNC, DNC TechnologiesVijay ShakarNoch keine Bewertungen

- CNC Programming Systems PDFDokument22 SeitenCNC Programming Systems PDFSurendra SainiNoch keine Bewertungen

- CNC Router Research PaperDokument7 SeitenCNC Router Research Paperafeawqynw100% (1)

- MillingDokument53 SeitenMillingMuhammad Asif Shehzad KhanNoch keine Bewertungen

- AMiT Products Solutions 2022 1 En-SmallDokument60 SeitenAMiT Products Solutions 2022 1 En-SmallMikhailNoch keine Bewertungen

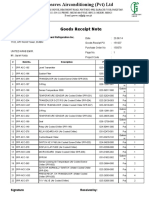

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDokument4 SeitenGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNoch keine Bewertungen

- Centrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringDokument4 SeitenCentrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringAmit PathaniaNoch keine Bewertungen

- History of Psychotherapy FinalDokument38 SeitenHistory of Psychotherapy FinalMarco BonettiNoch keine Bewertungen

- Modular Heavy Duty Truck TransmissionDokument6 SeitenModular Heavy Duty Truck Transmissionphucdc095041Noch keine Bewertungen

- Antenna Systems - Standard Format For Digitized Antenna PatternsDokument32 SeitenAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaNoch keine Bewertungen

- Cross Border Data Transfer Consent Form - DecemberDokument3 SeitenCross Border Data Transfer Consent Form - DecemberFIDELIS MUSEMBINoch keine Bewertungen

- Car Parking DesignDokument6 SeitenCar Parking Designcharler kinyuajNoch keine Bewertungen

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDokument8 SeitenDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNoch keine Bewertungen

- Er6f Abs 2013Dokument134 SeitenEr6f Abs 2013Calibmatic JobNoch keine Bewertungen

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDokument9 SeitenTypical Cable Laying Details For Direct Buried, Low Tension CableslataNoch keine Bewertungen

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDokument5 SeitenSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123Noch keine Bewertungen

- Waste Foundry Sand and Its Leachate CharDokument10 SeitenWaste Foundry Sand and Its Leachate CharJanak RaazzNoch keine Bewertungen

- Myers Briggs Type Indicator-2Dokument1 SeiteMyers Briggs Type Indicator-2api-261818438Noch keine Bewertungen

- Aicte Internship Approval Pending 1Dokument7 SeitenAicte Internship Approval Pending 1Anisha KumariNoch keine Bewertungen

- (14062020 0548) HF Uniform Logo GuidelinesDokument4 Seiten(14062020 0548) HF Uniform Logo GuidelinesBhargaviNoch keine Bewertungen

- Research Project Presentation of Jobairul Karim ArmanDokument17 SeitenResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNoch keine Bewertungen

- Tekla SoakwayDokument2 SeitenTekla SoakwayBalaji Naik100% (1)

- Evidence MODULE 1 Evidence DefinitionDokument8 SeitenEvidence MODULE 1 Evidence Definitiondave BarretoNoch keine Bewertungen

- Fanii 2Dokument55 SeitenFanii 2Remixer INDONESIANoch keine Bewertungen

- Dissertation MA History PeterRyanDokument52 SeitenDissertation MA History PeterRyaneNoch keine Bewertungen

- Noth PicturesDokument17 SeitenNoth PicturesJana AssaNoch keine Bewertungen

- IU IIDC Time Management and Organizational SkillsDokument40 SeitenIU IIDC Time Management and Organizational SkillsAsger HamzaNoch keine Bewertungen