Beruflich Dokumente

Kultur Dokumente

Hairpinexample 8-1

Hochgeladen von

citramuara0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten2 Seitenexcel

Originaltitel

Hairpinexample_8-1

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenexcel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten2 SeitenHairpinexample 8-1

Hochgeladen von

citramuaraexcel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

HAIRPIN CALCULATION

Introduce data in yellow cells Data corresponds to example 8-1

PROCESS DATA

Flowrate Inlet Temp(ºC) Outlet Temp(ºC)

TUBES 27000 kg/h 200 150

Shell 75330 kg/h 20 40

Fouling Resistance tubes 0.00053 m2K/W

Fouling resistance shell 0.00053 m2K/W

PHYSICAL PROPERTIES

carcasa tubos

densidad 30.7 kg/m3 790 kg/m3

viscosidad 0.0119 cp 0.46 cp

cond 0.0358 W/mK 0.11 W/mK

cp 2510 J/kgK 2800 J/kgK

visc a Tw 0.0119 cp 0.46 cp

Ft factor must be introduced manually

tube side calculations

DMLT corregida 144.481274 Mass flow density

Ft correction 1 Ret

LMTD corrected 144.481274 Prt

RESULTS hi

A required 12.9855965 hio

A unit 12.9031167 Rfio

Excess area 0.08247986 Overall heat transfer coefficient

U 559.765054

Tube side Pressure drop

friction factor

Deltap tubes

Deltap heads

Total deltap

HEAT BALANCE

Tube side duty 1050000 Watt

Shell side duty 1050435 Watt

Heat balance OK

Shell diameter Dio 0.489 m

Number of tubes N 70

Number of passes np 4

Tube internal diameter Di 0.01986

Tube external dameter Do 0.0254

Number of fins per tube Nf Nf 20

Fins height H 0.0125

Fins Thickness b 8.89E-04 m

Fins conductivity kf 43.25

length tubes L 2.31

Shell flow area as 0.13677853 m2 AD 0.06201664 m2/m

De (heat) De 0.01390691 m Af 0.5 m2/m

D'e (friction) 0.01338427 m Ao 0.07979664 m2/m

Flow area in tubes at 0.0054211 m2

ube side calculations Shell side calculations

Gt 1383.48301 kg/m2.s Mass flow density Gs 152.98454 kg/m2.s

59730.3751 Res heat) 178785.084

11.7090909 Re's (friction) 172066.037

1899.80978 W/m2K Prs 0.83432961

1485.44182 W/m2K Nu 407.99365

0.00067784 m2K/W hf 1050.28154 W/m2K

fer coefficient h'f 674.706624 W/m2K

W/m2k m 187.339151

mH 2.34173939

Omega 0.41920799

0.00610377 h'fo 2296.64107 W/m2K

13760.7199 N/m2

19382.534 N/m2 Shell side pressure drop

33143.2539 N/m2 friction factor 0.00503877

Deltap 1325.95367 N/m2

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- FabriPulse Fusion IOM PDFDokument58 SeitenFabriPulse Fusion IOM PDFArshath FleminNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Synonyms SDS Number/Grade: Hazard StatementsDokument14 SeitenSynonyms SDS Number/Grade: Hazard Statementserliana nduruNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Basic Data: Tank Sizing CalculationDokument1 SeiteBasic Data: Tank Sizing CalculationcitramuaraNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- FEED: Dahej Project: S.No Scope Items SafetyDokument2 SeitenFEED: Dahej Project: S.No Scope Items SafetycitramuaraNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Plan - RoofDokument1 SeitePlan - RoofcitramuaraNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Final LiquefiedNaturalGas 2016Dokument14 SeitenFinal LiquefiedNaturalGas 2016erliana nduruNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- FILMTEC™ Reverse Osmosis MembranesDokument181 SeitenFILMTEC™ Reverse Osmosis Membranesmanoj28280Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Pit VolumeDokument1 SeitePit VolumecitramuaraNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Equipment List Powder PDFDokument2 SeitenEquipment List Powder PDFcitramuaraNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- APV Puma Pump Curves (CIP Bali)Dokument3 SeitenAPV Puma Pump Curves (CIP Bali)citramuaraNoch keine Bewertungen

- Truck Limit FLDokument1 SeiteTruck Limit FLcitramuaraNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Utility Capacity RecordDokument1 SeiteUtility Capacity RecordcitramuaraNoch keine Bewertungen

- Truck Limit FLDokument1 SeiteTruck Limit FLcitramuaraNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Manufacturing of CPGDokument51 SeitenManufacturing of CPGcitramuaraNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Normal To ActualDokument2 SeitenNormal To Actualcitramuara100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Vent-O-Mat Catt Program: Version: 3.0.0Dokument1 SeiteVent-O-Mat Catt Program: Version: 3.0.0citramuaraNoch keine Bewertungen

- PVC Duct DesignDokument10 SeitenPVC Duct DesigncitramuaraNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- UBL3&4-E-1-LO-EF-CWO-001P - R5 - P&I Diagram Main Cooling Water System For Unit 3Dokument2 SeitenUBL3&4-E-1-LO-EF-CWO-001P - R5 - P&I Diagram Main Cooling Water System For Unit 3citramuaraNoch keine Bewertungen

- Huskyt 716 Air - Operated Diaphragm Pumps: Instructions - Parts ListDokument26 SeitenHuskyt 716 Air - Operated Diaphragm Pumps: Instructions - Parts ListHrafnæt SorgenNoch keine Bewertungen

- Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening MachineDokument5 SeitenDesign Calculation and Performance Testing of Heating Coil in Induction Surface Hardening MachineIjabiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- UBL3&4-E-1-LO-EF-CWO-001P - R5 - P&I Diagram Main Cooling Water System For Unit 3Dokument2 SeitenUBL3&4-E-1-LO-EF-CWO-001P - R5 - P&I Diagram Main Cooling Water System For Unit 3citramuaraNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Atria Hotel and Conference Malang 22-25 MAYDokument2 SeitenAtria Hotel and Conference Malang 22-25 MAYcitramuaraNoch keine Bewertungen

- Gravity 9.8 Tank Heigh 1 M Velocity 4.43 M/s Valve Size 0.1 M Suface Area 0.008 Flow 0.035 2.1 125 M/sDokument1 SeiteGravity 9.8 Tank Heigh 1 M Velocity 4.43 M/s Valve Size 0.1 M Suface Area 0.008 Flow 0.035 2.1 125 M/scitramuaraNoch keine Bewertungen

- UBL3&4 E 5 LO EF CDO 002P - R5 - P&I Diagram For Biocide Doing SystemDokument1 SeiteUBL3&4 E 5 LO EF CDO 002P - R5 - P&I Diagram For Biocide Doing SystemcitramuaraNoch keine Bewertungen

- Tanks NT Eng 50hzDokument4 SeitenTanks NT Eng 50hzcitramuaraNoch keine Bewertungen

- Baby Boiler Vs Electric HeaterDokument2 SeitenBaby Boiler Vs Electric HeatercitramuaraNoch keine Bewertungen

- 1 DWG - DD - PR - CA - 6 5 0 1 2 DWG - DD - PR - ST - 6 5 0 2 3 CAL - DD - PR - HC - 4 0 0 1 4 CAL - DD - ST - HC - 4 0 0 2Dokument3 Seiten1 DWG - DD - PR - CA - 6 5 0 1 2 DWG - DD - PR - ST - 6 5 0 2 3 CAL - DD - PR - HC - 4 0 0 1 4 CAL - DD - ST - HC - 4 0 0 2citramuaraNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Quotation Mediambbr BDFDokument8 SeitenQuotation Mediambbr BDFcitramuaraNoch keine Bewertungen

- Foam TankDokument6 SeitenFoam TankMarko MarkoNoch keine Bewertungen

- Q000201 FP Beiersdorf MPM 20181030Dokument7 SeitenQ000201 FP Beiersdorf MPM 20181030citramuaraNoch keine Bewertungen

- Food Biotechnology in Ethical PerspectiveDokument340 SeitenFood Biotechnology in Ethical Perspectivemojtaba2500100% (2)

- Exercise 9 Two Factor Factorial Experiments and Derivation of Expected Mean SquaresDokument14 SeitenExercise 9 Two Factor Factorial Experiments and Derivation of Expected Mean SquaresHasmaye PintoNoch keine Bewertungen

- Frontinus - Water Management of RomeDokument68 SeitenFrontinus - Water Management of RomezElfmanNoch keine Bewertungen

- Motor CAT C13 AcertDokument3 SeitenMotor CAT C13 AcertJosé Gonzalez100% (4)

- RhythmDokument10 SeitenRhythmSalcedo NoelNoch keine Bewertungen

- Index PDFDokument159 SeitenIndex PDFHüseyin IşlakNoch keine Bewertungen

- Efficient Rice Based Cropping SystemDokument24 SeitenEfficient Rice Based Cropping Systemsenthilnathan100% (1)

- DEEP ECOLOGY - An Intro - McLaughlinDokument5 SeitenDEEP ECOLOGY - An Intro - McLaughlinCarlo MagcamitNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hurricanes Grade5Dokument3 SeitenHurricanes Grade5Anonymous m3yrUPNoch keine Bewertungen

- Kuiz1 210114Dokument12 SeitenKuiz1 210114Vincent HoNoch keine Bewertungen

- Mathematical Modeling of Mechanical Systems and Electrical SystemsDokument49 SeitenMathematical Modeling of Mechanical Systems and Electrical SystemsMary DunhamNoch keine Bewertungen

- Math 202 Syllabus-Spring18 PDFDokument2 SeitenMath 202 Syllabus-Spring18 PDFvonacoc49Noch keine Bewertungen

- Superposition and Statically Indetermina - GDLCDokument25 SeitenSuperposition and Statically Indetermina - GDLCAnonymous frFFmeNoch keine Bewertungen

- Sch3u Exam Review Ws s2018 PDFDokument4 SeitenSch3u Exam Review Ws s2018 PDFwdsfNoch keine Bewertungen

- RMHE08Dokument2.112 SeitenRMHE08Elizde GómezNoch keine Bewertungen

- All Pop SongsDokument53 SeitenAll Pop SongsMadeleneQuiogueNoch keine Bewertungen

- Method Statement For Cable Trays & Cable Ladders InstallationDokument7 SeitenMethod Statement For Cable Trays & Cable Ladders InstallationJamal Budeiri0% (1)

- Five Star Hotel and ResortDokument9 SeitenFive Star Hotel and ResortAISHNoch keine Bewertungen

- Report - IvatanDokument28 SeitenReport - IvatanJohara Winel PerezNoch keine Bewertungen

- VTA28-G5: Fuel OptimizedDokument3 SeitenVTA28-G5: Fuel OptimizedIslam HemdanNoch keine Bewertungen

- Sketchup-Rhino Cheat SheetDokument1 SeiteSketchup-Rhino Cheat Sheetxanext7Noch keine Bewertungen

- Factors Affecting Physical FitnessDokument7 SeitenFactors Affecting Physical FitnessMary Joy Escanillas Gallardo100% (2)

- Propert 447-445Dokument11 SeitenPropert 447-445LUNA100% (1)

- Complete Processing Lines For Extruded Pet FoodDokument13 SeitenComplete Processing Lines For Extruded Pet FoodденисNoch keine Bewertungen

- Antoine Constants PDFDokument3 SeitenAntoine Constants PDFsofiaNoch keine Bewertungen

- Modified Phosphate and Silica Waste in Pigment PaintDokument12 SeitenModified Phosphate and Silica Waste in Pigment PaintDani M RamdhaniNoch keine Bewertungen

- Hazard Assessment For PPE - XX-DRAFTDokument4 SeitenHazard Assessment For PPE - XX-DRAFTWayne VanderhoofNoch keine Bewertungen

- Pythagorean Theorem WorksheetDokument11 SeitenPythagorean Theorem WorksheetJames ChanNoch keine Bewertungen

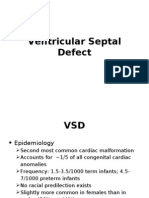

- Ventricular Septal DefectDokument9 SeitenVentricular Septal DefectpepotchNoch keine Bewertungen

- Viscous Fluid Flow Frank M White Third Edition - Compress PDFDokument4 SeitenViscous Fluid Flow Frank M White Third Edition - Compress PDFDenielNoch keine Bewertungen

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisVon EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (42)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisVon EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Why We Die: The New Science of Aging and the Quest for ImmortalityVon EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityBewertung: 4 von 5 Sternen4/5 (3)

- The Obesity Code: Unlocking the Secrets of Weight LossVon EverandThe Obesity Code: Unlocking the Secrets of Weight LossBewertung: 4 von 5 Sternen4/5 (6)

- The Comfort of Crows: A Backyard YearVon EverandThe Comfort of Crows: A Backyard YearBewertung: 4.5 von 5 Sternen4.5/5 (23)

- From Darkness to Sight: A Journey from Hardship to HealingVon EverandFrom Darkness to Sight: A Journey from Hardship to HealingBewertung: 4 von 5 Sternen4/5 (3)