Beruflich Dokumente

Kultur Dokumente

Heat Exchanger StageSizing

Hochgeladen von

nilesh100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

192 Ansichten4 SeitenOriginaltitel

Heat-Exchanger-StageSizing.xlsx

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

192 Ansichten4 SeitenHeat Exchanger StageSizing

Hochgeladen von

nileshCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Heat Exchanger Sizing Calculations This is rid

engineeri

figures an

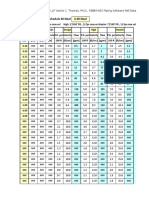

Heat Exchanger Type Shell Tube

Fluid Water Water

Inlet Temperature (C) 21 30

Outlet Temperature (C) 28 24

Flow Rate (kg/s) 5.55 6.47

Duty (W) 156311.4179 (same) 156078.6423

Log Mean Temp Difference ( C) 2.466303462

Overall Heat Transfer Coefficient (W/m2 C) 1000

Preliminary Heat Transfer Area (m2) 63.37882595

Outside Diameter (mm) 546.6 25.4

Thickness (BWG) - 14

Inside Diameter (mm) - 23.292

Length (m) 3.7008 3.65

Number of Tubes 217.6044318

Density (kg/m3) 998.08 995.71

Viscosity (kg/m s) 0.000979 0.000798

Reynolds Number

Prandlt Number 7.01 5.43

Nusselt Number

Side Heat Transfer Coefficient (W/m2 C)

Side Pressure Drop

Yellow fields are input The tubesheet thickness has no value or

importance at this stage of process design. I

Red fields are results will be calculated and determined by the

exchanger fabricator - not the process

Assumptions designer.

The tubesheet thickness has no value or

importance at this stage of process design. I

will be calculated and determined by the

exchanger fabricator - not the process

designer.

1. 1 tube pass countercurrent flow arrangement

2. 1.25 triangular pitch layout

3. 1 in. Tubesheet Thickness

4. Stainless Steel as metal

This is ridiculous information on an

engineering calculation. Use significant

figures and avoid mistakes, confusion, etc.

This is not only a ridiculous number, it is the wrong answer because it

is based on the transfer area - and not on the hydraulic requirements

that fix the inside heat transfer coefficient - such as the velocity inside

the tubes. That is why you must use engineering common sense and

plan the calculation procedure to enable you to depend on a

reasonable velocity and - therefore - a reasonable coeffient. If a true

counter-current configuration is required than common sense should

tell us that the tubes are either going to be much, much larger than

3.7 meters - or a different TEMA configuration is required , such as a

BFM or multiple shells in series.

ickness has no value or

s stage of process design. It

and determined by the

ator - not the process

ickness has no value or

s stage of process design. It

and determined by the

ator - not the process

Das könnte Ihnen auch gefallen

- Pipe Sizing Data.Dokument50 SeitenPipe Sizing Data.haqjmiNoch keine Bewertungen

- InsulationDokument6 SeitenInsulationBrinto VargheseNoch keine Bewertungen

- MD PV ASME v0.1Dokument34 SeitenMD PV ASME v0.1nileshNoch keine Bewertungen

- Coil DesignDokument7 SeitenCoil DesignSajal Kulshrestha100% (2)

- Experienced Based Rules of Chemical EngineeringDokument33 SeitenExperienced Based Rules of Chemical Engineeringintania66Noch keine Bewertungen

- Air Cooled ExchangerDokument4 SeitenAir Cooled Exchangermayurjannu100% (1)

- Heat Exchanger DesignDokument48 SeitenHeat Exchanger DesignJose SotoNoch keine Bewertungen

- Shell Tube Heat Exchanger CalculationDokument20 SeitenShell Tube Heat Exchanger CalculationĐoàn TrangNoch keine Bewertungen

- EIND 3184 15 Liquid Flash Vessel SizingDokument20 SeitenEIND 3184 15 Liquid Flash Vessel SizingzamijakaNoch keine Bewertungen

- Hydraulic Accumulators Store Energy for BOP ControlDokument65 SeitenHydraulic Accumulators Store Energy for BOP ControlKhaled YazidNoch keine Bewertungen

- Hydraulic Calculation - NFPA13DDokument6 SeitenHydraulic Calculation - NFPA13DTanvir HasanNoch keine Bewertungen

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDokument9 SeitenHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNoch keine Bewertungen

- RVD DatasheetDokument3 SeitenRVD Datasheetsushant_jhawerNoch keine Bewertungen

- Shell and Tube VaporizerDokument17 SeitenShell and Tube VaporizercontinentalflossNoch keine Bewertungen

- WHB Calculation for Flue Gas Heat RecoveryDokument1 SeiteWHB Calculation for Flue Gas Heat RecoveryDavid LambertNoch keine Bewertungen

- Double FdexchangerDokument8 SeitenDouble FdexchangerBoško IvanovićNoch keine Bewertungen

- PV Elite 2020 Licensee: Tubesheet Check CalculationDokument8 SeitenPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadNoch keine Bewertungen

- STEAMcalc 12.8 RupiahDokument1.009 SeitenSTEAMcalc 12.8 RupiahlightsonsNoch keine Bewertungen

- Elliptical Head Design ToolDokument1 SeiteElliptical Head Design ToolSudjono BroNoch keine Bewertungen

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Dokument1 SeiteTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Noch keine Bewertungen

- Heat ExchangerDokument53 SeitenHeat ExchangerNurulHidayahNoch keine Bewertungen

- Heat Exchanger - Preliminary Data SheetDokument4 SeitenHeat Exchanger - Preliminary Data SheetgksakthiNoch keine Bewertungen

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDokument20 SeitenHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNoch keine Bewertungen

- Fluid Mechanics ModuleDokument72 SeitenFluid Mechanics Moduleeric labordo100% (1)

- Heat Exchanger Calculation Version 2Dokument2 SeitenHeat Exchanger Calculation Version 2huangjlNoch keine Bewertungen

- Sizing For Vaporiser/Flash Vessel: InputsDokument3 SeitenSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNoch keine Bewertungen

- Heat Exchanger CalcDokument34 SeitenHeat Exchanger Calcميثة الغيثيةNoch keine Bewertungen

- Case 2 - Tank Heat LossDokument84 SeitenCase 2 - Tank Heat Lossahmad santosoNoch keine Bewertungen

- Shell and Tube Heat Exchanger Design CalculationsDokument6 SeitenShell and Tube Heat Exchanger Design CalculationsnileshNoch keine Bewertungen

- Shell and Tube Heat Exchanger Design CalculationsDokument6 SeitenShell and Tube Heat Exchanger Design CalculationsnileshNoch keine Bewertungen

- Heat Loss From An Insulated Pipe Calculated Using Thermophysical Properties of AirDokument32 SeitenHeat Loss From An Insulated Pipe Calculated Using Thermophysical Properties of AirDougMooreNoch keine Bewertungen

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDokument2 SeitenDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Noch keine Bewertungen

- Steam Boiler Spec.Dokument17 SeitenSteam Boiler Spec.bandithaguru6338100% (1)

- Tank Static Head CalculationDokument3 SeitenTank Static Head CalculationrohitkushNoch keine Bewertungen

- Air Fin Cooler DesignDokument3 SeitenAir Fin Cooler DesignAnonymous OFP2ygPIdNoch keine Bewertungen

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDokument8 SeitenHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNoch keine Bewertungen

- Maz - Design - Separator Capacity EvaluationDokument5 SeitenMaz - Design - Separator Capacity EvaluationNaeem HussainNoch keine Bewertungen

- Calculation For Pressure DropDokument2 SeitenCalculation For Pressure DropNakul AhirraoNoch keine Bewertungen

- Ibr RegulationsDokument9 SeitenIbr RegulationsAJITSPATILNoch keine Bewertungen

- Film Temp Calculation For Thermic Fluid ApplicationDokument2 SeitenFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNoch keine Bewertungen

- Input Output: Combustion Calculations For Fuel GasDokument33 SeitenInput Output: Combustion Calculations For Fuel GasgsdaundhNoch keine Bewertungen

- Organic Solvents and Water Shell and Tube Heat Exchanger DesignDokument31 SeitenOrganic Solvents and Water Shell and Tube Heat Exchanger Designramesh pokhrelNoch keine Bewertungen

- Surface Condenser Thermal Analysis (100914)Dokument11 SeitenSurface Condenser Thermal Analysis (100914)amlanfacebookNoch keine Bewertungen

- Shell and Tube Heat Exchanger1Dokument19 SeitenShell and Tube Heat Exchanger1Lily NurdianaNoch keine Bewertungen

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDokument7 SeitenDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNoch keine Bewertungen

- Shell and Tube Heat Exchanger DesignDokument19 SeitenShell and Tube Heat Exchanger DesignValium MorphineNoch keine Bewertungen

- 1 Darcy Friction CalculatorDokument2 Seiten1 Darcy Friction CalculatorTinashe MutetwaNoch keine Bewertungen

- Dish CalculationDokument2 SeitenDish CalculationRyan Goh Chuang HongNoch keine Bewertungen

- Reactor WeightsDokument2 SeitenReactor WeightsleekiangyenNoch keine Bewertungen

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDokument11 SeitenModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNoch keine Bewertungen

- Mass flow rates and gas properties data tableDokument3 SeitenMass flow rates and gas properties data tablemgkvprNoch keine Bewertungen

- Heat ExchangerDokument11 SeitenHeat ExchangerMangesh MandgeNoch keine Bewertungen

- Expansion Vessel CalculationDokument4 SeitenExpansion Vessel CalculationTsouki TsoukiNoch keine Bewertungen

- Mean Metal Temperature CalculationDokument28 SeitenMean Metal Temperature CalculationAvijit DasguptaNoch keine Bewertungen

- Air Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Dokument1 SeiteAir Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Honey TiwariNoch keine Bewertungen

- Steam Coil DesignDokument2 SeitenSteam Coil DesignHendri SinagaNoch keine Bewertungen

- Firetube Heaters: FIG. 8-31 Convection HeaterDokument7 SeitenFiretube Heaters: FIG. 8-31 Convection Heatery149487Noch keine Bewertungen

- Shell & Tube Condenser Design MethodDokument4 SeitenShell & Tube Condenser Design MethodwestewrNoch keine Bewertungen

- Heat Exchanger RatingDokument10 SeitenHeat Exchanger RatinggabrieltravassosNoch keine Bewertungen

- Numerical Analysis of Tube-Fin Heat Exchanger Using Fluent: M. V. Ghori & R. K. KirarDokument8 SeitenNumerical Analysis of Tube-Fin Heat Exchanger Using Fluent: M. V. Ghori & R. K. KirarSeane MelindaNoch keine Bewertungen

- CFD Analysis of Double Pipe Heat Exchang PDFDokument4 SeitenCFD Analysis of Double Pipe Heat Exchang PDFNayli AthirahNoch keine Bewertungen

- Enhancing The Heat-Transfer Co-Efficient by Using Taguchi Orthogonal ArrayDokument4 SeitenEnhancing The Heat-Transfer Co-Efficient by Using Taguchi Orthogonal ArrayinventionjournalsNoch keine Bewertungen

- Heat Exchanger DesignDokument8 SeitenHeat Exchanger DesignWilliam KearNoch keine Bewertungen

- Air Cooled Condenser DesignDokument5 SeitenAir Cooled Condenser Designamin shiranNoch keine Bewertungen

- Selecting The Right Level of Complexity For Thermal Modelling of Transformer WindingsDokument8 SeitenSelecting The Right Level of Complexity For Thermal Modelling of Transformer WindingsVenkatasubramanian IyerNoch keine Bewertungen

- Design Optimization of An Axial Flow Compressor For Industrial Gas TurbineDokument8 SeitenDesign Optimization of An Axial Flow Compressor For Industrial Gas TurbinealiNoch keine Bewertungen

- Numerical Investigation of 3D Flow and Thermal Effects in A Disc-Type TransformerDokument11 SeitenNumerical Investigation of 3D Flow and Thermal Effects in A Disc-Type TransformerdgtzagaNoch keine Bewertungen

- Cyclone DesignDokument1 SeiteCyclone DesignnileshNoch keine Bewertungen

- Steel ConnectionsDokument83 SeitenSteel ConnectionsMEPNoch keine Bewertungen

- Perhitungan Shell and TubeDokument24 SeitenPerhitungan Shell and Tuberyezhu100% (1)

- Dimensions For Deep Dished & Flanged Ends (Torispherical)Dokument8 SeitenDimensions For Deep Dished & Flanged Ends (Torispherical)nileshNoch keine Bewertungen

- Tank WT & Volume ConvertoreDokument11 SeitenTank WT & Volume ConvertorenileshNoch keine Bewertungen

- Contact DetailsDokument1 SeiteContact DetailsnileshNoch keine Bewertungen

- In Inches Non-Circular: Heat Transfer Coefficient CalculationsDokument1 SeiteIn Inches Non-Circular: Heat Transfer Coefficient CalculationsrodrigoperezsimoneNoch keine Bewertungen

- High Efficiency High ThroughputDokument1 SeiteHigh Efficiency High ThroughputnileshNoch keine Bewertungen

- Development of a Cone: Dimensions, Calculations & WeightDokument1 SeiteDevelopment of a Cone: Dimensions, Calculations & WeightnileshNoch keine Bewertungen

- Shaft Torsion 1Dokument2 SeitenShaft Torsion 1nileshNoch keine Bewertungen

- A B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YDokument2 SeitenA B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YnileshNoch keine Bewertungen

- Make in Two Sheets Development of Rect, Square To Circle: A B C DDokument1 SeiteMake in Two Sheets Development of Rect, Square To Circle: A B C DnileshNoch keine Bewertungen

- Tank WT & Volume ConvertoreDokument11 SeitenTank WT & Volume ConvertorenileshNoch keine Bewertungen

- Rules of Thumb Chapter 8: VesselsDokument4 SeitenRules of Thumb Chapter 8: VesselsAri KurniawanNoch keine Bewertungen

- VolumeDokument29 SeitenVolumealexnomitaNoch keine Bewertungen

- Two-Phase Flow Patterns and Flow-Pattern Maps: Fundamentals and ApplicationsDokument28 SeitenTwo-Phase Flow Patterns and Flow-Pattern Maps: Fundamentals and Applicationshoodyz_r_usNoch keine Bewertungen

- Fluid Properties and Kinematics GuideDokument1 SeiteFluid Properties and Kinematics Guideshalom_pkl100% (1)

- Initial Ring BendingDokument13 SeitenInitial Ring BendingmdabdullaNoch keine Bewertungen

- Fluid Statics Lecture NotesDokument69 SeitenFluid Statics Lecture NotesTommy CaddenNoch keine Bewertungen

- Metacentric Height PPT 3Dokument19 SeitenMetacentric Height PPT 3Ashok Kumar RajanavarNoch keine Bewertungen

- Incompressible Fluid Mechanics PDFDokument187 SeitenIncompressible Fluid Mechanics PDFPrabhat PiyushNoch keine Bewertungen

- Project'S Ideas I. Idea Title: Heron'S Fountain Ii. Reasons To Choose An IdeasDokument2 SeitenProject'S Ideas I. Idea Title: Heron'S Fountain Ii. Reasons To Choose An IdeasTiomeldaNoch keine Bewertungen

- Module 3 HW5Dokument14 SeitenModule 3 HW5hgfhfghfghgNoch keine Bewertungen

- Pitot Tube Exper.Dokument4 SeitenPitot Tube Exper.AbdulrazzaqAL-Maliky100% (1)

- Hydraulics & HydrologyDokument4 SeitenHydraulics & Hydrologyamitkap00rNoch keine Bewertungen

- Effect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorDokument17 SeitenEffect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorCristianNoch keine Bewertungen

- Applied Computational AerodynamicsDokument15 SeitenApplied Computational AerodynamicsjoereisNoch keine Bewertungen

- 8694 ch01Dokument35 Seiten8694 ch01Darwin MarNoch keine Bewertungen

- Leaflet S24 - Cavagna RegulatorDokument8 SeitenLeaflet S24 - Cavagna RegulatorWND PRTMNoch keine Bewertungen

- Effect of Dimples On Aerodynamics of An AirfoilDokument4 SeitenEffect of Dimples On Aerodynamics of An AirfoilHarish MathiazhahanNoch keine Bewertungen

- Stanford School of Engineering OverviewDokument39 SeitenStanford School of Engineering OverviewMohammad Shahban HashmiNoch keine Bewertungen

- AB4Dokument14 SeitenAB4Mohammad RawoofNoch keine Bewertungen

- Fluid Machinery: Textbook: Fluid Mechanics and Hydraulic Machines by Sukumar Pati M. G. HillsDokument23 SeitenFluid Machinery: Textbook: Fluid Mechanics and Hydraulic Machines by Sukumar Pati M. G. Hillsminesh.manu6531Noch keine Bewertungen

- Salman Mid SemDokument12 SeitenSalman Mid SemxxxxsalmanNoch keine Bewertungen

- Entire Thesis COMPREHENSIVE MECHANISTICDokument111 SeitenEntire Thesis COMPREHENSIVE MECHANISTICavinashpatil2408Noch keine Bewertungen

- EC290 MCV DescriptionDokument6 SeitenEC290 MCV Descriptionaungaungoomanual0% (1)

- The Venturi and Nozzle PDFDokument8 SeitenThe Venturi and Nozzle PDFlumengentiunNoch keine Bewertungen

- EME 109 Compressible Flow Nozzle ExperimentDokument11 SeitenEME 109 Compressible Flow Nozzle ExperimentSteelcover0% (1)

- FM 2 Unit 1 and 2Dokument28 SeitenFM 2 Unit 1 and 2shreNoch keine Bewertungen

- Department of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationDokument1 SeiteDepartment of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationSaifullah AhmadNoch keine Bewertungen

- 2016-Wang-Numerical Modeling of SFD by CFDDokument15 Seiten2016-Wang-Numerical Modeling of SFD by CFDAlex CooperNoch keine Bewertungen

- U-2-Turbulent Flow in Pipes and Channels PDFDokument23 SeitenU-2-Turbulent Flow in Pipes and Channels PDFLaxmi PrasannaNoch keine Bewertungen