Beruflich Dokumente

Kultur Dokumente

F 1852 - 04 Hot Dip Zinc Not Permitted

Hochgeladen von

ibson045001256Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

F 1852 - 04 Hot Dip Zinc Not Permitted

Hochgeladen von

ibson045001256Copyright:

Verfügbare Formate

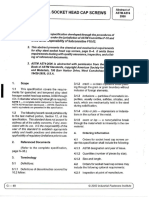

F 1852 – 04

3.1.4 tension control bolt—a bolt that includes an integral applied by the manufacturer, as the type and amount of lubrication is

spline end which extends beyond the threaded portion of the critical to performance.

bolt. The fastener is to be tightened using a special electric 6.5 Secondary Processing:

wrench and socket system which has an inner socket that 6.5.1 If heat treatment, zinc coating, lubrication or other

engages the spline end and with an outer socket that engages processing affecting properties are performed by any source on

and turns the nut. any unit of a component lot after the manufacturer’s test to

3.1.5 tension control bolt assembly—a tension control bolt, qualify a lot has been performed, the component lot shall be

nut and washer combination. treated as newly manufactured and shall be reinspected and

retested in accordance with the requirements of its original

4. Classification

manufacturing specification after such processing is com-

4.1 The tension control bolts are designed by type denoting pleted. Retesting shall be the responsibility of the party

chemical composition as follows: supplying the component.

4.1.1 Type 1—Plain carbon, carbon boron, or alloy steel. 6.5.2 Secondary processing shall not be permitted to an

4.1.2 Type 3—Weathering steel. Atmospheric corrosion re- assembly lot.

sistance and weathering characteristics are comparable to that 6.6 Assembly:

of steels in Specifications A 242/A 242M, A 588/A 588M,

6.6.1 The assemblies shall be of the type specified by the

A 709/A 709M, A 871/A 871M, (see 7.1.2).

purchaser.

5. Ordering Information 6.6.2 The assemblies shall consist of one tension control

bolt, with one lubricated nut and one or more washer(s).

5.1 Orders for assemblies shall include the items of infor-

6.6.3 Unless otherwise specified, nuts and washers used on

mation below. Optional items not on the purchase order shall

the assemblies shall conform to the requirements of the

be considered as not being required, (see Note 1):

specifications below:

5.1.1 Quantity of assemblies

Assembly Type Nut Specification, Washer Specification,

5.1.2 Size, include nominal tension control bolt diameter and Finish Class and Finish Type and Finish

and length (without the spline end)

Type 1 A 563 DH Plain F 436 Type 1

5.1.3 Name of product, that is, twist off type tension control Plain A 194 2H Plain Plain

bolt/nut/washer assemblies, A 563 C Plain

5.1.4 Head Style (see 10.1.1),

Type 1 A 563 DH Mech. Zinc F 436 Type 1

5.1.5 Type of Assembly, that is; Type 1 or Type 3 Mech. Zinc Coated Coated Mechanical Zinc Coated

5.1.6 ASTM designation and year of publication,

5.1.7 Mechanically zinc coated, if required, and Type 3 A 563 DH3 Plain F 436 Type 3 Plain

Plain A 563 C3 Plan

5.1.8 Special requirements, if required

NOTE 1—A typical order description follows: 2520 assemblies, 3 4 in. 6.6.4 All nuts shall be Heavy Hex. All washers used in the

diameter by 2 in. long Tension Control Bolt/Nut/Washer Assemblies, assembly shall be circular and through hardened.

Round Heads, Type 1 ASTM F 1852.

6. Materials and Manufacture 7. Chemical Composition

6.1 Heat Treatment: 7.1 Tension Control Bolts:

6.1.1 Tension control bolts made from carbon or carbon 7.1.1 Type 1 tension control bolts shall be plain carbon

boron steel shall be heat treated by quenching in a liquid steel, carbon boron steel, or alloy steel, at the manufacturers

medium from above the austenitizing temperature and then option, and shall conform to one of the chemical compositions

tempering by reheating to a temperature of at least 800°F specified in Table 1.

(425°C). 7.1.2 Type 3 tension control bolts shall be weathering steel

6.1.2 Tension control bolts made from alloy steel shall be and shall conform to one of the chemical compositions,

heat treated by quenching in oil from above the austenitizing specified in Table 2. The selection of the chemical composition

temperature and then tempering by reheating to a temperature A, B, C, D, E, or F, shall be at the option of the manufacturer.

of at least 800°F (425°C). See Guide G 101 for method of estimating the atmospheric

6.2 Thread—The threads of tension control bolts shall be corrosion resistance of low alloy steels.

rolled. 7.1.3 Product analysis, when performed, shall be made from

6.3 Mechanical Zinc Coating: finished material representing each lot. To meet the specifica-

6.3.1 When zinc coating is specified, each component of the tion, the chemical composition thus determined shall conform

assembly shall be mechanically zinc coated. The coating shall to the requirements specified in Table 1 or Table 2 as

conform to Specification B 695, Class 50 Type 1 as a minimum applicable.

thickness. 7.1.4 Heats of steel to which bismuth, selenium, tellurium,

6.3.2 Hot dip zinc coating shall not be permitted. or lead has been intentionally added shall not be permitted.

6.4 Lubrication— All nuts, plain and zinc coated, shall be

7.1.5 For Type 1 bolts made from plain carbon steel or alloy

lubricated. The lubricant shall be clean and dry to the touch.

steel, heats of steel which boron has been intentionally added

NOTE 2—No further lubrication shall be permitted other than that shall not be permitted.

Das könnte Ihnen auch gefallen

- Abstract of ASTM A574 2000Dokument8 SeitenAbstract of ASTM A574 2000Jesse ChenNoch keine Bewertungen

- B 653 - B 653M - 01 Qjy1my0wmqDokument3 SeitenB 653 - B 653M - 01 Qjy1my0wmqHéctor NossaNoch keine Bewertungen

- B 653 - B 653M - 02 Qjy1my9cnjuztqDokument3 SeitenB 653 - B 653M - 02 Qjy1my9cnjuztqHéctor NossaNoch keine Bewertungen

- 001-ASTM A394 StandardDokument6 Seiten001-ASTM A394 StandardRaulMoralesNoch keine Bewertungen

- Asmt A320 A320m 05aDokument8 SeitenAsmt A320 A320m 05aRonald SequeiraNoch keine Bewertungen

- ASTM A320-A320M-05aDokument8 SeitenASTM A320-A320M-05aNadhiraNoch keine Bewertungen

- A183 PDFDokument4 SeitenA183 PDFalifuat duygu100% (1)

- Astm A449 1993Dokument6 SeitenAstm A449 1993Jesse ChenNoch keine Bewertungen

- Astm A-322 PDFDokument4 SeitenAstm A-322 PDFedwinbadajos100% (1)

- Age-Hardening Stainless Steel Forgings: Standard Specification ForDokument7 SeitenAge-Hardening Stainless Steel Forgings: Standard Specification ForamerNoch keine Bewertungen

- A522A522MDokument4 SeitenA522A522MAlejandro GonzálezNoch keine Bewertungen

- Docking/Drain Plug and Boss Assemblies (Metric) : Standard Specification ForDokument3 SeitenDocking/Drain Plug and Boss Assemblies (Metric) : Standard Specification ForEduardoNoch keine Bewertungen

- A 322 - 91 R01 - Qtmymi05mviwmqDokument4 SeitenA 322 - 91 R01 - Qtmymi05mviwmqAhmad KhreisatNoch keine Bewertungen

- ASTM F1554 Anchor Rods PDFDokument9 SeitenASTM F1554 Anchor Rods PDFAdam JonesNoch keine Bewertungen

- Astm A394-07 PDFDokument6 SeitenAstm A394-07 PDFalifuat duyguNoch keine Bewertungen

- Asme 2a - Sa-350 PDFDokument12 SeitenAsme 2a - Sa-350 PDFEswaran100% (1)

- Astm b658 b658m 2001Dokument4 SeitenAstm b658 b658m 2001Greg YeeNoch keine Bewertungen

- Astm A320mDokument4 SeitenAstm A320mSHYAM SINGHNoch keine Bewertungen

- Anchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDokument9 SeitenAnchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDarwin DarmawanNoch keine Bewertungen

- A 489 Â " 03 QTQ4OQ - PDFDokument4 SeitenA 489 Â " 03 QTQ4OQ - PDFMytzy Godoy TapiaNoch keine Bewertungen

- Astm A 449Dokument7 SeitenAstm A 449Sasan AbbasiNoch keine Bewertungen

- Carbon and Alloy Steel Bars For SpringsDokument4 SeitenCarbon and Alloy Steel Bars For Springsbb bamNoch keine Bewertungen

- Steel Transmission Tower Bolts, Zinc-Coated and Bare: Standard Specification ForDokument7 SeitenSteel Transmission Tower Bolts, Zinc-Coated and Bare: Standard Specification ForRodrigoNoch keine Bewertungen

- Drawing Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledDokument4 SeitenDrawing Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledFelipe De la cruzNoch keine Bewertungen

- Astm A705 PDFDokument7 SeitenAstm A705 PDFCristian OtivoNoch keine Bewertungen

- Astm A322-91Dokument4 SeitenAstm A322-91Anıl ZiylanNoch keine Bewertungen

- Astm F 2329Dokument5 SeitenAstm F 2329Renan SouzaNoch keine Bewertungen

- Zinc Coat ASTM F 2329Dokument5 SeitenZinc Coat ASTM F 2329Nassim SabriNoch keine Bewertungen

- A 449 - 00 - Qtq0os1sruqDokument8 SeitenA 449 - 00 - Qtq0os1sruqAnderson VelandiaNoch keine Bewertungen

- Castings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing PartsDokument3 SeitenCastings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing PartsPEPENoch keine Bewertungen

- Sa 276Dokument10 SeitenSa 276ismaelarchilacastilloNoch keine Bewertungen

- Steel Screw Spikes: Standard Specification ForDokument2 SeitenSteel Screw Spikes: Standard Specification ForKrishna Sai100% (1)

- Castings, Austenitic, Austenitic-Ferritic (Duplex), For Pressure-Containing PartsDokument5 SeitenCastings, Austenitic, Austenitic-Ferritic (Duplex), For Pressure-Containing PartsElpidio ManansalaNoch keine Bewertungen

- Astm f1554 Grade 36Dokument9 SeitenAstm f1554 Grade 36AngelicaNoch keine Bewertungen

- Astm F959-09Dokument5 SeitenAstm F959-09Nhật NguyễnNoch keine Bewertungen

- A350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Dokument6 SeitenA350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Yilia WangNoch keine Bewertungen

- A354 PDFDokument7 SeitenA354 PDFnighat_fatima_12Noch keine Bewertungen

- A 574 - 00 - Qtu3naDokument8 SeitenA 574 - 00 - Qtu3naOswaldo Leyva RNoch keine Bewertungen

- "Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDokument8 Seiten"Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthRyanMcClureNoch keine Bewertungen

- Alloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledDokument4 SeitenAlloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledRoland CepedaNoch keine Bewertungen

- Astm A 478 - 97Dokument2 SeitenAstm A 478 - 97neno2405Noch keine Bewertungen

- A354Dokument7 SeitenA354siderqualidadeNoch keine Bewertungen

- A351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsDokument5 SeitenA351A351M 2003 Specification For Castings, Austenitic, Austenitic-Ferritic (Duplex), For Presure-Containing PartsPhong ThanhNoch keine Bewertungen

- Nickel-Alloy (UNS N06625, N06219and N08825) Welded Pipe: Standard Specification ForDokument2 SeitenNickel-Alloy (UNS N06625, N06219and N08825) Welded Pipe: Standard Specification ForGreg YeeNoch keine Bewertungen

- Astm F1554Dokument9 SeitenAstm F1554Mariela MurilloNoch keine Bewertungen

- Steel Bars, Alloy, Standard GradesDokument4 SeitenSteel Bars, Alloy, Standard GradesSofiaJabadanEspulgarNoch keine Bewertungen

- Astm A322 - 06Dokument4 SeitenAstm A322 - 06Lucas Prezotto Puertas ErnandesNoch keine Bewertungen

- A696 20875Dokument3 SeitenA696 20875DeepakNoch keine Bewertungen

- Astm A131Dokument6 SeitenAstm A131banglvhNoch keine Bewertungen

- A 877 - A877mDokument4 SeitenA 877 - A877mAon HemmatadNoch keine Bewertungen

- Astm A320 PDFDokument9 SeitenAstm A320 PDFFerri AguswanNoch keine Bewertungen

- Astm F 2329Dokument5 SeitenAstm F 2329haharameshNoch keine Bewertungen

- Sa 350Dokument12 SeitenSa 350ismaelarchilacastilloNoch keine Bewertungen

- A 983 - A 983M - 01 - Qtk4my0wmqDokument5 SeitenA 983 - A 983M - 01 - Qtk4my0wmqhoangNoch keine Bewertungen

- A 181 Â " A 181M Â " 01 - QTE4MS9BMTGXTQDokument3 SeitenA 181 Â " A 181M Â " 01 - QTE4MS9BMTGXTQhans ccNoch keine Bewertungen

- A 181 - A 181M - 01 Qte4ms9bmtgxtqDokument3 SeitenA 181 - A 181M - 01 Qte4ms9bmtgxtqfadjarNoch keine Bewertungen

- Astm A 668 - 98 PDFDokument7 SeitenAstm A 668 - 98 PDFRyan LasacaNoch keine Bewertungen

- Aluminum Structures: A Guide to Their Specifications and DesignVon EverandAluminum Structures: A Guide to Their Specifications and DesignBewertung: 5 von 5 Sternen5/5 (2)

- BoltsDokument4 SeitenBoltsibson045001256Noch keine Bewertungen

- MES Study Facilitation ServicesDokument1 SeiteMES Study Facilitation ServicesAJAY1381Noch keine Bewertungen

- BoltsDokument4 SeitenBoltsibson045001256Noch keine Bewertungen

- En 10168 Inspection InformationDokument12 SeitenEn 10168 Inspection InformationStefano Squadrani100% (2)

- MES Study Facilitation ServicesDokument1 SeiteMES Study Facilitation ServicesAJAY1381Noch keine Bewertungen

- RTJ Catalogue Rev1 PDFDokument9 SeitenRTJ Catalogue Rev1 PDFRanjan KumarNoch keine Bewertungen

- Design Calculation Anchor Flange ASME VIII Div 1 App 2Dokument4 SeitenDesign Calculation Anchor Flange ASME VIII Div 1 App 2ibson045001256Noch keine Bewertungen

- Hdpe Pipes VendorDokument2 SeitenHdpe Pipes VendorManjunath VenkateshNoch keine Bewertungen

- BoltsDokument4 SeitenBoltsibson045001256Noch keine Bewertungen

- Api 580Dokument60 SeitenApi 580ibson045001256Noch keine Bewertungen

- Trim Material Valve PlugDokument4 SeitenTrim Material Valve Plugalexmontell100% (1)

- Modeling Results Tutorial 2Dokument96 SeitenModeling Results Tutorial 2ibson045001256Noch keine Bewertungen

- Loads On FlangesDokument16 SeitenLoads On Flangesccoollest100% (3)

- Tutorial On Flange Qualification Using CAEPIPE: GeneralDokument20 SeitenTutorial On Flange Qualification Using CAEPIPE: Generalibson045001256Noch keine Bewertungen

- API 570 Pipiing InspectorDokument5 SeitenAPI 570 Pipiing InspectorMadidj_2014Noch keine Bewertungen

- Nozzle StressDokument25 SeitenNozzle StressvamsiNoch keine Bewertungen

- API 580 May02 PDFDokument60 SeitenAPI 580 May02 PDFibson045001256Noch keine Bewertungen

- CSP10 Test Panel - Coating System Qualification ProcedureDokument21 SeitenCSP10 Test Panel - Coating System Qualification Procedureibson045001256Noch keine Bewertungen

- F 1852 - 04 "Twist Off" Type Tension Control Structural BoltNutWasherDokument8 SeitenF 1852 - 04 "Twist Off" Type Tension Control Structural BoltNutWasheribson045001256Noch keine Bewertungen

- CSP14 Welding Control ProcedureDokument14 SeitenCSP14 Welding Control Procedureibson045001256100% (2)

- CSP15 Welding Qualification Test ProcedureDokument15 SeitenCSP15 Welding Qualification Test Procedureibson045001256Noch keine Bewertungen

- F 1852 - 04 "Twist Off" Type Tension Control Structural BoltNutWasherDokument8 SeitenF 1852 - 04 "Twist Off" Type Tension Control Structural BoltNutWasheribson045001256Noch keine Bewertungen

- CSP08 Surplus Material Returning Procedure PDFDokument10 SeitenCSP08 Surplus Material Returning Procedure PDFibson045001256Noch keine Bewertungen

- CSP08 Surplus Material Returning Procedure PDFDokument10 SeitenCSP08 Surplus Material Returning Procedure PDFibson045001256Noch keine Bewertungen

- Exchanger PDFDokument2 SeitenExchanger PDFmujahidali500Noch keine Bewertungen

- CSP02 Progress Measurement FormatDokument34 SeitenCSP02 Progress Measurement Formatibson045001256100% (1)

- B31J EssentialsDokument4 SeitenB31J EssentialssajadranjbaranNoch keine Bewertungen

- Tanques de Almacenamiento PRMDDokument62 SeitenTanques de Almacenamiento PRMDPedro Reynaldo Marin DominguezNoch keine Bewertungen

- Welding Inspection: BS 499 Part 2 Course Reference WIS 5Dokument11 SeitenWelding Inspection: BS 499 Part 2 Course Reference WIS 5ibson045001256Noch keine Bewertungen

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDokument9 SeitenKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanNoch keine Bewertungen

- Primera actividad economicaDokument3 SeitenPrimera actividad economicamaria fernanda parraNoch keine Bewertungen

- Renal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaDokument9 SeitenRenal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaFarhanNoch keine Bewertungen

- Writing Emails Part 1 Informal British English Teacher Ver2Dokument7 SeitenWriting Emails Part 1 Informal British English Teacher Ver2Madalina MandiucNoch keine Bewertungen

- PLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalDokument5 SeitenPLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalTriston DurbinNoch keine Bewertungen

- Handy 2010 Case StudyDokument6 SeitenHandy 2010 Case Studycancer6Noch keine Bewertungen

- Ajp Microproject ReportDokument9 SeitenAjp Microproject ReportRushikesh KanseNoch keine Bewertungen

- Green Screen Background Remover Using CV SystemDokument20 SeitenGreen Screen Background Remover Using CV SystemSubhamNoch keine Bewertungen

- WaidhanDokument86 SeitenWaidhanPatel Nitesh OadNoch keine Bewertungen

- Tes P 119 10 R0 PDFDokument43 SeitenTes P 119 10 R0 PDFAbin Meetu100% (4)

- Shadow The Hedgehog (Sonic Boom)Dokument11 SeitenShadow The Hedgehog (Sonic Boom)Tamajong Tamajong PhilipNoch keine Bewertungen

- Curriculum Vitae: Name: Mobile: EmailDokument3 SeitenCurriculum Vitae: Name: Mobile: EmailRākesh RakhiNoch keine Bewertungen

- Chlor Rid SlidesDokument47 SeitenChlor Rid Slidesmohammed goudaNoch keine Bewertungen

- Frame Fit Specs SramDokument22 SeitenFrame Fit Specs SramJanekNoch keine Bewertungen

- 1729Dokument52 Seiten1729praj24083302Noch keine Bewertungen

- The historical evolution of organizational behavior and how it shaped modern managementDokument3 SeitenThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- Vehicle Tracker Offer SheetDokument1 SeiteVehicle Tracker Offer SheetBihun PandaNoch keine Bewertungen

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDokument7 SeitenPlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNoch keine Bewertungen

- Computers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiDokument12 SeitenComputers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiQuỳnh NguyễnNoch keine Bewertungen

- Hardware Devices Used in Virtual Reality TechnologiesDokument6 SeitenHardware Devices Used in Virtual Reality TechnologiesTheMoon LightNoch keine Bewertungen

- Catering Reserving and Ordering System with MongoDB, Express, Node.js (39Dokument5 SeitenCatering Reserving and Ordering System with MongoDB, Express, Node.js (39radha krishnaNoch keine Bewertungen

- Audi A3 Injeção DiretaDokument109 SeitenAudi A3 Injeção Diretawesley candido100% (1)

- Cropprotectionequipment-Rocker Sprayer - Specification (: Indian StandardDokument9 SeitenCropprotectionequipment-Rocker Sprayer - Specification (: Indian Standardgini associatesNoch keine Bewertungen

- Physical Layer:: SwitchingDokument27 SeitenPhysical Layer:: SwitchingPKSachanNoch keine Bewertungen

- Low rank tensor product smooths for GAMMsDokument24 SeitenLow rank tensor product smooths for GAMMsDiego SotoNoch keine Bewertungen

- Creative WritingDokument2 SeitenCreative WritingSharmaine AsoyNoch keine Bewertungen

- Application of EbwDokument11 SeitenApplication of Ebwsuman kumarNoch keine Bewertungen

- Listening Script 11Dokument11 SeitenListening Script 11harshkumarbhallaNoch keine Bewertungen

- Mobile Phone: Service ManualDokument129 SeitenMobile Phone: Service ManualAlexNoch keine Bewertungen

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDokument24 SeitenGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNoch keine Bewertungen