Beruflich Dokumente

Kultur Dokumente

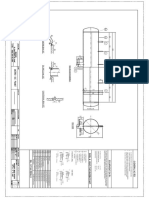

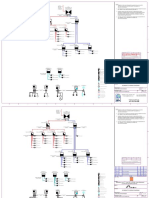

2.5.3 High Speed Coupling Drawing PDF

Hochgeladen von

Ewdes HernandezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2.5.3 High Speed Coupling Drawing PDF

Hochgeladen von

Ewdes HernandezCopyright:

Verfügbare Formate

TFI1310006.

dwg ()

DUTY REQUIREMENTS COUPLING MASS ELASTIC DATA COUPLING CAPACITIES

RATED POWER (HP), (KW) 3,600 , 2,684 MOMENTARY TORQUE (LB-IN), (NM) - MASS (LBS), (KG) 233.3 , 105.8 1st LATERAL CRITICAL (RPM) - CONTINUOUS TORQUE (LB-IN), (NM) -

RATED SPEED (RPM) 3,600 TRIP/OVERSPEED (RPM) - INERTIA (LB-IN²), (KG-M²) 2339.8, 0.686 DYNAMIC BALANCE GRADE API671-M2 PEAK TORQUE (LB-IN), (NM) -

RATED TORQUE (LB-IN), (NM) - TRANSIENT TORQUE (LB-IN), (NM) - TORSIONAL STIFFNESS x10 6 (LB-IN/RAD), (NM/RAD) 14.02 , 1.58 MAX. ALLOW. SPEED (RPM) 8,500 NO. OF CYCLES (FOR PEAK TORQUE) -

MAX TORQUE (LB-IN), (NM) - ACTUAL S.F. 1.5 (NM/RAD) (Incl. 1/3 shaft penetration) MAX TORQUE (LB-IN), (NM) -

NOTES:

1. EXTRA HARDWARE: INCLUDES 3 EXTRA BOLTS (ITEM 19).

2. REF: COUPLING MEETS API671, 4TH EDITION WITH EXCEPTIONS.

3. PHOSPHATE COAT HUBS, SPACER, AND ADAPTERS PER CP-191.

DRIVE END DRIVEN END

4. BALANCING NOTES:

21 22 23 4.1. ALL BALANCING SHOULD BE PERFORMED PRIOR TO CUTTING KEYWAYS IN

5 9 11 12 14 16 17 18 9 2

MATCH MARK MATCH MARK HUBS, IF NOT, THE HALF KEY WIEGHTS TO BE USED.

1 4 7 4.2. REF: COUPLING BALANCED PER API671 4TH EDITION METHOD 2, FOR 3,600

DRIVE END DRIVEN END RPM OPERATING SPEED PER THE FOLLOWING.

4.3. WEIGH BALANCE BOLTS (ITEMS 19) TO WITHIN 0.1 GRAMS.

4.4. SINGLE PLANE BALANCE TO WITHIN:

1.103 28.03

1.101 27.97 [ ] [

.878 22.29

.875 22.22 ] 4.4.1. DRIVE HUB (ITEM 1): 0.072 OZ*IN.

4.4.2. DRIVEN HUB (ITEM 2): 0.076 OZ*IN.

4.4.3. PACKING RING ADAPTER (ITEM 23): .01 OZ*IN.

]

]

]

88.862

3.4970 88.824

4.199 106.65

4.189 106.40

Ø9.488 [241]

3.902 99.11

3.887 98.73

Ø7.75 [196.9]

R.06 [R1.52] R.06 [R1.52] 4.5. DYNAMIC BALANCE THE SPACER SUB-ASSEMBLY (ITEM 4) TO WITHIN 0.055

Ø5.00 [127]

Ø4.83 [123]

TYP.

TYP.

OZ*IN. PER PLANE.

[

[

[

Ø3.4985

.75 [19.1] 4.6. PERFORM ASSEMBLY BALANCE CHECK.

.375 [9.53] TYP.

WALL

4.6.1. COUPLING SHALL BE ASSEMBLED AND RIGIDIZED USING PROVIDED

FLANGE HOLES (USE APPROPRIATE WEIGH BALANCED FASTENERS AS

REQUIRED)

4.6.2. PERFORM A BALANCE CHECK. IF UNBALANCE IS GREATER THAN 1.272

[

3.9322 99.878

3.9307 99.840 ] .75 TPF [

3.1626 80.329

3.1611 80.291 ] OZ*IN ON THE DRIVE END SIDE OR 1.318 OZ*IN ON THE DRIVEN SIDE, THEN

INSPECT TO DETERMINE THE CAUSE AND START AGAIN AT NOTE 4.1

ABOVE. NO ASSEMBLY BALANCE CORRECTIONS CAN BE MADE.

13.49 [342.6] ±.06 19 5. AFTER ASSEMBLY BALANCING, CUT KEYWAYS IN HUBS AS DETAILED IN THE HUB

.656 [16.67] 1.378 [35]

.060+.06 DRAWINGS.

4 SHIMS FITTED 6. COUPLING BOLTS AND NUTS (ITEM 14 & 18) TO BE TIGHTENED AND TORQUED AT

TYP. TYP.

4 SHIMS SPARE

18.00 [457.2] ±.12 FACTORY ASSEMBLY.

6.10 [155.0] 6.13 [155.7]

DBSE 7. AT FINAL ASSEMBLY, TORQUE CAPSCREWS (ITEM 19) TO 53 FT*LBS PER

INSTALLATION INSTRUCTIONS USING MOLYBDENUM DISULPHIDE GREASE.

30.23 [767.9] ±.12

8. DIMENSIONS IN INCHES AND [MM].

9. ITEM 21 FOR REMOVAL/INSTALLATION ONLY. REMOVE PRIOR TO OPERATION.

10. SPECIAL QUALITY DOCUMENTATION REQUIRED AS DETAILED IN THE "PROCESS

DOCUMENTATION REQUIREMENTS" TABLE. ALL DOCUMENTS TO BE INCLUDED

WITH WORK ORDER JACKETS. WORK ORDER JACKETS TO BE ROUTED TO QUALITY

MANAGER WHEN COMPLETE. REF: MEETS REQUIREMENTS OF EN10204 3.1.

11. TAPER ON HUB (ITEM 2) TO BE BLUED FIT INSPECTED FOR MIN 70% SURFACE

CONTACT USING APPROPRIATE PLUG GAGE.

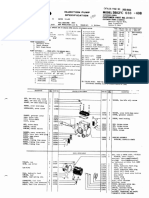

23 ADPTR TF1310PACKING RING A TF1310PR-001 1 R

22 SHIM TF1310SH .015 THK TF1310SH 8 LEGEND RECOMMENDED TIGHTENING TORQUES

21 SHCS GR12.9 M8X1.25X55MM LG YMAG-1420 6 (ALL BOLT VALUES ARE BASED ON USING ANTI-FRICTION BEARING

DOCUMENTS: GREASE i.e. BO ENERGREASE L21M OR EQUIVALENT)

20 SCR M12-1.75X1.787X.315 SPCLHX TFI-6-006 1 C

19 SCR M12-1.75X1.787X.315SHXWMCT TFI-6-006-WMCRT 27 ▲ R C-OF-C CERTIFICATE OF CONFORMANCE TORQUE (FT-LBS) [NM]

BOLT No.

18 NUT TF1310 M22 SL10 M22SL10 6 CHEM CHEMICAL CERTIFICATION

21 53, [71.9]

17 WASHER TF1310 ELEMENT D1923EW 6 BAL BALANCE REPORT

DO NOT TAMPER WITH THE FOLLOWING FASTENERS. THEY ARE

16 WASHER TF1310 OVERLOAD TF1310GZOW 6 UT WELD ULTRASONIC INSPECTION REPORT TIGHTENED BY AMERIDRIVE-BIBBY AS A FACTORY ASSEMBLED JOINT

15 BLT TF1310 DISC BOLT TF1310CB 1 C WMAG MAGNETIC PARTICLE INSPECTION BOLT No. NUT No. TORQUE (FT-LBS) [NM] STRETCH (IN.) [MM]

14 BLT TF1310 DISC BOLT WM/CERT TF1310CB-WMCERT 6 ▲ R DIM DIMENSIONAL INSPECTION 273, [370] 0.0044, [0.111]

14 18

13 BLADE D19 D19EB 1 C CODES: " C T.B. WOOD'S INCORPORATED.

12 BLADE D19 CERT D19EB-CERT 28 ▲ R RECORD REQUIRED THIS DRAWING CONTAINS

11 KIT TFI1310 ELEMENT API671 TFI1310EK-API 2 ▲ C CERTIFICATION REQUIRED

PROPRIETARY INFORMATION

AND SHALL NOT BE USED OR

10 STEEL 10 OD 4140 STL210 2.5 C REPRODUCED WITHOUT WRITTEN

9 FLNG TFI1310 WLD 4.25ID L1.75 TFI1310-12-03-001 2 ▲ CONSENT OR APPROVAL FROM

TB WOOD'S INCORPORATED.

8 TUBE TFI1310 5X.375 L10.43 CERT TFI1310S-05-001P 1 C

THIRD ANGLE PROJECTION R

7 SPC TFI1310 D17.56 L13.93 5X.38 API TFI1310S-05-001 1 ▲ R R F TB WOOD'S

6 STEEL 9 1/2 OD 1045 STL144 2.5 C INCORPORATED

E

5 ADPTR TF1310 ANTI-FLAIL CERT W/H TF1310AFA-002 2 ▲ R MECHANICAL DIVISION

4 SSA TFI1310 D17.56 5X.375 API671 TFI1310-2-05-001 1 ▲ R D

3 STEEL 10" OD 1045 STL146 6.45 6.46 C DESCRIPTION:

CUSTOMER:

2 HUB TFI1310 3.497/.75TPF ADHW TFI1310-3-05-001 1 ▲ R R R 11 C CPL TFI1310 D18 100MX3.5TP A

1 HUB TFI1310 3.9374/60A/B2/H/L/W TFI1310-3-06-001 1 ▲ R R CUST. P/N: COMP.:

2/5 ASSEMBLY

0 CPL TFI1310 D18 100MX3.5TP A TFI1310-006 ▲ C R B CHANGE FROM SD HUB 12620 JCD TDL

15 DRAWN: DATE: WR2-LBS. IN2 : PART NO.:

JCD 12/2/14

C-OF-C CHEM BAL UT WMAG DIM A ORIGINAL RELEASE JCD TDL

12/2

14 APPRVD: DATE:

SEE TABLE TFI1310-006

ITEM: DESCRIPTION: P/N: QTY: TDL 12/2/14 FINISH WT.-LBS.: DRAWING NUMBER: REV. LEVEL:

PROCESS DOCUMENTATION ECN CKD

REQ. REVISIONS NO.

BY

BY

DATE SHEET: 1 OF 1 SCALE:

NTS SEE TABLE TFI1310006 B

2 of 3

Das könnte Ihnen auch gefallen

- Top View L: General Arrangement Tank Mounted (240 Gallon) 22063374 JDokument4 SeitenTop View L: General Arrangement Tank Mounted (240 Gallon) 22063374 JJose Marie AsuncionNoch keine Bewertungen

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PVon EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNoch keine Bewertungen

- Working Ranges Specifications: SK17SR-5Dokument4 SeitenWorking Ranges Specifications: SK17SR-5Akhmad SebehNoch keine Bewertungen

- EVN-TC50 RevBDokument2 SeitenEVN-TC50 RevBGhodhelNoch keine Bewertungen

- Working Ranges Specifications: SK17SR-5Dokument8 SeitenWorking Ranges Specifications: SK17SR-5LU YONoch keine Bewertungen

- General Construction Notes: Bureau of DesignDokument15 SeitenGeneral Construction Notes: Bureau of DesignRicoyan YanNoch keine Bewertungen

- F2 - Liquid ReceiverDokument1 SeiteF2 - Liquid ReceiverStan LeyNoch keine Bewertungen

- p92-4441 Harness - Chassis Load CNTR MXDokument4 Seitenp92-4441 Harness - Chassis Load CNTR MXDiego Lira100% (1)

- Top View L: General Arrangement Tank Mounted (120 Gallon) 22063366 JDokument4 SeitenTop View L: General Arrangement Tank Mounted (120 Gallon) 22063366 JJose Marie AsuncionNoch keine Bewertungen

- General Construction NotesDokument1 SeiteGeneral Construction NotesCarlo M. FloresNoch keine Bewertungen

- P4-211-03-H-26006-00022 - 2 - A1 Cople 79006Dokument3 SeitenP4-211-03-H-26006-00022 - 2 - A1 Cople 79006Alce CdpemexNoch keine Bewertungen

- RS11 22i Baseplate GA 47637548 ADokument10 SeitenRS11 22i Baseplate GA 47637548 ALuis Miguel Brito BritoNoch keine Bewertungen

- DBGFC 633 - 4DB: ModelDokument2 SeitenDBGFC 633 - 4DB: Modeljohnny sabinNoch keine Bewertungen

- DS-613 - 75 Inch Pneumatic Ball Valve - Rev 3Dokument1 SeiteDS-613 - 75 Inch Pneumatic Ball Valve - Rev 3miguelsanguinettiNoch keine Bewertungen

- Warning!!!: 16V275Gl+ Lifting Eyes PlacementDokument1 SeiteWarning!!!: 16V275Gl+ Lifting Eyes PlacementDmitryNoch keine Bewertungen

- No. Despription Amount (USD) Remarks Architechture: Total #REF!Dokument63 SeitenNo. Despription Amount (USD) Remarks Architechture: Total #REF!tianhe zhaoNoch keine Bewertungen

- Wire Cable/ Wire Cable/: NotesDokument10 SeitenWire Cable/ Wire Cable/: Notesmahesh reddy mNoch keine Bewertungen

- Weatherford McMurry GLM - Gas Lift MandrelDokument25 SeitenWeatherford McMurry GLM - Gas Lift MandrelYovaraj KarunakaranNoch keine Bewertungen

- 1.epv - 3P20 HP Pump TitanDokument4 Seiten1.epv - 3P20 HP Pump TitanRob SchipperNoch keine Bewertungen

- General Construction NotesDokument1 SeiteGeneral Construction NotesLon OdiNoch keine Bewertungen

- Gel in Cil Idt V DRG 003Dokument25 SeitenGel in Cil Idt V DRG 003rinkukachhelaNoch keine Bewertungen

- C29732-01-Pid-02.0 - P&id Scrubber TT-006Dokument1 SeiteC29732-01-Pid-02.0 - P&id Scrubber TT-006omarNoch keine Bewertungen

- Notes:: TAG# SV-01Dokument1 SeiteNotes:: TAG# SV-01omarNoch keine Bewertungen

- STD WR 012Dokument1 SeiteSTD WR 012Tyburg R DhliwayoNoch keine Bewertungen

- 1153 MEP Drawings KEI 11-1102Dokument20 Seiten1153 MEP Drawings KEI 11-1102nfaa1986Noch keine Bewertungen

- Technical Specifications Premium 2-7/8" OD Drill Pipe, S-135, WT-23 Conn's. NewDokument2 SeitenTechnical Specifications Premium 2-7/8" OD Drill Pipe, S-135, WT-23 Conn's. NewAboozar FathinejadNoch keine Bewertungen

- JVC Service Manual mxgt80 PDFDokument48 SeitenJVC Service Manual mxgt80 PDFAlex GuerreroNoch keine Bewertungen

- Genral NotesDokument1 SeiteGenral NotesArjay AletaNoch keine Bewertungen

- Radiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCDokument3 SeitenRadiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCMehdi ChakrouneNoch keine Bewertungen

- C29732 03 Pid 06 - Rev - 1 PDFDokument1 SeiteC29732 03 Pid 06 - Rev - 1 PDFomarNoch keine Bewertungen

- Released For Production: RevisionsDokument1 SeiteReleased For Production: RevisionsFerney FonsecaNoch keine Bewertungen

- As Built: Smdb-5FDokument2 SeitenAs Built: Smdb-5FBalamurugan SUBRAMANIANNoch keine Bewertungen

- Notes Legends ECSDokument1 SeiteNotes Legends ECSAmando GonzalesNoch keine Bewertungen

- Revised Structural PlansDokument46 SeitenRevised Structural Plansangelandlucifergabriel009Noch keine Bewertungen

- General NotesDokument1 SeiteGeneral NotesJohn Paul IldefonsoNoch keine Bewertungen

- Etp 29.05.2023Dokument1 SeiteEtp 29.05.2023Ravpreet SinghNoch keine Bewertungen

- Etp 40 KLD 29.05.2023Dokument1 SeiteEtp 40 KLD 29.05.2023Ravpreet SinghNoch keine Bewertungen

- 1hyb906864 (As Built)Dokument10 Seiten1hyb906864 (As Built)Gastón MassaferroNoch keine Bewertungen

- Load ScheduleDokument18 SeitenLoad SchedulevijayNoch keine Bewertungen

- RCC31 One-Way Slabs (A&D)Dokument15 SeitenRCC31 One-Way Slabs (A&D)Md Mukarram RezaNoch keine Bewertungen

- S029-Standard Details-BlockworkDokument1 SeiteS029-Standard Details-BlockworkWNoch keine Bewertungen

- EE110 Obias Gilbert LM2 3-1Dokument1 SeiteEE110 Obias Gilbert LM2 3-1Gilbert ObiasNoch keine Bewertungen

- Outside Distribution Approved: Non-Production Drawing: Systems Maclean PowerDokument1 SeiteOutside Distribution Approved: Non-Production Drawing: Systems Maclean PowerJoakNoch keine Bewertungen

- 16 DX210W-TD - 2010-06-29 - LRDokument24 Seiten16 DX210W-TD - 2010-06-29 - LRMarcus LopesNoch keine Bewertungen

- p92-4440 Harness - Chassis Load CNTR CumminsDokument4 Seitenp92-4440 Harness - Chassis Load CNTR CumminsDiego Lira100% (1)

- Injection Pump Model Diesel Systems Specification Nay514958Dokument2 SeitenInjection Pump Model Diesel Systems Specification Nay514958dieselmotorsbogotasasNoch keine Bewertungen

- Wiring Design Analysis (Panel Board)Dokument1 SeiteWiring Design Analysis (Panel Board)John Michael Dioso PilongoNoch keine Bewertungen

- 01 StructuralDokument39 Seiten01 StructuralSaifullahNoch keine Bewertungen

- 4058 VW DN 00oo000021 Is2 Schematic Wiring DiagramDokument3 Seiten4058 VW DN 00oo000021 Is2 Schematic Wiring DiagramBadiNoch keine Bewertungen

- 2012 KW Oem Engine HarnessDokument4 Seiten2012 KW Oem Engine HarnessSergio HernandezNoch keine Bewertungen

- Compressor and Chiller of NGDokument1 SeiteCompressor and Chiller of NGMd. Rayhan TalukderNoch keine Bewertungen

- Working Ranges Specifications: Kobelco Construction Machinery Europe B.VDokument4 SeitenWorking Ranges Specifications: Kobelco Construction Machinery Europe B.VPHÁT NGUYỄN THẾNoch keine Bewertungen

- Engineering Data Sheet: PART NUMBER: 812EGF9015-FDokument2 SeitenEngineering Data Sheet: PART NUMBER: 812EGF9015-FLydia Eva HariniNoch keine Bewertungen

- Reporte Completamiento PCP: Informacion GeneralDokument1 SeiteReporte Completamiento PCP: Informacion GeneralEsteban santamaria ovalleNoch keine Bewertungen

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDokument1 SeiteThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110Noch keine Bewertungen

- Ysc Ms 769 DW 0004 SHT 2 of 2 Rev BDokument1 SeiteYsc Ms 769 DW 0004 SHT 2 of 2 Rev BbalamuralinakshatraNoch keine Bewertungen

- Ysc Ms 769 DW 0004 SHT 2 of 2 Rev BDokument1 SeiteYsc Ms 769 DW 0004 SHT 2 of 2 Rev BBala MuraliNoch keine Bewertungen

- Eco Tankering - First LegDokument1 SeiteEco Tankering - First LegCharles ArgoncilloNoch keine Bewertungen

- Hyundai Wheel Loader New 7 SeriesDokument6 SeitenHyundai Wheel Loader New 7 Serieshaiccdk6Noch keine Bewertungen

- Torsional Modal ShopDokument6 SeitenTorsional Modal ShopEwdes HernandezNoch keine Bewertungen

- 2.5.3 High Speed Coupling DrawingDokument1 Seite2.5.3 High Speed Coupling DrawingEwdes HernandezNoch keine Bewertungen

- 2.5.3 High Speed Coupling DrawingDokument1 Seite2.5.3 High Speed Coupling DrawingEwdes HernandezNoch keine Bewertungen

- Oreda 2009 - Topside Equipment PDFDokument796 SeitenOreda 2009 - Topside Equipment PDFEwdes Hernandez87% (15)

- Datasheet Chockfast RedDokument2 SeitenDatasheet Chockfast RedAlexander0% (1)

- Datasheet Chockfast RedDokument2 SeitenDatasheet Chockfast RedAlexander0% (1)

- The Modal Shop Sound and Vibration Systems Selection GuideDokument13 SeitenThe Modal Shop Sound and Vibration Systems Selection GuideEwdes Hernandez100% (1)

- Manual Modulo XM440Dokument100 SeitenManual Modulo XM440Ewdes HernandezNoch keine Bewertungen

- Manual Modulo XM440Dokument100 SeitenManual Modulo XM440Ewdes HernandezNoch keine Bewertungen

- IRJ November 2021Dokument44 SeitenIRJ November 2021sigma gaya100% (1)

- CA Level 2Dokument50 SeitenCA Level 2Cikya ComelNoch keine Bewertungen

- Dr. Babasaheb Ambedkar Technological UniversityDokument3 SeitenDr. Babasaheb Ambedkar Technological UniversityalfajNoch keine Bewertungen

- Cultural AnthropologyDokument12 SeitenCultural AnthropologyTRISH BOCANoch keine Bewertungen

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Dokument12 SeitenAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHNoch keine Bewertungen

- Interceptor Specifications FinalDokument7 SeitenInterceptor Specifications FinalAchint VermaNoch keine Bewertungen

- Basics of Petroleum GeologyDokument23 SeitenBasics of Petroleum GeologyShahnawaz MustafaNoch keine Bewertungen

- Creativity Triggers 2017Dokument43 SeitenCreativity Triggers 2017Seth Sulman77% (13)

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolDokument14 SeitenAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakNoch keine Bewertungen

- Case Studies InterviewDokument7 SeitenCase Studies Interviewxuyq_richard8867100% (2)

- Major Stakeholders in Health Care SystemDokument5 SeitenMajor Stakeholders in Health Care SystemANITTA S100% (1)

- The Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperDokument12 SeitenThe Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperIgor SangulinNoch keine Bewertungen

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDokument8 SeitenTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Libel Arraignment Pre Trial TranscriptDokument13 SeitenLibel Arraignment Pre Trial TranscriptAnne Laraga LuansingNoch keine Bewertungen

- F. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DDokument9 SeitenF. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DRose Nirwana HandayaniNoch keine Bewertungen

- (Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)Dokument192 Seiten(Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)BrunoRamosdeLima100% (1)

- ADP G2 Spreadsheet Loader Data Entry: End-User GuideDokument48 SeitenADP G2 Spreadsheet Loader Data Entry: End-User Guideraokumar250% (2)

- Using Ms-Dos 6.22Dokument1.053 SeitenUsing Ms-Dos 6.22lorimer78100% (3)

- MJDF Mcqs - Mixed - PDFDokument19 SeitenMJDF Mcqs - Mixed - PDFAyesha Awan0% (3)

- LCP-027 VectraLCPDesignGuideTG AM 0613Dokument80 SeitenLCP-027 VectraLCPDesignGuideTG AM 0613Evert100% (1)

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Dokument8 SeitenTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNoch keine Bewertungen

- Unix SapDokument4 SeitenUnix SapsatyavaninaiduNoch keine Bewertungen

- ZyLAB EDiscovery 3.11 What's New ManualDokument32 SeitenZyLAB EDiscovery 3.11 What's New ManualyawahabNoch keine Bewertungen

- Infor Mashup DesignerDokument95 SeitenInfor Mashup DesignerBalayogesh Alagesan100% (1)

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDokument3 SeitenComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077Noch keine Bewertungen

- HW Chapter 25 Giancoli Physics - SolutionsDokument8 SeitenHW Chapter 25 Giancoli Physics - SolutionsBecky DominguezNoch keine Bewertungen

- Jail Versus Substance Abuse TreatmentDokument5 SeitenJail Versus Substance Abuse Treatmentapi-240257564Noch keine Bewertungen

- Deep Sea 500 Ats ManDokument18 SeitenDeep Sea 500 Ats ManLeo Burns50% (2)

- Machine Tools PDFDokument57 SeitenMachine Tools PDFnikhil tiwariNoch keine Bewertungen

- Chapter 3.seed CertificationDokument9 SeitenChapter 3.seed Certificationalemneh bayehNoch keine Bewertungen