Beruflich Dokumente

Kultur Dokumente

Saudi Aramco LOTO Guide

Hochgeladen von

Musharaf ShahOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Saudi Aramco LOTO Guide

Hochgeladen von

Musharaf ShahCopyright:

Verfügbare Formate

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 1 OF 8

HJK

CONTENTS:

1.0 Purpose

2.0 Applicability

3.0 Responsibilities

4.0 General Requirements

5.0 Lock, Tag, Clear and Try Electrical Isolation Procedures

6.0 Procedure for Emergency Removal of Lockout Devices

7.0 Piping and Equipment Isolation Procedures

REFERENCES:

• GI 2.100 - Work Permit System

• OSHA 29 CFR 1910.147 - The Control of Hazardous Energy (Lockout/Tagout). In general, this

GI follows the requirements outlined in the OSHA requirements.

* 1.0 PURPOSE:

The purpose of this General Instruction is to define minimum requirements for isolation, lockout

and use of hold tag procedures at Saudi Aramco facilities to assure protection of assets and

personnel involved in maintenance/inspection of equipment.

2.0 APPLICABILITY:

All Saudi Aramco departments shall apply this instruction in situations where equipment could be

damaged or personnel injured due to an unexpected release of energy or hazardous materials.

Sources of energy include mechanical, electrical, hydraulic and pneumatic systems. Examples of

hazardous materials include H2S or other toxic chemicals, hydrocarbons, radioactive sources, hot

water, and steam.

** 3.0 RESPONSIBILITIES:

Department managers, division heads and supervisors are responsible for ensuring compliance

with this GI.

4.0 GENERAL REQUIREMENTS:

* 4.1 Whenever personnel work on equipment and could be injured because of energy in the

system, the equipment shall be isolated from its energy sources. For fluid systems this

could require the installation of blinds, the closure and locking of valves, the removal of

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 2 OF 8

HJK

fluid from the system, or the physical removal of piping. For electrical systems,

appropriate isolation could include the locking or removal of switches, circuit breakers,

fuses or other isolating devices, or disconnection of the power supplies. Residual energy in

any system must be removed before work begins. Proper isolation of equipment shall be

characterized by the nature of the material to be protected against, the specific work to be

conducted, and the piping configuration present at the job site.

* 4.2 Operations or controlling organizations shall develop isolation, lock, and hold tag

procedures for their operations or adopt this instruction as written if it will satisfy their

lock and hold tag requirements. Specific isolation, lock and hold tag procedures shall be

developed for any complex equipment or processes and incorporated into departmental

Operating Instruction Manuals (OIM's).

4.3 Operations and maintenance organizations and each department responsible for

implementing the lockout procedures per paragraph 4.2 shall train relevant personnel in all

elements of the program.

4.4 Operations and maintenance organizations shall provide necessary lockout equipment to

employees.

5.0 LOCK, TAG, CLEAR AND TRY ELECTRICAL ISOLATION PROCEDURES:

* 5.1 Prior to commencing work, operations shall identify isolating locations and types of

isolating devices required. If necessary, they shall consult with third parties, such as

electrical specialists. Equipment shall then be electrically isolated and locks and tags

installed by operations, the work area cleared of equipment and personnel, and the start

switch(es) tried. This is a distinct 4 step process to ensure that the equipment is properly

isolated.

5.1.1 Isolation will have been completed only when no associated control device, such as

a push button, control interlock or automatic start-up control circuit, shall have the

capability of energizing equipment.

5.1.2 In situations where it is not possible to lock out or chain off an isolating device,

isolation may be accomplished by removal of fuses, disconnection of electrical

cables, or physical removal of a component of the system supplying energy to the

equipment. The point of physical interruption shall be identified with a fully

completed hold tag.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 3 OF 8

HJK

5.1.3 When isolation has been completed (or before if appropriate), operations will de-

energize equipment and ensure that it contains no residual energy.

* 5.2 Other organizations or individuals working on equipment shall also install their locks and

tags at locations identified by operations. Multiple lockout clips shall be used if necessary.

Multiple lockout clips, locks and tags are available in B2B, (see appendix for SAP stock

numbers.)

5.3 Each lock on a piece of equipment, or on a multiple lockout clip, must be identified. A tag

(Saudi Aramco Form 525) shall be installed on each lock indicating plant number or

location, equipment name, date and time of lockout, name, badge number, organization,

contact phone and signature of the individual who installed the lock and the reason for the

lock's installation.

* 5.3.1 Each organization issuing locks shall have a system of uniquely identifying locks.

Acceptable methods include color coding, stamping or engraving locks

appropriately.

5.3.2 Each lock shall be keyed separately, with no duplicate key, to ensure removal only

by the authorized user.

5.4 Verification tests, in which all affected parties participate, shall be conducted by

Operations on each isolating device and on each piece of equipment isolated.

5.4.1 Each isolating device, such as a disconnect switch, shall be physically tested by

moving its operating mechanism against the padlock, multiple lockout clip, or

chain, to confirm that it cannot be operated.

5.5 When a craftsman leaves the job site temporarily, but intends to return to complete work,

his locks and tags may be left installed, provided this is acceptable to controlling

organizations. Operations may require craft locks and tags to be removed. Upon his return

to work, the employee shall verify his locks and tags are still in place ensuring the

equipment is still isolated prior to restarting his work.

** 5.6 Sometimes it is necessary for large numbers of maintenance personnel to lock and tag

process equipment and/or electrical breakers, such as during a T&I or repair of a

compressor. Each person must be afforded individual protection. In those cases, a "group

lockout" procedure can be employed to ensure individual protection while avoiding large

numbers of locks and tags on an isolation point as follows:

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 4 OF 8

HJK

5.6.1 An operations representative shall lock and tag each isolation point with single-

keyed locks as per written isolation procedure described in Section 4.2.

5.6.2 The maintenance supervisor/foreman shall also lock and tag the isolation points.

5.6.3 The maintenance supervisor/foreman's key(s) to these locks are placed in a Group

Lockout box. Lockout boxes can be acquired through B2B (see appendix for SAP

stock numbers).

5.6.4 Multiple lock clips (hasps) are then attached on the closed group lockout box.

5.6.5 The operations representative shall place his lock and tag on the box/hasp first and

maintain possession of his key(s) until job is complete.

5.6.6 Each member of the maintenance crew shall then place his lock and tag on the

multiple lock clip and maintain possession of his key(s) until job is complete.

5.7 When a craft shift change occurs and work is not complete, the oncoming shift may either:

5.7.1 Install their own locks and tags at locations where the previous shift had them - in

which case the off-going shift shall remove their tags and locks.

5.7.2 Effect a transfer of keys between shifts. This transfer requires the craft foremen or

supervisors to conduct a detailed review of installed locks and tags. Craft tags may

be endorsed by the oncoming shift or new tags may be installed.

5.8 When an operations shift change occurs, the oncoming supervisor shall review locations

and placement of isolated equipment, locks and tags. These operations tags and locks may

be left installed and do not require endorsement at each shift change. Keys to locks shall be

transferred at the time the review is made.

5.9 When a craftsman completes his work, or leaves the job site permanently, his tags and

lockout devices shall be removed. The craft foreman or supervisor shall advise the

Operations Supervisor that the craftsman has completed his work and is removing his locks

and tags.

5.10 Operations or controlling organizations shall always be the first to install a lock and tag on

a piece of equipment and the last to remove them. This lock and tag shall not be removed

until operations personnel have checked and examined equipment to ensure it can be safely

energized.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 5 OF 8

HJK

* 6.0 PROCEDURE FOR EMERGENCY REMOVAL OF LOCKOUT DEVICES:

6.1 No padlock/lockout device shall be cut or forcefully removed, without the permission of

the lock owner's superintendent or the operating shift superintendent.

6.1.1 (a) The operations shift superintendent will attempt to contact the individual who

installed the lock, or his supervisor, to confirm that the work is complete, that

the employee is safe and that the padlock can be removed.

(b) If the individual, his supervisor, or superintendent cannot be contacted, the shift

superintendent may remove the lock(s) and tag(s) only after reviewing the

equipment/process to be energized, to ensure that personnel and facilities are

safe from injury or damage.

6.1.2 The shift superintendent shall verbally advise the operations division

superintendent of the action taken and record the removal of the lockout device in

the operations log book. He will then document the incident in a written memo to

the operations division superintendent stating why the lockout device was removed,

the original purpose of the lockout device, and employees involved.

** 7.0 PIPING AND EQUIPMENT ISOLATION PROCEDURES:

There are four primary methods for isolating process lines and equipment to prevent the release of

harmful energy or materials into the work area during maintenance or construction activities.

Operations or controlling organizations shall ensure specific lock, tag and hold procedures are in

place to protect personnel. The methods are arranged below in general order of protection

provided, but the specific isolation method is determined by the task to be performed and the

material/stored energy to be protected against. These include:

7.1 Single block and tag.

7.1.1 This is the least desirable method for use in hydrocarbon service; it may be suitable

for routine maintenance activities such as sock filter changes, temporary isolation

while a blind is being installed, or cleaning of inline strainers. It is not acceptable

for hot work permit activities or entry into confined spaces.

7.1.2 The block valve shall be fully closed, locked and tagged.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 6 OF 8

HJK

7.1.3 The fluid shall be removed from the system safely and the valve shall be tested for

leakage before work begins.

7.2 Double block and bleed.

7.2.1 This method is superior to single lock and tag. It consists of the locking and tagging

of two consecutive valves on the same line that have a drain valve installed

between them that shall be opened as a drain to determine if the locked valves are

passing. It shall not be allowed for personnel entry into confined spaces.

7.2.2 The drain valve shall be checked to verify that it is not clogged or plugged and be

securely piped or hosed away from the work area to ensure that any fluids leaking

by the closed valves do not endanger the ongoing work.

7.3 Disconnection

A less frequent method of isolation for long term maintenance activities. The act of

dropping out a spool piece to form a physical disconnect in the piping, often because the

piping design will not allow the insertion of a fully rated blind. Steps shall be taken to

ensure no hazardous materials can leak or be discharged from the open ends of piping, e.g.

blind flanging as described in 7.4 below.

7.4 Blinding

The installation of a solid metal plate between two pipe flanges or on the end of a

disconnected pipe to prevent any materials from being released.

7.4.1 A blinding procedure and sketch shall be created showing blinding locations for

each piece of equipment requiring more than two isolation blinds. The blinding

procedure will include precautions to complete the work safely such as: proper line

entry, lock and tag locations, blind rating, location and size of blind, etc.

7.4.2 The breaking of any flange containing hazardous materials shall always be done

under the assumption that the line is pressurized. Appropriate personal protective

equipment (PPE) will be utilized. The stud bolts will be loosened so that any leak

from pressurized fluid will occur at the “5:00” position (down and away from the

person doing the work).

7.4.3 Blinds shall be fully rated for their service per ANSI/ASME B31.3 to withstand

potential internal pressures. Each blind shall be stamped with the pressure rating.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 7 OF 8

HJK

Factory produced blinds are recommended. Facility built blinds may be used but

must be approved by local engineering for service and rating and the results

documented.

7.4.4 Blinds shall be installed with matching gaskets to ensure effective isolation, with

all stud bolts in place and properly tensioned.

7.4.5 Slip blinds shall be equipped with a tail or “T”-handle drilled with a hole to attach a

tag.

7.4.6 Blinding shall be the only acceptable method of equipment isolation for entry into

confined spaces.

7.4.7 A blind list shall be prepared when more than two blinds are used to isolate

equipment to ensure proper installation and removal. The list shall, at a minimum,

include blind information on the following: blind number, date of installation,

location, blind rating, installer name, date of removal, and remover name.

7.4.8 Blinds shall be tagged with a unique number to ensure proper identification on the

blind list.

7.4.9 Blinds when not in use shall be properly stored to protect mating surfaces.

APPROVED: _________________________ DATE: _________________

MANAGER,

Loss Prevention Department

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Saudi Aramco 7180 (5/89)

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. NUMBER

GENERAL INSTRUCTION MANUAL 6.012

ISSUE DATE REPLACES

ISSUING ORG. LOSS PREVENTION DEPARTMENT 07/22/2007 07/22/2001

APPROVAL PAGE NO.

SUBJECT ISOLATION, LOCKOUT AND USE OF HOLD TAGS 8 OF 8

HJK

APPENDIX

LOCK/HOLD TAG SAUDI ARAMCO FORM #525

* LOCK-OUT; MULTIPLE SAP # 1000128114

SAP # 1000128118

* LOCK SAP # 1000162049

** GROUP LOCKOUT BOX SAP # 1000774337

** CIRCUIT BREAKER LOCKOUT DEVICE SAP # 1000774338

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

Free Engineering Books https://boilersinfo.com

Das könnte Ihnen auch gefallen

- Aramco Safety ManualDokument689 SeitenAramco Safety ManualMuhammad Farooq AwanNoch keine Bewertungen

- Saudi Aramco StandardsDokument23 SeitenSaudi Aramco Standardsbalaji100% (3)

- Front End Loader Pre Use Inspection SUP 142 e en 16 077Dokument1 SeiteFront End Loader Pre Use Inspection SUP 142 e en 16 077Musharaf ShahNoch keine Bewertungen

- Aramco Standards-B-4 & 5 For H2S-2013Dokument35 SeitenAramco Standards-B-4 & 5 For H2S-2013Nehemiah Cervantes100% (3)

- G.I. 6.004 - Near Miss Reporting Process PDFDokument5 SeitenG.I. 6.004 - Near Miss Reporting Process PDFJoypee MacasamponNoch keine Bewertungen

- Dump Truck SafetyDokument1 SeiteDump Truck SafetyMusharaf ShahNoch keine Bewertungen

- Schedule DDokument17 SeitenSchedule DSIVA100% (4)

- PLANO ELECTRICO Cat - Dcs.sis - Controller.Dokument4 SeitenPLANO ELECTRICO Cat - Dcs.sis - Controller.ctorres_505746Noch keine Bewertungen

- Sabic ExamDokument9 SeitenSabic ExamSyed Ahmed manzoor100% (3)

- Perator S Anual: Hydrostatic Garden Tractor, 900 SeriesDokument36 SeitenPerator S Anual: Hydrostatic Garden Tractor, 900 SeriesThomas SwinneyNoch keine Bewertungen

- Company OperationsDokument45 SeitenCompany OperationsMusharaf ShahNoch keine Bewertungen

- ISG-FM-HSE-WR-OP-002-LOTO (Lockout Tagout) ProcedureDokument10 SeitenISG-FM-HSE-WR-OP-002-LOTO (Lockout Tagout) ProcedureJulio GregorioNoch keine Bewertungen

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Dokument31 Seiten14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 000-ZA-E-009712 - 00 HSE Requirement For Subcontractor and Vendors Annexe 1 PDFDokument66 Seiten000-ZA-E-009712 - 00 HSE Requirement For Subcontractor and Vendors Annexe 1 PDFzizu1234Noch keine Bewertungen

- 0006 007Dokument10 Seiten0006 007Genaro Paypa100% (4)

- General Instruction Manual: ContentDokument13 SeitenGeneral Instruction Manual: Contentck19654840Noch keine Bewertungen

- Tier3 ElectricDokument10 SeitenTier3 ElectricLuong Nguyen Danh100% (1)

- Hazard Identification Plan (HIP) HaradhDokument29 SeitenHazard Identification Plan (HIP) HaradhAsif Khanzada63% (8)

- Work Permit Conditions and Firewatch DutiesDokument40 SeitenWork Permit Conditions and Firewatch DutiesClarissa Edwards75% (4)

- General Instruction Manual: Organization Consulting DepartmentDokument12 SeitenGeneral Instruction Manual: Organization Consulting DepartmentSathi sh94% (16)

- Docslide - Us Critical Lift Plan Gi 70281Dokument64 SeitenDocslide - Us Critical Lift Plan Gi 70281Mohamed rasheedNoch keine Bewertungen

- 3512B Air Starter PDFDokument8 Seiten3512B Air Starter PDFMohamed RedaNoch keine Bewertungen

- PDF Gi 0002721 2016 Arc Flash CompressDokument23 SeitenPDF Gi 0002721 2016 Arc Flash CompressMark DingalNoch keine Bewertungen

- Questions Bank For HSE PersonnelaDokument39 SeitenQuestions Bank For HSE PersonnelaJithu Thampi100% (3)

- G.I. 8.001 Issue Date 10-01-2011Dokument17 SeitenG.I. 8.001 Issue Date 10-01-2011Ruben Vasquez Laurente82% (17)

- G.I. 2.721 - Electrical Arc Flash Mitigation PDFDokument15 SeitenG.I. 2.721 - Electrical Arc Flash Mitigation PDFJoypee Macasampon100% (6)

- 0002 - 709 Gas Testing Using Portable Gas MonitorsDokument12 Seiten0002 - 709 Gas Testing Using Portable Gas MonitorsSrinivas Maddenapelli100% (2)

- Saudi Aramco Field ChecklistDokument6 SeitenSaudi Aramco Field Checklistjaslin78% (9)

- Fire Protection SystemsDokument107 SeitenFire Protection SystemsMusharaf ShahNoch keine Bewertungen

- Camp GI 298 - 010 - Revision - 03 May 2017 PDFDokument85 SeitenCamp GI 298 - 010 - Revision - 03 May 2017 PDFJoypee Macasampon100% (1)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Dokument25 SeitenGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Nasir IrfaniNoch keine Bewertungen

- General Instruction Manual: Organization Consulting DepartmentDokument12 SeitenGeneral Instruction Manual: Organization Consulting DepartmentChaudhary Wasim MurtazaNoch keine Bewertungen

- Sample PQRDokument2 SeitenSample PQRudaysrp33% (3)

- Classes of FireDokument12 SeitenClasses of FireMusharaf Shah100% (2)

- Aramco-GI Instruciton Manual PDFDokument12 SeitenAramco-GI Instruciton Manual PDFRiaz ahmed100% (2)

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Dokument27 Seiten20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- Safe Use of Site Dumpers On Construction SitesDokument4 SeitenSafe Use of Site Dumpers On Construction SitesMusharaf ShahNoch keine Bewertungen

- Aramco GenDokument21 SeitenAramco GenHaleem Ur Rashid Bangash0% (1)

- SHEM-08.07 Tools Handling PDFDokument19 SeitenSHEM-08.07 Tools Handling PDFsonalisabir100% (2)

- Aramco Safety Talk QSMDokument1 SeiteAramco Safety Talk QSMHaleem Ur Rashid BangashNoch keine Bewertungen

- CSM - Contractor Site Administrative Requirements (CSAR) November 2019 RevisionsDokument6 SeitenCSM - Contractor Site Administrative Requirements (CSAR) November 2019 RevisionsAkash K NairNoch keine Bewertungen

- Project Management For Construction and Civil Engg.Dokument487 SeitenProject Management For Construction and Civil Engg.TauseefNoch keine Bewertungen

- Schedule B - Attachment IDokument27 SeitenSchedule B - Attachment Imunna100% (2)

- ARAMCO Confined Space Entry BookletDokument44 SeitenARAMCO Confined Space Entry BookletYogesh Dagar75% (4)

- FiltrationDokument37 SeitenFiltrationLiz BargolaNoch keine Bewertungen

- 0007 026Dokument9 Seiten0007 026Mohammed Rizwan AhmedNoch keine Bewertungen

- Job Safety Analysis Work SheetDokument7 SeitenJob Safety Analysis Work SheetTomNoch keine Bewertungen

- Saudi Aramco LPD Team Review of Contractor CSAR Deliverable - Comment SheetDokument2 SeitenSaudi Aramco LPD Team Review of Contractor CSAR Deliverable - Comment SheetShahid BhattiNoch keine Bewertungen

- Steel Guide To SelectionDokument7 SeitenSteel Guide To Selectionsinetron88Noch keine Bewertungen

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Dokument1 SeiteProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNoch keine Bewertungen

- Gi-7.025 Heavy Equipment Operator Testing and CertificationDokument1 SeiteGi-7.025 Heavy Equipment Operator Testing and CertificationAkbarShareef60% (5)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Dokument25 SeitenGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)parijat pramanikNoch keine Bewertungen

- GI 6.030, Traffic and Vehicle SafetyDokument18 SeitenGI 6.030, Traffic and Vehicle SafetyFarrukh Ejaz0% (2)

- GI 2.709 Gas Testing PDFDokument12 SeitenGI 2.709 Gas Testing PDFMANI DEEP67% (3)

- 0002 - 100 Work Permit SystemDokument6 Seiten0002 - 100 Work Permit SystemOmar Santos90% (21)

- MIP17 - HSE - PP - 002 Contractor Site Safety Program (CSSP) REV 2Dokument210 SeitenMIP17 - HSE - PP - 002 Contractor Site Safety Program (CSSP) REV 2AmeerHamzaWarraichNoch keine Bewertungen

- G.I. 150.002 First Aid-CPR Training and First Aid KitsDokument5 SeitenG.I. 150.002 First Aid-CPR Training and First Aid KitsAbdulwahid KhakiNoch keine Bewertungen

- G.I. 151.006 Implementing Sanitary CodeDokument5 SeitenG.I. 151.006 Implementing Sanitary Codebryan100% (5)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument4 SeitenContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualjhoni100% (1)

- Gi-0008 001Dokument8 SeitenGi-0008 001Tasasdaq khan100% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument16 SeitenContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualbryanNoch keine Bewertungen

- Monthly Oxygen/Nitrous Oxide Cylinder Inspection ChecklistDokument1 SeiteMonthly Oxygen/Nitrous Oxide Cylinder Inspection ChecklistMusharaf ShahNoch keine Bewertungen

- Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument5 SeitenSaudi Arabian Oil Company (Saudi Aramco) General Instruction ManualGeorge Zormpas100% (1)

- Tranning Report Civil EnggineeringDokument121 SeitenTranning Report Civil Enggineeringabhishekmathur_er75% (28)

- 0000 - 000saudi Aramco GIDokument12 Seiten0000 - 000saudi Aramco GIRaheel Ahmed83% (6)

- Part I - 04 Work Permit SystemDokument7 SeitenPart I - 04 Work Permit Systemsalah abddayemNoch keine Bewertungen

- Laboratory Experiment 7: Mohd Ashraf Mohd IsmailDokument14 SeitenLaboratory Experiment 7: Mohd Ashraf Mohd IsmailMohd Ashraf Mohd Ismail100% (2)

- GI 8.001 Safety Requirements For ScaffoldsDokument2 SeitenGI 8.001 Safety Requirements For Scaffoldschassas56% (9)

- SAES-B-069 Editorial Revision (10-28-2021)Dokument11 SeitenSAES-B-069 Editorial Revision (10-28-2021)Daniel Meana100% (1)

- Beam and Slab Floor SystemDokument33 SeitenBeam and Slab Floor SystemmuskanNoch keine Bewertungen

- WorkPermitReceiver PDFDokument2 SeitenWorkPermitReceiver PDFAbu sufyanNoch keine Bewertungen

- Gi-0006 006Dokument7 SeitenGi-0006 006malika_00Noch keine Bewertungen

- Agroindustrial Laredo DiaposDokument14 SeitenAgroindustrial Laredo DiaposXimena AguilarNoch keine Bewertungen

- Work Permit System: Saudi Arabian Oil Company (Saudi Aramco)Dokument7 SeitenWork Permit System: Saudi Arabian Oil Company (Saudi Aramco)Danilo de JurasNoch keine Bewertungen

- 0007 GiDokument8 Seiten0007 GiMohammed Rizwan AhmedNoch keine Bewertungen

- Sabic Unified Work Permit Receiver CourseDokument12 SeitenSabic Unified Work Permit Receiver CourseSajjad AfzalNoch keine Bewertungen

- Contents:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokument4 SeitenContents:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualSAQIB100% (1)

- E30-E01-02 - 1 Elect Lockout-Tagout RequirementDokument5 SeitenE30-E01-02 - 1 Elect Lockout-Tagout RequirementMuhammad IrfanNoch keine Bewertungen

- AA - GTG - 000006 - V0 AFRG 6 IsolationDokument64 SeitenAA - GTG - 000006 - V0 AFRG 6 Isolationgaston_mendez_hNoch keine Bewertungen

- Compressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesDokument4 SeitenCompressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesMusharaf ShahNoch keine Bewertungen

- Ohdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIDokument2 SeitenOhdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIMusharaf ShahNoch keine Bewertungen

- Retard Chamber PDFDokument1 SeiteRetard Chamber PDFMusharaf ShahNoch keine Bewertungen

- Nazar Hussain: ObjectiveDokument2 SeitenNazar Hussain: ObjectiveMusharaf ShahNoch keine Bewertungen

- PSM DatasheetDokument2 SeitenPSM DatasheetMusharaf ShahNoch keine Bewertungen

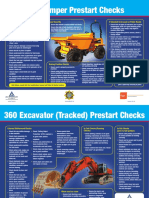

- Site Dumper 360 Excavator Pre-Start ChecksDokument2 SeitenSite Dumper 360 Excavator Pre-Start ChecksMusharaf ShahNoch keine Bewertungen

- Monthly Fire Fighters Training RecordDokument3 SeitenMonthly Fire Fighters Training RecordMusharaf ShahNoch keine Bewertungen

- Power GuillotinesDokument74 SeitenPower GuillotinesMusharaf ShahNoch keine Bewertungen

- CD Training School Faisalabad PDFDokument1 SeiteCD Training School Faisalabad PDFMusharaf ShahNoch keine Bewertungen

- CD Training School LahoreDokument1 SeiteCD Training School LahoreMusharaf ShahNoch keine Bewertungen

- cm04 09Dokument13 Seitencm04 09Musharaf ShahNoch keine Bewertungen

- ASP ReferencesDokument2 SeitenASP ReferencesMusharaf ShahNoch keine Bewertungen

- Pslgprinciples PDFDokument3 SeitenPslgprinciples PDFMusharaf ShahNoch keine Bewertungen

- 2 Aware S H ProgramsDokument23 Seiten2 Aware S H ProgramsMusharaf ShahNoch keine Bewertungen

- CAT988 BDokument14 SeitenCAT988 BMusharaf ShahNoch keine Bewertungen

- VFD 690vDokument104 SeitenVFD 690vnitzNoch keine Bewertungen

- DSU D InstallDokument2 SeitenDSU D InstallstarykNoch keine Bewertungen

- Operating Manual: Thyristor-Controlled Welding RectifierDokument12 SeitenOperating Manual: Thyristor-Controlled Welding Rectifierex-2156Noch keine Bewertungen

- Proj Accomplisment PDFDokument1 SeiteProj Accomplisment PDFJan Reoven SialanaNoch keine Bewertungen

- ManualDokument193 SeitenManualAlexander Diaz AlvarezNoch keine Bewertungen

- Tankguard Special Ultra Jotun PaintDokument5 SeitenTankguard Special Ultra Jotun PaintGurdeep Sungh AroraNoch keine Bewertungen

- Industrial Training ReportDokument26 SeitenIndustrial Training ReportDesh DeepakNoch keine Bewertungen

- Power Ups PDFDokument7 SeitenPower Ups PDFtsraj10Noch keine Bewertungen

- Newswave2015 02Dokument10 SeitenNewswave2015 02Juan Manuel JorqueraNoch keine Bewertungen

- Bio CaskDokument2 SeitenBio CaskHenry San PedroNoch keine Bewertungen

- About Activiser Technology: Private Limited", Are Prominent Inventors, ManufacturersDokument17 SeitenAbout Activiser Technology: Private Limited", Are Prominent Inventors, ManufacturersLmaoNoch keine Bewertungen

- PEIR - Vol 13 Figures Carnwath Road RiversideDokument32 SeitenPEIR - Vol 13 Figures Carnwath Road RiversidethamestunnelNoch keine Bewertungen

- RTD-201 203Dokument2 SeitenRTD-201 203amekhzoumiNoch keine Bewertungen

- 93964-Quickstart LMI Gocator 3100 Series PDFDokument2 Seiten93964-Quickstart LMI Gocator 3100 Series PDFrmorenodx4587Noch keine Bewertungen

- Data CollectionDokument15 SeitenData CollectionIrene Elizabeth MathewNoch keine Bewertungen

- Commissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiDokument4 SeitenCommissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiSwathi PriyaNoch keine Bewertungen

- GZYQ Liquid Soft StarterDokument15 SeitenGZYQ Liquid Soft StarterAlpha AgustinusNoch keine Bewertungen

- Piaggio Accessory Catalogues 2018 UsaDokument29 SeitenPiaggio Accessory Catalogues 2018 Usaganeshn1983631Noch keine Bewertungen