Beruflich Dokumente

Kultur Dokumente

RCC94 Two Way Slabs (Tables) MCY RF CT

Hochgeladen von

Yati ChanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RCC94 Two Way Slabs (Tables) MCY RF CT

Hochgeladen von

Yati ChanCopyright:

Verfügbare Formate

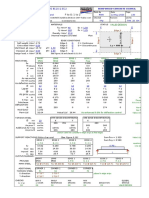

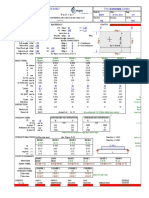

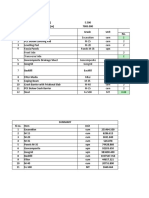

Project Spreadsheets to BS 8110 & EC2 REINFORCED CONCRETE COUNCIL

Client Advisory Group Made by Date Page

Location 32nd floor - corner panel F to G: 1 to 2 RMW 14-May-2018 130

2-WAY SPANNING INSITU CONCRETE SLABS to BS 8110:1997 (Table 3.14) Checked Revision Job No

Originated from RCC94.xls on CD © 1999 BCA for RCC

chg - R68

DIMENSIONS MATERIALS STATUS Fails on MAX SPACING,

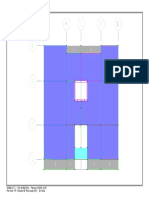

short span, lx m 2.30 fcu N/mm² 40 c 1.50 F G

long span, ly m 4.78 fy N/mm² 460 s 1.05 Edge 1

h mm 175 Density kN/m³ 24 1

Top cover mm 20 (Normal weight concrete) Plan

Btm cover mm 20

Lx = 2.3 m

Edge 4

Edge 2

LOADING characteristic EDGE CONDITIONS

Self weight kN/m² 4.20 Edge 1 D C = Continuous

Extra dead kN/m² 27.00 Edge 2 D D = Discontinuous Ly = 4.775 m

Total Dead, gk kN/m² 31.20 f= 1.40 Edge 3 C

Imposed, qk kN/m² 2.50 f= 1.60 Edge 4 C 2

Design load, n kN/m² 47.68 See Figure 3.8 and clauses 3.5.3.5-6 Edge 3

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4 BS8110

MAIN STEEL SPAN SPAN Free Free Continuous Continuous Reference

ßs 0.071 0.034 0.000 0.000 0.095 0.045 Table 3.14

M kNm/m 18.0 8.6 0.0 0.0 24.0 11.4

d mm 149.0 137.0 149.0 137.0 149.0 137.0

k' 0.156 0.156 0.156 0.156 0.156 0.156

k 0.020 0.011 0.000 0.000 0.027 0.015

Z mm 141.6 130.2 141.6 130.2 141.6 130.2 3.4.4.4

As req mm²/m 290 150 0 0 386 201

As min mm²/m 228 228 228 228 228 228 Table 3.25

As deflection mm²/m 290 150 ~ ~ ~ ~

Ø mm 12 12 12 12 12 12

Layer B1 B2 T1 T2 T1 T2

@ mm 375 750 475 475 275 475

As prov mm²/m 302 151 238 238 411 238

= % 0.202 0.110 0.160 0.174 0.276 0.174 %

S max mm 459 423 459 423 459 423 Clause

Subclause (a) (a) (a) (a) (a) (a) 3.12.11.2.7

DEFLECTION

fs 295 306 0 0 288 258 Eqn 8

Mod factor 1.439 Eqn 7

Perm L/d 37.42 Actual L/d 15.44 As enhanced 0.0% for deflection control Table 3.10

TORSION STEEL BOTH EDGES DISCONTINUOUS ONE EDGE DISCONTINUOUS

Ø mm 10 X Y X Y

As req mm²/m 238 228 228 3.5.3.5

As prov T mm²/m 238 238 238

Additional As T req mm²/m 0 0 0 0

As prov B mm²/m 302 151 302 151

Bottom steel not curtailed in edge strips at free edges

SUPPORT REACTIONS (kN/m char uno) (See Figure 3.10) Sum ßvx = 1.015 Table 3.15

EDGE 1 EDGE 2 EDGE 3 EDGE 4 Sum ßvy = 0.660

1, F-G G, 2-1 2, F-G F, 2-1 equations

ßv 0.406 0.264 0.609 0.396 19 & 20

Dead kN/m 29.15 18.94 43.72 28.42

Imposed kN/m 2.34 1.52 3.50 2.28

Vs kN/m 44.5 29.0 66.8 43.4

OUTPUT/SUMMARY

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4

PROVIDE SPAN SPAN 1, F-G G, 2-1 2, F-G F, 2-1

MAIN STEEL T12 @ 375 B1 T12 @ 750 B2 T12 @ 475 T1 T12 @ 475 T2 T12 @ 275 T1 T12 @ 475 T2

ADDITIONAL 0 CORNER 2 CORNER 3 CORNER 4

TORSION STEEL 0 G1 G2 F2

X direction 0 placed in edge strips

Y direction 0

CHECKS BAR Ø SINGLY MIN MAX GLOBAL

Lx > Ly < COVER REINFORCED SPACING SPACING DEFLECTION STATUS

OK OK OK OK FAILS OK Fails on MAX SPACING,

Das könnte Ihnen auch gefallen

- RCC94 Two Way Slabs (Tables) MCY 1f ChillerDokument1 SeiteRCC94 Two Way Slabs (Tables) MCY 1f ChillerYati ChanNoch keine Bewertungen

- Steel and Its Heat Treatment: Bofors HandbookVon EverandSteel and Its Heat Treatment: Bofors HandbookBewertung: 2.5 von 5 Sternen2.5/5 (3)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument1 SeiteF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNoch keine Bewertungen

- Spreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68Dokument1 SeiteSpreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68roshan034Noch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia Ghica100% (1)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNoch keine Bewertungen

- Two-Way Slab V2Dokument4 SeitenTwo-Way Slab V2Eric AbedaniaNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument5 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675Noch keine Bewertungen

- 2 Way Slab DesignDokument3 Seiten2 Way Slab DesignAhmedNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument4 SeitenRCC94 Two-Way Slabs (Tables)HAFEELNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument5 SeitenRCC94 Two-Way Slabs (Tables)thusiNoch keine Bewertungen

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Dokument1 SeiteSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNoch keine Bewertungen

- PANEL08Dokument1 SeitePANEL08Isaac JosephNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument1 SeiteF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Ujol PraNoch keine Bewertungen

- Two-Way Solid Slabs - 1Dokument4 SeitenTwo-Way Solid Slabs - 1rizwanjawaid.meenaNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNoch keine Bewertungen

- 2way Slab Output by RCCDokument4 Seiten2way Slab Output by RCCSherwin PonsNoch keine Bewertungen

- 5 To 6: A To B: Aktar BalushiDokument1 Seite5 To 6: A To B: Aktar BalushimohammedNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument1 SeiteF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument5 SeitenRCC94 Two-Way Slabs (Tables)christi SNoch keine Bewertungen

- 5 To 6: A To B: Villa BECDokument1 Seite5 To 6: A To B: Villa BECmohammedNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument5 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument4 SeitenRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Dokument4 Seiten2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument3 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNoch keine Bewertungen

- Sammy Kamau Njunguna-1Dokument7 SeitenSammy Kamau Njunguna-1NewtonNoch keine Bewertungen

- 1st Floor 2 Way SlabDokument4 Seiten1st Floor 2 Way SlabOyelade MuyiwaNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables) - RS2Dokument1 SeiteRCC94 Two-Way Slabs (Tables) - RS2Arnold TunduliNoch keine Bewertungen

- 35m Tower CheckDokument68 Seiten35m Tower CheckHarold Jackson MtyanaNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument1 SeiteRCC94 Two-Way Slabs (Tables)curiosity12Noch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument3 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument5 SeitenRCC94 Two-Way Slabs (Tables)adelalwailyNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument5 SeitenRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3Noch keine Bewertungen

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDokument12 SeitenDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNoch keine Bewertungen

- TCC94 Two-Way Slabs (Tables)Dokument1 SeiteTCC94 Two-Way Slabs (Tables)Kojo AsareNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument3 SeitenRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNoch keine Bewertungen

- 5 To 6: A To B: Twin VillaDokument1 Seite5 To 6: A To B: Twin VillamohammedNoch keine Bewertungen

- Two-Way Slabs (Tables)Dokument5 SeitenTwo-Way Slabs (Tables)hala_azhariNoch keine Bewertungen

- TCC94 Two-Way Slabs (Tables)Dokument5 SeitenTCC94 Two-Way Slabs (Tables)Mario Sajulga Dela CuadraNoch keine Bewertungen

- Dimensions Materials Status: Spreadsheets To Eurocode 2Dokument1 SeiteDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNoch keine Bewertungen

- RCC94 Two-Way Slabs TablesDokument3 SeitenRCC94 Two-Way Slabs TablesjohnyNoch keine Bewertungen

- TCC94 Two Way Slabs TablesDokument5 SeitenTCC94 Two Way Slabs TablesMihai JNoch keine Bewertungen

- CALC SHEET ZOLA - CompressedDokument33 SeitenCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNoch keine Bewertungen

- Most Critical Interior PanelDokument1 SeiteMost Critical Interior PanelKagwi MauriceNoch keine Bewertungen

- 5 To 6: A To B: VillaDokument1 Seite5 To 6: A To B: VillamohammedNoch keine Bewertungen

- Our Critical Slab DesignDokument5 SeitenOur Critical Slab DesignIsmail AbdiNoch keine Bewertungen

- Two-Way Slab DesignDokument4 SeitenTwo-Way Slab DesignRaghNoch keine Bewertungen

- RCC92 Ribbed Slabs (Tables)Dokument9 SeitenRCC92 Ribbed Slabs (Tables)christi SNoch keine Bewertungen

- RCC95 Continuous Beams (Tables)Dokument8 SeitenRCC95 Continuous Beams (Tables)Felicia GhicaNoch keine Bewertungen

- Valid Design: Design of Two Way Slab (S-1)Dokument1 SeiteValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNoch keine Bewertungen

- RCC91 One-Way Solid Slabs (Tables)Dokument7 SeitenRCC91 One-Way Solid Slabs (Tables)RalfNoch keine Bewertungen

- RCC92 Ribbed Slabs (Tables)Dokument9 SeitenRCC92 Ribbed Slabs (Tables)Murthy GunaNoch keine Bewertungen

- RCC91 One-Way Solid Slabs (Tables)Dokument7 SeitenRCC91 One-Way Solid Slabs (Tables)ery achjariNoch keine Bewertungen

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Dokument7 Seiten1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNoch keine Bewertungen

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Dokument7 Seiten1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNoch keine Bewertungen

- RCC95 Continuous Beams (Tables)Dokument9 SeitenRCC95 Continuous Beams (Tables)Murthy GunaNoch keine Bewertungen

- Transformer Slab PDFDokument1 SeiteTransformer Slab PDFfdfsdfsNoch keine Bewertungen

- Bagan House Hotel: Column ScheduleDokument1 SeiteBagan House Hotel: Column ScheduleYati ChanNoch keine Bewertungen

- Group Room Steel Frame PDFDokument2 SeitenGroup Room Steel Frame PDFYati ChanNoch keine Bewertungen

- ETABS2Dokument1 SeiteETABS2Yati ChanNoch keine Bewertungen

- HT Win House-Nno PDFDokument2 SeitenHT Win House-Nno PDFYati ChanNoch keine Bewertungen

- Group Room Steel Frame PDFDokument2 SeitenGroup Room Steel Frame PDFYati ChanNoch keine Bewertungen

- RSE Exam Time RecordDokument3 SeitenRSE Exam Time RecordYati ChanNoch keine Bewertungen

- HT Win House-Nno PDFDokument2 SeitenHT Win House-Nno PDFYati ChanNoch keine Bewertungen

- HD11 Damped - MDOF - Modal Analysis PDFDokument24 SeitenHD11 Damped - MDOF - Modal Analysis PDFYati ChanNoch keine Bewertungen

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDokument2 SeitenProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNoch keine Bewertungen

- Hydrotest ScheduleDokument1 SeiteHydrotest ScheduleYati ChanNoch keine Bewertungen

- Rfi For r2-Gvb87Dokument3 SeitenRfi For r2-Gvb87Yati ChanNoch keine Bewertungen

- Pile Installation LetterDokument1 SeitePile Installation LetterYati ChanNoch keine Bewertungen

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDokument2 SeitenProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNoch keine Bewertungen

- Project Name: Hlaine Tet Hotel Project Location: Kyaike WineDokument2 SeitenProject Name: Hlaine Tet Hotel Project Location: Kyaike WineYati ChanNoch keine Bewertungen

- Master Schedule - KeysDokument1 SeiteMaster Schedule - KeysYati ChanNoch keine Bewertungen

- Exhibit Progress (19.may.2018)Dokument1 SeiteExhibit Progress (19.may.2018)Yati ChanNoch keine Bewertungen

- ETABS v9.7.1 - File: 20180523-4s Change Beam and Col - May 23,2018 17:44 Plan View - 2F - Elevation 360 - Kip-In UnitsDokument1 SeiteETABS v9.7.1 - File: 20180523-4s Change Beam and Col - May 23,2018 17:44 Plan View - 2F - Elevation 360 - Kip-In UnitsYati ChanNoch keine Bewertungen

- Plinth Beam PlanDokument1 SeitePlinth Beam PlanYati ChanNoch keine Bewertungen

- Plinth Beam PlanDokument1 SeitePlinth Beam PlanYati ChanNoch keine Bewertungen

- PE Part II Exam Application FormDokument1 SeitePE Part II Exam Application FormYati ChanNoch keine Bewertungen

- ETABS v9.7.1 - File: 20180216-6s - February 18,2018 21:05 Plan View - RF - Elevation 68 Point Loads (WY) - LB-FT UnitsDokument1 SeiteETABS v9.7.1 - File: 20180216-6s - February 18,2018 21:05 Plan View - RF - Elevation 68 Point Loads (WY) - LB-FT UnitsYati ChanNoch keine Bewertungen

- AQ MilestonesDokument1 SeiteAQ MilestonesYati ChanNoch keine Bewertungen

- ETABS v9.7.1 - File: 20180216-6s - February 18,2018 21:15 Plan View - 1F - Elevation 216 Shear Reinforcing (ACI 318-99) - Kip-In UnitsDokument1 SeiteETABS v9.7.1 - File: 20180216-6s - February 18,2018 21:15 Plan View - 1F - Elevation 216 Shear Reinforcing (ACI 318-99) - Kip-In UnitsYati ChanNoch keine Bewertungen

- ETABS v9.7.1 - File: 20180216-6s - February 18,2018 20:58 3-D View of GF Frame Span Loads GRAVITY (WALL) - LB-FT UnitsDokument1 SeiteETABS v9.7.1 - File: 20180216-6s - February 18,2018 20:58 3-D View of GF Frame Span Loads GRAVITY (WALL) - LB-FT UnitsYati ChanNoch keine Bewertungen

- Nget Pyaw Taw Bridge (150'-0" Span) at Nget Pyaw Taw Village, Kawa Township, Bago RegionDokument7 SeitenNget Pyaw Taw Bridge (150'-0" Span) at Nget Pyaw Taw Village, Kawa Township, Bago RegionYati ChanNoch keine Bewertungen

- 1F To 5F SlabDokument1 Seite1F To 5F SlabYati ChanNoch keine Bewertungen

- Typical Column Upto 2fDokument1 SeiteTypical Column Upto 2fYati ChanNoch keine Bewertungen

- Roof SectionDokument1 SeiteRoof SectionYati ChanNoch keine Bewertungen

- LCP LYCORDECK SpecificationDokument1 SeiteLCP LYCORDECK SpecificationYati ChanNoch keine Bewertungen

- A+B Area - For NnoDokument1 SeiteA+B Area - For NnoYati ChanNoch keine Bewertungen

- Site Analysis Requirements PDFDokument24 SeitenSite Analysis Requirements PDFmuthukumar0% (1)

- ListaDokument11 SeitenListaJean J. Pozis DiazNoch keine Bewertungen

- Wso2 Whitepaper Enterprise Integration Patterns With Wso2 Esb PDFDokument206 SeitenWso2 Whitepaper Enterprise Integration Patterns With Wso2 Esb PDFMrProkeskaNoch keine Bewertungen

- BladeSystem Firmware Update ProcedureDokument55 SeitenBladeSystem Firmware Update Procedurests100Noch keine Bewertungen

- ReleaseNotes 15.40.4463Dokument4 SeitenReleaseNotes 15.40.4463Other RhymsNoch keine Bewertungen

- Background To The General Method of Shear DesignDokument14 SeitenBackground To The General Method of Shear Designyyanan1118Noch keine Bewertungen

- PINE-4: Intelligent Ethernet Demarcation DeviceDokument4 SeitenPINE-4: Intelligent Ethernet Demarcation DeviceParikshit BhardwajNoch keine Bewertungen

- What Is A Plinth Beam - Its Purpose, Applications and Construction PDFDokument3 SeitenWhat Is A Plinth Beam - Its Purpose, Applications and Construction PDFnasirjamal33Noch keine Bewertungen

- HSDPA Throughput Optimization Case StudyDokument18 SeitenHSDPA Throughput Optimization Case StudySandeepNoch keine Bewertungen

- 0-rc129 All Method Stts (K) 50 PG (7nos)Dokument50 Seiten0-rc129 All Method Stts (K) 50 PG (7nos)chengkhNoch keine Bewertungen

- Reinforced Earth WallDokument9 SeitenReinforced Earth WallPayal MondalNoch keine Bewertungen

- Sonar 1Dokument13 SeitenSonar 1Geolo PertaNoch keine Bewertungen

- Cisco TwinGig Converter ModuleDokument4 SeitenCisco TwinGig Converter ModulemonchoNoch keine Bewertungen

- Learner's Activity Sheet: MAPEH Arts (Quarter I - Week 4B)Dokument6 SeitenLearner's Activity Sheet: MAPEH Arts (Quarter I - Week 4B)She Ena Man UelNoch keine Bewertungen

- Paragraph Headings Answer Discussion Pat 1Dokument2 SeitenParagraph Headings Answer Discussion Pat 1seanjustineNoch keine Bewertungen

- CIS 18 2018 Cons. Industry STD Dec 2017 1Dokument29 SeitenCIS 18 2018 Cons. Industry STD Dec 2017 1Siti Rosila Bt BaharinNoch keine Bewertungen

- FREQUENCY BANDS FOR 5G 5G-mmWave-benefitsDokument1 SeiteFREQUENCY BANDS FOR 5G 5G-mmWave-benefitsgameOverNoch keine Bewertungen

- Tempcon Sandwich Panel BrochureDokument10 SeitenTempcon Sandwich Panel BrochureskmeshramNoch keine Bewertungen

- 3GPP TS 04.60 V8.27.0Dokument315 Seiten3GPP TS 04.60 V8.27.0Bouziane BeldjilaliNoch keine Bewertungen

- BMC ProactiveNet Administrator GuideDokument582 SeitenBMC ProactiveNet Administrator GuideSadyNoch keine Bewertungen

- CADS - M Dense Sand Unreinforced Phi 40Dokument2 SeitenCADS - M Dense Sand Unreinforced Phi 40DavidNoch keine Bewertungen

- List of Dissertation Topics in Landscape ArchitectureDokument4 SeitenList of Dissertation Topics in Landscape ArchitectureNeedHelpWritingMyPaperSingaporeNoch keine Bewertungen

- Vicidial Multi-Server Manual by Poundteam v1 1Dokument25 SeitenVicidial Multi-Server Manual by Poundteam v1 1Elyin Martinez0% (1)

- Amazon Kindle Publishing GuidelinesDokument63 SeitenAmazon Kindle Publishing Guidelinesa_rogall7926Noch keine Bewertungen

- DP Biometric 14060 DriversDokument159 SeitenDP Biometric 14060 Driversberto_716Noch keine Bewertungen

- Metro MBQ Heated CabinetDokument2 SeitenMetro MBQ Heated Cabinetwsfc-ebayNoch keine Bewertungen

- Group Policy Adobe Acrobat Reader - Spiceworks PDFDokument5 SeitenGroup Policy Adobe Acrobat Reader - Spiceworks PDFEmilio MartinezNoch keine Bewertungen

- Vesda Pipe Network Design Guide 10193Dokument50 SeitenVesda Pipe Network Design Guide 10193Juan Martinez100% (1)

- Peter and Jane 10bDokument29 SeitenPeter and Jane 10blydia lydia100% (1)

- Cim Provider GR Manual ElxDokument13 SeitenCim Provider GR Manual ElxIlnomeCompletosNoch keine Bewertungen