Beruflich Dokumente

Kultur Dokumente

Thermaline 450

Hochgeladen von

gowtham_venkat_4100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

826 Ansichten2 Seitendsfsfs

Originaltitel

thermaline 450

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendsfsfs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

826 Ansichten2 SeitenThermaline 450

Hochgeladen von

gowtham_venkat_4dsfsfs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

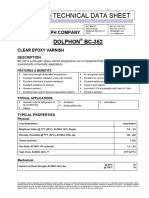

Thermaline® 450

Selection & Specification Data Substrates & Surface Preparation

Generic Type Amine-Cured Novolac Epoxy General Surfaces must be clean and dry. Employ

adequate methods to remove dirt, dust, oil

Description Highly cross-linked, glass flake-filled polymer and all other contaminants that could interfere

that offers exceptional barrier protection and with adhesion of the coating.

resistance to wet/dry cycling at elevated

temperatures. Suitable for insulated and non- Steel Non-Insulated: SSPC-SP6

insulated pipes, stacks and equipment operating Insulated: SSPC-SP10

up to 450°F (232°C). This coating provides Surface Profile: 2.0-3.0 mils (50-75 microns)

excellent resistance to corrosion, abrasion and

permeation, and its novolac-modification

resists severe chemical attack.

Performance Data

Features ƒ Temperature resistance up to 450°F (232°C)

ƒ High-build single-coat capabilities

ƒ Excellent resistance to thermal shock

ƒ Superior abrasion and chemical

Test Method System Results Report #

resistance

through internal reinforcement ASTM D3359 Blasted Steel

4A 08460

ƒ Ambient-temperature cure Adhesion 2 cts. 450

ƒ VOC compliant to current AIM regulations 171 mg loss after 1000

ASTM D4060 Blasted Steel

cycles; CS17 wheel, 02910

Abrasion 2 cts. 450

1000 gram load

Color Red , Grey are standard colors, also available in

other shades as per Carboline , RAL and IS ASTM D2794 Blasted Steel .375 in. from damaged

02675

Impact 1 ct. 450 area. 100-in./lbs

shade Cards .

No cracking, blistering or

Finish Eggshell delamination of film after

425°F for 1 hr/ambient/

Heat Cycling Blasted Steel

-10°F for 24 hrs/ambient/ SR342

Primers Self-priming. May be applied over epoxies and Test 1 ct. 450

425°F for 24 hrs/ambient/

phenolics. -10°F for 24 hrs/ambient/

425°F for 200 hr/ambient

Topcoats Epoxies, Polyurethanes

Modified No effect to coating film

NACE Std. Blasted Steel except discoloration after

Dry Film 8.0-10.0 mils (200-250 microns) 02551

TM-01-74B 2 cts. 450 6 month exposure,

Thickness Do not exceed 15 mils (375 microns) per coat. Immersion Deionized water

Resistant to fumes of

Solids Content By Volume: 70% ± 2% commons acids, alkalis,

2 2

solvents and

Theoretical 1117 mil ft (27.9 m /l at 25 microns) hydrocarbon compounds. SR 359

Coverage Rate Allow for loss in mixing and application Chemical Blasted Steel Resistant to splash and 02735

Resistance 1 ct. 450 spillage of alkalis, 03133

VOC Values As supplied: 2.08 lbs/gal (250 g/l) solvents and 02794

hydrocarbons. Acid

Thinned:

contact may cause

13 oz/gal w/ #213: 2.58 lbs/gal (308 g/l) discoloration of coating.

13 oz/gal w/#2 2.54 lbs/gal (305 g/l)

Test reports and additional data available upon written request.

These are nominal values.

Dry Temp. Continuous: 425°F (218°C)

Resistance Non-Continuous: 450°F (232°C)

Discoloration and loss of gloss may be observed

above 200°F (93°C).

Limitations Epoxies lose gloss, discolor and eventually chalk

in sunlight exposure.

June 2006 replaces June 2005 0928

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER W ARRANTY OR GUARANTEE OF ANY KIND IS MADE BY

CARBOLINE, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERW ISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline® and

Thermaline® are registered trademarks of Carboline Company.

Thermaline® 450

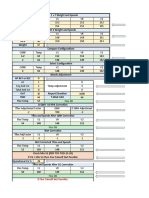

Application Equipment Application Conditions

Listed below are general equipment guidelines for the application of this product.

Job site conditions may require modifications to these guidelines to achieve the

Condition Material Surface Ambient Humidity

desired results. 65°-85°F 65°-85°F 65°-85°F

General Guidelines: Normal 30-60%

(18°-29°C) (18°-29°C) (18°-29°C)

Spray Application The following spray equipment has been found suitable 55°F 50°F 50°F

(General) and is available from manufacturers such as Binks, Minimum 0%

(13°C) (10°C) (10°C)

DeVilbiss and Graco.

90°F 110°F 100°F

Maximum 85%

Conventional Pressure pot equipped with dual regulators, ½” I.D. (32°C) (43°C) (38°C)

Spray minimum material hose, .110” I.D. fluid tip and

This product simply requires the substrate temperature to be above the dew

appropriate air cap.

point. Condensation due to substrate temperatures below the dew point can

Airless Spray Pump Ratio: 45:1 (min.)* cause flash rusting on prepared steel and interfere with proper adhesion to

GPM Output: 3.0 (min.) the substrate. Special application techniques may be required above

Material Hose: ½” I.D. (min.) or below normal application conditions.

Tip Size: .035-.041”

Output PSI: 2200-2500

*Teflon packings are recommended and available from Curing Schedule

the pump manufacturer.

Surface Temp.

Brush For striping of welds and touch-up of small areas only. Dry to Dry to Topcoat w/ Final

& 50% Relative

Use a medium natural bristle brush and Handle Other Finishes Cure

Humidity

avoid rebrushing.

50°F (10°C) 18 Hours 48 Hours 21 Days

Roller Not recommended.

60°F (16°C) 12 Hours 32 Hours 14 Days

Mixing & Thinning 75°F (24°C) 6 Hours 16 Hours 7 Days

90°F (32°C) 3 Hours 8 Hours 4 Days

Mixing Power mix separately, then combine and power mix.

DO NOT MIX PARTIAL KITS.

These times are based on a 10.0 mil (250 micron) dry film thickness. Higher

film thickness, insufficient ventilation or cooler temperatures will

Ratio 4:1 Ratio (A to B) require longer cure times and could result in solvent entrapment and

premature failure. Excessive humidity or condensation on the surface

Thinning May be thinned up to 13 oz/gal (10%) with Thinner during curing can interfere with the cure, can cause discoloration and

#213. For application on horizontal surfaces, may be may result in a surface haze. Any haze or blush must be removed by

thinned up to 13 oz/gal (10)% with Thinner #2. Agitate water washing before recoating. During high humidity conditions, it is

Thinner #213 before use. Thinner #213 will have a thick recommended that the application be done while temperatures are

viscous appearance which is normal. Use of increasing. If the final cure time is exceeded, the surface must be

thinners other than those supplied by Carboline may abraded by sweep blasting prior to the application of additional coats.

adversely affect product performance and void

product warranty, whether expressed or implied.

Packaging, Handling & Storage

Pot Life 3 Hours at 75°F (24°C). Pot life ends when coating

loses body and begins to sag. Pot life times will be less Shipping Weight 1 Gallon Kit 5 Gallon Kit

at higher temperatures.

(Approximate) 12 lbs (6 kg) 58 lbs (26 kg)

Cleanup & Safety Flash Point (Setaflash) Part A: 53°F (12°C)

Part B: >200°F (93°C)

Cleanup Use Thinner #2 or Acetone. In case of spillage, absorb

and dispose of in accordance with local applicable Storage (General) Store Indoors.

regulations.

Storage Temperature 40° - 110°F (4°-43°C)

Safety Read and follow all caution statements on this product & Humidity 0-90% Relative Humidity

data sheet and on the MSDS for this product.

Employ

normal workmanlike safety precautions. Hypersensitive Shelf Life Part A & B: Min. 36 months at 75°F (24°C)

persons should wear protective clothing, gloves and use

protective cream on face, hands and all exposed areas. *Shelf Life: (actual stated shelf life) when kept at

Ventilation When used in enclosed areas, thorough air

recommended storage conditions and in original

circulation must be used during and after unopened containers.

application until the coating is cured. The

ventilation system should be capable of preventing

the solvent vapor concentration from reaching the lower

explosion limit for the solvents used. User should test

and monitor exposure levels to insure all personnel are

below guidelines. If not sure or if not able to monitor

levels, use MSHA/NIOSH approved supplied air

respirator.

Caution This product contains flammable solvents. Keep

away from sparks and open flames. All electrical

equipment and installations should be made and

grounded in accordance with the National Electric

Code. In areas where explosion hazards exist,

workmen should be required to use non-ferrous tools

and wear conductive and non-sparking shoes.

June 2006 replaces June 2005

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER W ARRANTY OR GUARANTEE OF ANY KIND IS MADE BY

CARBOLINE, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERW ISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline® and

Thermaline® are registered trademarks of Carboline Company.

Das könnte Ihnen auch gefallen

- Mineral Wool Pipe InsulationDokument4 SeitenMineral Wool Pipe InsulationMiguel Martinez GuerreroNoch keine Bewertungen

- Carboguard 890 PDSDokument5 SeitenCarboguard 890 PDScrisNoch keine Bewertungen

- Rti Prorox WM 940 Es ExpDokument1 SeiteRti Prorox WM 940 Es ExpMadiaw NajaNoch keine Bewertungen

- Sanitile 120 PDSDokument4 SeitenSanitile 120 PDSDuongthithuydungNoch keine Bewertungen

- Carboguard 893: Selection & Specification DataDokument5 SeitenCarboguard 893: Selection & Specification DataQuy RomNoch keine Bewertungen

- Colmonoy 5-S Data SheetDokument2 SeitenColmonoy 5-S Data SheetLuis Hernandez0% (1)

- Almasol 2002 LEDokument2 SeitenAlmasol 2002 LEUdit JainNoch keine Bewertungen

- Carboguard 893 PDSDokument2 SeitenCarboguard 893 PDSNguyễn Thị Châu TâyNoch keine Bewertungen

- Carboguard 890 PDSDokument5 SeitenCarboguard 890 PDSAchraf BoudayaNoch keine Bewertungen

- 1 Ceramic Fiber BoardsDokument2 Seiten1 Ceramic Fiber BoardsMahesh MishraNoch keine Bewertungen

- Hoja Tecnica Amerlock 400 PDFDokument3 SeitenHoja Tecnica Amerlock 400 PDFJesy M. Maldonado SalinasNoch keine Bewertungen

- Technical Data: Impact Grease / TackyDokument3 SeitenTechnical Data: Impact Grease / TackyRodrigo RiosNoch keine Bewertungen

- Royal 876 EP GreaseDokument3 SeitenRoyal 876 EP GreaseVictor ZhicayNoch keine Bewertungen

- Technical Insulation Heavy Duty Wired MatDokument2 SeitenTechnical Insulation Heavy Duty Wired Matwassim nasriNoch keine Bewertungen

- 3750-3752 Product InfoDokument2 Seiten3750-3752 Product InfoVendy KurniawanNoch keine Bewertungen

- TDS Fosroc Polyurea WH 200 IndiaDokument4 SeitenTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraNoch keine Bewertungen

- Atlas Grade Datasheet 410 Rev May 2008Dokument2 SeitenAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNoch keine Bewertungen

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDokument2 SeitenSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNoch keine Bewertungen

- Molylube Extreme Pressure High Viscosity GreaseDokument2 SeitenMolylube Extreme Pressure High Viscosity GreaseGilmer Williams Cáceres BenaventeNoch keine Bewertungen

- BPXE-94C7V8Dokument3 SeitenBPXE-94C7V8Banti SidhiwalaNoch keine Bewertungen

- AÇOS VILLARES VF800-AT - InglesDokument2 SeitenAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- Carboguard 893 PDSDokument5 SeitenCarboguard 893 PDSTrịnh Minh KhoaNoch keine Bewertungen

- Product 266: Technical Data SheetDokument2 SeitenProduct 266: Technical Data SheetFabio ParceroNoch keine Bewertungen

- Carboguard 893 PDSDokument5 SeitenCarboguard 893 PDSUtomoNoch keine Bewertungen

- Loctite EA 3476: Technical Data SheetDokument4 SeitenLoctite EA 3476: Technical Data SheetKarsa SambasNoch keine Bewertungen

- Phenoline 187 Primer and FinishDokument2 SeitenPhenoline 187 Primer and Finish이선엽Noch keine Bewertungen

- Bitumastic 300 MDokument2 SeitenBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Prorox WM 960 Sa PDFDokument1 SeiteProrox WM 960 Sa PDFr afriantoNoch keine Bewertungen

- Ceran-Xm-220 TDS v171128Dokument2 SeitenCeran-Xm-220 TDS v171128phucdc095041Noch keine Bewertungen

- Fibra de VidrioDokument2 SeitenFibra de VidrioLuis Eduardo Champi sullcaNoch keine Bewertungen

- Resicoat V - F R4 ESDokument3 SeitenResicoat V - F R4 ESABHISHEK SINGHNoch keine Bewertungen

- Ficha Tecnicas Royal Hammer Paste PDS XDokument2 SeitenFicha Tecnicas Royal Hammer Paste PDS XAndres AgudeloNoch keine Bewertungen

- Dol_BC352Dokument2 SeitenDol_BC352Jerry Mar LucenaNoch keine Bewertungen

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDokument5 SeitenHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNoch keine Bewertungen

- RW Ti Pds Prorox Ps 970 Astm IndiaDokument1 SeiteRW Ti Pds Prorox Ps 970 Astm IndiaLee Kok RoyNoch keine Bewertungen

- LEXANDokument2 SeitenLEXANYAKOVNoch keine Bewertungen

- İlocut 315Dokument2 Seitenİlocut 315Vusal HasanovNoch keine Bewertungen

- Zylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Dokument3 SeitenZylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Fernando Garcia HiguitaNoch keine Bewertungen

- Carbozinc 11 HS PDSDokument2 SeitenCarbozinc 11 HS PDSvietrossNoch keine Bewertungen

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNoch keine Bewertungen

- BR-352-TDSDokument2 SeitenBR-352-TDSJerry Mar LucenaNoch keine Bewertungen

- Amerlock 400: Product Data/ Application InstructionsDokument4 SeitenAmerlock 400: Product Data/ Application InstructionsPedro Nelvedir Barrera CelyNoch keine Bewertungen

- Silicone Compound Dm-2: Moisture Proofing Sealant & LubricantDokument1 SeiteSilicone Compound Dm-2: Moisture Proofing Sealant & LubricantvarunchNoch keine Bewertungen

- SW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFDokument2 SeitenSW13494 - Heat-Flex - 3500. Loai Thay The Bao On PDFtienNoch keine Bewertungen

- Honilo OilDokument2 SeitenHonilo Oilpiston brokeNoch keine Bewertungen

- 993 STRL Glazing Sealant-Product InfoDokument4 Seiten993 STRL Glazing Sealant-Product InfocurlyjockeyNoch keine Bewertungen

- Bestolife 72733Dokument1 SeiteBestolife 72733raseen pNoch keine Bewertungen

- PTRSSERIESDokument1 SeitePTRSSERIESAILTON ORIEDROCNoch keine Bewertungen

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDokument4 SeitenProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNoch keine Bewertungen

- Akfix Eng Technical Catalog 2022 Rev16Dokument211 SeitenAkfix Eng Technical Catalog 2022 Rev16ahmed.serefNoch keine Bewertungen

- E Shield6421 Datasheet PDFDokument1 SeiteE Shield6421 Datasheet PDFYo ANoch keine Bewertungen

- Rockwool Slab SL930Dokument1 SeiteRockwool Slab SL930Lee Kok RoyNoch keine Bewertungen

- Fosroc Polyurea WH 200Dokument4 SeitenFosroc Polyurea WH 200Arun KumarNoch keine Bewertungen

- Prorox SL 950 SaDokument1 SeiteProrox SL 950 SaHardiman ArbiNoch keine Bewertungen

- PPA 571 EsDokument4 SeitenPPA 571 EsRohit Sangwan0% (1)

- Product Data: Sealants, IncDokument2 SeitenProduct Data: Sealants, IncSantoshNoch keine Bewertungen

- Prorox WM 950 SaDokument1 SeiteProrox WM 950 SaHanief AnsharNoch keine Bewertungen

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Dokument2 SeitenPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation EditionDokument3 SeitenPDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Editiongowtham_venkat_4Noch keine Bewertungen

- Caltech - Coatem NF6Dokument1 SeiteCaltech - Coatem NF6gowtham_venkat_4Noch keine Bewertungen

- FDA 21 CFR Part 11 Compliance DocumentDokument15 SeitenFDA 21 CFR Part 11 Compliance DocumentRamón CéspedNoch keine Bewertungen

- WHO 2019 Ncov IPC - Masks 2020.4 Eng PDFDokument16 SeitenWHO 2019 Ncov IPC - Masks 2020.4 Eng PDFSyed DanishNoch keine Bewertungen

- Indian Standard875Dokument10 SeitenIndian Standard875Mohammad Tawfiq WaraNoch keine Bewertungen

- QA & QC Shift Details - February 2021Dokument2 SeitenQA & QC Shift Details - February 2021gowtham_venkat_4Noch keine Bewertungen

- Staff Details - SANKARANDokument1 SeiteStaff Details - SANKARANgowtham_venkat_4Noch keine Bewertungen

- Untitled DiagramDokument1 SeiteUntitled Diagramgowtham_venkat_4Noch keine Bewertungen

- Staff Details - GOWTHAMDokument1 SeiteStaff Details - GOWTHAMgowtham_venkat_4Noch keine Bewertungen

- Thermaline 4700: Selection & Specification DataDokument4 SeitenThermaline 4700: Selection & Specification Datagowtham_venkat_4Noch keine Bewertungen

- FlowcharTDokument1 SeiteFlowcharTgowtham_venkat_4Noch keine Bewertungen

- Respirator Vs Surgical Mask Flyer - Final PDFDokument2 SeitenRespirator Vs Surgical Mask Flyer - Final PDFshanu khanNoch keine Bewertungen

- Supply and Fabrication Steel Structures SpecificationDokument18 SeitenSupply and Fabrication Steel Structures Specificationgowtham_venkat_4Noch keine Bewertungen

- Is 2830 1992Dokument9 SeitenIs 2830 1992Sunny SaparNoch keine Bewertungen

- Properties of Common AbrasivesDokument1 SeiteProperties of Common Abrasivesgowtham_venkat_4Noch keine Bewertungen

- VSM 1Dokument1 SeiteVSM 1gowtham_venkat_4Noch keine Bewertungen

- Indian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksDokument15 SeitenIndian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksjndlsmtNoch keine Bewertungen

- Avesta Welding ManualDokument300 SeitenAvesta Welding Manual66apenlullenNoch keine Bewertungen

- Nitric Acid Manufacturing ProcessDokument7 SeitenNitric Acid Manufacturing ProcessLenin PrabhuNoch keine Bewertungen

- Weldability of High Performance SteelsDokument16 SeitenWeldability of High Performance Steelsgowtham_venkat_4Noch keine Bewertungen

- Surface Preparation Standards OverviewDokument38 SeitenSurface Preparation Standards OverviewEric So100% (1)

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDokument6 SeitenGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4Noch keine Bewertungen

- Pregatirea Suprafetelor Pentru VopsireDokument4 SeitenPregatirea Suprafetelor Pentru VopsireValentin GalbenNoch keine Bewertungen

- VSM For Job No J1947 A1 Time Log SheetDokument6 SeitenVSM For Job No J1947 A1 Time Log Sheetgowtham_venkat_4Noch keine Bewertungen

- 1 .ASM HandbookDokument3 Seiten1 .ASM Handbookgowtham_venkat_40% (2)

- Threads Standard Reference Guide Rev4 PDFDokument21 SeitenThreads Standard Reference Guide Rev4 PDFPham CongNoch keine Bewertungen

- Flow Side Asy LHDokument1 SeiteFlow Side Asy LHgowtham_venkat_4Noch keine Bewertungen

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDokument1 SeiteEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4Noch keine Bewertungen

- Cosmos Products: Technical Service Data SheetDokument1 SeiteCosmos Products: Technical Service Data Sheetgowtham_venkat_4Noch keine Bewertungen

- 21055-Acoustics India - 15nosDokument27 Seiten21055-Acoustics India - 15nosgowtham_venkat_4Noch keine Bewertungen

- COE 107.04 Cathodic Protection Monitoring Instruments and ProceduresDokument42 SeitenCOE 107.04 Cathodic Protection Monitoring Instruments and ProceduresMo'tasem Serdaneh100% (1)

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDokument5 SeitenPlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraNoch keine Bewertungen

- Mahusay Module 4 Acc3110Dokument2 SeitenMahusay Module 4 Acc3110Jeth MahusayNoch keine Bewertungen

- C146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandDokument12 SeitenC146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandAhmed AlzubaidiNoch keine Bewertungen

- Balino, Shedina D. Beed 2-CDokument5 SeitenBalino, Shedina D. Beed 2-CSHEDINA BALINONoch keine Bewertungen

- Bucket Elevators GuideDokument20 SeitenBucket Elevators GuideLeonardo De la CruzNoch keine Bewertungen

- Types of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaDokument7 SeitenTypes of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaJimnadominicNoch keine Bewertungen

- SPMPDokument39 SeitenSPMPAnkitv PatelNoch keine Bewertungen

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityDokument2 SeitenEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantNoch keine Bewertungen

- EPABX User's Guide for Making Calls and Using FeaturesDokument4 SeitenEPABX User's Guide for Making Calls and Using FeaturesPraveen KumarNoch keine Bewertungen

- Standard 2Dokument10 SeitenStandard 2Bridget GumboNoch keine Bewertungen

- Magazine 55 EnglishPartDokument50 SeitenMagazine 55 EnglishPartAli AwamiNoch keine Bewertungen

- Presostatos KPI 1Dokument10 SeitenPresostatos KPI 1Gamaliel QuiñonesNoch keine Bewertungen

- How To Think Like Leonarda Da VinciDokument313 SeitenHow To Think Like Leonarda Da VinciAd Las94% (35)

- Telescopic sight basics and reticle typesDokument18 SeitenTelescopic sight basics and reticle typesKoala LumpurNoch keine Bewertungen

- ButeDokument89 SeitenButeNassime AmnNoch keine Bewertungen

- Reliance - Formulas & Calculations PDFDokument5 SeitenReliance - Formulas & Calculations PDFkrishbistNoch keine Bewertungen

- Phil of DepressDokument11 SeitenPhil of DepressPriyo DjatmikoNoch keine Bewertungen

- Cylindrical Plug Gage DesignsDokument3 SeitenCylindrical Plug Gage DesignskkphadnisNoch keine Bewertungen

- Process Strategy PPT at BEC DOMSDokument68 SeitenProcess Strategy PPT at BEC DOMSBabasab Patil (Karrisatte)100% (1)

- A Data-Based Reliability Analysis of ESPDokument19 SeitenA Data-Based Reliability Analysis of ESPfunwithcubingNoch keine Bewertungen

- Hydro Cyclone: Centripetal Force Fluid ResistanceDokument10 SeitenHydro Cyclone: Centripetal Force Fluid ResistanceMaxwell ToffahNoch keine Bewertungen

- Follow The Directions - GR 1 - 3 PDFDokument80 SeitenFollow The Directions - GR 1 - 3 PDFUmmiIndia100% (2)

- Field Behaviour of Stiffened Deep Cement Mixing PilesDokument17 SeitenField Behaviour of Stiffened Deep Cement Mixing PilesNguyen Quoc KhanhNoch keine Bewertungen

- TFT-LCD TV/MONITOR SERVICE MANUALDokument54 SeitenTFT-LCD TV/MONITOR SERVICE MANUALhimkoNoch keine Bewertungen

- Noam Text ליגר טסקט םעֹנDokument20 SeitenNoam Text ליגר טסקט םעֹנGemma gladeNoch keine Bewertungen

- Nursing ProcessDokument88 SeitenNursing ProcessGerard On LineNoch keine Bewertungen

- Research Proposal of SheepDokument37 SeitenResearch Proposal of SheepDabalo Garama67% (3)

- Ichiban Ushiro No Daimaou Act 7Dokument161 SeitenIchiban Ushiro No Daimaou Act 7Haif Al HajrafNoch keine Bewertungen

- A320 Flex CalculationDokument10 SeitenA320 Flex CalculationMansour TaoualiNoch keine Bewertungen