Beruflich Dokumente

Kultur Dokumente

Punching Shear Calculation AS Per ACI - 318

Hochgeladen von

Mohammed SumerOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Punching Shear Calculation AS Per ACI - 318

Hochgeladen von

Mohammed SumerCopyright:

Verfügbare Formate

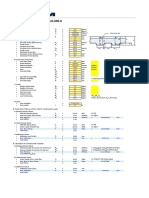

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE ACI 318-08 RC-PN-001

Slab Punching Shear Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab punching shear design in SAFE.

The numerical example is a flat slab that has three 24-foot-long spans in each

direction, as shown in Figure 1.

A B C D

1' 24' 24' 24' 1'

2'

4 17 18 19 20

10" thick flat slab

24'

13 14 15

3

Columns are 12" x 36"

24' with long side parallel

to the Y-axis, typical

9 10 11 12

2 Concrete Properties

Unit weight = 150 pcf

f'c = 4000 psi

24'

Y Loading

DL = Self weight + 20 psf

5 X 6 7 8 LL = 80 psf

1

2'

Figure 1: Flat Slab For Numerical Example

EXAMPLE ACI 318-08 RC-PN-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

The slab overhangs the face of the column by 6 inches along each side of the

structure. The columns are typically 12 inches wide by 36 inches long, with the

long side parallel to the Y-axis. The slab is typically 10 inches thick. Thick plate

properties are used for the slab.

The concrete has a unit weight of 150 pcf and an f 'c of 4000 psi. The dead load

consists of the self weight of the structure plus an additional 20 psf. The live load

is 80 psf.

TECHNICAL FEATURES OF SAFE TESTED

Calculation of punching shear capacity, shear stress, and D/C ratio.

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE punching shear capacity, shear stress

ratio, and D/C ratio with the punching shear capacity, shear stress ratio and D/C

ratio obtained by the analytical method. They match exactly for this example.

Table 1 Comparison of Design Results for Punching

Shear at Grid B-2

Shear Stress Shear Capacity

Method (ksi) (ksi) D/C ratio

SAFE 0.1930 0.158 1.22

Calculated 0.1930 0.158 1.22

COMPUTER FILE: ACI 318-08 RC-PN-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE ACI 318-08 RC-PN-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

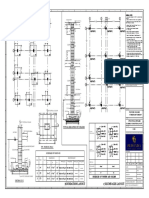

HAND CALCULATION

Hand Calculation for Interior Column Using SAFE Method

d = [(10 - 1) + (10 - 2)] / 2 = 8.5"

Refer to Figure 2.

b0 = 44.5 + 20.5 + 44.5 + 20.5 = 130"

20.5"

Y

Critical section for

4.25" 6" 6" 4.25"

punching shear shown

dashed.

A B

Column Side 2

4.25"

18"

Side 1

Side 3

X

44.5"

Center of column is

18"

point (x1, y1). Set

this equal to (0,0).

4.25"

Side 4

D

C

Figure 2: Interior Column, Grid B-2 in SAFE Model

V2 1

1

0.4955

2 44.5

1

3 20.5

V3 1

1

0.3115

2 20.5

1

3 44.5

The coordinates of the center of the column (x1, y1) are taken as (0, 0).

EXAMPLE ACI 318-08 RC-PN-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

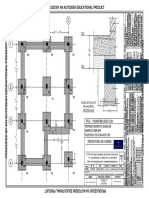

The following table is used for calculating the centroid of the critical section for

punching shear. Side 1, Side 2, Side 3, and Side 4 refer to the sides of the critical

section for punching shear, as identified in Figure 2.

Item Side 1 Side 2 Side 3 Side 4 Sum

x2 10.25 0 10.25 0 N.A.

y2 0 22.25 0 22.25 N.A.

L 44.5 20.5 44.5 20.5 b0 = 130

d 8.5 8.5 8.5 8.5 N.A.

Ld 378.25 174.25 378.25 174.25 1105

Ldx2 3877.06 0 3877.06 0 0

Ldy2 0 3877.06 0 3877.06 0

x3

Ldx 2

0

0"

Ld 1105

y3

Ldy 2

0

0"

Ld 1105

The following table is used to calculate IXX, IYY and IXY. The values for IXX, IYY and IXY

are given in the “Sum” column.

Item Side 1 Side 2 Side 3 Side 4 Sum

L 44.5 20.5 44.5 20.5 N.A.

d 8.5 8.5 8.5 8.5 N.A.

x2 - x3 10.25 0 10.25 0 N.A.

y2 - y3 0 22.25 0 22.25 N.A.

Parallel to Y-Axis X-axis Y-Axis X-axis N.A.

Equations 5b, 6b, 7 5a, 6a, 7 5b, 6b, 7 5a, 6a, 7 N.A.

IXX 64696.5 86264.6 64696.5 86264.6 301922.3

IYY 39739.9 7151.5 39739.9 7151.5 93782.8

IXY 0 0 0 0 0

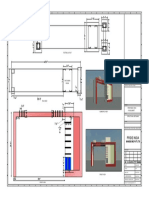

From the SAFE output at Grid B-2:

VU = 189.45 k

V 2 M U 2 = 156.39 k-in

V 3 M U 3 = 91.538 k-in

EXAMPLE ACI 318-08 RC-PN-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

At the point labeled A in Figure 2, x4 = 10.25 and y4 = 22.25, thus:

189.45 156.39 93782.8 22.25 0 0 10.25 0

vU

130 8.5 (301922.3)(93782.8) (0) 2

91.538 301922.3 10.25 0 0 22.25 0

301922.3 93782.8 0 2

vU = 0.1714 0.0115 0.0100 = 0.1499 ksi at point A

At the point labeled B in Figure 2, x4 = 10.25 and y4 = 22.25, thus:

189.45 156.39 93782.8 22.25 0 0 10.25 0

vU

130 8.5 301922.3 93782.8 0 2

91.538 301922.3 10.25 0 0 22.25 0

301922.3 93782.8 0 2

vU = 0.1714 0.0115 + 0.0100 = 0.1699 ksi at point B

At the point labeled C in Figure 2, x4 = 10.25 and y4 = 22.25, thus:

189.45 156.39 93782.8 22.25 0 0 10.25 0

vU

130 8.5 301922.3 93782.8 0 2

91.538 301922.3 10.25 0 0 22.25 0

301922.3 93782.8 0 2

vU = 0.1714 + 0.0115 + 0.0100 = 0.1930 ksi at point C

At the point labeled D in Figure 2, x4 = 10.25 and y4 = 22.25, thus:

189.45 156.39 93782.8 22.25 0 0 10.25 0

vU

130 8.5 301922.3 93782.8 0 2

91.538 301922.3 10.25 0 0 22.25 0

301922.3 93782.8 0 2

vU = 0.1714 + 0.0115 - 0.0100 = 0.1729 ksi at point D

EXAMPLE ACI 318-08 RC-PN-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

Point C has the largest absolute value of vu, thus vmax = 0.1930 ksi

The shear capacity is calculated based on the smallest of ACI 318-08 equations 11-34,

11-35 and 11-36 with the b0 and d terms removed to convert force to stress.

4

0.75 2 4000

vC 36 /12

0.158 ksi in accordance with equation 11-34

1000

40 8.5

0.75 2 4000

vC 130 0.219 ksi in accordance with equation 11-35

1000

0.75 4 4000

vC 0.190 ksi in accordance with equation 11-36

1000

Equation 11-34 yields the smallest value of vC = 0.158 ksi and thus this is the shear

capacity.

vU 0.193

Shear Ratio 1.22

vC 0.158

EXAMPLE ACI 318-08 RC-PN-001 - 6

Das könnte Ihnen auch gefallen

- 10 Essential Books For Active TradersDokument6 Seiten10 Essential Books For Active TradersChrisTheodorou100% (2)

- Fence Calculation FinalDokument200 SeitenFence Calculation FinalMohamed HassanNoch keine Bewertungen

- Steel Corbel Design For Truss SupportDokument3 SeitenSteel Corbel Design For Truss Supportriyazkader100% (1)

- LicencesDokument5 SeitenLicencesstopnaggingmeNoch keine Bewertungen

- Typical Anchor BoltsDokument33 SeitenTypical Anchor BoltslucianduNoch keine Bewertungen

- DECKSLABDokument13 SeitenDECKSLABASQ100% (1)

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Dokument15 SeitenDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- Composite Slab DesignDokument6 SeitenComposite Slab DesignFranklyn GenoveNoch keine Bewertungen

- Design of Composite BeamDokument7 SeitenDesign of Composite BeamMohammed SumerNoch keine Bewertungen

- Wind Load Calculation As Per Euro Code: Input DetailsDokument2 SeitenWind Load Calculation As Per Euro Code: Input DetailsAsaru Deen100% (1)

- RC Corbel Design (ACI318)Dokument2 SeitenRC Corbel Design (ACI318)Emad KhanNoch keine Bewertungen

- Design of One Way SlabDokument2 SeitenDesign of One Way Slabpathan is khanNoch keine Bewertungen

- Rectangular Concrete Beam Analysis - Design Per ACI 318-99Dokument20 SeitenRectangular Concrete Beam Analysis - Design Per ACI 318-99Anonymous w5SJiLs100% (1)

- Session4 Automotive Front End DesignDokument76 SeitenSession4 Automotive Front End DesignShivprasad SavadattiNoch keine Bewertungen

- Labone Office Complex Structural Design Report Rev 01 PDFDokument99 SeitenLabone Office Complex Structural Design Report Rev 01 PDFBoris Escubio100% (1)

- Anchor Bolt - ACIDokument10 SeitenAnchor Bolt - ACIYatendra TyagiNoch keine Bewertungen

- Design Non-Composite Deck SlabDokument1 SeiteDesign Non-Composite Deck SlabNobitaKunNoch keine Bewertungen

- ANCHOR - REINFORCEMENT (Metric)Dokument10 SeitenANCHOR - REINFORCEMENT (Metric)Tarek AbulailNoch keine Bewertungen

- Staad Input ParametersDokument3 SeitenStaad Input Parametersdesikudi90000% (1)

- Sample Cross-Complaint For Indemnity For CaliforniaDokument4 SeitenSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Chequered DesignDokument2 SeitenChequered DesignSaravana N100% (1)

- Reinforcing Bar Development and Splice Lengths ACI 318-11Dokument8 SeitenReinforcing Bar Development and Splice Lengths ACI 318-11lucianduNoch keine Bewertungen

- Rigid Pavement DesignDokument8 SeitenRigid Pavement Designisaacjoe77Noch keine Bewertungen

- RCC92 Ribbed Slabs (Tables)Dokument8 SeitenRCC92 Ribbed Slabs (Tables)lucianduNoch keine Bewertungen

- Column Base Plate Design PDFDokument2 SeitenColumn Base Plate Design PDFDrewNoch keine Bewertungen

- Isolated Footing Design (ACI 318-14) - Metric: Footing No. Group ID Foundation Geometry - Length Width ThicknessDokument48 SeitenIsolated Footing Design (ACI 318-14) - Metric: Footing No. Group ID Foundation Geometry - Length Width ThicknessRoberto BautistaNoch keine Bewertungen

- Design Calculation of Signage Foundation 24-11-18Dokument13 SeitenDesign Calculation of Signage Foundation 24-11-18syed saleemNoch keine Bewertungen

- Foundation Design: Theory and PracticeVon EverandFoundation Design: Theory and PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- MV Lec PDFDokument102 SeitenMV Lec PDFJonas Datu100% (1)

- Post-Tensioned Slab Design ExampleDokument9 SeitenPost-Tensioned Slab Design ExampleLaura ManolacheNoch keine Bewertungen

- PAEC2016 - Rect. Beam Analysis Using ACI 318-14Dokument24 SeitenPAEC2016 - Rect. Beam Analysis Using ACI 318-14Sayavi Nicole Sayavi NickNoch keine Bewertungen

- Check For Requirement of Boundary ElementDokument9 SeitenCheck For Requirement of Boundary ElementJai ThakkarNoch keine Bewertungen

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDokument9 SeitenACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezNoch keine Bewertungen

- Rebars Splice and Column RebarDokument11 SeitenRebars Splice and Column RebarIrfan KhanNoch keine Bewertungen

- Design Calculation of PavementDokument4 SeitenDesign Calculation of Pavementorode franklyn100% (1)

- Column & Footing LayoutDokument1 SeiteColumn & Footing LayoutMohammed SumerNoch keine Bewertungen

- Staad Pro - Mat FoundationDokument16 SeitenStaad Pro - Mat FoundationV.m. Rajan100% (1)

- One Way Slab DesignDokument4 SeitenOne Way Slab DesignMario FeghaliNoch keine Bewertungen

- ETABS Load CombinationsDokument1 SeiteETABS Load CombinationsNiyat PatelNoch keine Bewertungen

- Composite Slab DesignDokument6 SeitenComposite Slab DesignFranklyn GenoveNoch keine Bewertungen

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Dokument18 SeitenPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNoch keine Bewertungen

- Short Term Deflection Calculation (Subramanyam Example 12.4)Dokument9 SeitenShort Term Deflection Calculation (Subramanyam Example 12.4)Saugat ThapaNoch keine Bewertungen

- Aci 318-14 RC-PN-001Dokument6 SeitenAci 318-14 RC-PN-001Bunkun15Noch keine Bewertungen

- ACI 318-08 - Slab Punching - Design For Interior ColumnDokument9 SeitenACI 318-08 - Slab Punching - Design For Interior Columnamin alzuraikiNoch keine Bewertungen

- Calculation 1.0 Design Information 1.1 Building DescriptionDokument20 SeitenCalculation 1.0 Design Information 1.1 Building Descriptionerkapil1120Noch keine Bewertungen

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Dokument8 SeitenReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNoch keine Bewertungen

- Column DesignDokument56 SeitenColumn DesignSakar ShresthaNoch keine Bewertungen

- Anchor DesignDokument30 SeitenAnchor DesignAdinda dwiNoch keine Bewertungen

- En 50124 1 2001Dokument62 SeitenEn 50124 1 2001Vivek Kumar BhandariNoch keine Bewertungen

- PAEC2017 - Slab On Grade InvestigationDokument2 SeitenPAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickNoch keine Bewertungen

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Dokument14 SeitenGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNoch keine Bewertungen

- Design of Underground Water TankDokument6 SeitenDesign of Underground Water TankAlfred PatrickNoch keine Bewertungen

- Participate in Safe Food Handling Practices SITXFSA002 - PowerpointDokument71 SeitenParticipate in Safe Food Handling Practices SITXFSA002 - PowerpointJuan Diego Pulgarín Henao100% (2)

- 2 Piles Cap Design bs8110Dokument3 Seiten2 Piles Cap Design bs8110Faizal ImranNoch keine Bewertungen

- Beam Ledge DesignDokument2 SeitenBeam Ledge Designauatipu100% (1)

- Solid Slab Inspection ChecklistsDokument2 SeitenSolid Slab Inspection ChecklistsMohammed SumerNoch keine Bewertungen

- Flat Slab Design To Bs8110-Part 1-1997Dokument23 SeitenFlat Slab Design To Bs8110-Part 1-1997sskamalakannanNoch keine Bewertungen

- Dialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Dokument1 SeiteDialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Al ImranNoch keine Bewertungen

- Process Strategy: Powerpoint Slides by Jeff HeylDokument13 SeitenProcess Strategy: Powerpoint Slides by Jeff HeylMuizzNoch keine Bewertungen

- MenuDokument6 SeitenMenuMatthew AtkinsNoch keine Bewertungen

- Design of Continuous Footing-1 PDFDokument8 SeitenDesign of Continuous Footing-1 PDFSamuel Antobam100% (2)

- Pile Cap DesignDokument5 SeitenPile Cap DesignAddrien DanielNoch keine Bewertungen

- Busunju - Site (3141) - Structural Analysis Report 1 of 2 - Version 1Dokument26 SeitenBusunju - Site (3141) - Structural Analysis Report 1 of 2 - Version 1Emmanuel MusaasiziNoch keine Bewertungen

- 1106.ductile Intermediate Beam Design As Per ACI 318MDokument4 Seiten1106.ductile Intermediate Beam Design As Per ACI 318MNapoleon CarinoNoch keine Bewertungen

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Dokument4 SeitenDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Tapered I-Section Design in StaadproDokument1 SeiteTapered I-Section Design in StaadproMichael DixonNoch keine Bewertungen

- Class A Loads Govt. of West Pakistan - Code of Practice Highway BridgesDokument1 SeiteClass A Loads Govt. of West Pakistan - Code of Practice Highway BridgesBunkun150% (1)

- Design of Square Footing F2Dokument18 SeitenDesign of Square Footing F2Mohammed Sumer100% (1)

- Crack Width Calculation For Rectangular RC BeamDokument1 SeiteCrack Width Calculation For Rectangular RC BeamRomyMohanNoch keine Bewertungen

- Nib CalculationDokument1 SeiteNib CalculationKen LuuNoch keine Bewertungen

- ACI 318-14 RC-PN Example 001Dokument6 SeitenACI 318-14 RC-PN Example 001Novin KamyabNoch keine Bewertungen

- Software Verification: Example 10Dokument5 SeitenSoftware Verification: Example 10Haytham ZaghloulNoch keine Bewertungen

- Jdivision Name: Find I NextDokument2 SeitenJdivision Name: Find I NextMohammed SumerNoch keine Bewertungen

- Yahoo Mail - Hello and Thank You From DAT!Dokument2 SeitenYahoo Mail - Hello and Thank You From DAT!Mohammed SumerNoch keine Bewertungen

- South - PPT - PPT HydDokument6 SeitenSouth - PPT - PPT HydMohammed SumerNoch keine Bewertungen

- 2016-FL3030说明书50m臂长最后版-2016 11 3 PDFDokument96 Seiten2016-FL3030说明书50m臂长最后版-2016 11 3 PDFMohammed SumerNoch keine Bewertungen

- Requirement of DrawingDokument1 SeiteRequirement of DrawingMohammed SumerNoch keine Bewertungen

- Eng - Khalil&mr - Basem With Majid Hilal AgreementDokument7 SeitenEng - Khalil&mr - Basem With Majid Hilal AgreementMohammed SumerNoch keine Bewertungen

- Khalfan Final All (30.aug.2016) - Model - pdf5Dokument1 SeiteKhalfan Final All (30.aug.2016) - Model - pdf5Mohammed SumerNoch keine Bewertungen

- A B C D E F G A': Ground FloorplanDokument1 SeiteA B C D E F G A': Ground FloorplanMohammed SumerNoch keine Bewertungen

- Khalfan Final All (30.aug.2016) - Model - pdf1Dokument1 SeiteKhalfan Final All (30.aug.2016) - Model - pdf1Mohammed SumerNoch keine Bewertungen

- Produced by An Autodesk Educational ProductDokument1 SeiteProduced by An Autodesk Educational ProductMohammed SumerNoch keine Bewertungen

- Analysis of Stress-Strain and DeflectionDokument12 SeitenAnalysis of Stress-Strain and DeflectionMohammed SumerNoch keine Bewertungen

- Johnson Lifts SpecsDokument4 SeitenJohnson Lifts SpecsMohammed Sumer60% (5)

- TABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoDokument27 SeitenTABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoMohammed SumerNoch keine Bewertungen

- T8@7"C/C 4 T12: Schedule of FootingsDokument1 SeiteT8@7"C/C 4 T12: Schedule of FootingsMohammed SumerNoch keine Bewertungen

- Foundation Details For Boundary Wall Lake TownDokument1 SeiteFoundation Details For Boundary Wall Lake TownMohammed SumerNoch keine Bewertungen

- Soil Test For Hospital BuildingDokument8 SeitenSoil Test For Hospital BuildingMohammed SumerNoch keine Bewertungen

- Entrance ArchDokument1 SeiteEntrance ArchMohammed SumerNoch keine Bewertungen

- Hindi ShivpuranDokument40 SeitenHindi ShivpuranAbrar MojeebNoch keine Bewertungen

- Dehn Brian Intonation SolutionsDokument76 SeitenDehn Brian Intonation SolutionsEthan NealNoch keine Bewertungen

- Vedic Maths Edited 2Dokument9 SeitenVedic Maths Edited 2sriram ANoch keine Bewertungen

- Electric Motor Cycle and ScooterDokument9 SeitenElectric Motor Cycle and ScooterA A.DevanandhNoch keine Bewertungen

- Power Control 3G CDMADokument18 SeitenPower Control 3G CDMAmanproxNoch keine Bewertungen

- Baxter - Heraeus Megafuge 1,2 - User ManualDokument13 SeitenBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliNoch keine Bewertungen

- PDF of Tally ShortcutsDokument6 SeitenPDF of Tally ShortcutsSuraj Mehta100% (2)

- Timetable - Alton - London Timetable May 2019 PDFDokument35 SeitenTimetable - Alton - London Timetable May 2019 PDFNicholas TuanNoch keine Bewertungen

- Protection in Distributed GenerationDokument24 SeitenProtection in Distributed Generationbal krishna dubeyNoch keine Bewertungen

- AstmDokument5 SeitenAstmyanurarzaqaNoch keine Bewertungen

- Getting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeDokument28 SeitenGetting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeSan Mateo Daily JournalNoch keine Bewertungen

- Pest of Field Crops and Management PracticalDokument44 SeitenPest of Field Crops and Management PracticalNirmala RameshNoch keine Bewertungen

- The BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptDokument19 SeitenThe BetterPhoto Guide To Creative Digital Photography by Jim Miotke and Kerry Drager - ExcerptCrown Publishing GroupNoch keine Bewertungen

- Manual Ares-G2 2Dokument78 SeitenManual Ares-G2 2CarolDiasNoch keine Bewertungen

- Progress Report 1Dokument3 SeitenProgress Report 1api-302815786Noch keine Bewertungen

- Rubric For Aet570 BenchmarkDokument4 SeitenRubric For Aet570 Benchmarkapi-255765082Noch keine Bewertungen

- Blake 2013Dokument337 SeitenBlake 2013Tushar AmetaNoch keine Bewertungen

- Kefauver Harris AmendmentsDokument7 SeitenKefauver Harris AmendmentsAnil kumarNoch keine Bewertungen

- Technion - Computer Science Department - Technical Report CS0055 - 1975Dokument25 SeitenTechnion - Computer Science Department - Technical Report CS0055 - 1975MoltKeeNoch keine Bewertungen

- Neelima A Kulkarni ResumeDokument3 SeitenNeelima A Kulkarni ResumeAcademics LecturenotesNoch keine Bewertungen

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Dokument2 SeitenInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadNoch keine Bewertungen