Beruflich Dokumente

Kultur Dokumente

DBR-Electrical Rev 0

Hochgeladen von

psjjoshiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DBR-Electrical Rev 0

Hochgeladen von

psjjoshiCopyright:

Verfügbare Formate

CONSTRUCTION OF OFFICE BUILDING ON PLOT AT

GULISTAN BUNGALOW AT R C BUTT ROAD, ALKAPURI,

VADODARA

Design Basis Report

– Electrical Installation –

October 2013

47305000/EL/DBR/001 Rev – R0

CONSULTING ENGINEERING SERVICES (I) PVT. LTD.

NEW DELHI MUMBAI KOLKATA

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

Table of Contents

1. INTRODUCTION 3

2. SCOPE OF WORK 3

3. PROJECT OBJECTIVES 3

4. MAIN POWER SYSTEM 4

4.1 Reference Documents, Codes & Standards 4

4.2 Site Condition 5

4.3 Utility Substation 5

4.4 Distribution System 5

4.5 UPS System 7

4.6 11 / 0.433 kV Transformer 7

4.7 Emergency Power Back up 7

4.8 Rising Mains 8

4.9 Power Factor Correction 8

5 CABLING SYSTEM 8

6 LIGHTING SYSTEM 10

7 EARTHING SYSTEM 12

8 LIGHTNING PROTECTION SYSTEM 12

9 LOAD ESTIMATE 13

Design Basis Report - Electrical Page : 2 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

ELECTRICAL DISTRIBUTION SYSTEM

1. INTRODUCTION

Bank of Baroda has proposed to construct Administrative office Building at Gulistan

Bungalow at R C Dutta Road, Alkapuri, Vadodara. The building is proposed with

Basement + Ground + 7 Storied. Built-up area of the Office Building will be approx

125,000 Sq. ft,

This report outlines the overall Design Scheme for the Electrical Distribution for the

proposed Office Building. Detailed Engineering of the Electrical System would be carried

out on approval of this Concept Design. Design Report is prepared based on the input

data assumed and overall electrical load estimate, sizing calculation of various

equipments.

2. SCOPE OF WORK

The objective of this report is to give an overview of services designed for the proposed

Office Building at Alkapuri, Vadodara. The design of Electrical Services undertaken

includes following:

HVAC System

External and Internal electrical distribution including substation.

UPS Power

Emergency DG set

HT and LT cabling system

LT Bus riser system

Earthing system.

Lightning protection

3. PROJECT OBJECTIVES

The project objectives include eco-friendly and energy efficient design, centralized

grouped location of services installation to ensure easy maintenance, state of the art

technology, fast track installation and compliance to all statutory regulations.

Design Basis Report - Electrical Page : 3 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

4. MAIN POWER SYSTEM

4.1 Reference Documents, Codes & Standards

Electrical Systems Design shall be carried out in accordance with following Codes and

Standards :

Indian Electricity Act, 2003.

Indian Electricity Rules, 1956.

National Building Code of India – 2005.

IS 7098 Cross linked polyethylene insulated PVC sheathed cables.

IS 1646 : Code of Practice for the Fire Safety of Buildings - General Electrical

Installations.

IS 1913 : General and Safety requirements for Luminaries.

IS : 2026 / IEC 60076 : Transformers (Oil filled).

IS 2309 : Lightning Protection System.

IS 3043 : Grounding & Bonding.

IS 3231 Electrical relays for Power Systems Protection

IS 3427 : 1997 / IEC 298 A.C. Metal Enclosed Switchgear and Controlgear for

Rated Voltages Above 1 kV and Up to and Including 52 kV.

IS - 3646 : Code of Practice for Interior Illumination.

IS 10322 Specification for Luminaries

IS 12063 Classification of degrees of protection provided by enclosures of electrical

equipment.

IS 13340 & IS 13341 / IEC 60831 : Capacitors.

IS 13947 / IEC 60947 : Specification for Low Voltage Switchgear & Controlgear.

IEC 60034 for Rotating Electrical Machines.

IEC 62271 High Voltage Switchgear and Controlgear – All parts.

IEC 60364 : Requirements for Electrical installation

IEC 62040 for Uninterruptible Power Supply.

IEC 61439 (1&6) & IS (8623 (1&2) for Bus Trunking System

IS 1255 for Cable laying

Design Basis Report - Electrical Page : 4 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

.

4.2 Site Condition

Altitude 35.5 above MSL

Ambient Temperature Design 45 deg. C

Maximum Temperature 43.3 deg. C

Minimum Temperature 10 deg.C

Humidity 68% RH during summer

Soil Resistivity 1.28 Ohm m

Rainfall 93 cm

Seismic Zone Zone III

Environment Normal

4.3 Utility Substation

Main power will be received at 11 kV from local power Supply Company. An 11 KV

Panel with one incomer and two outgoing panel will be installed at the proposed

substation building which will be located outside the building premises.

11 kV Power supply will be step down to 415 Volts LT supply through a suitable rated 11

/ 0.433 kV Transformer, which will be installed outside the substation premises. LT

supply from the transformer will be fed to an LT Panel to be housed in the Substation

building. Provision for installation of 2nd Transformer to be considered in the proposed

layout for future load growth and redundancy.

4.4 Distribution System

The cable for 11 kV supply will be 11 kV earthed grade, aluminum conductor, XLPE

insulated, semi conducting compound screened, the extruded inner sheathed, armored

and extruded outer sheathed.

The cables for LV power supply will be 1100 V grade aluminium conductor, XLPE

insulated; the cables for emergency services will be with additional FRLS properties.

Design Basis Report - Electrical Page : 5 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

The control cables will be FRLS except with stranded copper conductor. The cables

within the building will be routed through cable trays. The cables coming from Substation

will be run through the cable trenches. Fireproof sealing will be done at all the shafts at

each floor, wall entries and floor entries.

Power cables will be sized considering applicable derating factors. Bus duct will be

provided from the Transformer and DG sets upto Low voltage switchgears. From the low

voltage switchgear upto rising mains suitably rated cables will be provided.

Rising Mains are proposed to be used as the backbone for power distribution throughout

the building. Rising mains system of sandwiched type will be provided along the

electrical shaft to provide power supply to each floor for lighting and general power.

Cables from Main LT Panel will be terminated at End Feed Bos of the rising main at

basement. Power supply for each floor will be tapped from rising mains from plug in tap

of box through cables. Each floor will be provided dedicated LT distribution board for

power distribution.

Dedicated UPS and Battery system for each floor is proposed to cater office area

computer load, BMS load. While sizing UPS, a design margin of 10% considered in case

Client considered catering other load through UPS syste. Power supply to UPS syetm

will be received from dedicated LT distribution panel at each floor. UPS and Battery

room at each floor shall be air conditioned. Additionally adequate ventilation shall be

proved for Battery room for Hydrogen emmission.

Main LT Panel which will be located at Utility substation shall be free standing, floor

mounted, fully compartmentalized, cubicle type panel having separate enclosures for

bus bars, chambers & feeder breakers with associated cable terminations. Power supply

to Utility load at Terrace will be fed separately from Main LT Panel. Rising mains will

cater power supply for Power, lighting of each floor, Lifts, UPS, BMS, HVAC system of

each floor and Plumbing system. For Utility load at Terrace, a separate cable system will

run along a separate shaft from basement.

Design Basis Report - Electrical Page : 6 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

Sub panels and the subsequent distribution boards (DB) at different floor will receive

power from rising mains in Electrical shaft from tap off boxes as mentioned above. The

lighting/power DB would be provided with ELCB for protection as per IE Regulations. All

wiring for light and power points shall be with PVC conduits for concealed wiring and MS

conduits for surface wiring. Wiring shall be carried out with FRLS copper wires as per

the requirement. The full distribution network from the incoming feeders to each point of

usage is designed to be fuse-less system comprising of Molded Case Circuit Breakers

(MCCB), Miniature Circuit Breakers (MCB) and Earth Leakage Circuit Breakers (ELCB)

and therefore intrinsically fire-safe.

4.5 UPS System

Based on estimated office area load and BMS load, dedeicated UPS system for each

floor is sized considering an overall Diversity Factor (DF) of 90%. UPS system with N+N

is considered for the purpose. Battery backup for UPS will be designed to provide 30

minutes of back up time. UPS system shall be designed for limit the harmonic distortion

of input supply to maximum 3% THD. For UPS sizing refer Annexure 1

4.6 11 / 0.433 kV Transformer

1 No.11 / 0.433 kV, 1500 kVA Dry Type (Resin Cast), Dyn11 with Z = 6.25%, with off

Load Tap Changer (Tap+/- 5% in steps of 2.5%) outdoor type transformers. Transformer

capacity will be selected considering 90% maximum loading. For Transformer sizing

refer Annexure 1

4.7 Emergency Power Back up

Emergency power generation is planned to be provided through HSD fired DG set with

AMF provision capable of meeting entire lighting and power demand of the Building. In

order to meet the statutory regulation regarding noise and air pollution, DG set is housed

in acoustic and weather proof enclosures have been proposed. The sets would conform

to the latest enforced regulatory norms with regard to the noise and air pollution.

Design Basis Report - Electrical Page : 7 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

In the event of any failure of the mains grid, emergency backup power supply system

has been designed to come in to operation automatically to support 100% load to avoid

any down time in the proposed Office Building.

DG set is proposed outside the Utility building shall be mounted inside individual

acoustic enclosure in order to minimize disturbance to occupants. The ambient noise

level from DG set shall not exceed 75 dB (A) at 1 m distance, during day time and 70 dB

(A) during night time. For DG sizing refer Annexure 1

4.8 Rising Mains

The complete prefabricated bus way distribution system shall be for 433 Volts 3-phase 4

wire with integral grounding bar. The neutral bar shall be 100% cross sectional area of

phase conductors. The bus way system shall be of the low impedance type and totally

enclosed for protection against mechanical damage and dust accumulation.

Fire stops or barriers shall be included as an integral part of each feeder bus way length

& fitting. Degree of protection shall be IP-65 for outdoor and IP-54 for indoor application.

Rising Mains will be provided with End Feed Box at basement and End cover at terrace

level. Tap of box will be provided at each floor.

4.9 Power Factor Correction

Power factor correction unit shall be of Active harmonics / PF filter design. The final size

of the power factor correction units to be designed during the detailed engineering.

Power factor shall be maintained at 0.95 or higher through APFC panel. APFC Panel will

be installed mear Main LT Panel at Substation.

5 CABLING SYSTEM

All high-tension cables shall be laid and jointed in accordance with IS: 1255. A minimum

separation of one cable diameter will be maintained between any two horizontal cables.

Accordingly derating factor will be considered. To reduce the total width required, the

two circuits will be vertically separated by 200 mm edge to edge.

Design Basis Report - Electrical Page : 8 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

A separating distance between parallel runs of Instrument and Electrical cables shall be

as follows, except in substation:

For 11 kV Cables – 1000 mm

For 415 V Cables – 600 mm

For 240, 110 V Cables – 300 mm

Above ground cables shall be supported by cable racks or trays. Power cables shall

generally be laid on racks or trays in a single layer. Cables trays shall be secured at

required intervals.

Power (and associated control) and instrumentation / telecommunication cables shall

be run in different racks.

GI ladder type cable trays are proposed for laying cables in preformed trenches, laying

cables for various equipments along the shaft, in plant room etc. and perforated cable

trays for cables from panels to distribution boards etc.

The enclosure degree of protection for various electrical equipment shall be as per the

requirements below as a minimum:

HT Switchgear : IP 4X

Distribution Transformers : IP 55

Cable Box : IP 55

i) Kiosks and Marshalling Box : IP 55

ii) Bus Duct (Indoor) / (Outdoor) : IP 54 / IP-55

(Indoor) / (Outdoor)

iii) 415 V PCC / MCC / DBs : IP 42

iv) Pushbutton Station and any other Kiosk /

Box / Panel / Enclosure Indoor / Outdoor : IP 55

v) Junction Boxes for Cables / Wires : IP 55

vi) Outdoor Lighting Fixtures : IP 55

vii) Battery Charger Panel : IP 42

Design Basis Report - Electrical Page : 9 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

6 LIGHTING SYSTEM

Lighting arrangement for the Office Building is proposed with the use of high efficiency,

mirror optic light fixtures equipped with very low loss electronic ballasts and high

efficacy tri-phosphate coated T-5 tubes. The average lighting level is proposed to be

500 lux. Since 100% of lighting is backed-up with inverter floor wise, in the event of any

failure of mains power, all the lights would be re-energized after a break of about 15

seconds. Further to provide continuity of lighting to facilitate safe evacuation in extreme

situation, emergency lights including EXIT signage lights fed from a separate inverter

would be provided at strategic locations in and around the Office Building.

The illumination levels considered for calculation for various areas will be as follows:

Sl.

Area Lux level

No.

1 Office Area / Cabin / Secretary 300

2 Server Room 300

3 Corridors 100

4 Conference Room 300

5 Reception / Lounge 150

6 Toilet / Locker Room 150

7 Library 200

8 Electrical Room 200

9 Chiller Area 100

10 Storage Area 100

11 DG Room 200

12 Car Park 100

13 Xerox / Fax / EPABX Room 150

14 Documentation Room 150

The luminaries will be selected to suit architectural, functional & aesthetic requirement,

for office areas in general & for other areas, energy saving fluorescent lamps and high

efficiency lamps will be used. Common areas will be provided with 1 x 11 or 1 - x 18 w

CFL lamps. Reflector shall be made out of high purity aluminum scientifically designed

Design Basis Report - Electrical Page : 10 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

for high optical performance. All conference rooms and auditorium lighting shall be

dimmer controlled.

The wiring will be done with copper wires in using 3 cores 2.5 sqmm cables for point

wiring and looping and 2.5 sq.mm copper multistrand FRLS for circuit mains wiring.

HDPE conduits shall be used for concealed wiring and Galvanized conduits for surface

wiring. The lighting panels will be 3-phase type with outgoing MCB circuits. Third core

for earthing the lighting fittings, plug points, exhaust fans, etc. The lighting circuits for

the car park and common areas will be contactor controlled so that the illumination level

can be controlled during off peak periods by remote control from building automation

system. Similarly the circuits / feeders for outdoor lighting will be contactor controlled for

remote controlling purposes.

Each workstation shall have 2 nos. 6/16A switched & sockets. Cabins & secretary area

will have 2 nos. 6/16A switched sockets and 1 no. Extra-switched socket shall be

provided for laptop. 1 no. Additional switched 6/16A socket shall be provided in

secretary space for printer.

Internal Distribution

Light fittings & socket outlets for raw power in common areas will be fed from MCBDBs

in the respective areas. Emergency lighting for specified areas will be provided by

essential MCB DB’s.

For concealed and surface wiring rigid MS conduits will be used. For wiring FRLS PVC

sheathed 2.5 sq.mm copper wire shall be used. FRLS wires shall be provided for all

systems.

The lighting fixtures will get power supply from lighting distribution boards fed from

lighting panel through wiring. All the lighting fixtures are of with electronic ballast and

power factor improvement capacitors. Each lighting fixture will be provided with the

earthing terminal. All metal will be bonded to earth. Switch controlling light point will be

connected the phase wire of the circuit and not more than the 10 lights will be

connected on one circuit. The load of each circuit will be not more than 800Watt.The

minimum size of wiring for lighting will be 2.5 Sq.mm. Power sockets of 6A, 16A & 20A

Design Basis Report - Electrical Page : 11 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

will be getting supply from power distribution boards through the wiring. All sockets

switches and other receptacle will be rust proof and will be 2 mm thick mild steel with

HOT dipped galvanized having smooth external and internal surface to true finish. Wall

socket will be three-pin type. All 16A sockets will be connected to the independent

circuit. An earth wire will be provided along with the circuit wires and will be connected

to the earthing screw in side the box. All sockets will be shutter type.

For lighting and raw power one essential as well as nonessential lighting and raw power

panels will also be provided. These will feed to the emergency as well as normal

lighting and power load through suitable distribution boards.

7 EARTHING SYSTEM

There would be two separate grounding systems for the Office Building; one catering to

the safety requirement of the entire electrical distribution system and the other (known

as Dedicated Earthing) catering to the sensitive servers with in the Office Building. The

two systems would be bonded together with equi-potential bond as per the requirement

of IEEE code of practice. The dedicated earthing system would be laid out separately

using green-yellow PVC insulated copper cables terminated on a purpose built Earth

Bus which in turn would be connected to two separate earth pits specially created for

the purpose. Isolated Ground (IG) for the entire computer power supply is designed and

executed as per IEEE Standard- 1100 (Emerald Book).

8 LIGHTNING PROTECTION SYSTEM

Lightning protection system with early streamer is proposed. This system is an

controlled streamer Emission based lightning protection suitable for protecting of

buildings against direct lightning strike and has controlled streamer emission (CSE)

lightning conductor air terminal held in position at the highest point of building with

supporting mast and accessories comprising of the insulated FRP pipe mast & high

grade aluminium of required height as per vendor design, U bolts etc to withstand wind

velocities of 100 kmph. This system intercepts lightning discharges at a preferred point

earlier than conventional lightning protection system.

Design Basis Report - Electrical Page : 12 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

Earthing is done using minimum 4 nos of copper bonded steel earth rods of 250

microns with minimum 4 feet length and half inch dia joined with 25 mm x 3 mm copper

strip and the surrounding space is treated with ground enhancement material (GEM) to

reduce the overall impedance offered by earth. Lightning counter is also proposed

which gives the no. of lightning strokes captured by the each area.

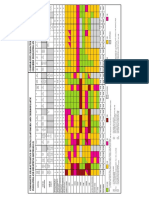

9 LOAD ESTIMATE

The estimated connected electrical load for the entire Office Building comprising of

HVAC system, Lifts, Lighting, Computers, UPS etc. works out to 1206 KW considering

design margin of 10%, whereas operating load is 1098 KW. For detail load list and

sizing calculation of Transformer, UPS system and DG, refer Annexure 1

Design Basis Report - Electrical Page : 13 of 14

Project : Construction of Office Building on Plot at Gulistan Bungalow at October, 2013

R C Dutta Road, Alkapuri, Vadodara

Client : Bank of Baroda Revision : R0

Document : 47305000/DBR/EL/Rep-04

ANNEXURE 1

Design Basis Report - Electrical Page : 14 of 14

Das könnte Ihnen auch gefallen

- Proposed BMC Office Building Electrical Design ReportDokument19 SeitenProposed BMC Office Building Electrical Design ReportAmit Kumar MishraNoch keine Bewertungen

- Addc Sector Measuring Point (Ip54) : Uncontrolled If PrintedDokument1 SeiteAddc Sector Measuring Point (Ip54) : Uncontrolled If PrintedWael AlmassriNoch keine Bewertungen

- LIGHTING CALCULATION FOR MCC PLANTDokument138 SeitenLIGHTING CALCULATION FOR MCC PLANTElectrical PCBL TeamNoch keine Bewertungen

- S Aaa SWG MV Dist 11 Fixed 0.4 Ac (Rev.0 2011)Dokument23 SeitenS Aaa SWG MV Dist 11 Fixed 0.4 Ac (Rev.0 2011)mahmoudNoch keine Bewertungen

- Calculate Lightning Protection For BuildingDokument4 SeitenCalculate Lightning Protection For BuildingKamran Afzal100% (2)

- 1 Outdoor Substation CalculationDokument52 Seiten1 Outdoor Substation Calculationpaolo sangalangNoch keine Bewertungen

- Switchboards, Distribution Boards and Control PanelsDokument45 SeitenSwitchboards, Distribution Boards and Control PanelsRachel IngramNoch keine Bewertungen

- Khazzan Project Earthing System CalculationDokument21 SeitenKhazzan Project Earthing System CalculationbhavikNoch keine Bewertungen

- ERT Report For Paudi Amarai Substation Project 25th JulyDokument30 SeitenERT Report For Paudi Amarai Substation Project 25th JulySagun KatuwalNoch keine Bewertungen

- G + 5 (Calculation Details)Dokument104 SeitenG + 5 (Calculation Details)shashikantcivil025Noch keine Bewertungen

- Need of Electrical SubstationDokument3 SeitenNeed of Electrical Substationakshay7573Noch keine Bewertungen

- Engineering 0001 Standard For General Electrical Design - OnshoreDokument35 SeitenEngineering 0001 Standard For General Electrical Design - Onshoremarin cristianNoch keine Bewertungen

- PABRIK NPK FUSION II PEMBANGUNANDokument1 SeitePABRIK NPK FUSION II PEMBANGUNANwitpur2014Noch keine Bewertungen

- Earth Mat Design 33-11KV SSDokument5 SeitenEarth Mat Design 33-11KV SSDipak BandyopadhyayNoch keine Bewertungen

- Universal Cable (M) Berhad - Bending Radius, Side Wall Pressure and Copper Screen RequirementsDokument1 SeiteUniversal Cable (M) Berhad - Bending Radius, Side Wall Pressure and Copper Screen RequirementsMuhammad RosliNoch keine Bewertungen

- Technical Data Sheet (33-11kV Substation Construction) - Rev.0Dokument109 SeitenTechnical Data Sheet (33-11kV Substation Construction) - Rev.0elsayedNoch keine Bewertungen

- NGR Brochure 2009Dokument7 SeitenNGR Brochure 2009Amit sahaNoch keine Bewertungen

- Subst A T Ion de Sign ManualDokument127 SeitenSubst A T Ion de Sign ManualVinothNoch keine Bewertungen

- Trench SpecificationsDokument4 SeitenTrench SpecificationsFatoni Gea AirlanggaNoch keine Bewertungen

- EnergyCalculator AspxDokument2 SeitenEnergyCalculator AspxWael AlmassriNoch keine Bewertungen

- Earthing Resistance Calculations Is 3043Dokument14 SeitenEarthing Resistance Calculations Is 3043haris100% (1)

- Metro Cash & Carry 800A LT Panel Test ReportDokument3 SeitenMetro Cash & Carry 800A LT Panel Test ReportAROCKIA STEPHAN SESUMANINoch keine Bewertungen

- Aviation Light BOQDokument6 SeitenAviation Light BOQkkjha31Noch keine Bewertungen

- Standard Calculation For Outdoor Lighting PDFDokument7 SeitenStandard Calculation For Outdoor Lighting PDFankit50% (2)

- EE-442 (Electric Energy Utilization)Dokument2 SeitenEE-442 (Electric Energy Utilization)dhineshkm10100% (1)

- Cost Summary of Electrical WorkDokument12 SeitenCost Summary of Electrical WorkHailuGelanHubena100% (1)

- 11kV Dist Xfmr SpecDokument33 Seiten11kV Dist Xfmr SpecKarthikNoch keine Bewertungen

- GA Sample Full ICOG PDFDokument17 SeitenGA Sample Full ICOG PDFSundaresan SabanayagamNoch keine Bewertungen

- Sample Template - Distribution Panel Board ScheduleDokument1 SeiteSample Template - Distribution Panel Board Schedulemusleh19100% (4)

- Comparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialsDokument1 SeiteComparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialskapilNoch keine Bewertungen

- QCS-2010 Section 21 Part 21 Lightning ProtectionDokument4 SeitenQCS-2010 Section 21 Part 21 Lightning Protectionbryanpastor106Noch keine Bewertungen

- 2 - Earthing Calculation No.1Dokument2 Seiten2 - Earthing Calculation No.1Sharik KhanNoch keine Bewertungen

- ELECTRICAL DESIGN InternDokument35 SeitenELECTRICAL DESIGN Internomair sirajNoch keine Bewertungen

- Operation and Maintenance Instructions for Air Insulated Metal-Clad Switchgear Type 8BK88PLUSDokument36 SeitenOperation and Maintenance Instructions for Air Insulated Metal-Clad Switchgear Type 8BK88PLUSRitesh Maheshwari100% (1)

- Bel-Electrical SubstationDokument21 SeitenBel-Electrical SubstationGagan MaheyNoch keine Bewertungen

- Circuit Breaker SpecificationDokument60 SeitenCircuit Breaker SpecificationYash YadavNoch keine Bewertungen

- Site Acceptance Test Report of MV Switchgear: SnagDokument5 SeitenSite Acceptance Test Report of MV Switchgear: SnagGajendran SriramNoch keine Bewertungen

- I S 732Dokument79 SeitenI S 732Hariprasad gantyala100% (1)

- 7 Extra Low Voltage System PDFDokument83 Seiten7 Extra Low Voltage System PDFManjunath Beleri0% (1)

- Old Sample Electrical BaseDokument31 SeitenOld Sample Electrical BaseRahulNoch keine Bewertungen

- ETHIHAD RAIL NETWORK PACKAGE 2S BILL OF QUANTITIESDokument68 SeitenETHIHAD RAIL NETWORK PACKAGE 2S BILL OF QUANTITIESMohammad UmmerNoch keine Bewertungen

- Amtech ProDesign Product GuideDokument3 SeitenAmtech ProDesign Product GuideShanti Naidu0% (1)

- DG BusductDokument16 SeitenDG BusductanandpurushothamanNoch keine Bewertungen

- Design of 132-33kV SSDokument13 SeitenDesign of 132-33kV SSSemifallen100% (2)

- Technical Spec Vol II 1 of 2 REMCODokument442 SeitenTechnical Spec Vol II 1 of 2 REMCOdilipeline100% (3)

- Combined DrawingDokument1 SeiteCombined DrawingWael AlmassriNoch keine Bewertungen

- LDN Consultants v0.6Dokument29 SeitenLDN Consultants v0.6Wael AlmassriNoch keine Bewertungen

- MOTOR SOFT STARTERS - Air Core ReactorsDokument3 SeitenMOTOR SOFT STARTERS - Air Core Reactorsmv_mallikNoch keine Bewertungen

- 1MWp SOLAR PLANT SLDDokument1 Seite1MWp SOLAR PLANT SLDUnique FriendNoch keine Bewertungen

- 32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Dokument50 Seiten32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Haytham BafoNoch keine Bewertungen

- Air Insulated 8BK80Dokument32 SeitenAir Insulated 8BK80Koushik DeyNoch keine Bewertungen

- DBRDokument13 SeitenDBRpsjjoshiNoch keine Bewertungen

- Poly Hub - 1 MWP Ground Mounted Solar Project QuotationDokument22 SeitenPoly Hub - 1 MWP Ground Mounted Solar Project Quotationchander100% (1)

- Design Calculation: Dhaka Mtr-5 Line NorthDokument10 SeitenDesign Calculation: Dhaka Mtr-5 Line NorthManglesh SinghNoch keine Bewertungen

- Sub 02 006Dokument30 SeitenSub 02 006Christopher StewartNoch keine Bewertungen

- Electric Drive Specifications SummaryDokument24 SeitenElectric Drive Specifications SummaryBrandon FloresNoch keine Bewertungen

- Approved by General Director Eng. Abedelwhab Alkhtib: Specification FOR Low Voltage Circuit BreakerDokument13 SeitenApproved by General Director Eng. Abedelwhab Alkhtib: Specification FOR Low Voltage Circuit Breaker红星Noch keine Bewertungen

- Subject: - Electrical Estimation and Contracting (22627)Dokument11 SeitenSubject: - Electrical Estimation and Contracting (22627)Onkar MamidwarNoch keine Bewertungen

- Anexo 5 IDO-L.18.001-1212-EBD-5000-0 Electrical Design CriteriaDokument48 SeitenAnexo 5 IDO-L.18.001-1212-EBD-5000-0 Electrical Design CriteriaRusNoch keine Bewertungen

- Results and Discussion: 4.1generalDokument38 SeitenResults and Discussion: 4.1generalpsjjoshiNoch keine Bewertungen

- Sales Catalogue - 40LW AHU - Gurgaon India FactoryDokument2 SeitenSales Catalogue - 40LW AHU - Gurgaon India FactorypsjjoshiNoch keine Bewertungen

- Electrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)Dokument2 SeitenElectrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)psjjoshiNoch keine Bewertungen

- B E - Civil Engg - Solid Waste SyllabusDokument5 SeitenB E - Civil Engg - Solid Waste SyllabuspsjjoshiNoch keine Bewertungen

- Chemical Filtration UnitDokument5 SeitenChemical Filtration UnitpsjjoshiNoch keine Bewertungen

- Door LeakagesDokument1 SeiteDoor LeakagespsjjoshiNoch keine Bewertungen

- Chapter 1Dokument12 SeitenChapter 1psjjoshiNoch keine Bewertungen

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDokument1 SeiteDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiNoch keine Bewertungen

- Expansion Tank CalculationsDokument3 SeitenExpansion Tank CalculationspsjjoshiNoch keine Bewertungen

- Cleveland Clinic Master Specifications PDFDokument768 SeitenCleveland Clinic Master Specifications PDFTerry BuddNoch keine Bewertungen

- Chapter 4 VentilationDokument4 SeitenChapter 4 VentilationKaushik Krishnan0% (1)

- DBR-HVAC Rev 0Dokument16 SeitenDBR-HVAC Rev 0psjjoshiNoch keine Bewertungen

- Declaration FormDokument5 SeitenDeclaration FormpsjjoshiNoch keine Bewertungen

- Chapter 4 VentilationDokument4 SeitenChapter 4 VentilationKaushik Krishnan0% (1)

- DBRDokument13 SeitenDBRpsjjoshiNoch keine Bewertungen

- I I & T M: Nstallation Nstructions Echnical Anual T F PDokument36 SeitenI I & T M: Nstallation Nstructions Echnical Anual T F PmohammadNoch keine Bewertungen

- Kitchen Ventilation Systeme Design Green Heck)Dokument56 SeitenKitchen Ventilation Systeme Design Green Heck)sbragdon0% (1)

- Piping Isometric TutorialDokument45 SeitenPiping Isometric Tutorialcepong89100% (1)

- Heat Load OutputDokument42 SeitenHeat Load OutputpsjjoshiNoch keine Bewertungen

- Plant Design ReportsDokument7 SeitenPlant Design ReportspsjjoshiNoch keine Bewertungen

- Technical specifications for repairing water distribution networksDokument24 SeitenTechnical specifications for repairing water distribution networksSIVANoch keine Bewertungen

- EMS 13 Fans and PumpsDokument119 SeitenEMS 13 Fans and PumpspsjjoshiNoch keine Bewertungen

- EMS 13 Fans and PumpsDokument119 SeitenEMS 13 Fans and PumpspsjjoshiNoch keine Bewertungen

- VRF EvalutionDokument13 SeitenVRF EvalutiontvscribdNoch keine Bewertungen

- Heat Load OutputDokument42 SeitenHeat Load OutputpsjjoshiNoch keine Bewertungen

- 125 Years of Cooling Innovation and LeadershipDokument32 Seiten125 Years of Cooling Innovation and Leadershippsjjoshi100% (1)

- TallyDokument91 SeitenTallyNadella Gopi Krishna0% (1)

- Basic Computer Use Notes PDFDokument25 SeitenBasic Computer Use Notes PDFpsjjoshiNoch keine Bewertungen

- Chapter 6 Residential and Commercial BuildingsDokument60 SeitenChapter 6 Residential and Commercial BuildingsIntergovernmental Panel on Climate ChangeNoch keine Bewertungen

- AM 600A, 600AJ JLG Parts English PDFDokument412 SeitenAM 600A, 600AJ JLG Parts English PDFOmar Sanchez GongoraNoch keine Bewertungen

- Industrial Valves Ð Metallic Butterfly Valves: British Standard BS EN 593:1998Dokument14 SeitenIndustrial Valves Ð Metallic Butterfly Valves: British Standard BS EN 593:1998panduranganraghurama100% (1)

- Installation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyDokument26 SeitenInstallation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyBharat TailorNoch keine Bewertungen

- Ethics in JournalismDokument2 SeitenEthics in JournalismYatharth KohliNoch keine Bewertungen

- Air Handlers Service InstructionsDokument93 SeitenAir Handlers Service InstructionsAnonymous uGPcnH0XppNoch keine Bewertungen

- Cisco Ipv6 SG01Dokument444 SeitenCisco Ipv6 SG01kayudo80Noch keine Bewertungen

- Practical Non-Scientific Field or Bench TestDokument12 SeitenPractical Non-Scientific Field or Bench TestPaulNoch keine Bewertungen

- PCB Layer StackupDokument92 SeitenPCB Layer Stackupdanielradu27Noch keine Bewertungen

- D870 15Dokument3 SeitenD870 15mithilesh100% (1)

- Pressure Reducing Valve Technical SpecificationsDokument4 SeitenPressure Reducing Valve Technical SpecificationsjajakaNoch keine Bewertungen

- Tutorial #12 - Expert View, Step Generator and CheckpointsDokument8 SeitenTutorial #12 - Expert View, Step Generator and Checkpointsmanu2020Noch keine Bewertungen

- SAE Flywheel & Bell Housing ChartDokument3 SeitenSAE Flywheel & Bell Housing ChartRogelio Reyes Romero100% (1)

- 2G Ericsson Nokia MappingDokument139 Seiten2G Ericsson Nokia MappingRinaldi AzharNoch keine Bewertungen

- Logical Addressing: Faisal Karim ShaikhDokument69 SeitenLogical Addressing: Faisal Karim Shaikhsindhu4sindNoch keine Bewertungen

- Pig Launcher and ReceiverDokument16 SeitenPig Launcher and ReceiverBolarinwa100% (5)

- Introduction to XHTML Syntax and StructureDokument17 SeitenIntroduction to XHTML Syntax and StructureSofea KhalidNoch keine Bewertungen

- BeoLink Converter NL/ML Service ManualDokument28 SeitenBeoLink Converter NL/ML Service ManualJannik EriksenNoch keine Bewertungen

- Mil S 7742DDokument17 SeitenMil S 7742DihavnoclueNoch keine Bewertungen

- Cisco CCNA Security Chapter 8 ExamDokument7 SeitenCisco CCNA Security Chapter 8 ExamPaulina EcheverríaNoch keine Bewertungen

- Maintain 15 737-Max AircraftDokument3 SeitenMaintain 15 737-Max AircraftBrandon SookdeoNoch keine Bewertungen

- Shell Omala BrochureDokument3 SeitenShell Omala Brochurenata siagianNoch keine Bewertungen

- Sinkrotakt Manual 5Dokument39 SeitenSinkrotakt Manual 5Vlado RadojsolicNoch keine Bewertungen

- Construction Safety ManagementDokument16 SeitenConstruction Safety ManagementNoman100% (3)

- S SRM 90350 KW BrochureDokument62 SeitenS SRM 90350 KW BrochureLAURA VANESA HERREROS QUISPE100% (2)

- 5 GSM Radio Network Planning and Optimization - Influence Factors + Troubleshooting Methods and Tools + Deliverables 20121031Dokument285 Seiten5 GSM Radio Network Planning and Optimization - Influence Factors + Troubleshooting Methods and Tools + Deliverables 20121031Musa Elsiddig ElsheikhNoch keine Bewertungen

- BS en 12507-2010Dokument18 SeitenBS en 12507-2010Yonathan Kristiawan B HutapeaNoch keine Bewertungen

- MODEM CONNECTION GUIDEDokument8 SeitenMODEM CONNECTION GUIDEDavid SaldarriagaNoch keine Bewertungen

- C 907 - 98 Qzkwny05oaDokument3 SeitenC 907 - 98 Qzkwny05oaRufo CascoNoch keine Bewertungen

- SAP R/3 Forecasting Module GuideDokument34 SeitenSAP R/3 Forecasting Module GuideAjitabh SinghNoch keine Bewertungen

- ABB Duty Selector SwithDokument68 SeitenABB Duty Selector SwithfayasNoch keine Bewertungen