Beruflich Dokumente

Kultur Dokumente

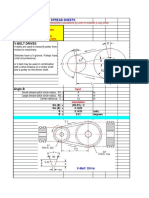

Caja Reductora 2da Etapa

Hochgeladen von

Edwin Paco PovedaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Caja Reductora 2da Etapa

Hochgeladen von

Edwin Paco PovedaCopyright:

Verfügbare Formate

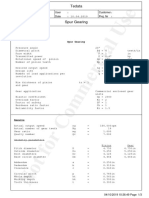

Tedata

Program : MDESIGN User : Customer :

se

Version : 1.1.2 Date : 11.05.2018 Proj. Nr :

Helical Gearing

U

Input data:

Helical Gearing

al

Normal pressure angle 20°

Helix angle = 15 °

Normal diametral pitch Pdn = 11 teeth/in

Face width F = 2.5 in

rci

Transmitted power P = 26 hp

Rotational speed of pinion np = 907.692 rpm

Number of pinion teeth Np = 26

Desired output speed ng = 290.927 rpm

Design life L = 25000 h

Number of load applications per q = 1

revolution

Rim thickness of

and gear

pinion

me tr = 1 1 in

Bending geometry factor of J = 0.451 0.512

pinion and gear

om

Pitting geometry factor I = 0.207

Gear application Commercial enclosed gear

units

Elastic coefficient Cp = 2300

Overload factor Ko = 1.25

Factor of safety SF = 1

Hardness ratio factor Ch = 1

rC

Reliability factor Kr = 1

Results

Diametral pitch Pd = 10.625 teeth/in

Transverse pressure angle t = 20.647 °

t fo

Actual output speed ng = 291.358 rpm

Actual number of gear teeth Ng = 81

Gear ratio mg = 3.115

Qualty number Qv = 7.000

Geometry parameters

Pinion Gear

No

Pitch diameter D = 2.447 7.623 in

Outside diameter Do = 2.635 7.812 in

Root diameters Dr = 2.212 7.388 in

Base circle diameter Db = 2.290 7.134 in

05/11/2018 12:37:34 Page 1/2

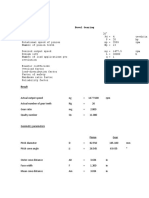

Tedata

Program : MDESIGN User : Customer :

se

Version : 1.1.2 Date : 11.05.2018 Proj. Nr :

Helical Gearing

U

Addendum a = 0.094 in

Dedendum b = 0.118 in

Clearance c = 0.023 in

al

Circular pitch p = 0.296 in

Normal circular pitch Pn = 0.286 in

Axial pitch Px = 1.103 in

Whole depth ht = 0.212 in

Working depth hk = 0.188 in

rci

Tooth thickness t = 0.143 in

Center distance C = 5.035 in

Fillet radius in basic rack rf = 0.028 in

Force and speed factors

Pitch line speed vt = 581.492 ft/min

Tangential force

Normal force

Radial force

me Wt

Wn

Wr

=

=

=

1474.920

1624.946

555.764

lbf

lbf

lbf

Axial force Wx = 395.204 lbf

Size factor Ks = 1.000

Load distribution factor Km = 1.262

om

Dynamic factor Kv = 1.259

Face width/Axial pitch F/Px = 2.266

Pinion Gear

Rim thickness factor Kb = 1.000 1.000

Number of load cycle Nc = 1.4e+009 4.4e+008

Bending stress cycle factor Yn = 0.932 0.951

rC

Pitting stress cycle factor Zn = 0.893 0.917

Expected bending stress St = 27608.072 24318.829 psi

Expected contact stress Sc = 1.106e+005 1.106e+005 psi

Allowable bending stress number Sat = 29609.166 25559.259 psi

Allowable contact stress number Sac = 1.239e+005 1.207e+005 psi

t fo

Note

After computing the values for allowable bending stress number and for

allowable

contact stress number, you should go to the data in AGMA Standard 2001-C95,

to

select a suitable material. Consider first whether the material should be

steel,

cast iron, bronze, or plastic. Then consult the related tables of data.

No

For instance use through-hardened steel with hardness, HB

Pinion Gear

Grade 1 294.291 256.623

Grade 2 284.367 247.468

05/11/2018 12:37:34 Page 2/2

Das könnte Ihnen auch gefallen

- Not For Commercial Use: TedataDokument3 SeitenNot For Commercial Use: TedataMayber DelgadoNoch keine Bewertungen

- Tedata: Programm Benutzer Datum Kunde Proj. NRDokument3 SeitenTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNoch keine Bewertungen

- Tedata: Programm Benutzer Datum Kunde Proj. NRDokument3 SeitenTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoNoch keine Bewertungen

- Not For Commercial Use: TedataDokument2 SeitenNot For Commercial Use: Tedatawilly rojas zeballosNoch keine Bewertungen

- Tedata: Program User Date Customer Proj. NR: Mdesign: 1.1.2:: 10.04.2019Dokument3 SeitenTedata: Program User Date Customer Proj. NR: Mdesign: 1.1.2:: 10.04.2019Juanjo Torrez V100% (1)

- Astorga Entrada ConicosDokument3 SeitenAstorga Entrada ConicosGadiel BalderasNoch keine Bewertungen

- Input Data MijaDokument3 SeitenInput Data MijaMijael Tarqui PortilloNoch keine Bewertungen

- Involute Spur Gear Geometry Calculations: Input DataDokument11 SeitenInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVNoch keine Bewertungen

- DiseñoDokument2 SeitenDiseñobombon fabeNoch keine Bewertungen

- First Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2Dokument4 SeitenFirst Worm Finding Number of Teeth and Gear Diameter: DW+DG 2 1.5 in +4.7 in 2mitha07Noch keine Bewertungen

- V-Belt, US StandardsDokument1 SeiteV-Belt, US StandardsErick SalmonesNoch keine Bewertungen

- Machine DesignDokument15 SeitenMachine DesignYaNoch keine Bewertungen

- Input Data: Narrow V-Belt GeometryDokument2 SeitenInput Data: Narrow V-Belt GeometryJohnPérezNoch keine Bewertungen

- Form M Date 10/15/82 Time 16:41 Pinion Gear: Appendix BDokument3 SeitenForm M Date 10/15/82 Time 16:41 Pinion Gear: Appendix BCarlos GonzalesNoch keine Bewertungen

- Ejemplo de Engranajes HelicoidalesDokument2 SeitenEjemplo de Engranajes HelicoidalesMijhael Anatholi Romero MamaniNoch keine Bewertungen

- CURELEDokument2 SeitenCURELEDiana Maria CozmaNoch keine Bewertungen

- Segunda ChavetaDokument1 SeiteSegunda ChavetaAntonio MoscosoNoch keine Bewertungen

- This Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Dokument3 SeitenThis Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Thomas StephenNoch keine Bewertungen

- Mod10 1ToothBendingDokument4 SeitenMod10 1ToothBendingMario AndradeNoch keine Bewertungen

- Project Gear Design TemplateDokument38 SeitenProject Gear Design Templatenofal AdreesNoch keine Bewertungen

- 6.3 Wind Load Calculation: Description Variable Formula Value UnitDokument4 Seiten6.3 Wind Load Calculation: Description Variable Formula Value UnitNitesh SinghNoch keine Bewertungen

- Chabeta Con MDESIGNDokument1 SeiteChabeta Con MDESIGNEbanderNoch keine Bewertungen

- Teds CheckDokument5 SeitenTeds Checkkidist.bedadaNoch keine Bewertungen

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Dokument2 SeitenFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNoch keine Bewertungen

- Priner ChaveteroDokument1 SeitePriner ChaveteroAntonio MoscosoNoch keine Bewertungen

- FWEFJLNIY4QKLQXDokument13 SeitenFWEFJLNIY4QKLQXSoldan MihaiNoch keine Bewertungen

- Design of Agitator 8 Batch Volume PDFDokument3 SeitenDesign of Agitator 8 Batch Volume PDFakash kumarNoch keine Bewertungen

- Joint Check 1Dokument9 SeitenJoint Check 1abin100% (1)

- Calculation of Seismic Coefficient: ProjectDokument1 SeiteCalculation of Seismic Coefficient: Projectnandu523Noch keine Bewertungen

- Tension Member Double AngleDokument1 SeiteTension Member Double AnglechaNoch keine Bewertungen

- Machine Design Formula ListDokument7 SeitenMachine Design Formula ListHarpreet Randhawa100% (3)

- Spur Gear CalculationsDokument7 SeitenSpur Gear Calculationsaniket patilNoch keine Bewertungen

- EPM-GL-PI-CLC-0003 - Rev 0 - PSV Reaction Force CalculationDokument5 SeitenEPM-GL-PI-CLC-0003 - Rev 0 - PSV Reaction Force CalculationHernán DazaNoch keine Bewertungen

- V Belt CalculationDokument5 SeitenV Belt Calculationashey7777100% (1)

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionDokument6 SeitenChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionGaurav BedseNoch keine Bewertungen

- MB4 (Rafter To Corner Column)Dokument63 SeitenMB4 (Rafter To Corner Column)Crystal JaneNoch keine Bewertungen

- Mechanical Engineering Handbook 96 105Dokument10 SeitenMechanical Engineering Handbook 96 105basaricaNoch keine Bewertungen

- Gears Spur Agma SI v0Dokument5 SeitenGears Spur Agma SI v0PuBg PrONoch keine Bewertungen

- Chain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Dokument1 SeiteChain Drive Calculation - 31-May-2017: Chain: ANSI 60 (ISO 606) Duplex Renold Synergy Serial Number: GY60A2Principe Reyes JuniorNoch keine Bewertungen

- Design of Spur Helicoidal Gears Initial Input DataDokument3 SeitenDesign of Spur Helicoidal Gears Initial Input DataMijhael Anatholi Romero MamaniNoch keine Bewertungen

- Flange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 EditionDokument1 SeiteFlange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 Editionגרבר פליקסNoch keine Bewertungen

- Project:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed byDokument1 SeiteProject:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed bySantosh BapuNoch keine Bewertungen

- Milling PowerDokument1 SeiteMilling PowerRicardo VitorianoNoch keine Bewertungen

- L Angle TensionDokument1 SeiteL Angle TensionchaNoch keine Bewertungen

- 참고자료 12. Lifting Lug AnalysisDokument3 Seiten참고자료 12. Lifting Lug Analysisaoaaoa1122Noch keine Bewertungen

- Appendix A1Dokument5 SeitenAppendix A1Thomas Stephen100% (1)

- Reference:: Anchor ChairDokument4 SeitenReference:: Anchor ChairShaheed HossainNoch keine Bewertungen

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDokument1 SeiteChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNoch keine Bewertungen

- Turbine Sizing DatedDokument29 SeitenTurbine Sizing Datedjhaamit4Noch keine Bewertungen

- Lifting Lug CalculatorDokument3 SeitenLifting Lug CalculatoranufabdesignsNoch keine Bewertungen

- Pump Sizing Calculation SheetDokument10 SeitenPump Sizing Calculation SheetSteve WanNoch keine Bewertungen

- Bearing (WF & Builtup)Dokument71 SeitenBearing (WF & Builtup)faizan ashiqueNoch keine Bewertungen

- Relief Case Eng TipsDokument6 SeitenRelief Case Eng TipspartoNoch keine Bewertungen

- Langston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFDokument9 SeitenLangston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFeacondeNoch keine Bewertungen

- Pulley Calculations Data SheetDokument1 SeitePulley Calculations Data SheetazharscarNoch keine Bewertungen

- External Applied Torque: Applying, We: A B A BDokument1 SeiteExternal Applied Torque: Applying, We: A B A BJuan BlanquicettNoch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- Electromagnetic Foundations of Electrical EngineeringVon EverandElectromagnetic Foundations of Electrical EngineeringNoch keine Bewertungen

- Dvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302Dokument14 SeitenDvp-Es2 Ss2 Sa2 Sx2-Program o en 20110302yasinNoch keine Bewertungen

- Manual of Metal Bellows - 0441e S 56-77!2!04!10!20 - WebDokument11 SeitenManual of Metal Bellows - 0441e S 56-77!2!04!10!20 - Webadfafad gfadfNoch keine Bewertungen

- Planning For Urban Scale Photovoltaic SystemsDokument43 SeitenPlanning For Urban Scale Photovoltaic SystemsRoseRosaNoch keine Bewertungen

- RDM-chapter 1Dokument35 SeitenRDM-chapter 1Mat MatttNoch keine Bewertungen

- Prismic R10: Product SpecificationDokument2 SeitenPrismic R10: Product SpecificationParag HemkeNoch keine Bewertungen

- Viado, Emmanuel Russell PDokument27 SeitenViado, Emmanuel Russell PRussell ViadoNoch keine Bewertungen

- Capacidad de ConductoresDokument4 SeitenCapacidad de ConductoresCämpänitä FentyNoch keine Bewertungen

- Some Practical Laboratory ExperimentsDokument15 SeitenSome Practical Laboratory ExperimentsZwinky ManlaiNoch keine Bewertungen

- Quility Geo ScicenceDokument28 SeitenQuility Geo ScicenceAsfandiyar SareerNoch keine Bewertungen

- Integration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmDokument1 SeiteIntegration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmMeteodyn_EnergyNoch keine Bewertungen

- Grade 7 Mixtures and Solutions Full ReviewDokument28 SeitenGrade 7 Mixtures and Solutions Full Reviewblackcat657Noch keine Bewertungen

- Pollen and Spore Morphology, Plant Taxonomy - ErdtmanDokument178 SeitenPollen and Spore Morphology, Plant Taxonomy - ErdtmanAndres Elgorriaga100% (1)

- Instruction Manual PHE PDFDokument78 SeitenInstruction Manual PHE PDFzniperxNoch keine Bewertungen

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Dokument150 SeitenSM MultiV IV Air Outdoor Units 4 15 - 20150414080917Gino Waximinguirijillo Santana100% (3)

- Thermodynamic Optimization of A Trigeneration System Based On Biomass CombustionDokument9 SeitenThermodynamic Optimization of A Trigeneration System Based On Biomass CombustionTiago HenriquesNoch keine Bewertungen

- Icho1986-1994p Technical and PhysicalDokument38 SeitenIcho1986-1994p Technical and PhysicalAlexandra AlgueraNoch keine Bewertungen

- Etoos Solid State PS SirDokument27 SeitenEtoos Solid State PS SirGyandeep KalitaNoch keine Bewertungen

- CycloalkanesDokument60 SeitenCycloalkanesmeri hardina zd100% (1)

- Osmosis LabDokument3 SeitenOsmosis LabMutuluShakurNoch keine Bewertungen

- Tachi e 2004Dokument12 SeitenTachi e 2004Ahsan Habib TanimNoch keine Bewertungen

- Astm D36Dokument4 SeitenAstm D36Sachin Kumar Singh33% (3)

- Vibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsDokument44 SeitenVibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsVyankatesh AshtekarNoch keine Bewertungen

- Rankine Cycle Notes PDFDokument6 SeitenRankine Cycle Notes PDFmizpah mae jolito0% (1)

- CS3205 A8Dokument10 SeitenCS3205 A8Rian BattlaxNoch keine Bewertungen

- PART 4 Problemsinmathem031405mbpDokument125 SeitenPART 4 Problemsinmathem031405mbpnaytpuri montemayorNoch keine Bewertungen

- New Cosmos PDFDokument32 SeitenNew Cosmos PDFIshan RanganathNoch keine Bewertungen

- MDOT Research Report NMB Splice PDFDokument74 SeitenMDOT Research Report NMB Splice PDFRajnikanth GedhadaNoch keine Bewertungen

- PV Elite Tips and TricksDokument50 SeitenPV Elite Tips and TricksHoracio Rodriguez80% (5)

- Role of Physics in Daily LifeDokument2 SeitenRole of Physics in Daily LifeSadam MaharNoch keine Bewertungen