Beruflich Dokumente

Kultur Dokumente

Hwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDF

Hochgeladen von

Eduardo MarquesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDF

Hochgeladen von

Eduardo MarquesCopyright:

Verfügbare Formate

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 97-S4

Analytical Model for Predicting Shear Strengths of Interior

Reinforced Concrete Beam-Column Joints for Seismic

Resistance

by Shyh-Jiann Hwang and Hung-Jen Lee

A softened strut-and-tie model has previously been developed for

determining the shear strengths of exterior beam-column joints for

seismic resistance. This existing model originates from the strut-and-

tie concept and satisfies equilibrium, compatibility, and the constitu-

tive laws of cracked reinforced concrete. This paper examines the

applicability of the previously proposed model to interior beam-

column joints. The calculated shear capacities of 56 interior joints

were compared with the experimental results, and good agreement

was obtained.

Keywords: beams (supports); compressive strength; reinforced concrete;

shear properties; strength.

INTRODUCTION

Beam-column joints are critical because they ensure conti-

nuity of a structure and transfer forces from one element to

another. The flow of forces within beam-column joints may

be interrupted if the shear strengths of the joints are not

adequately provided. Understanding the strength behavior of

a beam-column joint under seismic actions and being able to

model it analytically are important aims in the achievement Fig. 1—External actions and internal shears at interior joint.

of safe reinforced concrete structures.

A rational model for determining the shear strengths of exte- SOFTENED STRUT-AND-TIE MODEL

Before introducing the analytical model, the forces around

rior beam-column joints for seismic resistance has been

and within a joint should be identified. Figure 1 shows the

proposed in a companion paper.1 The proposed model, called

earthquake-induced forces acting on an interior joint. The

the softened strut-and-tie model, is based on the concept of horizontal joint shear force can be calculated as

struts and ties and derived to satisfy equilibrium, compatibility,

and the constitutive laws of cracked reinforced concrete. V jh = T b1 + C b2 – V c1 (1)

This paper represents a continuation of the previously

mentioned research. The applicability of the proposed where Vjh is the horizontal joint shear force; Tb1 is the tensile

model1 to interior beam-column joints is explored. Also, the force resulting from the steel of the beam at the right of the

precision of the analytical model is further gaged by the joint; C b2 is the compressive force resulting from the

available experimental data. compression zone of the beam at the left of the joint; and Vc1

is the horizontal column shear above the joint. Actually the

RESEARCH SIGNIFICANCE tensile force T b1 is not necessarily coincided with the

The current design provisions on the beam-column joints compressive force C b2 , and Fig. 1 is only a simplified

of the ACI 318-95 Code2 are based empirically on results of version on this matter.

tests. Consequently, they must be restricted to joints whose Considering the dimensions of beam and column tension-

properties closely match those of the tested joints. This leads compression couples (Fig. 1), the intensity of the vertical

to many design limitations, and little guidance is provided joint shear force Vjv can be approximated

for the design of joints that may not meet these limitations.

h′b

A good physical model is needed to predict the shear V jv ≈ ------

- × V jh (2)

h′c

strengths of joints under seismic attack. It becomes an imper-

ative necessity to the seismically insufficient joints that typi-

cally fall outside of the limited range of those considered in ACI Structural Journal, V. 97, No. 1, January-February 2000.

Received June 18, 1998, and reviewed under Institute publication policies. Copy-

the ACI 318-95 Code.2 This paper presents a rational model right © 2000, American Concrete Institute. All rights reserved, including the making

that is capable of predicting the shear strengths of interior of copies unless permission is obtained from the copyright proprietors. Pertinent discus-

sion will be published in the November-December 2000 ACI Structural Journal if

beam-column joints for seismic resistance. received by July 1, 2000.

ACI Structural Journal/January-February 2000 35

The proposed model consists of the diagonal, horizontal, and

ACI member Shyh-Jiann Hwang is Professor of Construction Engineering at the

National Taiwan University of Science and Technology. He received his MS and PhD vertical mechanisms as shown in Fig. 2. The diagonal mech-

from the University of California at Berkeley. His research interests include seismic anism (Fig. 2(a)) is a single diagonal compression strut

behavior of beam-column joints, shear strengths of reinforced concrete members, and

bond and anchorage.

whose angle of inclination θ is defined as

Hung-Jen Lee is a PhD candidate in construction engineering at the National – 1 h′′

θ = tan ---------

Taiwan University of Science and Technology. His research interests include behavior b

(3)

and design of RC beam-column joints. h′′c

where hb′′ and hc′′ are the distances between the extreme

longitudinal reinforcement in the beams and columns,

respectively. It is also assumed that the direction of the diag-

onal concrete strut coincides with the direction of the prin-

cipal compressive stress of the concrete.

The effective area of the diagonal strut Astr is defined as

Astr = as × bs (4)

where as is the depth of the diagonal strut, and bs is the width

of the diagonal strut, which can be taken as the effective

width of the joint as per the ACI 318-95 Code.2

According to the recommendation of Zhang and Jirsa,3 the

depth of a strut without a beam hinge occurring at the face of

the column can be determined as

2 2

as = ab + a c (5)

where ab and ac are the depths of the compression zones in

the beam and column, respectively. For joints where a beam

hinge occurs at the face of the column, the spalling of the

compression zone in the beam is frequently observed. Since

the crushing of concrete produces a small compression zone

in the beam, the neglect of ab in computing as is assumed.

Therefore, the depth of the strut can be estimated as3

as = ac (6)

Following the suggestion of Paulay and Priestley,4 the depth

of the flexural compression zone of the elastic column can be

approximated by

a c = 0.25 + 0.85 ----------- h c

N

(7)

A g f c ′

where N is the axial force acting on the column; f c′ is the

compressive strength of a standard concrete cylinder; Ag is

the gross area of the column section; and hc is the thickness

of the column in the direction of loading.

The horizontal mechanism (Fig. 2(b)) is composed of one

horizontal tie and two flat struts. The joint hoops constitute the

horizontal tie. It is roughly assumed that the joint hoops within

Fig. 2—Joint shear-resisting mechanisms. the center half of the core are considered fully effective when

computing the cross area of the horizontal tie, and that the other

where hb′ and hc′ are the internal lever arms in the beams and joint core hoops are included at a rate of 50%. Figure 3 explains

columns, respectively. The column axial load coupled with how to determine the area of the horizontal tie.

moment will increase the vertical joint shear force Vjv and The proposed vertical mechanism (Fig. 2(c)) includes one

decrease the internal lever arm in the column hc′ . vertical tie and two steep struts. The vertical tie is made up

of the intermediate column bars. The way to estimate the

Macromodel cross area of the vertical tie is also presented in Fig. 3.

Statically indeterminate strut-and-tie load paths are The proposed model is a statically indeterminate system.

proposed to model the force transferring within the joint.1 The yielding of ties does not stop the development of the

36 ACI Structural Journal/January-February 2000

Fig. 3—Determination of areas of horizontal and vertical ties.

shear strength of the joint5 because the inherent diagonal strut

is capable of transferring shear force alone. Failure is defined Fig. 4—Strut-and-tie model at maximum response.

as the crushing of concrete in the compression strut adjacent

to the nodal zone (Fig. 1). Therefore, the shear strength of the

joint is calculated as the concrete compressive stress on the Schäfer,7 the statically indeterminate tie-force Fh in the

nodal zone as it reaches its capacity. The boundary of the reduced mechanisms (Fig. 5(a)) is assumed to be

nodal zone coincides with the diagonal strut boundary, but the

concrete bearing force to be examined is the summation of F h = γ h × V jh (10)

compressions from the diagonal, flat, and steep struts (Fig. 2).

2 tan θ – 1

Equilibrium γ h = --------------------- for 0 ≤ γh ≤ 1

Figure 4 shows the proposed strut-and-tie model for an 3

interior beam-column joint. The horizontal joint shear to be

resisted by the strut-and-tie model is found as where γh is the fraction of horizontal shear transferred by the

horizontal tie in the absence of the vertical tie. Equation (10)

V jh = – D cos θ + F h + F v cot θ (8) is a linear interpolation of Fh between two borderline cases,

namely, that the entire horizontal shear is carried by the indi-

rect load-path (Fh = Vjh) for θ ≥ tan–1(2) and that the entire

where D is the compression force in the diagonal strut; Fh is horizontal shear is transferred by the direct compression strut

the tension force in the horizontal tie; and Fv is the tension

force in the vertical tie. Similarly, the vertical joint force is (Fh = 0) for θ ≤ tan–1(1/2).

expressed as (Fig. 4)

The vertical shear (or increment) is resisted only by the

V jv = – D sin θ + F h tan θ + F v (9) diagonal and vertical mechanisms in the absence or yielding

of the horizontal tie. Figure 5(b) presents the fraction of the

It is of interest to note that the ratio of Vjv/Vjh = tanθ is vertical shear assigned to the vertical tie6,7 in the previous case

always maintained for any combination of the selected

mechanisms. F v = γ v × V jv (11)

There are three load-paths in the joint region, and the

ratios to divide the joint shear forces among the resisting

2 cot θ – 1

mechanisms should be determined. If the intermediate γ v = ----------------------- for 0 ≤ γv ≤ 1

column bars do not exist or the yielding of the vertical tie 3

occurs, the horizontal shear (or increment) is then resisted

only by the diagonal and horizontal mechanisms as shown in where γ v is the fraction of vertical shear carried by the

Fig. 5(a). According to Schäfer et al.6 and Jennewein and vertical tie in the absence of the horizontal tie.

ACI Structural Journal/January-February 2000 37

–1 Rd

D = ------------ × ----------------------------------

- × V jh (17)

cos θ ( R d + R h + R v )

Rh

- × V jh

F h = ---------------------------------- (18)

( Rd + Rh + Rv )

1 Rv

F v = ----------- × ----------------------------------- × V jh (19)

cot θ ( R d + R h + R v )

To check whether the joint strength is being reached, the

bearing pressure on the nodal zone (Fig. 2) where the

compressive forces from the diagonal, flat, and steep struts

meet at a node (Fig. 4) should be estimated. Since the

inclined joint shear is mainly transferred in the d-direction

(Fig. 1), the maximum compressive stress σd,max acting on

the nodal zone is assumed to govern the failure. With some

algebraic efforts, the value of σd,max is given by

– 1 h′′

cos θ – tan -----------

b

2h′′

-

= -------- D – ------------------------------------------------------ F h

1 c

σ d, max (20)

A str – 1 h′′

cos tan -----------

b

-

2h′′ c

– 1 2h ′′

Fig. 5—Forces in struts and ties. cos tan ----------- b

- – θ

h c′′

– ------------------------------------------------------ F v

– 1 2h b′′

sin tan ----------- -

Based on the previous finding of Schäfer et al.6 and Jenne- h c′′

wein and Schäfer,7 it is further assumed that the ratios of the

horizontal shear Vjh assigned among the three mechanisms

are defined as Constitutive laws

The ascending branch of the softened stress-strain curve of

the cracked concrete, as proposed by Zhang and Hsu,8 is as

– D cos θ: F h :F v cot θ = R d :R h :R v (12) follows

Also, the same fractions of the vertical shear Vjv are shared –ε –ε 2 –ε

among the three mechanisms σ d = – ζ f c′ 2 -------d- – -------d- for -------d- ≤ 1 (21)

ζε o ζε o ζε o

– D sin θ: F h tan θ:F v = R d :R h :R v (13)

5.8 1 0.9

ζ = --------- --------------------------- ≤ --------------------------- (22)

where Rd , Rh , and Rv are the ratios of the joint shears resisted f c′ 1 + 400ε r 1 + 400ε r

by the diagonal, horizontal, and vertical mechanisms,

respectively. The values of these ratios are defined as where σd is the average principal stress of concrete in the d-

direction; ζ is the softening coefficient; f c′ is the compressive

( 1 – γh ) ( 1 – γv ) strength of a standard concrete cylinder in units of MPa; εd

R d = ------------------------------------

- (14) and εr are the average principal strains in the d- and r- direc-

1 – γh γv

tions, respectively; and εo is the concrete cylinder strain

corresponding to the cylinder strength f c′ that can be defined

γh ( 1 – γv ) approximately as9

R h = ----------------------

- (15)

1 – γh γv

f c′ – 20

ε o = 0.002 + 0.001 ----------------

- for (23)

γv ( 1 – γh ) 80

R v = ----------------------

- (16)

1 – γh γv

20 ≤ fc′ ≤ 100 MPa

It is carefully scaled such that the sum of Rd, Rh, and Rv

equals unity. To facilitate the calculation, Eq. (12) can be By recognizing Eq. (21), the shear strength of the joint is

restated as assumed to be reached whenever the compressive stress and

38 ACI Structural Journal/January-February 2000

strain of the concrete diagonal strut arrive at the following

situations

σd = –ζ · fc′ (24)

εd = –ζ ⋅ εo (25)

If the stress-strain relationships of bare mild steel for the

joint hoops and the intermediate column bars are assumed to

be elastic-perfectly-plastic, then

f s = E s ε s for ε s < ε y (26)

f s = f y for ε s ≥ ε y (27)

where Es is the elastic modulus of the steel bars; and fs and

εs are stress and strain in the mild steel, respectively. fs

becomes fh or fv, εs becomes εh or εv, and fy becomes fyh or

fyv when applied to joint hoop reinforcement or intermediate

column bars, respectively.

Neglecting the tension stiffening effect due to concrete,

the relationship between forces and strains of the tension ties

can be constructed.

F h = A th E s ε h ≤ F yh (28)

F v = A tv E s ε v ≤ F yv (29)

where Ath and Atv are the areas of the horizontal and vertical

ties, respectively; and Fyh and Fyv are the yielding forces of

the horizontal and vertical ties, respectively.

Compatibility

Accepting the predetermined angle of inclination of the

principal compressive stress θ, the principal tensile strain εr

can be related to the horizontal strain εh, the vertical strain

εv , and the magnitude of the principal compressive strain εd

based on the two-dimensional compatibility condition10

Fig. 6—Flow chart showing efficient algorithm.

εr + εd = εh + εv (30)

This equality states that the sum of the normal strains in the constraining the cracks. The Type-YV analysis treats the case

perpendicular direction is a constant. that the yielding of the vertical tie precedes the reaching of the

Equation (30) is used to estimate the value of the principal concrete strength, whereas the horizontal tie is still in the elastic

tensile strain εr , which is directly related to the extent of soft- range. The scope of the Type YHV includes the case where the

ening of the concrete as per Eq. (22). The treatment of Eq. yielding of the horizontal tie occurs first, then the vertical tie

(30) is different from that which had been used in Reference yields, and finally the concrete strut arrives at its capacity. The

1, and Eq. (30) is a simple but effective way for solution yielding sequence of the ties for Type YVH is in reverse. More

procedures. details of these analyses can be found in Reference 1.

Solution procedures EXPERIMENTAL VERIFICATION

A set of solution procedures is proposed, as shown in the The proposed model was used to calculate the joint shear

flow charts in Fig. 6 and 7. The solution procedure is catego- strengths of 56 test specimens (Table 1) described in the

rized into five types of analyses (Type E, YH, YV, YHV, and literature. Twenty of these joints were tested in the United

YVH) for varied yielding conditions of the ties. The case of States,12,15,18,21,23 ten in New Zealand,5,11,13,14,16,17 and 26

Type E means that the concrete strut reaches its strength in Japan.19,20,22,24-27 In selecting these test data, a number of

while the horizontal and vertical ties remain in the elastic screens were applied. They were as follows:

range. The Type-YH analysis deals with the case that the 1. Specimens with floor slab, transverse beam, lightweight

yielding of the horizontal tie precedes the reaching of the concrete, or eccentricity between column and beam axes

concrete strength but the vertical tie is still effective in were omitted; and

ACI Structural Journal/January-February 2000 39

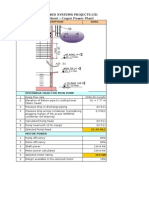

Table 1—Experimental verification

fc′ , fyh, fyv, Vjh,test Failure Astr , Ath , Atv , Calculation Vjh,calc , Vjh,test/

Authors Specimens MPa MPa MPa N/Ag fc′ kN mode θ degree cm2 mm2 mm2 type kN Vjh,calc

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14) (15)

Blakeley et al.11 Interior 48.5 297 289 0.03 1722 F1 54 1285 9088 4914 E 2669 0.65

I 26.2 409 457 0.39 1090 J3 44 980 516 1548 YH 1142 0.95

II 41.8 409 449 0.25 1597 J3 45 804 516 3276 YH 1476 1.08

III 26.6 409 402 0.39 1228 J3 46 973 516 6036 YH 1180 1.04

IV 36.1 409 438 0.29 1454 J3 59 903 1032 1290 YH 1138 1.28

V 35.9 409 449 0.04 1530 J3 45 593 516 3276 YH 971 1.58

Meinheit et al.12

VI 36.8 409 449 0.47 1646 J2 45 979 516 3276 YH 1582 1.04

VII 37.2 409 438 0.46 1468 J3 59 110 1032 1290 YH 1375 1.07

XII 35.2 423 449 0.29 1948 J2 46 755 2000 3276 E 1315 1.48

XIII 41.3 409 449 0.25 1557 J3 45 808 1290 3276 E 1562 1.00

XIV 33.2 409 438 0.31 1539 J3 59 932 2580 1290 E 1309 1.18

Unit 1 42.9 275 280 0.00 521 J1 45 188 1533 402 E 391 1.33

Fenwick et al.13

Unit 3 39.3 275 318 0.00 437 J1 47 188 1799 452 E 365 1.20

BI 27.9 346 427 0.05 1217 J2 55 617 1520 1810 E 759 1.60

Birss14

B2 31.5 398 427 0.44 1213 J1 55 1302 398 1810 YH 1405 0.86

Viwathanatepa BC3 31.1 448 490 0.36 793 F1 42 1038 633 1136 E 1444 0.55

et al.15 BC4 31.5 448 490 0.36 874 F1 42 1030 633 1136 E 1451 0.60

B11 35.9 336 423 0.04 965 F1 55 596 3096 1548 E 977 0.99

Beckingsale16 B12 34.6 336 422 0.04 982 F1 55 599 3096 1548 E 949 1.03

B13 31.4 336 398 0.26 1015 F1 55 976 2580 1548 E 1328 0.76

Park et al.17 Interior 34.0 305 412 0.24 966 J2 49 559 1608 628 E 841 1.15

5 Unit 1 41.3 320 473 0.10 1001 J1 50 415 2413 905 E 799 1.25

Park et al.

X1 34.3 352 414 0.05 840 J2 51 388 881 1020 E 592 1.42

Durrani et al.18 X2 33.6 352 414 0.06 853 J1 51 389 881 1020 E 583 1.46

X3 31.0 352 345 0.05 629 J1 51 386 881 568 E 529 1.19

J1 25.6 367 374 0.08 516 J1 45 284 128 762 YH 330 1.56

J2 24.0 367 374 0.08 536 J1 45 288 256 762 E 328 1.63

J3 24.0 367 374 0.08 576 J1 45 288 640 762 E 353 1.63

Otani et al.19,20

J4 25.7 367 374 0.23 503 J1 45 400 128 762 YH 455 1.11

J5 28.7 367 374 0.07 491 J1 45 277 128 0 YVH 308 1.60

J6 28.7 367 374 0.07 336 F1 45 277 256 284 E 349 0.96

C1 25.6 324 422 0.08 436 F1 45 284 128 762 YH 334 1.31

Otani et al.19,20 C2 25.6 324 422 0.08 432 F1 45 284 512 762 E 364 1.19

C3 25.6 324 422 0.08 410 F1 45 284 512 762 E 364 1.13

LIJ3 31.1 400 470 0.00 724 J1 33 392 284 0 YV 554 1.31

Abrams 21

LIJ4 34.3 400 470 0.00 789 F1 34 392 284 0 YV 598 1.32

No. 2 32.9 330 348 0.06 553 J1 45 271 64 762 YH 396 1.40

No. 4 32.9 330 348 0.06 623 J1 45 271 64 762 YH 396 1.57

Noguchi et al.22

No. 5 28.5 330 348 0.07 570 F1 45 278 640 762 E 398 1.43

No. 7 28.5 330 348 0.07 605 F1 45 278 64 762 YH 356 1.70

BCJ2 30.3 414 448 0.00 358 J2 52 161 190 774 YH 205 1.75

Leon23 BCJ3 27.4 414 448 0.00 394 J1 45 194 190 774 E 252 1.56

BCJ4 27.2 414 448 0.00 462 F1 40 226 190 516 E 323 1.43

B8-HH 25.6 1320 404 0.15 272 F1 50 342 400 762 E 380 0.72

HL 27.4 1320 404 0.14 277 F1 50 335 400 762 E 394 0.70

Joh et al.24 MH 28.1 377 404 0.14 275 F1 50 332 280 762 YH 387 0.71

LH 26.9 377 404 0.15 274 F1 50 337 168 762 YH 365 0.75

MHUB 26.1 377 404 0.15 239 F2 50 340 280 0 YVH 371 0.64

A1 30.6 320 540 0.06 689 J3 46 355 168 1194 YH 486 1.42

B1 24.5 235 351 0.08 570 J1 46 286 168 1194 YH 331 1.72

Kitayama et al.25

B2 24.5 235 351 0.08 570 J2 46 286 168 1194 YH 331 1.72

B3 24.5 235 371 0.08 515 J1 45 286 420 762 E 348 1.48

A1 40.2 291 644 0.08 412 J3 51 223 112 762 YH 353 1.17

A2 40.2 291 387 0.08 380 J3 51 223 112 762 YH 353 1.08

Fujii et al.26

A3 40.2 291 644 0.23 412 J3 51 269 112 762 YH 421 0.98

A4 40.2 291 644 0.23 421 J3 51 269 336 762 YH 441 0.95

Average 48 Average 1.2

Total 56

COV 0.11 COV 0.27

40 ACI Structural Journal/January-February 2000

Fig. 7—Algorithm for post-yielding cases.

2. Only specimens failing in a joint or a beam adjacent to According to the seismic performance of the beam-

a column were considered; specimens with a relocated beam column subassemblages, the failure modes of the selected

hinge or those that had failed prematurely in a column were specimens were classified into F1, J1, J2, and J3 groups (Fig. 8).

omitted. The letter “F” designates beam flexural failure, and “J” indi-

The specimens selected encompass a wide range of cates joint shear failure. The behavior of the subassemblage

material properties, geometry, loading, loading sequence, (Fig. 8) is judged by the H-Δ response. The quantity H

represents the equivalent horizontal load capacity of the

and reinforcement detailing, as summarized in Table 1

subassemblage, including the P-Δ effect, and it can be

according to chronological order. The experimental joint

expressed as28

strengths (Vjh,test) in Table 1 were either reported in the

literature or derived using Eq. (1) based on the maximum

value of the column or beam shears measured during the Δ

H = H + N ----- (31)

test. Lc

ACI Structural Journal/January-February 2000 41

Fig. 8—Classification of failure modes of interior beam- Fig. 9—Correlation of experimental and predicted joint shear

column subassemblage. strengths.

where H is the horizontal load applied at the column end; Δ

is the horizontal displacement measured at the column end; Table 2—Statistics of shear strength ratios

and Lc is the hinge-to-hinge distance of the column. between experimental and predicted values

The classification of F1 and J1 means that the joint Failure mode

Calculation

strength can reach its design value and that the ductility of type F1 J1 J2 J3 Total

beam-column subassemblages is up to 4 (Fig. 8). The design

0.93† 1.42 1.41 1.09 1.17

level of the joint shear strength was gaged by the ratio of E 13* 9 4 2 28

Hmax/Hy to exceed 1.1 (Fig. 8), which is explained in Refer- 0.32‡ 0.13 0.14 0.12 0.28

ence 1. Yielding load Hy is defined as the equivalent hori- 1.12 1.37 1.50 1.14 1.24

YH 4 6 3 11 24

zontal load when yielding of the subassemblage occurred. 0.42 0.24 0.27 0.18 0.26

Yielding of the subassemblage occurred when the yielding 1.32 1.31 1.31

YV 1 1 None None 2

moment was exceeded in both beams at the column face. — — 0.01

The failure Mode J2 means that the yielding load H y 1.60 1.60

precedes the joint shear failure, and the above sequence of J3 YVH None 1 None None 1

— —

is in reverse (Fig. 8). It is noted that, in the proposed model, 1.0 1.40 1.45 1.14 1.21

the depth of the diagonal strut as of Specimens F1, J1, and J2 Total 18 17 7 13 55

0.34 0.16 0.19 0.17 0.27

was determined by Eq. (6), and that the as of Specimen J3 *

No. of specimens.

was calculated by Eq. (5). For J3 specimens, the ab in Eq. (5) †

Average of Vjh,test/Vjh,calc.

corresponds to the smaller value of the depths of the ‡

COV of Vjh,test/Vjh,calc.

compression zones in the elastic beams at the right and left

of the joint.

In Fig. 9 the experimentally determined shear strengths Examination of existing experimental data indicated that

from 56 joint tests are compared to the shear strengths the proposed model is also capable of predicting the shear

predicted by the method presented in this paper. The strength strengths of the interior beam-column joints. Table 2 shows

ratios that are defined as the ratio of the measured to the that the proposed model yields higher strength ratio for the

calculated strength are listed in Table 1 to indicate the preci- interior joint with the J1 failure mode (mean = 1.40) than that

sion of the proposed model. Figure 9 shows that satisfactory of the exterior joint (mean = 1.07).1 The higher strength ratio

results were obtained for the comparison of measured and for the interior joint, approximately 1.3 (1.40/1.07) times

computed strengths. The average strength ratio is 1.20 and higher, is attributed to the better end conditions of its diag-

the coefficient of variation is 27% (Table 1). onal strut provided by the compression zones in beams and

The accuracy of the proposed model under varied conditions columns. Further investigation on selecting the depth of

is further examined in Table 2. Table 2 displays a similar diagonal Strut a s seems to be needed. It is interesting,

tendency as obtained in the previous analyses for the shear however, to note that the predicting ratio 1.3 (1.40/1.07)

strengths of the exterior joints.1 For F1 specimens, the value between the interior to exterior joints is close to the shear

of V jh,test was determined mainly by the beam flexural strength ratio 1.25 (15/12) recommended by the ACI 318-95

strength and not necessarily by the joint shear strength. Code2 for different conditions of joint confinement provided

Therefore, Table 2 shows a wider dispersion for F1 speci- by the framing beams.

mens (COV = 34%) and also the lowest strength ratio (mean The proposed model suggests that the bond strength

= 1.0). The occurrence of more yielding mechanisms leads to between member longitudinal reinforcement and joint core

greater damage accumulating within the joint. Because the concrete deteriorates under reversed cyclic loading. The

proposed model does not include the effect of progressive complete loss of the bond strength along the beam reinforce-

deterioration, the strength ratios of Type E are larger than ment, however, may impair the development of the vertical

those of Type YH for cases with joint failures (J1; Table 2). mechanism, since the horizontal force needed for the equi-

42 ACI Structural Journal/January-February 2000

librium of vertical tie and steep strut (Fig. 4) is probably

missing. Specimen MHUB, tested by Joh et al.,24 was given

the unbond treatment of the beam bars within the joint by

using vinyl chloride pipes. This specimen, categorized as the

F2 failure mode (Table 1), failed by flexure of the beams but

it did not reach the strain hardening range.24 Because the

beam bars had no bond within the joint, it is recommended

to remove the vertical mechanism from the shear resistance

by setting Atv = 0 in the analytical model (Table 1). The

detailed calculation of the specimen MHUB is provided in

the Appendix.* A similar approach may be applied to the

precast beam-to-column joint with unbonded tendons.

The strength behavior of the beam-column joints under

seismic actions is very complicated. The sensitivities of the

related parameters are still not very clear. The proposed

model maintains consistency in its estimations from one situ-

ation to another.

Therefore, the model proposed herein can be used as a tool

to clarify the roles of different parameters. The effect of

column axial load on the joint shear strength is briefly eval-

uated in the following paragraphs.

In the proposed model, the column axial load provides the

beneficial effect on the joint shear strength because it increases

the depth of the strut (Eq. (7)). Figure 10(a) shows the strength

ratios predicted by the proposed model if the beneficial effect

of the column axial load is removed. As shown in Fig. 10(a),

the normalized tested results indicate that the increasing

column axial loads do increase the strength ratios.

By using Eq. (7) to include the effect of column axial load,

Fig. 10(b) presents the strength ratios listed in Table 1. It

seems that the proposed model with Eq. (7) can reasonably

estimate the joint shear strength for the range of N/Ag fc′ less Fig. 10—Effect of column axial load on joint shear strength.

than 0.1 (Fig. 10(b)). The proposed model overestimates the

joint shear strengths for the cases with higher axial loads

(Fig. 10(b), N/Ag fc′ ≥ 0.2). the shear strengths of the interior beam-column joints for

The overestimations in Fig. 10(b) come from the adopted seismic resistance. The so-called softened strut-and-tie

assumption of the proposed model. The angle of inclination model is based on the strut-and-tie concept and derived to

θ of the diagonal strut is assumed to be oriented between the satisfy equilibrium, compatibility, and the constitutive laws

extreme longitudinal reinforcement in the columns for of cracked reinforced concrete.

simplicity, but this assumption is violated by the high axial The proposed method was found to reproduce 56 test

loads in the columns. To direct the angle of inclination θ results from the literature with reasonable accuracy. The

within the centroids of the compression zones of the elastic effect of column axial load on the shear strength of the inte-

columns (ac /3) is more realistic for the high axial loads in the rior joint was briefly studied. One illustrative example that

columns, and this results in a steeper θ (Fig. 10(c)). Consid- describes the computational procedures for the joint spec-

ering the previously mentioned adjustments, the overestima- imen with unbonded beam reinforcement is also provided.

tions for shear strengths of the joints with N/Ag fc′ greater

than 0.35 are corrected (Fig. 10(c)). ACKNOWLEDGMENTS

In contrast to the beneficial effect of the column axial load This research study was sponsored by the National Science Council of the

Republic of China under Project NSC 88-2211-E-011-011. The authors

to increase the depth of the diagonal strut, the high axial would like to express their gratitude for the support.

compression load in the column was reported to accelerate

the deterioration of the joint shear resisting mechanism.19,27 NOTATION

This detrimental effect of the column axial load can be read ab = depth of compression zone in beam adjacent to joint

from Fig. 10(c), where the predicting strength ratios are ac = depth of compression zone in column adjacent to joint

decreased with increased column axial load. With a suffi- as = depth of diagonal strut

cient amount of test data, the beneficial, as well as detri- Ag = gross area of column section

Astr = effective area of diagonal strut

mental, effects of the column axial loads on the joint shear Ath , Atv = areas of horizontal and vertical ties, respectively

strength can be estimated with the aid of the proposed model. bs = width of diagonal strut

Cb1,Cb2 = compressive forces resulting from compression zones of

CONCLUSIONS beams at right and left of joint, respectively

Cc1, Cc2 = compressive forces resulting from compression zone of

Examination of existing experimental data indicated that columns above and below joint, respectively

the previously proposed model1 is also capable of predicting d = direction of diagonal concrete strut

= assumed direction of principal compressive stress of concrete

* D = compression force in diagonal strut (negative for compression)

The Appendix is available in xerographic or similar form from ACI headquarters,

where it will be kept permanently on file at a charge equal to the cost of reproduction Es = elastic modulus of steel bar

plus handling at time of request. fc′ = compressive strength of standard concrete cylinder

ACI Structural Journal/January-February 2000 43

fh, fv = steel stresses in h- and v-directions, respectively Column Joints and Tests Results from Four Units Designed According to the

fs = average tensile stress of mild steel bars, taken as fh and fv in h- New Zealand Code,” Bulletin of the New Zealand National Society for Earth-

and v- directions, respectively quake Engineering, V. 16, No. 1, Mar. 1983, pp. 3-24.

fy = yield strength of bare mild steel 6. Schäfer, K., “Strut-and-Tie Models for the Design of Structural

fyh, fyv = yield strength of bare mild steel of joint hoop reinforcement Concrete,” Notes of Workshop, Department of Civil Engineering, National

and intermediate column bars, respectively Cheng Kung University, Tainan, Taiwan, Mar. 1996, 140 pp.

Fh, Fv = tension forces in horizontal and vertical ties, respectively 7. Jennewein, M., and Schäfer, K., “Standardisierte Nachweise von

(positive for tension) häufigen D-Bereichen,” DAfStb. Heft No. 430, Beuth-Verlag, Berlin, 1992.

Fyh, Fyv = yielding forces of horizontal and vertical ties, respectively (in German)

h = direction of joint hoop reinforcement 8. Zhang, L. X. B., and Hsu, T. T. C., “Behavior and Analysis of 100

hb = beam depth MPa Concrete Membrane Elements,” Journal of Structural Engineering,

h'b = internal lever arm in beam ASCE, V. 124, No. 1, Jan. 1998, pp. 24-34.

hb′′ = distance between extreme longitudinal reinforcement in beams 9. Foster, S. J., and Gilbert, R. I., “The Design of Nonflexural Members

hc = thickness of column in direction of loading with Normal and High-Strength Concretes,” ACI Structural Journal, V. 93,

h'c = internal lever arm in column No. 1, Jan.-Feb. 1996, pp. 3-10.

hc′′ = distance between extreme longitudinal reinforcement in columns 10. Hsu, T. T. C., Unified Theory of Reinforced Concrete, CRC Press,

H = horizontal load applied at column end Inc., Boca Raton, 1993, 336 pp.

H = equivalent horizontal load capacity of subassemblage 11. Blakeley, R. W. G.; Megget, L. M.; and Priestley, M. J. N., “Seismic

including the P-Δ effect Performance of Two Full Size Reinforced Concrete Beam-Column Joint

= H + NΔ/Lc Units,” Bulletin of the New Zealand National Society for Earthquake Engi-

Hmax = maximum value of H neering, V. 8, No. 1, Mar. 1975, pp. 38-69.

Hy = load H at the yielding of both beams at column face 12. Meinheit, D. F., and Jirsa, J. O., “The Shear Strength of Reinforced

Lc = hinge-to-hinge distance of column Concrete Beam-Column Joints,” CESRL Report No. 77-1, Department of

N = axial force acting on column (positive for compression) Civil Engineering, University of Texas at Austin, Jan. 1977, 271 pp.

r = direction perpendicular to d 13. Fenwick, R. C., and Irvine, H. M., “Reinforced Concrete Beam-

= assumed direction of principal tensile stress Column Joints for Seismic Loading,” School of Engineering Report No.

Rd,Rh,Rv = ratios of joint shears carried by diagonal, horizontal, and 142, Department of Civil Engineering, University of Auckland, Auckland,

vertical mechanisms, respectively New Zealand, Mar. 1977, 50 pp.

sh = spacing of joint hoops 14. Birss, G. R., “The Elastic Behaviour of Earthquake Resistant Rein-

sv = spacing of intermediate column bars forced Concrete Beam-Column Joints,” Research Report No. 78-13,

Tb1, Tb2 = tensile forces resulting from steel of beams at right and left of Department of Civil Engineering, University of Canterbury, Christchurch,

joint, respectively New Zealand, Feb. 1978, 105 pp.

Tc1, Tc2 = tensile forces resulting from tensile steel of columns above 15. Viwathanatepa, S.; Popov, E. P.; and Bertero, V. V., “Seismic

and below joint, respectively Behavior of R/C Interior Beam-Column Subassemblages,” Earthquake

v = direction of intermediate column bars Engineering Research Center, Report No. UCB/EERC-79/14, University of

Vb1, Vb2 = vertical beam shears at right and left of joint, respectively California, Berkeley, 1979, 184 pp.

Vc1, Vc2 = horizontal column shears above and below the joint, respectively 16. Beckingsale, C. W., “Post-Elastic Behaviour of Reinforced Concrete

Vjh, Vjv = horizontal and vertical joint shear forces, respectively Beam-Column Joints,” Research Report No. 80-20, Department of Civil

Δ = horizontal displacement measured at column end Engineering, University of Canterbury, Christchurch, New Zealand, Aug.

Δy = horizontal displacement Δ at Hy 1980, 379 pp.

γh = fraction of horizontal shear transferred by horizontal tie in 17. Park, R.; Gaerty, L.; and Stevenson, E. C., “Tests on an Interior Rein-

absence of vertical tie forced Concrete Beam-Column Joint,” Bulletin of the New Zealand National

γv = fraction of vertical shear carried by vertical tie in absence of Society for Earthquake Engineering, V. 14, No. 2, June 1981, pp. 81-92.

horizontal tie 18. Durrani, A. J., and Wight, J. K., “Behavior of Interior Beam-to-

= 0.002 + 0.001(fc′ – 20)/80 (fc′ in units of MPa) Column Connections under Earthquake-Type Loading,” ACI JOURNAL,

εd, εr = average normal strains in d- and r- directions, respectively, Proceedings V. 82, No. 3, May-June 1985, pp. 343-349.

(positive for tension) 19. Otani, S.; Kobayashi, Y.; and Aoyama, H., “Reinforced Concrete Inte-

= assumed principal strains rior Beam-Column Joints under Simulated Earthquake Loading,” First

εh, εϖ = average normal strains in h- and v- directions, respectively, U.S.-N.Z.-Japan Seminar, Monterey, July-Aug. 1984.

(positive for tension) 20. Otani, S.; Kitayama, K.; and Aoyama, H., “Beam Bar Bond Stress

εo = strain at peak stress of standard concrete cylinder and Behavior of Reinforced Concrete Interior Beam-Column Connec-

= 0.002 + 0.001(fc′ – 20)/80 (fc′in units of MPa) tions,” Second U.S.-N.Z.-Japan Seminar, Tokyo, May 1985.

εs = average tensile strain of mild steel bars, taken as εh and εv in 21. Abrams, D. P., “Scale Relations for Reinforced Concrete Beam-Column

h- and v- directions, respectively Joints,” ACI Structural Journal, V. 84, No. 6, Nov.-Dec. 1987, pp. 502-512.

εyh, εyv = yield strain of bare mild steel of horizontal and vertical rein- 22. Noguchi, H., and Kurusu, K., “The Effects of Beam Bar Bond and

forcement, respectively Joint Shear on the Behavior of Reinforced Concrete Interior Beam-Column

θ = angle of inclination of h-axis with respect to d-axis Joints,” Third U.S.-N.Z.-Japan Seminar, Christchurch, Aug. 1987.

ζ = softening coefficient of concrete in compression 23. Leon, R. T., “Shear Strength and Hysteretic Behavior of Interior

σd, σr = average normal stresses in d- and r- directions, respectively, Beam-Column Joints,” ACI Structural Journal, V. 87, No. 1, Jan.-Feb.

(positive for tension) 1990, pp. 3-11.

= assumed principal stresses 24. Joh, O.; Goto, Y.; and Shibata, T., “Influence of Transverse Joint and

σd,max = maximum compressive stress exerting on nodal zone in d- Beam Reinforcement and Relocation of Plastic Hinge Region on Beam-

direction Column Joint Stiffness Deterioration,” Design of Beam-Column Joints for

Seismic Resistance, SP-123, American Concrete Institute, Farmington

Hills, Mich., 1991, pp. 187-224.

REFERENCES 25. Kitayama, K.; Otani, S.; and Aoyama, H., “Development of Design

1. Hwang, S. J., and Lee, H. J., “Analytical Model for Predicting Shear Criteria for RC Interior Beam-Column Joints,” Design of Beam-Column

Strengths of Exterior Reinforced Concrete Beam-Column Joints for Joints for Seismic Resistance, SP-123, American Concrete Institute, Farm-

Seismic Resistance,” ACI Structural Journal, V. 96, No. 5, Sept.-Oct.1998, ington Hills, Mich., 1991, pp. 97-123.

pp. 846-857.

2. ACI Committee 318, “Building Code Requirements for Structural 26. Fujii, S., and Morita, S., “Comparison between Interior and Exterior

Concrete (ACI 318-95) and Commentary (318R-95),” American Concrete RC Beam-Column Joint Behavior,” Design of Beam-Column Joints for

Institute, Farmington Hills, Mich., 1995, 369 pp. Seismic Resistance, SP-123, American Concrete Institute, Farmington

3. Zhang, L., and Jirsa, J. O., “A Study of Shear Behavior of Reinforced Hills, Mich., 1991, pp. 145-165.

Concrete Beam-Column Joints,” PMFSEL Report No. 82-1, Department of 27. Kurose, Y., “Recent Studies on Reinforced Concrete Beam-Column

Civil Engineering, University of Texas at Austin, Feb. 1982, 118 pp. Joints in Japan,” PMFSEL Report No. 87-8, Department of Civil Engi-

4. Paulay, T., and Priestley, M. J. N., Seismic Design of Reinforced neering, University of Texas, Austin, Dec. 1987, 164 pp.

Concrete and Masonry Buildings, John Wiley & Sons, 1992, 744 pp. 28. Bertero, V. V.; Popov, E. P.; and Forzani, B., “Seismic Behavior of

5. Park, R., and Milburn, J. R., “Comparison of Recent New Zealand and Lightweight Concrete Beam-Column Subassemblages,” ACI JOURNAL,

United States Seismic Design Provisions for Reinforced Concrete Beam- Proceedings V. 77, No. 1, Jan.-Feb. 1980, pp. 44-52.

44 ACI Structural Journal/January-February 2000

Das könnte Ihnen auch gefallen

- Shear Strength of RC Jacketed Interior Beam-Column Joints Without Horizontal Shear ReinforcementDokument17 SeitenShear Strength of RC Jacketed Interior Beam-Column Joints Without Horizontal Shear ReinforcementPaul KohanNoch keine Bewertungen

- Hwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For SeismicDokument14 SeitenHwang Et All - Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam-Column Joints For Seismicbllld100% (1)

- Shear Strength Prediction For Deep Beams: Aci Structural Journal Technical PaperDokument10 SeitenShear Strength Prediction For Deep Beams: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Effects of beam bar anchorage on beam-column joint behaviourDokument10 SeitenEffects of beam bar anchorage on beam-column joint behaviourMarimuthu KaliyamoorthyNoch keine Bewertungen

- Alnauimi - Direct Design of Hollow Reinforced Concrete Beams. Part 1 - Design ProcedureDokument8 SeitenAlnauimi - Direct Design of Hollow Reinforced Concrete Beams. Part 1 - Design ProcedureAshrethNoch keine Bewertungen

- FraMCOS-8 Conference Paper on Strengthening Shear Deficient RC Beam-Column JointsDokument12 SeitenFraMCOS-8 Conference Paper on Strengthening Shear Deficient RC Beam-Column JointsJawad HussainNoch keine Bewertungen

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDokument14 SeitenAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNoch keine Bewertungen

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDokument14 SeitenAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNoch keine Bewertungen

- 2018 Hanssan Moehle Shear Strength of Exterior Beam Column Joint WO Transverse ReinforcementDokument10 Seiten2018 Hanssan Moehle Shear Strength of Exterior Beam Column Joint WO Transverse ReinforcementFernando TorresNoch keine Bewertungen

- Theory of Shear Transfer Strength of Reinforced Concrete PDFDokument12 SeitenTheory of Shear Transfer Strength of Reinforced Concrete PDFPremasiri Karunarathna100% (2)

- Influence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsDokument11 SeitenInfluence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsRaja ShekarNoch keine Bewertungen

- 103-s76 - Behavior of Reinforced Concrete Members Prone To Shear Deformations Part I - Effect of ConfinementDokument11 Seiten103-s76 - Behavior of Reinforced Concrete Members Prone To Shear Deformations Part I - Effect of ConfinementJitendraNoch keine Bewertungen

- Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorDokument12 SeitenSeismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorpaulkohanNoch keine Bewertungen

- ddf66ff0-19db-47ed-828b-acc094189835Dokument7 Seitenddf66ff0-19db-47ed-828b-acc094189835nseara100% (1)

- Inelastic Analysis of Reinforced Concrete Space Frames Influenced BY Axial, Torsional and Bending InteractionDokument15 SeitenInelastic Analysis of Reinforced Concrete Space Frames Influenced BY Axial, Torsional and Bending Interactionjuan carlos molano toroNoch keine Bewertungen

- Kim 2008Dokument11 SeitenKim 2008ahmerNoch keine Bewertungen

- A New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsDokument18 SeitenA New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsRosNoch keine Bewertungen

- Cyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementDokument7 SeitenCyclic Loading of Exterior Beam - Column Joint With Threaded Headed ReinforcementShreyas AlagundiNoch keine Bewertungen

- Database Investigation On Bond Performance of Interior Beam-Column Joints With High-Strength ReinforcementDokument8 SeitenDatabase Investigation On Bond Performance of Interior Beam-Column Joints With High-Strength ReinforcementPaul KohanNoch keine Bewertungen

- Analysis and Design For TorsionDokument50 SeitenAnalysis and Design For TorsionJin-hwan KimNoch keine Bewertungen

- Binding Bar4Dokument11 SeitenBinding Bar4Jeno MscNoch keine Bewertungen

- 06 DesignAndRetroffitingStrategyOfRCBCJoints PDFDokument0 Seiten06 DesignAndRetroffitingStrategyOfRCBCJoints PDFmy09Noch keine Bewertungen

- Shear Strength of Reinforced Concrete MeDokument10 SeitenShear Strength of Reinforced Concrete MeAquila1952Noch keine Bewertungen

- Behavior and Analysis of Inverted T Shaped RC Beams Under Shear and Torsion PDFDokument14 SeitenBehavior and Analysis of Inverted T Shaped RC Beams Under Shear and Torsion PDFJing CaoNoch keine Bewertungen

- 21853Dokument13 Seiten21853saeedNoch keine Bewertungen

- J Engstruct 2018 12 064Dokument17 SeitenJ Engstruct 2018 12 064Mladen MilićevićNoch keine Bewertungen

- 81 88 STR120 Ketiyot July 2018 - 24 - 1 - FinalDokument8 Seiten81 88 STR120 Ketiyot July 2018 - 24 - 1 - FinalChayanon HansapinyoNoch keine Bewertungen

- 109 s14 PDFDokument12 Seiten109 s14 PDFMarimuthu KaliyamoorthyNoch keine Bewertungen

- Pushover AnalysisDokument12 SeitenPushover AnalysisJonathan FelixNoch keine Bewertungen

- Behavior of Interior Beam-to-Column Connections UnderDokument7 SeitenBehavior of Interior Beam-to-Column Connections UnderMarimuthu KaliyamoorthyNoch keine Bewertungen

- Strong-Column-Weak-Beam Criterion For Reinforced Concrete Frames Subjected To Biaxial Seismic ExcitationDokument16 SeitenStrong-Column-Weak-Beam Criterion For Reinforced Concrete Frames Subjected To Biaxial Seismic Excitationmarcob74Noch keine Bewertungen

- Engineering Structures: Thai X. Dam, James K. WightDokument11 SeitenEngineering Structures: Thai X. Dam, James K. WightÍcaro RodriguesNoch keine Bewertungen

- ShearStrengthofHSCBeams-2003 05 May PDFDokument6 SeitenShearStrengthofHSCBeams-2003 05 May PDFAlessio FicocielloNoch keine Bewertungen

- Stress Analysis of C-Section Steel Purlins Under Uplift LoadsDokument9 SeitenStress Analysis of C-Section Steel Purlins Under Uplift LoadsJan LerryNoch keine Bewertungen

- Beam - Column Joint EC2Dokument11 SeitenBeam - Column Joint EC2undf25Noch keine Bewertungen

- 5 - Paulay Equilibrium Criteria For Reinforced ConcreteDokument9 Seiten5 - Paulay Equilibrium Criteria For Reinforced ConcreteMarimuthu KaliyamoorthyNoch keine Bewertungen

- Analysis of Sections Subjected To Combined Shear and Torsion-A Theoretical ModelDokument13 SeitenAnalysis of Sections Subjected To Combined Shear and Torsion-A Theoretical ModelMishraq ul quraishNoch keine Bewertungen

- Shear Strength Prediction For Reinforced Concrete Beams Without StirrupsDokument8 SeitenShear Strength Prediction For Reinforced Concrete Beams Without Stirrupsjuan carlos molano toroNoch keine Bewertungen

- Behaviour of Non-Seismic Detailed RC BC ConnectionDokument17 SeitenBehaviour of Non-Seismic Detailed RC BC ConnectionmekidesNoch keine Bewertungen

- Interactive Mechanical Model For Shear Strength of Deep-TanDokument11 SeitenInteractive Mechanical Model For Shear Strength of Deep-TanmunnaiitrNoch keine Bewertungen

- (Asce) ST 1943-541X 0002294Dokument14 Seiten(Asce) ST 1943-541X 0002294Sergio Alejandro barreiroNoch keine Bewertungen

- Applsci 12 12632Dokument21 SeitenApplsci 12 12632Mustafa NabeelNoch keine Bewertungen

- Ijser: Beam-Column Connection With Crossed Inclined Reinforcement Bars: An OverviewDokument5 SeitenIjser: Beam-Column Connection With Crossed Inclined Reinforcement Bars: An OverviewNishma GuragaiNoch keine Bewertungen

- Shear Wall - CouplingDokument6 SeitenShear Wall - CouplingZack JspNoch keine Bewertungen

- Moment Transfer From Concrete Slabs To ColumnsDokument12 SeitenMoment Transfer From Concrete Slabs To ColumnsGustavo PrimoNoch keine Bewertungen

- 1978-T. PAULAY, R. PARK, and M. J. N. PRIESTLEY-Reinforced Concrete Beam-Column Joints Under Seismic ActionsDokument9 Seiten1978-T. PAULAY, R. PARK, and M. J. N. PRIESTLEY-Reinforced Concrete Beam-Column Joints Under Seismic ActionsRomanbabu OinamNoch keine Bewertungen

- Petersen 2018Dokument10 SeitenPetersen 2018Suvendu ParidaNoch keine Bewertungen

- A Kinematics-Based Approach For The Shear Strength of Short Fibre-Reinforced Concrete Coupling Beams Boyan MihaylovDokument9 SeitenA Kinematics-Based Approach For The Shear Strength of Short Fibre-Reinforced Concrete Coupling Beams Boyan MihaylovYollanda LorenzaNoch keine Bewertungen

- Design For shear-LSDDokument11 SeitenDesign For shear-LSDAmanuelNoch keine Bewertungen

- Compatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryDokument11 SeitenCompatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryMishraq ul quraishNoch keine Bewertungen

- A New Model For Joint Shear Failure of Reinforced Concrete Interior Beam-To-Column JointDokument30 SeitenA New Model For Joint Shear Failure of Reinforced Concrete Interior Beam-To-Column JointMarimuthu KaliyamoorthyNoch keine Bewertungen

- Optimal Domains For Flexural and Axial Loading: Aci Structural Journal Technical PaperDokument9 SeitenOptimal Domains For Flexural and Axial Loading: Aci Structural Journal Technical PaperangthiankongNoch keine Bewertungen

- Soil Dynamics and Earthquake Engineering: SciencedirectDokument12 SeitenSoil Dynamics and Earthquake Engineering: SciencedirectPrateek PandaNoch keine Bewertungen

- Shear Design Consideration For Prestressed Beams: Aci Structural Journal Technical PaperDokument7 SeitenShear Design Consideration For Prestressed Beams: Aci Structural Journal Technical PaperKoresh KhalpariNoch keine Bewertungen

- Unit-2 FLEXUREDokument49 SeitenUnit-2 FLEXURENicholas ThompsonNoch keine Bewertungen

- Seismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. GhaffarzadehDokument8 SeitenSeismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. Ghaffarzadehhlong123123Noch keine Bewertungen

- Reinforced Concrete Beam Analysis Supplementing Concrete Constribution in Truss ModelsDokument10 SeitenReinforced Concrete Beam Analysis Supplementing Concrete Constribution in Truss ModelsSon NguyenNoch keine Bewertungen

- Stress Transfer Across Interfaces in Reinforced Concrete Due To Aggregate Interlock and Dowel Action - Maekawa&qureshi PDFDokument14 SeitenStress Transfer Across Interfaces in Reinforced Concrete Due To Aggregate Interlock and Dowel Action - Maekawa&qureshi PDFRômulo Menck Romanichen100% (1)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionVon EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionBewertung: 2.5 von 5 Sternen2.5/5 (4)

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Guo 2012 ImpactStiffnessofDokument31 SeitenGuo 2012 ImpactStiffnessofEduardo MarquesNoch keine Bewertungen

- Morteza e I 2011Dokument24 SeitenMorteza e I 2011Eduardo MarquesNoch keine Bewertungen

- Outriggers PDFDokument135 SeitenOutriggers PDFEduardo MarquesNoch keine Bewertungen

- 1 PunchingLoadCheckDokument2 Seiten1 PunchingLoadCheckindracivilengineerNoch keine Bewertungen

- Machine - Foundations 1.0Dokument33 SeitenMachine - Foundations 1.0Eduardo Marques0% (1)

- Sapatas Alex TomanovichDokument6 SeitenSapatas Alex TomanovichAdailton Dos Santos de MouraNoch keine Bewertungen

- Sapatas Assimétricas Alex TomanovichDokument5 SeitenSapatas Assimétricas Alex TomanovichEduardo MarquesNoch keine Bewertungen

- Soft Storey Weak Storey WCEE2012 0183Dokument10 SeitenSoft Storey Weak Storey WCEE2012 0183gorgika papandNoch keine Bewertungen

- RC Elements Analysis & Design ProjectDokument51 SeitenRC Elements Analysis & Design ProjectAbhay YadavNoch keine Bewertungen

- IksaPro en v1.0 Demo 3anchorsDokument20 SeitenIksaPro en v1.0 Demo 3anchorsEduardo MarquesNoch keine Bewertungen

- Corbel Analysis Design 1.0Dokument19 SeitenCorbel Analysis Design 1.0Eduardo Marques0% (1)

- Bored Pile Analysis For Layered SoilDokument74 SeitenBored Pile Analysis For Layered SoilEduardo MarquesNoch keine Bewertungen

- EXCretwall Ver. 1.1Dokument10 SeitenEXCretwall Ver. 1.1Eduardo MarquesNoch keine Bewertungen

- Estaqueamento Alex TomanovichDokument13 SeitenEstaqueamento Alex TomanovichEduardo MarquesNoch keine Bewertungen

- Axial and Lateral Load Piles Fem v1.6Dokument60 SeitenAxial and Lateral Load Piles Fem v1.6Shahab KhaledNoch keine Bewertungen

- 1 PunchingLoadCheckDokument2 Seiten1 PunchingLoadCheckindracivilengineerNoch keine Bewertungen

- Quadros GeraisDokument1 SeiteQuadros GeraisEduardo MarquesNoch keine Bewertungen

- Aula 4 - ExerccioDokument1 SeiteAula 4 - ExerccioEduardo MarquesNoch keine Bewertungen

- ADM GEN - CHEMISTRY 2 Lesson 1Dokument23 SeitenADM GEN - CHEMISTRY 2 Lesson 1EDGAR RIVERANoch keine Bewertungen

- Fabtek Case AnalysisDokument3 SeitenFabtek Case AnalysisPreeti SoniNoch keine Bewertungen

- GE 1151 Engineering MachinesDokument31 SeitenGE 1151 Engineering MachineskalirajgurusamyNoch keine Bewertungen

- Torsion 91Dokument1 SeiteTorsion 91bagmass0% (1)

- Mock Che1Dokument5 SeitenMock Che1nassorussi9Noch keine Bewertungen

- Thermo2 MidDokument4 SeitenThermo2 MidnoelNoch keine Bewertungen

- Spectrophotometry in Forensic Analysis: Accurately Identifying Chemical MakeupDokument3 SeitenSpectrophotometry in Forensic Analysis: Accurately Identifying Chemical Makeupone_kender9064100% (1)

- 10th MG Cup 2022 Physics English ProblemsDokument12 Seiten10th MG Cup 2022 Physics English Problemsmilos9444Noch keine Bewertungen

- Coupling Adapter Marca Tschan Tipo Nor MexDokument18 SeitenCoupling Adapter Marca Tschan Tipo Nor MexhectorNoch keine Bewertungen

- ATC-115+Roadmap Final 022715Dokument197 SeitenATC-115+Roadmap Final 022715Nestor Walter Barrera RomeroNoch keine Bewertungen

- Technical Data Sheet: Typical PropertiesDokument2 SeitenTechnical Data Sheet: Typical PropertiesahmedNoch keine Bewertungen

- En - Spectroquant Prove - Operating - Manual PDFDokument216 SeitenEn - Spectroquant Prove - Operating - Manual PDFjohnar94Noch keine Bewertungen

- Every Day Science PDFDokument115 SeitenEvery Day Science PDFmuhammad ihtishamNoch keine Bewertungen

- MCW Pump Head & Piping Pressure DropDokument3 SeitenMCW Pump Head & Piping Pressure DropKarthy GanesanNoch keine Bewertungen

- GF Series TDS 1046 PDFDokument1 SeiteGF Series TDS 1046 PDFDon HowardNoch keine Bewertungen

- Tinrhert Field Development Project - Epc 1: Inlet Separation and Boosting Facility in OhanetDokument35 SeitenTinrhert Field Development Project - Epc 1: Inlet Separation and Boosting Facility in OhanetsathishNoch keine Bewertungen

- CMM MQCDokument36 SeitenCMM MQCThanigaivel ANoch keine Bewertungen

- General Chemistry 1: Quarter 2 - Module 2 The Chemical BondingDokument17 SeitenGeneral Chemistry 1: Quarter 2 - Module 2 The Chemical BondingKaren de los Reyes100% (1)

- Anchor Bolt Design For Shear and TensionDokument2 SeitenAnchor Bolt Design For Shear and Tensionk.m.ariful islamNoch keine Bewertungen

- Lee 2019Dokument9 SeitenLee 2019OkymailNoch keine Bewertungen

- Pet Engineering College Department of Mechanical EngineeringDokument3 SeitenPet Engineering College Department of Mechanical EngineeringAHAMED SULBIHAR MNoch keine Bewertungen

- Analysis of Doubly Reinforced Concrete BeamDokument4 SeitenAnalysis of Doubly Reinforced Concrete BeamAnton_Young_1962Noch keine Bewertungen

- Introduction To Molecular Spectros PDFDokument333 SeitenIntroduction To Molecular Spectros PDFmekoki86% (7)

- Experiment 2: Brinell Hardness TestDokument5 SeitenExperiment 2: Brinell Hardness TestseifNoch keine Bewertungen

- Memorial de Cálculo de espessura mínima do costadoDokument13 SeitenMemorial de Cálculo de espessura mínima do costadofabio50002Noch keine Bewertungen

- Conarc85 EngDokument2 SeitenConarc85 EngRaviTeja Bhamidi100% (1)

- High-Performance Concrete Characteristics and PropertiesDokument16 SeitenHigh-Performance Concrete Characteristics and PropertiesChukwuma OgbonnaNoch keine Bewertungen

- 03 Metal Packing Support PlatesDokument3 Seiten03 Metal Packing Support PlatesypatelsNoch keine Bewertungen

- Solid Ground CuringDokument10 SeitenSolid Ground CuringAkshay Hejjaji100% (2)

- Class 6 Science: Shah SeriesDokument16 SeitenClass 6 Science: Shah SeriesAgha Khan DurraniNoch keine Bewertungen