Beruflich Dokumente

Kultur Dokumente

Hexagon After Application of Surgical Placement Torque Simulating Implant Locking

Hochgeladen von

Jose Damian Lemus IbacacheOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hexagon After Application of Surgical Placement Torque Simulating Implant Locking

Hochgeladen von

Jose Damian Lemus IbacacheCopyright:

Verfügbare Formate

Implantology

Implantology

In vitro integrity of implant external

hexagon after application of surgical

placement torque simulating

implant locking

Letícia Resende Davi(a) Abstract: The aim of this study was to evaluate the integrity of the ex-

Alexsander Luiz Golin(b) ternal hexagon of an implant system with internal and external hexagons

Sérgio Rocha Bernardes(c)

Cleudmar Amaral de Araújo(d) but with prosthetic connection through the external hexagon (Internal

Flávio Domingues Neves(e) Torque, IT) in comparison with that of an implant system with external

hexagon with mount (External Hexagon, EH). A device was made to

measure the rotational freedom angles between implant and abutment

(a)

M aster of Science; (e) Associate Professor

– Department of Occlusion, Fixed Prosthesis hexagons in 10 implants from each group after the application of surgi-

and Dental Materials, School of Dentistry,

Federal University of Uberlândia.

cal placement torques of 45, 60 and 80 Ncm simulating implant locking.

The distances between the vertices of the external hexagon were also ob-

(b)

M aster of Science, Department of

Mechanical Engineering, School of tained. Rotational freedom data were subjected to ANOVA and Tukey’s

Mechanical Engineering, Pontifical Catholic test (P < .05) showing no significant difference between the angles of the

University of Curitiba.

intact implants (EH – 3.31 ± 0.41° and IT – 3.30 ± 0.17°) and after ap-

(c)

Professor, Scientific Department, Latin

American Institute of Dental Research and plication of a 45 Ncm torque (EH – 3.27 ± 0.38° and IT – 3.31 ± 0.22°).

Education (ILAPEO). However, after application of a 60 Ncm torque there were significant dif-

(d)

A ssociate Professor, Department of Projects ferences (IT – 3.40 ± 0.20° and EH – 4.03 ± 0.54°). After application of

and Mechanical Systems, School of

Mechanical Engineering, Federal University a 80 Ncm torque, the IT implant presented values of 3.39 ± 0.21° where-

of Uberlândia. as the EH did not support the torque, suffering deformation of its exter-

nal hexagon. Within the limits of this study, it can be concluded that the

IT implant system may be preferable in clinical situations where implant

placement within a certain bone density could generate torques higher

than 60 Ncm.

Descriptors: Biomechanics; Dental implants; Torque; Dental prosthesis.

Corresponding author:

Flávio Domingues Neves

Av. Pará, 1720 - Bloco 2B, Sala 2B01

Uberlândia - Minas Gerais - Brazil

CEP: 38400-902

E-mail: neves@triang.com.br

Received for publication on Oct 23, 2006

Accepted for publication on Jun 08, 2007

Braz Oral Res 2008;22(2):125-31 125

In vitro integrity of implant external hexagon after application of surgical placement torque simulating implant locking

Introduction higher torques during surgical placement, with ef-

Over the last few decades, the use of dental im- fective screw joint stability.8 Sometimes these inter-

plants in partially edentulous patients, including nal geometries make the prosthetic procedure more

single tooth replacements, has revolutionized esthet- difficult and reduce the number of implant manu-

ic and functional rehabilitation. Brånemark et al.1 facturing companies with compatible systems.

(1977) reported the principles of osseointegration Considering the hypothesis that implant systems

of titanium implants in bone tissue and their clini- with external hexagon devices for prosthesis con-

cal application in rehabilitating edentulous patients, nection and internal torque can improve the stabili-

thus reestablishing masticatory function. ty of the system, it could also speed up and facilitate

The initial purpose of external hexagon implants surgical placement. Therefore, this in vitro study

was to transmit torque during surgical placement. evaluated the integrity of the external hexagon of an

Afterwards, the external hexagon was also shown to implant system with internal and external hexagons,

work as an antirotational mechanism and to orient but with prosthetic connection through the external

the abutment in single tooth prostheses. Although hexagon, in comparison with that of a conventional

these implants have been the ones most commonly external hexagon implant with mount, by means of

used, and are designed by several companies all over different levels of surgical placement torque applied

the world, possible fatigue or overload failures could simulating implant locking.

occur due to different manufacturing tolerances.

The biomechanical complications reported are loos- Material and Methods

ening or fracturing of the abutment and prostheses Ten implants with external hexagon (Titamax

screws. 2-11 Therefore, the external hexagon connec- Pores with mount – EH; 3.75 mm-wide, Neodent

tion continues to be comprehensively studied with Implante Osteointegrável, Curitiba, PR, Brazil) and

the aim of improving the dimensional machining ten implants with internal and external hexagons

tolerances of the components,12 and making this but with prosthetic connection through the exter-

screwed junction more stable. 3-5,7,9 nal hexagon (Cortical Titamax – IT; 3.75 mm-wide,

The rotational freedom between implant and Neodent Implante Osteointegrável, Curitiba, PR,

abutment depends on the hexagon dimensions that Brazil), both with 4.1 mm-wide platform size, were

are in connection. 3-5,9,10 These dimensions can be used in this study.

compromised during surgical placement, depending An experimental device was designed and made

on the torque applied, and after connection of the to apply surgical placement torque on the dental

prosthesis, when the masticatory load could gener- implants and to measure rotational freedom angles

ate micromovements and deform the implant hexa- between the abutment and the implant. The device

gon. 5 consists of an apparatus to lock the implant using

In the last few years, the surgical process was two side screws with nuts, a graduated scale with

changed to a single stage, with immediate loading precision of 0.025°, a rod to measure the rotational

using the prosthesis connected to the implant.13,14 freedom angle, and a steel device fitted to the abut-

The advantages of immediate loading include less ment under pressure, as shown in Figure 1.

chair time and simplification of the dental replace- Each implant was placed in the device and fit-

ment process.15 However, implants submitted to im- ted to the abutment and the rod, without requiring

mediate loading need primary stability to prevent the abutment screw. Initially, the rotational freedom

failure of osseointegration.13-15 This primary stabil- angle readings were taken with the intact implants

ity is obtained by attaching the implant to the bone positioned in the device.

and is normally checked by the value of the torque The graduated scale can be moved to locate the

applied. initial point of the rotational angle reading at the

Recently, some internal implant connections have reference mark of 0 degree, and is then fixed by a

appeared on the market, which are able to receive lateral screw. This initial point is marked when

126 Braz Oral Res 2008;22(2):125-31

Davi LR, Golin AL, Bernardes SR, Araújo CA, Neves FD

Figure 1 - Experimental device used to measure rotational

freedom angles.

one of the vertices of the implant external hexagon ed. After the readings, the same analysis was made,

touches one of the sides of the abutment internal successively, for the torques of 60 and 80 Ncm, with

hexagon. To obtain the initial point, the rod was the aid of a surgical torquemeter ratchet (Neodent

turned by hand in a counterclockwise direction un- Implante Osteointegrável, Curitiba, PR, Brazil).

til it encountered slight resistance from the connec- The distances between the vertices of the exter-

tion. Next, the rod was moved in a clockwise direc- nal hexagon were also used to evaluate the integrity

tion, again until there was slight resistance from the of the external hexagon of the two groups of im-

connection. At this moment, the values of the angles plants. These measurements were obtained for all

read on the scale were recorded. In order to mini- intact implants, before any mechanical contact, and

mize the errors in the measurements, each reading after each torque applied. Two operators measured

was repeated twice by two operators and the mean the three distances between the vertices of each ex-

average of the four measurements was obtained. ternal hexagon and the mean value was determined.

The operators were trained by measuring together The measurements were carried out using an optical

two implants of each type and by analyzing how to microscope (Carl Zeiss, Jena, TH, Germany), with

obtain the angles on the graduated scale. a 20 times magnification. Each implant was placed

The implants were submitted to three levels of in a device with a handle to turn the implant and

surgical placement torques: 45, 60 and 80 Ncm. The place the vertex of the hexagon at the initial point of

torque of 45 Ncm was applied in the groups with measurement.

the aid of an electronic torque controller handpiece The rotational freedom angles and the distances

(DEA 020, Brånemark System, Nobelpharma AB, between the vertices of the external hexagons of the

Gothenburg, Sweden) at low-speed rotation. The implants after different levels of torque were submit-

values of the rotational freedom angles were taken ted to statistical analysis by ANOVA and Tukey’s

in a similar manner to that in which the rotational test (P < .05), with the aid of the statistical program

freedom values for the intact implants were record- SPSS 12.0 (SPSS Inc., Chicago, IL, USA).

Braz Oral Res 2008;22(2):125-31 127

In vitro integrity of implant external hexagon after application of surgical placement torque simulating implant locking

Results plants became deformed, annulling their antirota-

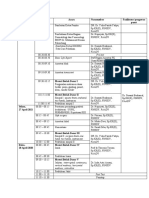

Mean values of rotational freedom angles are tional effect, and making it impossible to measure

presented in Table 1. Statistical analysis by ANO- the respective angles (Figure 2).

VA and Tukey’s test showed that there was no sig- The mean distances between the hexagon verti-

nificant difference between the angles of the intact ces of the samples measured in the microscope, un-

EH and IT implants and after application of the der different levels of torque, are shown in Graph 1.

torque of 45 Ncm. After application of the torque of The statistical analysis showed that there was no

60 Ncm, significant difference (P < .05) was found significant difference between the distances between

between the EH and IT systems. After application the vertices of intact EH and IT implants and after

of the torque of 80 Ncm, the vertices of the EH im- application of the torques of 45 and 60 Ncm. After

application of the torque of 80 Ncm, the vertices of

the EH implants became deformed, and Tukey’s test

Table 1 - Mean ± SD values of the rotational freedom an- showed significant difference between the values for

gles (°) for the EH and IT implants.

the EH and IT implants (Table 2).

Torque EH Implants* IT Implants

0 3.308 ± 0.406° A 3.298 ± 0.168° A Discussion

45 Ncm 3.274 ± 0.380° A 3.309 ± 0.220° A Dental implants are placed by means of external

or internal connections and by the application of a

60 Ncm 4.029 ± 0.544° B 3.405 ± 0.197° A

certain level of torque. The connection could there-

80 Ncm – 3.387 ± 0.215° A

fore become deformed and result in biomechani-

*After application of the torque of 80 Ncm the vertices of the EH implants

cal complications over time. The Internal Torque

became deformed, annulling their antirotational effect. Groups that are

significantly different (P < .05) are marked with different letters. implant that requires an implant driver to connect

After 45 Ncm After 60 Ncm After 80 Ncm

EH EH EH

IT IT IT

Figure 2 - EH and IT implants after application of 45, 60 and 80 Ncm torques.

128 Braz Oral Res 2008;22(2):125-31

Davi LR, Golin AL, Bernardes SR, Araújo CA, Neves FD

3.5 IT Implants EH Implants loosening or fracturing, microfractures of bone, and

loss of osseointegration. 2,10

3.0

The integrity of the external hexagon was evalu-

3.088

3.087

3.084

3.078

3.074

3.073

3.063

2.861

2.5 ated in all implants before torque application, and

both the rotational freedom measurements and the

Distances (mm)

2.0

distances of the hexagon vertices showed no signifi-

1.5 cant differences between values for the EH and IT

implants, because of the same machining tolerances.

1.0

This result proves that the industrial production of

0.5 the analyzed implants was standardized, and elimi-

nates the possibility of initial failings.

0.0

0 45 60 80 Considering the technique of implant placement

Torque - Ncm

with immediate loading, there is a single-stage sur-

Graph 1 - Mean distances between the hexagon vertices

gical procedure that has the advantage of immediate

of the implant hexagons under different levels of torque

(P < .05). rehabilitation by means of fixed prostheses. In these

cases, primary stability into the bone is very impor-

tant, and this depends on the value of the torque

Table 2 - Mean ± SD values of the distances (mm) between

applied during surgical placement.11,16,17 Misch14

the vertices of the EH and IT implants.

(2004) established a minimum torque of 30 Ncm

Implants Torque Mean ± SD so that the implants could obtain primary stability

0 3.084 ± 0.009 mm A for immediate loading. In other words, to be consid-

External 45 Ncm 3.078 ± 0.015 mm A ered stable, the implant could not turn or show any

Hexagon 60 Ncm 3.063 ± 0.020 mm A mobility after the torque of 30 Ncm was reached.

80 Ncm 2.861 ± 0.073 mm B Bahat18 (2000) evaluated the long-term success of

implants placed in the posterior area of the maxilla,

0 3.088 ± 0.006 mm A

under a condition of primary stability with a mini-

45 Ncm 3.087 ± 0.006 mm A

Internal Torque mum torque of 40 Ncm. Both authors referred to a

60 Ncm 3.074 ± 0.009 mm A

minimum torque for immediate loading, but there

80 Ncm 3.073 ± 0.009 mm A was no evidence about the maximum torque that

Values with different letters are significantly different (P < .05). could be applied on the implants without deforming

the external hexagon.

Until the year of 1995, the electronic torque con-

it to the internal hexagon and transmit torque for trollers available from Nobelpharma for implant

implant placement showed improved mechanical placement were DEC 100 and DEA 020 (Nobel-

properties, confirming the hypothesis proposed in pharma AB, Gothenburg, Sweden), which allowed

this study. a maximum torque of 45 Ncm. They were used in

The fragility of the external hexagon of some the majority of the long-term studies published in

systems can compromise the future dental prosthe- the literature.1,2,6 Some of the implants, however, still

sis if deformation of the hexagon vertices occurs due required the manual torque wrench (DIA 250; No-

to the torque applied in the implant mount when the belpharma AB, Gothenburg, Sweden) to complete

implant is placed. In these situations, the angles of the implant seating, with uncontrolled torque but

rotational freedom between abutment and implant higher than 45 Ncm. Degidi, Piattelli16 (2005), in a

are increased, and this is especially critical in single study with 702 implants, reported torques higher

prostheses. 5 Greater rotation at the interface im- than 76 Ncm. In vitro studies showed that place-

plant-abutment transfers stress to the implant com- ment torques above 100 Ncm increase the primary

ponents and to the bone, which could lead to screw stability of different implant systems by reducing

Braz Oral Res 2008;22(2):125-31 129

In vitro integrity of implant external hexagon after application of surgical placement torque simulating implant locking

the amount of micromotion.19 Moreover, local bone preload are compromised when the rotational angles

density varies according to each surgical site, and the exceed 5 degrees, leading to failure of the screwed

same drilling protocol could lead the implant to re- junction by screw loosening and movement of the

ceive different levels of torque during placement until abutment. In the present study, it was observed that

complete seating.20 The surgical torquemeter ratch- the EH and IT implants maintained angles of rota-

ets available in the market are graduated with the tional freedom below 5 degrees under the different

minimum torque (32 Ncm) (28839 – Nobel Biocare, levels of torque. But under the torque of 80 Ncm, it

TMEC – SIN Sistema de Implante) and allow higher was impossible to measure the angles of the EH im-

measurements, achieving 80 Ncm (104027 – Neo- plants, due to deformation of the external hexagon.

dent Implante Osteointegrável, 401000 – Conexão It is important to emphasize that the EH implants

Sistemas de Prótese). may be indicated for cases where the applied torque

With the application of surgical placement does not exceed 60 Ncm. In this case, predictability

torques it was possible to evaluate the deformations may be achieved for implant-supported prostheses.

of the conventional external hexagon vertices and

consequent changes in the system rotation. Differ- Conclusions

ent levels of torque were applied to the samples and According to the methodology used in this study

the accumulative effects, although having small in- and based on the data analysis, it was possible to

fluence, were the same for the IT and EH implants. conclude that:

Thus, the load effect and possible deformation • Before and after application of a torque of

were equal for the implants. The torque of 60 Ncm 45 Ncm, the IT and EH implants presented

caused a significant increase of the rotational free- similar rotational freedom. After application of

dom of the EH implants and the torque of 80 Ncm a torque of 60 Ncm, although the IT implant

deformed the hexagon completely. Such deforma- obtained statistically better results, the EH im-

tions were not found in the IT implants because it plants did not present rotational freedom over 5

uses the internal hexagon to transmit the torque for degrees, which is suggested as optimal for screw

implant placement. joint stability, justifying the clinical success of

The junction between the abutment and the ex- these implants.

ternal hexagon of the EH and IT implants needs to • The use of the IT implant may be preferable in

be reliable for appropriate functioning and stability clinical situations where implant placement with-

of implant-supported prostheses.8 For this to occur, in a certain bone density could generate torques

the differences between the dimensions of the abut- higher than 60 Ncm.

ment hexagons and the respective implant must be

minimal to favor the passive fit of the components Acknowledgements

and prevent stress from emerging in the screw due The authors would like to acknowledge the sup-

to rotational misfit. 21 port of Neodent Implante Osteointegrável, Curitiba,

According to Binon4 (1996), joint stiffness and PR, Brazil, for their contribution to this work.

References

1. Brånemark PI, Hansson BO, Adell R, Breine U, Lindström J, 3. Binon PP. Evaluation of machining accuracy and consistency

Hallén O et al. Osseointegrated implants in the treatment of of selected implants, standard abutments, and laboratory ana-

the edentulous jaw: experience from a 10-year period. Scand logs. Int J Prosthodont. 1995;8(2):162-78.

J Plast Reconstr Surg. 1977;16(Suppl):1-132. 4. Binon PP. The effect of implant/abutment hexagonal misfit on

2. Adell R, Lekholm U, Rockler B, Brånemark PI. A 15-year screw joint stability. Int J Prosthodont. 1996;9(2):149-60.

study of osseointegrated implants in the treatment of the eden- 5. Binon PP, McHugh MJ. The effect of eliminating implant/

tulous jaw. Int J Oral Surg. 1981;10(6):387-416. abutment rotational misfit on screw joint stability. Int J Pros

thodont. 1996;9(6):511-9.

130 Braz Oral Res 2008;22(2):125-31

Davi LR, Golin AL, Bernardes SR, Araújo CA, Neves FD

6. Haas R, Mensdorff-Pouilly N, Mailath G, Watzek G. Bråne- the denture conversion technique. J Oral Maxillofac Surg.

mark single tooth implants: a preliminary report of 76 im- 2004;62(9 Suppl 2):106-15.

plants. J Prosthet Dent. 1995;73(3):274-9. 15. Cunha HA, Francischone CE, Nary Filho H, Oliveira RCG. A

7. Lang LA, Wang R-F, May KB. The influence of abutment comparison between cutting torque and resonance frequency

screw tightening on screw joint configuration. J Prosthet Dent. in the assessment of primary stability and final torque capacity

2002;87(1):74-9. of standard and TiUnite single-tooth implants under immedi-

8. Merz BR, Hunenbart S, Belser UC. Mechanics of the im- ate loading. Int J Oral Maxillofac Implants. 2004;19(4):578-

plant-abutment connection: an 8-degree taper compared 85.

to a butt joint connection. Int J Oral Maxillofac Implants. 16. Degidi M, Piattelli A. Comparative analysis study of 702

2000;15(4):519-26. dental implants subjected to immediate functional loading

9. Vigolo P, Majzoub Z, Cordioli G. Measurement of the dimen- and immediate nonfunctional loading to traditional healing

sions and abutment rotational freedom of gold-machined 3i periods with a follow-up of up to 24 months. Int J Oral Maxil-

UCLA-type abutments in the as-received condition, after cast- lofac Implants. 2005;20(1):99-107.

ing with a noble metal alloy and porcelain firing. J Prosthet 17. Lioubavina-Hack N, Lang NP, Karring T. Significance of

Dent. 2000;84(5):548-53. primary stability for osseointegration of dental implants. Clin

10. Vigolo P, Fonzi F, Majzoub Z, Cordioli G. An in vitro evalu- Oral Implants Res. 2006;17(3):244-50.

ation of ZiReal abutments with hexagonal connection: in 18. Bahat O. Brånemark system implants in the posterior maxilla:

original state and following abutment preparation. Int J Oral clinical study of 660 implants followed for 5 to 12 years. Int

Maxillofac Implants. 2005;20(1):108-14. J Oral Maxillofac Implants. 2000;15(5):646-53.

11. Wicks RA, deRijk WG, Windeler AS. An evaluation of fit in 19. Wang HL, Ormianer Z, Palti A, Perel ML, Trisi P, Sam-

osseointegrated implant components using torque/turn analy- martino G. Consensus conference on immediate loading:

sis. J Prosthodont. 1994;3(4):206-12. the single tooth and partial edentulous areas. Implant Dent.

12. Schulte JK. External hex manufacturing tolerances of six im- 2006;15(4):324-33.

plant systems: a pilot study. Implant Dent. 1994;3(1):51-3. 20. Johansson P, Strid KG. Assessment of bone quality from cut-

13. Gapski R, Wang HL, Mascarenhas P, Lang NP. Critical re- ting resistance during implant surgery. Int J Oral Maxillofac

view of immediate implant loading. Clin Oral Implants Res. Implants. 1994;9(3):279-88.

2003;14(5):515-27. 21. Ma T, Nicholls JI, Rubenstein JE. Tolerance measurements of

14. Misch CM. Immediate loading of definitive implants in the various implant components. Int J Oral Maxillofac Implants.

edentulous mandible using a fixed provisional prosthesis: 1997;12(3):371-5.

Braz Oral Res 2008;22(2):125-31 131

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Health Care's Service Fanatics (HBR)Dokument19 SeitenHealth Care's Service Fanatics (HBR)Edgard SantosNoch keine Bewertungen

- 2019 - 3 1357NI Blue Cross of Idaho Prior Authorization List Fully InsuredDokument1 Seite2019 - 3 1357NI Blue Cross of Idaho Prior Authorization List Fully InsuredRaja Churchill DassNoch keine Bewertungen

- Prolene Hernia System Herniorraphy Versus Open Inguinal Hernia Repair by Lichtenstein Tension Free Mesh Hernioplasty - A Randomized StudyDokument5 SeitenProlene Hernia System Herniorraphy Versus Open Inguinal Hernia Repair by Lichtenstein Tension Free Mesh Hernioplasty - A Randomized StudyInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Batiquin Vs Court of AppealDokument2 SeitenBatiquin Vs Court of AppealFer Grace AniñonAcabalcuid CatayloNoch keine Bewertungen

- Wound Dressing Checklist SKL 112 FINAL EDITDokument5 SeitenWound Dressing Checklist SKL 112 FINAL EDITCamille GuintoNoch keine Bewertungen

- NHSCT/18/1216 Sterilisation GuidelineDokument8 SeitenNHSCT/18/1216 Sterilisation Guidelineana mariaNoch keine Bewertungen

- Dilatation and Curettage ProcedureDokument3 SeitenDilatation and Curettage Proceduresagi muNoch keine Bewertungen

- Thrombosis Risk Assessment As A Guide To Quality Patient CareDokument9 SeitenThrombosis Risk Assessment As A Guide To Quality Patient CareRachel RiosNoch keine Bewertungen

- HydronephrosisDokument2 SeitenHydronephrosisStefan ZemoraNoch keine Bewertungen

- 3320 PDFDokument7 Seiten3320 PDFLouis HutahaeanNoch keine Bewertungen

- UntitledDokument287 SeitenUntitledDeshraj TanwarNoch keine Bewertungen

- Resume 2021Dokument3 SeitenResume 2021api-539899039Noch keine Bewertungen

- Effect of Selective PercutaneouSDokument6 SeitenEffect of Selective PercutaneouSMarcin ChłostaNoch keine Bewertungen

- Revision StapedectomyDokument21 SeitenRevision Stapedectomyapi-19500641100% (1)

- THIEME Atlas of Anatomy Head and NeuroanatomyDokument1 SeiteTHIEME Atlas of Anatomy Head and NeuroanatomyP Venkata Sai ACRNoch keine Bewertungen

- Jindal HospitalDokument61 SeitenJindal HospitalGajula AnilNoch keine Bewertungen

- Video Telescopic Operating Microscope - A Recent Development in Reptile MicrosurgeryDokument4 SeitenVideo Telescopic Operating Microscope - A Recent Development in Reptile MicrosurgeryChecko LatteNoch keine Bewertungen

- Form Kridential 1Dokument3 SeitenForm Kridential 1Sekar CiptaningrumNoch keine Bewertungen

- 32671086-USX-1804 Ankylos Surgical Manual - LRDokument60 Seiten32671086-USX-1804 Ankylos Surgical Manual - LRBokiNoch keine Bewertungen

- Use of Co Mupimet As A Local Therapeutic Agent in Lacerated WoundDokument5 SeitenUse of Co Mupimet As A Local Therapeutic Agent in Lacerated WoundAB MISHRANoch keine Bewertungen

- Rehabilitation Protocol For LatarjetDokument4 SeitenRehabilitation Protocol For LatarjetalizzxNoch keine Bewertungen

- Jamaophthalmology Biswas 2016 Oi 160055Dokument8 SeitenJamaophthalmology Biswas 2016 Oi 160055Ghalia HayetNoch keine Bewertungen

- Hari Waktu Acara Narasumber Fasilitator/ Pengawas Pusat Senin, 26 April 2021Dokument2 SeitenHari Waktu Acara Narasumber Fasilitator/ Pengawas Pusat Senin, 26 April 2021Larvahmir SpDVNoch keine Bewertungen

- 2018 @dentallib Douglas Deporter Short and Ultra Short ImplantsDokument170 Seiten2018 @dentallib Douglas Deporter Short and Ultra Short Implantsilter burak köseNoch keine Bewertungen

- Anchorage of Partial Avulsion of The Heel Pad With Use of Multiple Kirschner WiresDokument4 SeitenAnchorage of Partial Avulsion of The Heel Pad With Use of Multiple Kirschner WiresPrabhjeet singhNoch keine Bewertungen

- Pan India Network ListDokument230 SeitenPan India Network ListParag RautNoch keine Bewertungen

- Immediate Restoration and Loading of Dental Implants: Clinical Considerations and ProtocolsDokument6 SeitenImmediate Restoration and Loading of Dental Implants: Clinical Considerations and ProtocolsArlette MegNoch keine Bewertungen

- Outline Perioperative NursingDokument8 SeitenOutline Perioperative NursingMM VNoch keine Bewertungen

- NCP FormDokument2 SeitenNCP FormFranz goNoch keine Bewertungen

- Chapter 5 FINALDokument1 SeiteChapter 5 FINALKayle MatabalanNoch keine Bewertungen