Beruflich Dokumente

Kultur Dokumente

AW Tech Datasheet Inconel X 750

Hochgeladen von

stevemwilliamsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AW Tech Datasheet Inconel X 750

Hochgeladen von

stevemwilliamsCopyright:

Verfügbare Formate

Technical Datasheet AWS 014 Rev.

INCONEL® X-750

Key Features

Good creep rupture strength at high temperatures

Very good at cryogenic temperatures

Age hardenable

y

High temperature dynamic applications

IMPORTANT

We will manufacture to your required mechanical properties.

key advantages INCONEL® X-750 available in:-

to you, our customer Round wire

n

Bars or lengths

n

Flat wire

n

Shaped wire

n

Rope/Strand

n

0.025mm to 21mm Order 3m to 3t Delivery:

(.001” to .827”) (10 ft to 6000 Lbs) within 3 weeks

Packaging

CAN I H

Coils

n

HOW

EL

P?

Spools

n

Wire to your spec E.M.S available Technical support Bars or lengths

n

®Trade name of Special Metals Group of Companies.

Manufacturing quality, delivering reliability | alloywire.com

Copyright © 2016 Alloy Wire International Ltd.

Technical Datasheet AWS 014 Rev.1

INCONEL® X-750

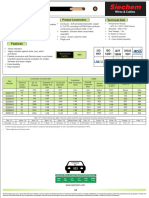

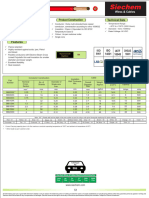

Chemical Composition Specifications Key Features Typical Applications

Element Min % Max % AMS 5667 Good creep rupture strength at Nuclear reactors

C - 0.08 AMS 5671 high temperatures Gas turbines

Mn - 1.00 AMS 5698 (No 1 Spring Temper) Not as strong as Nimonic 90 Rocket engines

AMS 5699 (Spring Temper)

Si - 0.50 Very good at cryogenic Pressure vessels

ASTM B637

S - 0.01 temperatures

BS HR 505 Aircraft structures

Cr 14.00 17.00 GE B14H41 Age hardenable

Ni 70.00 - ISO 15156-3 y

High temperature dynamic

(NACE MR 0175) applications

Nb/Cb 0.70 1.20

Ti 2.25 2.75 Designations

Al 0.40 1.00

W.Nr. 2.4669

Fe 5.00 9.00 UNS N07750

Co - 1.00 AWS 014

Ta - 0.05

Cu - 0.50

Density 8.28 g/cm³ 0.299 lb/in³

Melting Point 1430 °C 2600 °F

Coefficient of Expansion 12.6 μm/m °C (20 – 100 °C) 7.0 x 10-6 in/in °F (70 – 212 °F)

Modulus of Rigidity 75.8 kN/mm² 10994 ksi

Modulus of Elasticity

(Spring Temper + Aged) 218.0 kN/mm² 31619 ksi

(Spring Temper + 3 Part Heat Treated) 212.4 kN/mm² 30806 ksi

(No.1 Spring Temper + Aged) 213.7 kN/mm² 30995 ksi

Heat Treatment of Finished Parts

Temperature

Condition as supplied by Alloy Wire Type Time (Hr) Cooling

°C °F

Spring Temper Age Harden 650 1200 4 Air

Anneal 1150 2100 2 Air

Spring Temper (3 Part) Stabalize 843 1550 24 Air

Age Harden 704 1300 20 Air

No. 1 Temper Age Harden 730 1350 16 Air

Properties

Approx. tensile strength Approx. operating temperature

Condition

N/mm² ksi °C °F

Annealed 800 – 1000 116 – 145 - -

No. 1 Temper 900 – 1150 130 – 167 - -

Spring Temper 1100 – 1500 159 – 217 - -

No. 1 Temper + Aged 1300 – 1450 188 – 210 -200 to +550 -330 to +1020

Spring Temper + Aged 1350 – 1750 196 – 254 -200 to +370 -330 to +700

Spring Temper + 3 part heat treated 1100 – 1250 159 – 181 -200 to +550 -330 to +1020

The above tensile strength ranges are typical. If you require different please ask.

for diameters below 1.00mm contact AWI Technical department y

Dynamic applications = active/lively/changing

AS 9100 ISO 9001 ISO 14001 OHSAS 18001

Narrowboat Way, Hurst Business Park, Brierley Hill, West Midlands, DY5 1UF, UK

t +44 (0)1384 262022 e sales@alloywire.com w alloywire.com

Aerospace & Defence Quality Management Environmental Health & Safety

Das könnte Ihnen auch gefallen

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenVon EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenBewertung: 4 von 5 Sternen4/5 (2)

- AW Tech Datasheet 80 20 NI CRDokument2 SeitenAW Tech Datasheet 80 20 NI CRtrần quang đứcNoch keine Bewertungen

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Von EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Noch keine Bewertungen

- Multi-Set II Drop-In AnchorsDokument5 SeitenMulti-Set II Drop-In AnchorsReinel OrjuelaNoch keine Bewertungen

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionVon EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNoch keine Bewertungen

- Track Master: Festoon SystemsDokument32 SeitenTrack Master: Festoon SystemsRenwick69Noch keine Bewertungen

- Herc-Alloy 1000 Chain Clevlok Lodelok Hook: Types of Chain SlingsDokument1 SeiteHerc-Alloy 1000 Chain Clevlok Lodelok Hook: Types of Chain SlingsMinhKhuongHieuNoch keine Bewertungen

- Tsubaki Power Lock Ad N SeriesDokument5 SeitenTsubaki Power Lock Ad N SeriesRizal IephoNoch keine Bewertungen

- Data MP35N Rev-2Dokument2 SeitenData MP35N Rev-2Nishant MehtaNoch keine Bewertungen

- Nasarc Technologies REVOVER The Power of Spin 1695300632Dokument6 SeitenNasarc Technologies REVOVER The Power of Spin 1695300632VVan TanNoch keine Bewertungen

- CCBT CablesDokument1 SeiteCCBT CablesVijay KarthikeyanNoch keine Bewertungen

- Panasonic 300WY4 TIG Welding MachineDokument2 SeitenPanasonic 300WY4 TIG Welding MachineYm PrathishNoch keine Bewertungen

- CABT CablesDokument1 SeiteCABT CablesKristaNoch keine Bewertungen

- SRP 810 road lighting luminaire for high-pressure lampsDokument1 SeiteSRP 810 road lighting luminaire for high-pressure lampsBagus SaputroNoch keine Bewertungen

- Butterfly Valve Q 011Dokument4 SeitenButterfly Valve Q 011JOHNNoch keine Bewertungen

- RK CableDokument1 SeiteRK CableKristaNoch keine Bewertungen

- FLRYWK CablesDokument1 SeiteFLRYWK CablesKristaNoch keine Bewertungen

- SXL CableDokument1 SeiteSXL CableVijay KarthikeyanNoch keine Bewertungen

- Rohit Damodaran AVSSXDokument1 SeiteRohit Damodaran AVSSXVijay KarthikeyanNoch keine Bewertungen

- Torsiflex-I Disc Couplings: For General Purpose ApplicationsDokument8 SeitenTorsiflex-I Disc Couplings: For General Purpose Applicationsmarcelo castilloNoch keine Bewertungen

- RB Ate EngDokument6 SeitenRB Ate EngFathi FathiNoch keine Bewertungen

- R2 CableDokument1 SeiteR2 CableKristaNoch keine Bewertungen

- Security Lighting: Dimensions in MM FGP 280Dokument1 SeiteSecurity Lighting: Dimensions in MM FGP 280sihabudin kolyubiNoch keine Bewertungen

- FLALRY CablesDokument1 SeiteFLALRY CablesKristaNoch keine Bewertungen

- FLALRY CablesDokument1 SeiteFLALRY CablesVijay KarthikeyanNoch keine Bewertungen

- HG140Dokument1 SeiteHG140zeshankhanNoch keine Bewertungen

- Power Cable: Unshielded, Without Inner Sheath RJ0201 90 C/105 CDokument3 SeitenPower Cable: Unshielded, Without Inner Sheath RJ0201 90 C/105 CNimesh GoyalNoch keine Bewertungen

- EYS SeriesDokument2 SeitenEYS Seriesjuwinthir putra bengawanNoch keine Bewertungen

- Carretes Gleason Reel 36Dokument24 SeitenCarretes Gleason Reel 36Isaac LopbenNoch keine Bewertungen

- Tomacarga CHANCEDokument18 SeitenTomacarga CHANCEBenjamin HidalgoNoch keine Bewertungen

- AVSS CablesDokument1 SeiteAVSS CablesVijay KarthikeyanNoch keine Bewertungen

- Spring Rewind Reels: To Handle 3/4" or 1" I.D. HoseDokument1 SeiteSpring Rewind Reels: To Handle 3/4" or 1" I.D. Hosegustavoac834217Noch keine Bewertungen

- STX CableDokument1 SeiteSTX CableVijay KarthikeyanNoch keine Bewertungen

- Dynabolt CatalogDokument3 SeitenDynabolt Cataloggirlie fabroNoch keine Bewertungen

- 1DB 10881 enDokument1 Seite1DB 10881 enFreddy MormontoyNoch keine Bewertungen

- Auto 85 CableDokument1 SeiteAuto 85 CableVijay KarthikeyanNoch keine Bewertungen

- Since We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualityDokument48 SeitenSince We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualitynateNoch keine Bewertungen

- TMC - Thomas & BettsDokument2 SeitenTMC - Thomas & BettsJFPA2012Noch keine Bewertungen

- FLR4Y CablesDokument1 SeiteFLR4Y CablesVijay KarthikeyanNoch keine Bewertungen

- SGX CableDokument1 SeiteSGX CableVijay KarthikeyanNoch keine Bewertungen

- SGX CableDokument1 SeiteSGX CableKristaNoch keine Bewertungen

- High voltage wound-rotor motors series guideDokument21 SeitenHigh voltage wound-rotor motors series guideAmazonas ManutençãoNoch keine Bewertungen

- AVSSH CablesDokument1 SeiteAVSSH CablesVijay KarthikeyanNoch keine Bewertungen

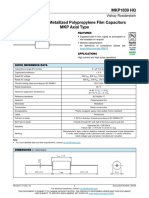

- MKP1839 HQ: Vishay RoedersteinDokument13 SeitenMKP1839 HQ: Vishay RoedersteinSTE ABMCNoch keine Bewertungen

- Leaky Wave Cable Installation: Falcon Autotech Pvt. Ltd. - ConfidentialDokument27 SeitenLeaky Wave Cable Installation: Falcon Autotech Pvt. Ltd. - ConfidentialytdvshuvnkdNoch keine Bewertungen

- UTP Bestseller PDFDokument28 SeitenUTP Bestseller PDFdaha333Noch keine Bewertungen

- 3TH Series Section GrayDokument24 Seiten3TH Series Section Graymarcos luqueNoch keine Bewertungen

- IWISS Crimping ToolsDokument66 SeitenIWISS Crimping Toolsv.kotekNoch keine Bewertungen

- Tecnotion TBW Series SpecsheetDokument2 SeitenTecnotion TBW Series SpecsheetElectromateNoch keine Bewertungen

- SRC510 511Dokument1 SeiteSRC510 511Bagus SaputroNoch keine Bewertungen

- R4 CableDokument1 SeiteR4 CableVijay KarthikeyanNoch keine Bewertungen

- SK 02Dokument3 SeitenSK 02ASDNoch keine Bewertungen

- E Clip DatahseetDokument2 SeitenE Clip DatahseetLeonel BerlinNoch keine Bewertungen

- Interconnects: P. Vaishnavi - 208221020Dokument39 SeitenInterconnects: P. Vaishnavi - 208221020Palawar VaishnaviNoch keine Bewertungen

- Lincoln Power Wave 455M welding package BOMDokument1 SeiteLincoln Power Wave 455M welding package BOMnobamoNoch keine Bewertungen

- TS - 72-100-A (5) ApolloDokument4 SeitenTS - 72-100-A (5) ApolloAndres Felipe Gonzalez UrbeNoch keine Bewertungen

- FLR2X11Y CablesDokument1 SeiteFLR2X11Y CablesVijay KarthikeyanNoch keine Bewertungen

- FLR2X11Y CablesDokument1 SeiteFLR2X11Y CablesKristaNoch keine Bewertungen

- Prima Catalouge 6 Pgs-MinDokument6 SeitenPrima Catalouge 6 Pgs-MinVarun KapoorNoch keine Bewertungen

- Nexans - 19 33kV Three CoreDokument5 SeitenNexans - 19 33kV Three CoreRonit KayasthaNoch keine Bewertungen

- Troubled Seaside Town - S Huge New 2bn P... Best Again - UK - News - Express - Co.ukDokument6 SeitenTroubled Seaside Town - S Huge New 2bn P... Best Again - UK - News - Express - Co.ukstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N8 Ironwork-SDokument8 SeitenThe Georgian Group Guides N8 Ironwork-SstevemwilliamsNoch keine Bewertungen

- Lytham - Windmill - Brochure 2024Dokument2 SeitenLytham - Windmill - Brochure 2024stevemwilliamsNoch keine Bewertungen

- Wes Mason Sporting Cyclist Mar63Dokument4 SeitenWes Mason Sporting Cyclist Mar63stevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N7 MOULDINGSDokument8 SeitenThe Georgian Group Guides N7 MOULDINGSstevemwilliamsNoch keine Bewertungen

- Historic England Corporate Plan 2019-22Dokument11 SeitenHistoric England Corporate Plan 2019-22stevemwilliamsNoch keine Bewertungen

- Heritage Sector in England and Its Impact On The Economy Oct 2018Dokument45 SeitenHeritage Sector in England and Its Impact On The Economy Oct 2018stevemwilliamsNoch keine Bewertungen

- A Guide For Owners of Listed Buildings PDFDokument20 SeitenA Guide For Owners of Listed Buildings PDFstevemwilliamsNoch keine Bewertungen

- Historic England Corporate Plan 2019-22Dokument11 SeitenHistoric England Corporate Plan 2019-22stevemwilliamsNoch keine Bewertungen

- 2 Preface - Will The Real Edward Kemp Step Forward Robert Lee GH-46-00Dokument9 Seiten2 Preface - Will The Real Edward Kemp Step Forward Robert Lee GH-46-00stevemwilliamsNoch keine Bewertungen

- Newton Hall: and The Cruck Buildings of North West EnglandDokument16 SeitenNewton Hall: and The Cruck Buildings of North West EnglandstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N9 Fireplaces-SDokument8 SeitenThe Georgian Group Guides N9 Fireplaces-SstevemwilliamsNoch keine Bewertungen

- Approved Process: HERITAGE WORKS ManagementDokument60 SeitenApproved Process: HERITAGE WORKS ManagementstevemwilliamsNoch keine Bewertungen

- Meoles and ST Cuthbert 76-5-CheethamDokument29 SeitenMeoles and ST Cuthbert 76-5-CheethamstevemwilliamsNoch keine Bewertungen

- A Beautiful Balance Edward Kemp and Grosvenor Park - David Lambert GH-46-5 - PaperDokument16 SeitenA Beautiful Balance Edward Kemp and Grosvenor Park - David Lambert GH-46-5 - PaperstevemwilliamsNoch keine Bewertungen

- How To Lay Out A Very Large Garden Indeed Layton Jones GH-46-4 - PaperDokument11 SeitenHow To Lay Out A Very Large Garden Indeed Layton Jones GH-46-4 - PaperstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N2 Brickwork-SDokument8 SeitenThe Georgian Group Guides N2 Brickwork-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides Georgian Chimneypieces by N.burton L.porten-SDokument48 SeitenThe Georgian Group Guides Georgian Chimneypieces by N.burton L.porten-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N4 Paint Colour-SDokument8 SeitenThe Georgian Group Guides N4 Paint Colour-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N3 Doors-SDokument8 SeitenThe Georgian Group Guides N3 Doors-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides Georgian Stairs by N.burton-SDokument56 SeitenThe Georgian Group Guides Georgian Stairs by N.burton-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N6 Wallpaper-SDokument8 SeitenThe Georgian Group Guides N6 Wallpaper-SstevemwilliamsNoch keine Bewertungen

- The Georgian Group Guides N1 Windows-SDokument8 SeitenThe Georgian Group Guides N1 Windows-SstevemwilliamsNoch keine Bewertungen

- FuelInjectorNozzles enDokument20 SeitenFuelInjectorNozzles enVijayendran VijayNoch keine Bewertungen

- Lifeboat 150 - The Samuel Fletcher' - Fylde CoasterDokument23 SeitenLifeboat 150 - The Samuel Fletcher' - Fylde CoasterstevemwilliamsNoch keine Bewertungen

- World of Model BoatingDokument100 SeitenWorld of Model BoatingJoãoGilbertoAraújoPontes100% (3)

- Suzuki Garphyttan Product Information 2016Dokument29 SeitenSuzuki Garphyttan Product Information 2016stevemwilliamsNoch keine Bewertungen

- 10 Effect of Speed of ProductionDokument2 Seiten10 Effect of Speed of ProductionstevemwilliamsNoch keine Bewertungen

- Suzuki Garphyttan Brochure 2016Dokument25 SeitenSuzuki Garphyttan Brochure 2016stevemwilliams100% (1)

- Manual de Instruções Iveco Eurocargo Euro 6Dokument226 SeitenManual de Instruções Iveco Eurocargo Euro 6rsp filmes100% (1)

- 02 - Order Quantities When Demand Is Approximately LevelDokument2 Seiten02 - Order Quantities When Demand Is Approximately Levelrahma.samyNoch keine Bewertungen

- Science SimulationsDokument4 SeitenScience Simulationsgk_gbuNoch keine Bewertungen

- MMADDokument2 SeitenMMADHariharan SNoch keine Bewertungen

- Project Report VajDokument15 SeitenProject Report VajTamil SelvanNoch keine Bewertungen

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Dokument7 SeitenHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranNoch keine Bewertungen

- Business Plan1Dokument38 SeitenBusiness Plan1Gwendolyn PansoyNoch keine Bewertungen

- Rhetorical Analysis ArticleDokument6 SeitenRhetorical Analysis Articleapi-242472728Noch keine Bewertungen

- Electronics HubDokument9 SeitenElectronics HubKumaran SgNoch keine Bewertungen

- Filler SlabDokument4 SeitenFiller Slabthusiyanthanp100% (1)

- Types of Stress: Turdalieva Daria HL 2-19 ADokument9 SeitenTypes of Stress: Turdalieva Daria HL 2-19 ADaria TurdalievaNoch keine Bewertungen

- Kanavos Pharmaceutical Distribution Chain 2007 PDFDokument121 SeitenKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaNoch keine Bewertungen

- Youre The Inspiration CRDDokument3 SeitenYoure The Inspiration CRDjonjammyNoch keine Bewertungen

- Book3 79 111000 0000100120 DAH MPL RPT 000005 - ADokument101 SeitenBook3 79 111000 0000100120 DAH MPL RPT 000005 - ANassif Abi AbdallahNoch keine Bewertungen

- Socio-cultural influences on educationDokument4 SeitenSocio-cultural influences on educationofelia acostaNoch keine Bewertungen

- Ceeshsworkingstudents Abm Group2Dokument18 SeitenCeeshsworkingstudents Abm Group2kzz9c5hqrwNoch keine Bewertungen

- Ubiquiti Af60-Xr DatasheetDokument3 SeitenUbiquiti Af60-Xr Datasheetayman rifaiNoch keine Bewertungen

- Journal Sleep Walking 1Dokument7 SeitenJournal Sleep Walking 1Kita SemuaNoch keine Bewertungen

- Remembrance 23 Names PDFDokument1 SeiteRemembrance 23 Names PDFJennifer ThuncherNoch keine Bewertungen

- History of English Prose PDFDokument21 SeitenHistory of English Prose PDFMeisyita QothrunnadaNoch keine Bewertungen

- Philippine Politics Concepts ExplainedDokument3 SeitenPhilippine Politics Concepts ExplainedAngel Lyn A Lacerna100% (1)

- Tendernotice 2Dokument20 SeitenTendernotice 2VIVEK SAININoch keine Bewertungen

- Assignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodDokument4 SeitenAssignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodEric GozzerNoch keine Bewertungen

- Psalms Magick of The Old Testament PDFDokument129 SeitenPsalms Magick of The Old Testament PDFirrrs100% (1)

- Elements of Ayurveda Daily Routine GuideDokument1 SeiteElements of Ayurveda Daily Routine GuideShivani GargNoch keine Bewertungen

- Pmls 1 Final Exam Reviewer: Clinical Chemistry ContDokument14 SeitenPmls 1 Final Exam Reviewer: Clinical Chemistry ContPlant in a PotNoch keine Bewertungen

- History shapes Philippine societyDokument4 SeitenHistory shapes Philippine societyMarvin GwapoNoch keine Bewertungen

- New Company Profile.Dokument8 SeitenNew Company Profile.Allen AsirNoch keine Bewertungen

- FED - Summer Term 2021Dokument18 SeitenFED - Summer Term 2021nani chowdaryNoch keine Bewertungen

- OM - Rieter - UNIMix A76Dokument321 SeitenOM - Rieter - UNIMix A76Phineas FerbNoch keine Bewertungen

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Handbook on Battery Energy Storage SystemVon EverandHandbook on Battery Energy Storage SystemBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Incidents That Define Process SafetyVon EverandIncidents That Define Process SafetyNoch keine Bewertungen

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryVon EverandSafety Fundamentals and Best Practices in Construction IndustryNoch keine Bewertungen

- Inherently Safer Chemical Processes: A Life Cycle ApproachVon EverandInherently Safer Chemical Processes: A Life Cycle ApproachBewertung: 5 von 5 Sternen5/5 (1)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyVon EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNoch keine Bewertungen

- The Way Home: Tales from a life without technologyVon EverandThe Way Home: Tales from a life without technologyBewertung: 4 von 5 Sternen4/5 (45)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsVon EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNoch keine Bewertungen

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- The Rare Metals War: the dark side of clean energy and digital technologiesVon EverandThe Rare Metals War: the dark side of clean energy and digital technologiesBewertung: 5 von 5 Sternen5/5 (2)