Beruflich Dokumente

Kultur Dokumente

Scan 001

Hochgeladen von

FedericoC0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten2 Seitenwps smaw carbon steel

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenwps smaw carbon steel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten2 SeitenScan 001

Hochgeladen von

FedericoCwps smaw carbon steel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Certficsteno: VEN 129099878

Page tof 2

loyds

Regs Welding Procedure Specification (WPS)

‘unification Codetandard:

Lloyel's Register - Rules for the Manufacture, Testing and Certification of Materials, July 2012

Manufacturer's Name: Manufacure's Adres:

CRNS.p.A. Via Enrico Mattei, 26

60125 Ancona, Italy

WHS Murer and Rein: ote king Proce Qulcaiontecord POR CeesteN:

Nowan:

oun 12 october 2012 VEN 1290988/7

ekg Process pe

136- MAG Semb-automatict

Weng Techie

Mult Run both sides welding with temporary backing strip and gouging

ig Poston

X- Horizontal

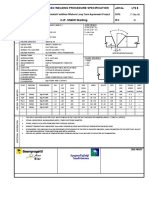

Weld Preparation Details (Sketch) ae: hs a ew

rant es5n ‘kn eaves

60°

1 LPG A]

ft CAGRLEL

whe

Ke

15mm 8m

‘Base Material Details Dt aN ae Suu aS a

Specieabon and Grade se

Wa 01-LR Grade AH 36

Speccaton and Grade sce 2

WO 01-LR Grade AH 36

Fear ‘Thickness Range (un pe Outside Ore i:

Plater 3-20 :

‘Consumable Details ia eee MRIS RAY ie Se

File Meta

Name: Grading aol Ciasicaton i any:

‘erlikon / Fluxofil 19 HD / 1.2 mm 3405 - HS EN 1SO 17632-A-T 46.3 PC1 HS

Filer Metal Ses rm Fie Type ad ade Name

12mm Rutile, fast freezing slag

shi rbon Dioxide ie in

papauarras ing (99.9 % Carbon Dioxide cae Shieing 18 Ui

acting 99.9% Carbon Dioxide Backing 18min

Tungsten Cectrode Type 8 Se

Backing Stip Type 8 Size: Liquide Weldline -Keraline TA3 - 13 mm,

{Select trom dopdown mena

Delt ar soproprite

ya's Register Group United ts afflats and subscares and the respective ofces, employees or agents ae nda and collectively, refered to inthe clase 35

"oj's Reps lyd's Rageie assumes ho responsi ar shal no be table to any patson for any ls, damage 0: expense caused by relance on he nfomation oF

gece inthe dociment er hovsoere powde, ess a potson has ined a contact wih the rewant Lloye's Register ent forthe provsion af ths infrmation or

osce andin that case ay tesponslty holy exci onthe tes and cona ons set out in ha contact.

Ferm 5206 2012.08)

‘Proheat/Heat Treatment Details bg

Fre Heat Temperature" (ik

Post weld Heat Treatment andor Ageing:

Meted

Heating and Cosing Rates

Technique Details:

Metiod of Back Goosing ad Cleaning

Brushing and Grinding

String or Weave Bead

suing

oe Ample

Contac tbe to work dtc

ue Welding etal:

tse Cert dase Time

Welding Details URS

fin Roce: —‘Saeof Filer Curent,

ta *

12136 jamm 143

a 136 12mm 138

46 136 12mm 125

7 136 samm 12

8-9 136 jamm 158

0 136 12mm 160

1 | oe jam 158

2 16 tamm 158

B86 12mm 156

14-19 136 sam 156

“Other information ese

Frequency

ABS

ae

Certificate no:

Page 201 2

Inerpass Temperature" (man- 250°C

Temperate’: Tew:

‘Weaving (Maximum with of run)

3mm

net tine

mea Cure Feat Tne

ay ao

‘ypectWiereed Tal sped

Coren Speed

four,

pew) |

a) 430 mm/min

oc 312 mm/min

oc) £85 mm/min

pce) 370 mm/min

ecw) (444 even

Dew) 310 mm/min

ocw) 385 mm/min

pew) 379 maven

oc) 500 mm/min

1 a a

For backing welding detals see Welding Procedure Qualification Record (PQR) VEN 1290998/7

Mantacter

CRNS.D.A,

Name

‘eral Younes

bate:

Signature

1. Tis WS vad oli used bythe above manufactur

01 February 2013

Surveyor to y's Register EMEA,

| subsidy of Uoy's Register Group Limited

ffee: Ravenna,

Angel Solano

31 January 2013,

Sonate: =

2 The manuocturr response for esaing tae WPS meets te techn requtements for the appcation

Frm 5205 2012.08)

VEN 129099878

mes

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- DRS Laser Users Guide 790309-0706Dokument145 SeitenDRS Laser Users Guide 790309-0706FedericoCNoch keine Bewertungen

- 2009 NC New Top InstallDokument21 Seiten2009 NC New Top InstallFedericoCNoch keine Bewertungen

- 790280-1009 Measure-X FastStart GuideDokument117 Seiten790280-1009 Measure-X FastStart GuideFedericoCNoch keine Bewertungen

- 6538Dokument2 Seiten6538FedericoCNoch keine Bewertungen

- DFMA TipsDokument81 SeitenDFMA TipsFedericoCNoch keine Bewertungen

- Wps Saldatura A T GMAW SteelDokument4 SeitenWps Saldatura A T GMAW SteelFedericoCNoch keine Bewertungen

- Wps Saldatura A T GTAW AluminiumDokument3 SeitenWps Saldatura A T GTAW AluminiumFedericoCNoch keine Bewertungen

- 1.1.1.1.1 Costo Del Materiale: Formule ForgiaturaDokument2 Seiten1.1.1.1.1 Costo Del Materiale: Formule ForgiaturaFedericoCNoch keine Bewertungen

- Wps SmawDokument1 SeiteWps SmawFedericoC67% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)