Beruflich Dokumente

Kultur Dokumente

SL No Description Symbol Unit Value Remark: Calculation of Shell Thickness

Hochgeladen von

alvinchuan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten1 SeiteThis document provides specifications for an air vessel, including:

1. Maximum working pressure is 7.5 kg/cm2(g)

2. Design pressure is 8.5 kg/cm2(g)

3. Hydrotest pressure is 12.75 kg/cm2(g), which is 1.5 times the design pressure for a 30 minute test.

4. Dimensions include an outside diameter of 1216 mm and inside diameter of 1200 mm.

Originalbeschreibung:

stress calcuation

Originaltitel

Air Reciever Stress Calculation

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides specifications for an air vessel, including:

1. Maximum working pressure is 7.5 kg/cm2(g)

2. Design pressure is 8.5 kg/cm2(g)

3. Hydrotest pressure is 12.75 kg/cm2(g), which is 1.5 times the design pressure for a 30 minute test.

4. Dimensions include an outside diameter of 1216 mm and inside diameter of 1200 mm.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten1 SeiteSL No Description Symbol Unit Value Remark: Calculation of Shell Thickness

Hochgeladen von

alvinchuanThis document provides specifications for an air vessel, including:

1. Maximum working pressure is 7.5 kg/cm2(g)

2. Design pressure is 8.5 kg/cm2(g)

3. Hydrotest pressure is 12.75 kg/cm2(g), which is 1.5 times the design pressure for a 30 minute test.

4. Dimensions include an outside diameter of 1216 mm and inside diameter of 1200 mm.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

SL NO DESCRIPTION SYMBOL UNIT VALUE REMARK

It is defined as the maximum gauge pressure, at the

coincident (which the air is in touch with), that is

1 Maximum working pressure Pmw kg/cm²(g) 7.5 permitted for the vessel in operation.

The pressure (internal or external) including the

static head used in the design calculation of a vessel

in operation for determining the thickness of various

2 Design pressure Pd kg/cm²(g) 8.5 components

It is defined as the pressure at which the fluid must

be kept inside the vessel to check if there is any

seepage . This value shall be taken as 1.5 times

design pressure (NTPC specfification) for 30 minutes

3 Hydro.test pressure Ph kg/cm²(g) 12.75 duration of test

4 Outside diameter of shell Do mm 1216

Di=Do-2 x thickness. Assume the thickness to be

6mm for 1 m³ air receivers and 8mm for 2 m³ to

5 Inside diameter of shell (or cylinder) Di mm 1200 calculate inner diameter

6 Maximum working temperature Tmax °C 60

7 Design temperature Td °C 100

It is defined as the maximum stress permissible at

8 Maximum allowable stress S kgf/mm² 12.75 the design temperature for any specified material

9 Inside Crown radius Ro mm 1080 To detaermine the crown radius and knuckle radius

10 Inside knukle radius ro mm 204 refer table 1 of IS 4049

11 L/r ratio 10

Refer figure 3.7 of IS 2825. Shape factor can be

obtained from the ratio of height of cylinder/outside

12 Shape factor M 1.02 diameter of the cylinder

13 Length of straight flange Sf mm 38 3 times shell thickness or 38 mm whichever is larger

14 Height of cylinder H mm 2700

For medium duty applications (DFDS, DE), consider

15 Weld joint efficiency E 0.85 Joint efficiecny in 0.8-0.85 range.

16 Corrosion allowance C/A mm 1.5

CALCULATION OF SHELL THICKNESS

Minimum thickness of shell inclusive of corrosion IS 2825 page no 13, eqn 3.1; tsmin=Pd x Di/(200S x E-

17 allowance tsmin mm 6.224409449 Pd)+C/A

18 thickness selected ts mm 8

CALCULATION OF DISHED END THICKNESS

Thickness of ends concave to internal pressure

19 (domed ends/dished ends) tdmin mm 7.068627451 tdmin= Pd x Do x M/(200S x E)+C/A

20 Thickness of ends selected td mm 8

CALCULATION OF VOLUME

Volume of the dished ends= 2/3rd volume of sphere

with diameter equal to diameter of the

cylinder+twice the volume of cylinder whose height

is equal to the length of straight flange and internal

diameter is equal to the internal diameter of the

21 Volume of 2 dished ends Vd m³ 0.538343317 cylinder

22 Volume of cylinder Vc m³ 3.053628059

23 Total Volume of cylinder V m³ 3.591971376

Das könnte Ihnen auch gefallen

- Calculate The Pump Discharge Pressure From The Pump Total HeadDokument8 SeitenCalculate The Pump Discharge Pressure From The Pump Total HeadMansuri Tausif AhmedNoch keine Bewertungen

- Air Receiver CalculationDokument4 SeitenAir Receiver CalculationManish PatelNoch keine Bewertungen

- Restrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazineDokument1 SeiteRestrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazinealvinchuanNoch keine Bewertungen

- Flange DesignDokument30 SeitenFlange Designravielb9873Noch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument16 SeitenThickness Calculation of Pressure Vessel ShellRamuAlagappan100% (4)

- Water Heater Calculation Rev ADokument1 SeiteWater Heater Calculation Rev AalvinchuanNoch keine Bewertungen

- Volume Nodes DetectorDokument21 SeitenVolume Nodes DetectorJohn Aejandro Salazar Tapasco0% (1)

- Nozzle and ReinforcementDokument23 SeitenNozzle and ReinforcementAzharyanto Fadhli100% (1)

- CK Tourqe CalculationDokument7 SeitenCK Tourqe Calculationamit amity100% (1)

- Pressure Vessel Calculation Report PDFDokument12 SeitenPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

- Piepline Thickness CalculationDokument6 SeitenPiepline Thickness CalculationAneeq NaufalNoch keine Bewertungen

- API 650 RF Pad Calculation PDFDokument1 SeiteAPI 650 RF Pad Calculation PDFRakeshNoch keine Bewertungen

- Calculation Sheet For Slug CatcherDokument12 SeitenCalculation Sheet For Slug CatcherchumaNoch keine Bewertungen

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDokument25 SeitenBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagNoch keine Bewertungen

- Design and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016Dokument13 SeitenDesign and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016renu rani100% (1)

- HDD Calculation - CH 15Dokument23 SeitenHDD Calculation - CH 15Binay Kumar100% (1)

- Flat Ends With A Hub For Uniform Thickness ShellDokument5 SeitenFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNoch keine Bewertungen

- v756373001xb - Mds Sludge Decant TankDokument50 Seitenv756373001xb - Mds Sludge Decant TankInamullah KhanNoch keine Bewertungen

- ستيل ستركشرDokument73 Seitenستيل ستركشرAws SamaNoch keine Bewertungen

- Pipe Insulation CalculationDokument2 SeitenPipe Insulation CalculationalvinchuanNoch keine Bewertungen

- Assignment Design 2Dokument20 SeitenAssignment Design 2Nadia Refai100% (1)

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDokument12 SeitenR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Annex II (Detail Calculation of High Pressure Penstock Pipe)Dokument16 SeitenAnnex II (Detail Calculation of High Pressure Penstock Pipe)Sudan ShakyaNoch keine Bewertungen

- TubesheetDokument8 SeitenTubesheetVaibhavNoch keine Bewertungen

- Storage Tank DesignDokument21 SeitenStorage Tank Designravi456compNoch keine Bewertungen

- Jep Specific WeightDokument2 SeitenJep Specific Weightjep castanedaNoch keine Bewertungen

- Buffer Tank DesignDokument1 SeiteBuffer Tank DesignSuresh Damu BhadNoch keine Bewertungen

- FRP PipeDokument4 SeitenFRP PipealvinchuanNoch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument16 SeitenThickness Calculation of Pressure Vessel ShellClaudia BonocoreNoch keine Bewertungen

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDokument3 SeitenRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNoch keine Bewertungen

- SS 532-2016+corr 1 - PreviewDokument11 SeitenSS 532-2016+corr 1 - PreviewalvinchuanNoch keine Bewertungen

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDokument10 SeitenTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNoch keine Bewertungen

- Hydroprocessing Rate Increase Using Shaped ChangeDokument11 SeitenHydroprocessing Rate Increase Using Shaped ChangeAndri SaputraNoch keine Bewertungen

- Equipment Design As Per Russian Norms - 20090218Dokument45 SeitenEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Sif B31.3Dokument10 SeitenSif B31.3Rob Gillespie100% (1)

- DD41 Manhole FlotationDokument4 SeitenDD41 Manhole FlotationalvinchuanNoch keine Bewertungen

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDokument13 SeitenProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (1)

- Spherical Shells (7.4.3) EN 13445-3Dokument3 SeitenSpherical Shells (7.4.3) EN 13445-3met-calcNoch keine Bewertungen

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresVon EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresBewertung: 4 von 5 Sternen4/5 (1)

- Ibr Stand PipeDokument11 SeitenIbr Stand PipeP s JagatheesanNoch keine Bewertungen

- Du BushDokument39 SeitenDu BushDevang RathodNoch keine Bewertungen

- Vessel ThicknessDokument7 SeitenVessel ThicknessShishupal ChoudharyNoch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument16 SeitenThickness Calculation of Pressure Vessel ShellRamalingameSattiamoortyNoch keine Bewertungen

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDokument2 SeitenSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNoch keine Bewertungen

- Kalkulasi HEDokument4 SeitenKalkulasi HEagusnnnNoch keine Bewertungen

- Torispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREDokument3 SeitenTorispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191Noch keine Bewertungen

- Final Reactor DesignDokument28 SeitenFinal Reactor DesignGaurav Kakad0% (1)

- 6 Inch NB Nozzle Calulation For TankDokument12 Seiten6 Inch NB Nozzle Calulation For TankSACHIN PATELNoch keine Bewertungen

- ASME BPVC VIII MinT CalculationsDokument2 SeitenASME BPVC VIII MinT CalculationsSbuZikalalaNoch keine Bewertungen

- API 650 RF Pad Calculation PDFDokument1 SeiteAPI 650 RF Pad Calculation PDFBimal DeyNoch keine Bewertungen

- VSL CalDokument50 SeitenVSL CalEmrahCayboyluNoch keine Bewertungen

- Design Calculation For Tank 1st TrialDokument8 SeitenDesign Calculation For Tank 1st TrialBimal DeyNoch keine Bewertungen

- Flange Calculation As Per BS - XLSX - 170111Dokument7 SeitenFlange Calculation As Per BS - XLSX - 170111sandesh sadvilkarNoch keine Bewertungen

- Du Dub PDFDokument55 SeitenDu Dub PDFSURESH100% (1)

- NASA Vacuum Vessel Weight and Volume CalculationsDokument11 SeitenNASA Vacuum Vessel Weight and Volume CalculationsVarun MalhotraNoch keine Bewertungen

- 02 - Vessel Pressure & Thickness CalculationDokument3 Seiten02 - Vessel Pressure & Thickness CalculationPankaj SinglaNoch keine Bewertungen

- D.M Tank-DesignDokument13 SeitenD.M Tank-DesignvandhyathevanNoch keine Bewertungen

- 12Dokument119 Seiten12Salihin FhooziNoch keine Bewertungen

- Delta PTDokument6 SeitenDelta PTWK SinnNoch keine Bewertungen

- Brgclear PDFDokument13 SeitenBrgclear PDFvijaykhandgeNoch keine Bewertungen

- 강도계산프로그램Dokument16 Seiten강도계산프로그램심판자Noch keine Bewertungen

- Component DesignDokument32 SeitenComponent Designdaniel hambissaNoch keine Bewertungen

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREDokument3 SeitenEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191Noch keine Bewertungen

- Tebalvesel PerhitunganDokument16 SeitenTebalvesel Perhitungancharleshutabara951Noch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument16 SeitenThickness Calculation of Pressure Vessel ShellSateesh MokasiNoch keine Bewertungen

- Tanque A PresionDokument16 SeitenTanque A PresionJuan MendozaNoch keine Bewertungen

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Relative Discharging Power of Pipe LineDokument1 SeiteRelative Discharging Power of Pipe LinealvinchuanNoch keine Bewertungen

- Solve Differential EquationDokument4 SeitenSolve Differential EquationalvinchuanNoch keine Bewertungen

- Mass BalanceDokument4 SeitenMass BalancealvinchuanNoch keine Bewertungen

- DD - 22 Floatation of Circular PipeDokument6 SeitenDD - 22 Floatation of Circular PipealvinchuanNoch keine Bewertungen

- Extracts PG - 12 &13 of SS636Dokument2 SeitenExtracts PG - 12 &13 of SS636alvinchuanNoch keine Bewertungen

- Extracts of SS636Dokument2 SeitenExtracts of SS636alvinchuanNoch keine Bewertungen

- PE Pipeline Analysis & CalculationDokument2 SeitenPE Pipeline Analysis & CalculationalvinchuanNoch keine Bewertungen

- PUB Simplified Submission ProcessDokument1 SeitePUB Simplified Submission ProcessalvinchuanNoch keine Bewertungen

- Pipe ThicknessDokument1 SeitePipe ThicknessalvinchuanNoch keine Bewertungen

- PE Pipeline Analysis & CalculationDokument2 SeitenPE Pipeline Analysis & CalculationalvinchuanNoch keine Bewertungen

- API Sizing KIM - XLSMDokument1 SeiteAPI Sizing KIM - XLSMalvinchuanNoch keine Bewertungen

- Pipeline Analysis & Calculation Environment: Pipe SelectionDokument6 SeitenPipeline Analysis & Calculation Environment: Pipe SelectionalvinchuanNoch keine Bewertungen

- Kimgds Flyer - 1Dokument2 SeitenKimgds Flyer - 1alvinchuanNoch keine Bewertungen

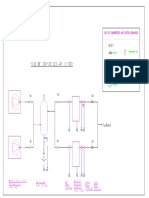

- Compressed Air P&ID DrawingDokument1 SeiteCompressed Air P&ID DrawingalvinchuanNoch keine Bewertungen

- Mariya International School Math Worksheet Term: 2 (2017-2018)Dokument13 SeitenMariya International School Math Worksheet Term: 2 (2017-2018)Tawfik Mohamed Abu ZaidNoch keine Bewertungen

- Using and Understanding Mathematics 6th Edition Bennett Test BankDokument24 SeitenUsing and Understanding Mathematics 6th Edition Bennett Test BankAndreaMccluredewri100% (38)

- PC 11 Final Exam Review Multiple ChoiceDokument8 SeitenPC 11 Final Exam Review Multiple ChoiceSean Lehmar CapariñoNoch keine Bewertungen

- Understanding by Design Unit TemplateDokument28 SeitenUnderstanding by Design Unit Templateapi-248700303Noch keine Bewertungen

- Subwoofer Box For Skar VD10 - Ported Box - SlotDokument2 SeitenSubwoofer Box For Skar VD10 - Ported Box - SlotMarvin RiveraNoch keine Bewertungen

- Estimation of Male and Female Body Segment Parameters of TheDokument8 SeitenEstimation of Male and Female Body Segment Parameters of TheTitiwat Triwong100% (1)

- Conversion of Units of Volume and Capacity: WorkedDokument1 SeiteConversion of Units of Volume and Capacity: WorkedPaul TurnerNoch keine Bewertungen

- IGCSE Maths - Advanced Information Summer 2022Dokument32 SeitenIGCSE Maths - Advanced Information Summer 2022Muaad AidarusNoch keine Bewertungen

- Uconeer - Units Conversion For EngineersDokument4 SeitenUconeer - Units Conversion For EngineersQtie_1158241Noch keine Bewertungen

- Test Bank For Chemistry 8th Edition Jill Kirsten Robinson John e Mcmurry Robert C FayDokument49 SeitenTest Bank For Chemistry 8th Edition Jill Kirsten Robinson John e Mcmurry Robert C FayLouis Craig100% (30)

- Average TZDokument6 SeitenAverage TZvictor javier nuñezNoch keine Bewertungen

- Grade 4 DLLDokument48 SeitenGrade 4 DLLMarwinnie Deola0% (1)

- Characterization of Solid ParticlesDokument8 SeitenCharacterization of Solid ParticlesShary Mosquera50% (2)

- Project CLASS IxDokument5 SeitenProject CLASS Ixanananha62Noch keine Bewertungen

- 〈697〉 Container Content for InjectionsDokument1 Seite〈697〉 Container Content for Injectionsmehrdarou.qaNoch keine Bewertungen

- Investigation of Linearity, Detection Limit (LD) and Quantitation Limit (LQ) of Active Substance From Pharmaceutical TabletsDokument4 SeitenInvestigation of Linearity, Detection Limit (LD) and Quantitation Limit (LQ) of Active Substance From Pharmaceutical TabletsCristian-Catalin GavatNoch keine Bewertungen

- Section 6-3: Volumes of Solids of Revolution / Method of RingsDokument10 SeitenSection 6-3: Volumes of Solids of Revolution / Method of RingsFa'izah MusraNoch keine Bewertungen

- UntitledDokument20 SeitenUntitledapi-63318741Noch keine Bewertungen

- Cs Record Class 12Dokument156 SeitenCs Record Class 12Ram SiddeshNoch keine Bewertungen

- 1 (A) State The Difference Between A Scalar Quantity and A Vector QuantityDokument39 Seiten1 (A) State The Difference Between A Scalar Quantity and A Vector QuantityAbdul RafayNoch keine Bewertungen

- Solid GeometryDokument9 SeitenSolid Geometryfachira_humairaNoch keine Bewertungen

- ABE 315 - Module 2 - CoursepackDokument18 SeitenABE 315 - Module 2 - CoursepackRouge WintersNoch keine Bewertungen

- C 4Dokument52 SeitenC 4saur1Noch keine Bewertungen

- Maths ProblemDokument28 SeitenMaths ProblemlaibaNoch keine Bewertungen

- DEFORM3D v10.2 PreformDesign Manual (WWW - Wenkuxiazai.com)Dokument4 SeitenDEFORM3D v10.2 PreformDesign Manual (WWW - Wenkuxiazai.com)MZSHBNoch keine Bewertungen

- Piston Displacement LessonDokument8 SeitenPiston Displacement LessonZheejae Lao-atenNoch keine Bewertungen