Beruflich Dokumente

Kultur Dokumente

Construction Brochure A4 WHITE FINAL2 PDF

Hochgeladen von

luismdmjOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Construction Brochure A4 WHITE FINAL2 PDF

Hochgeladen von

luismdmjCopyright:

Verfügbare Formate

Your Global Resource

Carlisle Brake & Friction is the leading global solutions provider for high performance and severe duty

brake, clutch, and transmission systems to OEM and aftermarket customers in the construction, mining,

military, agricultural, motorsports, industrial, and aerospace markets.

The strength of Carlisle's broad technology, product, and system portfolio gives our customers access to a

diverse range of the most highly engineered braking, hydraulic, clutch, and transmission products available

on the market today.

With more than 1,700 employees and 11 manufacturing facilities globally located in the U.S., U.K., Italy,

India, China, and Japan, Carlisle serves more than 100 leading original equipment manufacturers in 50

countries. Carlisle is the right choice for your new brake or friction system design, no matter where you are

in the world.

CONSTRUCTION VEHICLE

BRAKING SYSTEMS

To learn more about Carlisle's construction vehicle braking systems contact one of Friction Materials | Service Brakes

our sales offices or visit www.carlislecbf.com Park & Emergency Brakes | Hydraulics

United States Europe Asia-Pacific

6180 Cochran Road Via Pacinotti 9 Orzinuovi Suite E & F, 9th Floor

Solon, OH 44139 (BS) 25034 Majesty Building

USA Italy No. 138 Pudong Ave.

1 855 403 9083 PH +39 030 994 1016+39 PH Shanghai, P.R. China 200120

440 528 4099 fax 030 994 2768 fax +86 21 6100 5222 PH

+86 21 6100 5220 fax ©2015 Carlisle Brake & Friction

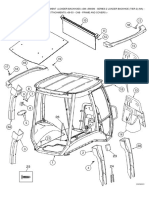

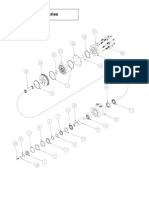

CONSTRUCTION VEHICLE BRAKING SYSTEMS Friction Materials

Backhoe loaders, wheel loaders, pavers, graders, excavators, rollers,

bulldozers, agricultural vehicles, underground mining, mobile cranes,

telehanders, industrial equipment, and haulage trucks

Product Description Features

Paper Paper-based friction materials for transmission, - Oil cooled friction materials with high energy capacity

The construction machine market has been a cornerstone of Carlisle Brake & Friction for decades. (Wet) clutch, and wet brake applications - Tolerance to operate under high unit loading

- High dynamic and static coefficients of friction

Our products are used by the most recognized construction OEMs in the world in applications as - Available in a range of thicknesses and oil groove patterns

diverse as articulated dump trucks to backhoe loaders. We designed the first caliper disc brakes Carbon Cloth/ Carbon rich friction materials for - Displays high heat capability

Paper (Wet) dynamic applications - Conforms uniformly onto the opposing plate

for CAT wheel loaders in the 1950s, and in 1975 we introduced high density paper friction discs - Ability to withstand very high unit loading

- Smooth engagement characteristics

for the emerging wet brake system technology.

Bronze Bronze-based friction material for - Abuse resistant formulation capable of surviving high temperatures

(Wet) transmission and clutch applications - Excellent erosion resistance against oil cavitation

- Good load and wear resistance

In every intense envirornment of controlled movement, rely on the best brake Dry Metallic, semi-metallic, organic, and carbon-carbon - High quality materials provide long life and consistency

technology. Demand Carlisle Brake & Friction. materials for wide range of industrial applications - Parts available up to 46" diameter

- 100+ non-asbestos formulas with wide range of friction coefficients

- Available in a range of sizes and shapes

Today Carlisle offers a wide range of motion control solutions, including friction, brake, and hydraulic

systems for wet brake, dry brake, clutch, and transmission applications. If you pass a construction Service Brakes

Backhoe loaders, wheel loaders, ADTs, mobile cranes, scrapers,

logging equipment, lift trucks, and industrial equipment

site during your day, chances are you've seen a vehicle with a Carlisle system on it.

Product Description Features

Carlisle applies lean Two Piston A, B, and C Series two piston caliper brakes - Carlisle premium linings

manufacturing principles Brakes with hydraulic actuation - Flexible mounting alternatives to fit a wide range of vehicles

throughout our entire - B and C brakes have retracting springs and automatic adjustors

production process.

Four Piston A, M, H, and SCL2 Series four piston caliper - Open caliper provides easy access for service

Brakes brakes with hydraulic actuation - Aluminum housings available for some models

Carlisle is also experienced

with ITAR regulations. Six Piston H, M, HDB640, and SCL35 Series six piston - Multiple calipers can be mounted on a single disc -

Brakes caliper brakes with hydraulic actuation - Options for mounting direct to the axle or bracket

Strength

Full Circle Dry FCL, FCS, and FCP (SAHR) Series full circle - High torque output and quiet operation

Disc Brakes dry disc brakes - Enclosed design eliminates brake contamination

- Adaptable to a variety of applications

Replacement Wide range of linings, pistons, and seal kits - Manufactured to original brake design for longer life and exact fit

Parts - Design, testing, and field application support

The highest quality braking systems in the - Available for the full line of brakes

industry

Front-end loaders, backhoe loaders, telehandlers, haulage trucks,

Park & Emergency Brakes tractors, ADTs, rough terrain cranes, underground mining, winches,

and industrial applications

Durability Product

SA Series

Description

Spring Applied Hydraulic Release (SAHR)

brake calipers for medium duty dynamic and

Features

- Less fade than drum brakes

- Quick change and quick adjustment linings -

Made with long lasting, endurance-tested static applications - Lining retraction spring eliminates drag

- Multiple lining and actuation options available

materials RT Series Mechanically actuated sliding caliper brakes - Quick change organic or sintered metal linings -

designed for static or secondary - Less fade in emergency than drum brakes

applications - Open caliper for easy access and serviceability

Versatility

SCL25 Series Caliper brakes designed for static and limited - Floating caliper design with manual spring release -

dynamic applications - Simple lining adjustment and high torque options

ADTs, haulage trucks, mobile cranes, lift trucks, tractors, backhoe

Braking systems that work off-highway, in Hydraulics loaders, industrial equipment, airport tugs, wheel loaders,

telehandlers, and other industrial applications

sand, snow, water, or mud

Product Description Features

Master Wide range of master cylinders for brake - Available for mineral or Glycol based fluids

Breadth

Cylinders and clutch applications - Conventional and step bore master cylinders available -

- Pressure balanced design for dual pedal applications

Boosted Patented design of Boosted Master Cylinder for - Progressiv, modulated braking response for improved driver comfort

Cylinders best-in-class brake and clutch system - Single, Twin, Tandem, Midi, Compact and Maxi versions available - -

performance for medium to high horsepower - Utilizes supply pressure from vehicles hydraulic system

From the pedal to the wheel, a complete applications - Utilizes PTFE seal technology providing extended service life

system to meet your needs Power

Valves

Modulating output pressure valves for

high capacity/high pressure brake

- Single, Tandem, and Parallel circuit options available -

- Multiple pedal and switch options available

systems

Das könnte Ihnen auch gefallen

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Case-580SM Series 3Dokument164 SeitenCase-580SM Series 3luismdmj100% (2)

- Catalog NeosetDokument173 SeitenCatalog NeosetCarmen Draghia100% (1)

- Hyundai ExcavatorsDokument12 SeitenHyundai Excavatorsluismdmj33% (3)

- Carlisle Aftermarket Catalog 070115 SM - CompressedDokument65 SeitenCarlisle Aftermarket Catalog 070115 SM - CompressedAgus Yulfizar100% (1)

- Surface Belt Structure: Cema C & D SeriesDokument8 SeitenSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniNoch keine Bewertungen

- Bucket Elev - Low X Ser TubeDokument8 SeitenBucket Elev - Low X Ser TubeMauri AlvarezNoch keine Bewertungen

- CAT SealsDokument40 SeitenCAT SealsMohammed NiyamatullahNoch keine Bewertungen

- Compact SD100DDokument2 SeitenCompact SD100DAnonymous QRenwrmJsLNoch keine Bewertungen

- Ansi B18 2.2Dokument48 SeitenAnsi B18 2.2Anonymous 6cpXAaNoch keine Bewertungen

- Input and Output Statements PDFDokument11 SeitenInput and Output Statements PDFRajendra BuchadeNoch keine Bewertungen

- Dynamic Shear Modulus SoilDokument14 SeitenDynamic Shear Modulus SoilMohamed A. El-BadawiNoch keine Bewertungen

- AFA Electronic Parts Catalog PDFDokument90 SeitenAFA Electronic Parts Catalog PDFYew Lim100% (1)

- GoodElearning TOGAF Poster 46 - Adapting The ADMDokument1 SeiteGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoNoch keine Bewertungen

- Complete Track RangeDokument17 SeitenComplete Track RangeBenjamin MurphyNoch keine Bewertungen

- Miba Friction 16-17Dokument172 SeitenMiba Friction 16-17Pedro Alberto Benites100% (1)

- Melco Corporate BrochureDokument16 SeitenMelco Corporate Brochurechintan mistryNoch keine Bewertungen

- Mine TruckDokument2 SeitenMine TruckyesNoch keine Bewertungen

- Parts and Service Guide: SINCE 1842Dokument8 SeitenParts and Service Guide: SINCE 1842Luis Gustavo Escobar MachadoNoch keine Bewertungen

- Pirelli NovateckDokument4 SeitenPirelli NovateckRaza MajeedNoch keine Bewertungen

- SP XX Mobilfluid 424Dokument4 SeitenSP XX Mobilfluid 424Juan Carlo PanchoNoch keine Bewertungen

- CTV WT5556 Rotafrix Catalog enDokument44 SeitenCTV WT5556 Rotafrix Catalog enAhmet HamamcıoğluNoch keine Bewertungen

- SRT Dirjen Spek Khusus Preventif Jalan SKh-1.6.11 S.D. SKh-1.6.14 (Stempel)Dokument16 SeitenSRT Dirjen Spek Khusus Preventif Jalan SKh-1.6.11 S.D. SKh-1.6.14 (Stempel)Eka PrasadaNoch keine Bewertungen

- Racing Transmission FluidDokument2 SeitenRacing Transmission FluidBruce WappmanNoch keine Bewertungen

- Ceran Greases TdsDokument4 SeitenCeran Greases TdsАлексейNoch keine Bewertungen

- Construction: Hydraulic Control Valve Hydraulic Release Park BrakeDokument2 SeitenConstruction: Hydraulic Control Valve Hydraulic Release Park BrakeluismdmjNoch keine Bewertungen

- Waste and Recycling: Industry SolutionsDokument24 SeitenWaste and Recycling: Industry SolutionsIan WoodsNoch keine Bewertungen

- Tds Flexi-Stop Aus 29april2019Dokument2 SeitenTds Flexi-Stop Aus 29april2019IvanRomanovićNoch keine Bewertungen

- WetFrictionBroch WEBDokument12 SeitenWetFrictionBroch WEBAS LO ProveedoresNoch keine Bewertungen

- LUBCON Train Rail and Wheel - EngDokument3 SeitenLUBCON Train Rail and Wheel - EngMontserrat BustiosNoch keine Bewertungen

- Technoroll BrosureDokument13 SeitenTechnoroll BrosurephitokrioNoch keine Bewertungen

- The Tigon: Industrial Firefighting VehicleDokument20 SeitenThe Tigon: Industrial Firefighting VehicleGinoGuanNoch keine Bewertungen

- PEDJ0193-04 FINAL - Low ResDokument16 SeitenPEDJ0193-04 FINAL - Low ResCarlos Indigoyen LimaymantaNoch keine Bewertungen

- AmsoilSyntheticOilProductInfo SheetsDokument2 SeitenAmsoilSyntheticOilProductInfo Sheetsapi-19921780Noch keine Bewertungen

- Catalogue MP en LowresDokument252 SeitenCatalogue MP en Lowresjt4fdsNoch keine Bewertungen

- File Smoothy Polyurethane Wheels December 2022Dokument2 SeitenFile Smoothy Polyurethane Wheels December 2022georgesfsequipmentsNoch keine Bewertungen

- All Shafting Is Not Alike: Thomson 60 Case Linearrace Shafting Is Available in Two Distinct Product CategoriesDokument36 SeitenAll Shafting Is Not Alike: Thomson 60 Case Linearrace Shafting Is Available in Two Distinct Product CategoriesSueli ZaniNoch keine Bewertungen

- Bardken Crawler Systems BrochureDokument9 SeitenBardken Crawler Systems BrochureAlex LeeNoch keine Bewertungen

- Rema Tip Top Catalogue 2018Dokument256 SeitenRema Tip Top Catalogue 2018Dedison Rumanga'Noch keine Bewertungen

- ScreedMax Pro S30 TDS and MSDS PDFDokument16 SeitenScreedMax Pro S30 TDS and MSDS PDFfuaunNoch keine Bewertungen

- VT Sprinter Truck Market Flyer2Dokument2 SeitenVT Sprinter Truck Market Flyer2luismdmjNoch keine Bewertungen

- VT Sprinter Truck Market Flyer2Dokument2 SeitenVT Sprinter Truck Market Flyer2luismdmjNoch keine Bewertungen

- TyresDokument2 SeitenTyres2october1988Noch keine Bewertungen

- US Mobiltrans HD SeriesDokument3 SeitenUS Mobiltrans HD SeriesOscar IngaNoch keine Bewertungen

- Weatherly No. 400 Catalog No. 431-2030 Edition 2016Dokument756 SeitenWeatherly No. 400 Catalog No. 431-2030 Edition 2016Erick Vg100% (1)

- Mobilfluid 424 Mobilfluid 424 Mobilfluid 424 Mobilfluid 424Dokument4 SeitenMobilfluid 424 Mobilfluid 424 Mobilfluid 424 Mobilfluid 424Sounak SasmalNoch keine Bewertungen

- REMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesDokument16 SeitenREMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesBaihaki StNoch keine Bewertungen

- Amsoil 75w90Dokument2 SeitenAmsoil 75w90sxysideNoch keine Bewertungen

- Why Choose Falk Steelflex Couplings?Dokument2 SeitenWhy Choose Falk Steelflex Couplings?priteshNoch keine Bewertungen

- EN PC8000 11SE01 - ExcavatorDokument2 SeitenEN PC8000 11SE01 - ExcavatorjoseolivapNoch keine Bewertungen

- TBW - FC Acoplamiento FrickDokument88 SeitenTBW - FC Acoplamiento Frickjuan leyyonNoch keine Bewertungen

- Dozer M SeriesDokument16 SeitenDozer M SeriesKumari SandhyaNoch keine Bewertungen

- 5918 Machine Tool CatalogDokument178 Seiten5918 Machine Tool CatalogrguillenjrNoch keine Bewertungen

- Rambal - HD Shocks & Cabin DampersDokument12 SeitenRambal - HD Shocks & Cabin DampersRaja Sekaran SajjaNoch keine Bewertungen

- Bearings Brochure Rev5Dokument3 SeitenBearings Brochure Rev5Pratyush25Noch keine Bewertungen

- Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424Dokument3 SeitenMobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424Dinh SangNoch keine Bewertungen

- Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424Dokument3 SeitenMobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424 Mobilfluid™ 424Oscar Mauricio Madero CortezNoch keine Bewertungen

- Aeroquip - A-HOOV-MC001-E1 - Overview - LRDokument6 SeitenAeroquip - A-HOOV-MC001-E1 - Overview - LRMarcelo MalagoNoch keine Bewertungen

- SERVO Transclean C4 SAE 30Dokument1 SeiteSERVO Transclean C4 SAE 30Shubham SinghNoch keine Bewertungen

- TechNix CatalogueDokument94 SeitenTechNix CatalogueamitNoch keine Bewertungen

- Mitco Tire - Sales - ManualDokument17 SeitenMitco Tire - Sales - ManualBALANoch keine Bewertungen

- Inometa Protek Coatings en LowDokument16 SeitenInometa Protek Coatings en LowsakthivelNoch keine Bewertungen

- CM20150421 35555 26171Dokument68 SeitenCM20150421 35555 26171motasem alqaisiNoch keine Bewertungen

- We Support PV Systems: Product Catalog 2021Dokument27 SeitenWe Support PV Systems: Product Catalog 2021Жељко КелекоNoch keine Bewertungen

- MOBIL - Delvac Tractor Hydraulic FluidDokument3 SeitenMOBIL - Delvac Tractor Hydraulic Fluidjorge torricoNoch keine Bewertungen

- VT Sprinter Truck Market Flyer2Dokument2 SeitenVT Sprinter Truck Market Flyer2luismdmjNoch keine Bewertungen

- Minicargador Case Kit Alto FlujoDokument9 SeitenMinicargador Case Kit Alto FlujoluismdmjNoch keine Bewertungen

- Ficha Tecnica Vidro Ingersoll - Sd-100dDokument2 SeitenFicha Tecnica Vidro Ingersoll - Sd-100dJozé Paxtian100% (1)

- IR SD-100 B 22 15282-B-01xx PDFDokument4 SeitenIR SD-100 B 22 15282-B-01xx PDFDiego Alvarez AlvarezNoch keine Bewertungen

- B Iny R500lc-7a PDFDokument4 SeitenB Iny R500lc-7a PDFluismdmjNoch keine Bewertungen

- Bobcat 753 SpecsDokument2 SeitenBobcat 753 SpecsJennifer Williams LawlessNoch keine Bewertungen

- 125lcr 9a WebDokument4 Seiten125lcr 9a WebluismdmjNoch keine Bewertungen

- 520LC 9A Web PDFDokument20 Seiten520LC 9A Web PDFluismdmjNoch keine Bewertungen

- R180LC 9Arev1prnENG Web PDFDokument11 SeitenR180LC 9Arev1prnENG Web PDFluismdmjNoch keine Bewertungen

- 480LC 9A Web PDFDokument20 Seiten480LC 9A Web PDFluismdmjNoch keine Bewertungen

- BFM 2012 Mobile Machinery enDokument2 SeitenBFM 2012 Mobile Machinery enluismdmjNoch keine Bewertungen

- 125LCR 9A Web PDFDokument24 Seiten125LCR 9A Web PDFluismdmjNoch keine Bewertungen

- Quality Replacement Parts CatalogDokument69 SeitenQuality Replacement Parts CatalogluismdmjNoch keine Bewertungen

- 125lcr 9a WebDokument4 Seiten125lcr 9a WebluismdmjNoch keine Bewertungen

- 140LC 9a-Web PDFDokument24 Seiten140LC 9a-Web PDFluismdmjNoch keine Bewertungen

- B Iny R500lc-7aDokument4 SeitenB Iny R500lc-7aluismdmjNoch keine Bewertungen

- Catalog 2Dokument1 SeiteCatalog 2luismdmjNoch keine Bewertungen

- BFM 2012 Mobile Machinery enDokument2 SeitenBFM 2012 Mobile Machinery enluismdmjNoch keine Bewertungen

- FirewallDokument1 SeiteFirewallluismdmjNoch keine Bewertungen

- 500 - Parts Motor de HormigoneraDokument2 Seiten500 - Parts Motor de HormigoneraluismdmjNoch keine Bewertungen

- Catalog 3Dokument2 SeitenCatalog 3luismdmjNoch keine Bewertungen

- CatalogDokument2 SeitenCatalogluismdmjNoch keine Bewertungen

- Catalo 15Dokument1 SeiteCatalo 15luismdmjNoch keine Bewertungen

- CatalogDokument1 SeiteCatalogluismdmjNoch keine Bewertungen

- Catalog 1Dokument1 SeiteCatalog 1luismdmjNoch keine Bewertungen

- Engine Thermostat and Thermostat HousingDokument2 SeitenEngine Thermostat and Thermostat HousingluismdmjNoch keine Bewertungen

- Catalo 14Dokument1 SeiteCatalo 14luismdmjNoch keine Bewertungen

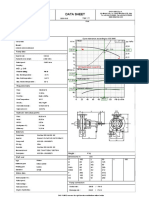

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Dokument3 SeitenData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNoch keine Bewertungen

- Num Sheet 1Dokument1 SeiteNum Sheet 1Abinash MohantyNoch keine Bewertungen

- Sentence Diagramming:: Prepositional PhrasesDokument2 SeitenSentence Diagramming:: Prepositional PhrasesChristylle RomeaNoch keine Bewertungen

- Ge 6 Art Appreciationmodule 1Dokument9 SeitenGe 6 Art Appreciationmodule 1Nicky Balberona AyrosoNoch keine Bewertungen

- Slipform Construction TechniqueDokument6 SeitenSlipform Construction TechniqueDivyansh NandwaniNoch keine Bewertungen

- List of Important Books of PhysicsDokument6 SeitenList of Important Books of PhysicsAbubakar Mughal0% (1)

- Lecture 11 - Performance AppraisalsDokument23 SeitenLecture 11 - Performance AppraisalsCard CardNoch keine Bewertungen

- Operations and Service ManualDokument311 SeitenOperations and Service ManualELARD GUILLENNoch keine Bewertungen

- Hawassa University Institute of Technology (Iot) : Electromechanical Engineering Program Entrepreneurship For EngineersDokument133 SeitenHawassa University Institute of Technology (Iot) : Electromechanical Engineering Program Entrepreneurship For EngineersTinsae LireNoch keine Bewertungen

- The Practice Book - Doing Passivation ProcessDokument22 SeitenThe Practice Book - Doing Passivation ProcessNikos VrettakosNoch keine Bewertungen

- 8 Lesson 13 Viking FranceDokument2 Seiten8 Lesson 13 Viking Franceapi-332379661Noch keine Bewertungen

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersDokument18 SeitenContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanNoch keine Bewertungen

- Abstract Cohort 1 Clin Psych FZ 20220323Dokument31 SeitenAbstract Cohort 1 Clin Psych FZ 20220323Azizah OthmanNoch keine Bewertungen

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDokument1 SeiteSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiNoch keine Bewertungen

- Thesis StoryboardDokument5 SeitenThesis StoryboardJill Brown100% (2)

- 13 SK Kader Pendamping PGSDokument61 Seiten13 SK Kader Pendamping PGSrachman ramadhanaNoch keine Bewertungen

- Company Profile PT. Geo Sriwijaya NusantaraDokument10 SeitenCompany Profile PT. Geo Sriwijaya NusantaraHazred Umar FathanNoch keine Bewertungen

- TOA Project Presentation (GROUP 5)Dokument22 SeitenTOA Project Presentation (GROUP 5)Khadija ShahidNoch keine Bewertungen

- DYCONEX Materials en 2020 ScreenDokument2 SeitenDYCONEX Materials en 2020 ScreenhhaiddaoNoch keine Bewertungen

- Analysis of Green Entrepreneurship Practices in IndiaDokument5 SeitenAnalysis of Green Entrepreneurship Practices in IndiaK SrivarunNoch keine Bewertungen

- Zoom g2 1nu Manual Do Utilizador PDFDokument56 SeitenZoom g2 1nu Manual Do Utilizador PDFEliude Gonçalves FerreiraNoch keine Bewertungen

- Introducing Eventstorming-4Dokument1 SeiteIntroducing Eventstorming-4Alex TrujilloNoch keine Bewertungen

- Changing Historical Perspectives On The Nazi DictatorshipDokument9 SeitenChanging Historical Perspectives On The Nazi Dictatorshipuploadimage666Noch keine Bewertungen

- Kimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Dokument6 SeitenKimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Mayuresh GaikarNoch keine Bewertungen

- Marketing Plan Outline-Fall 23Dokument6 SeitenMarketing Plan Outline-Fall 23arbelsb3Noch keine Bewertungen

- Motive 27Tmx: Data SheetDokument2 SeitenMotive 27Tmx: Data SheetUlisesGómezNoch keine Bewertungen